How To Design Automated Light For Bed Room, Well, you might have heard of the design of automated light, but you may not have seen such lights before. The project is regarding making a do it your own design automated light for the bedroom of your house. The light will switch ON and OFF without your effort. Yes, it is possible to make a light that would get ON and OFF whenever you enter the room and switch off when you leave the room. The automated design light could merely be made with the help of an operational amplifier and a timer along with a lamp or bulb. This project will be a small part of the automated home system if you are ever interested in making your entire home autonomous, i.e., the operation of all electrical equipment itself.

1. List of Components Required for the Project

The following is the entire list of components that you would need to do the project.

1.Resistors of different values (70K, 10K, 50K, and 5K).

2.Capacitors of different values (470uF and 0.01uF).

3.IC of Operational Amplifier, i.e., LM741.

4.An IC of the timer, i.e., IC555.

5.A transistor.

6.A bulb or Lamp of 12 Volts.

7.Wires for circuit completion.

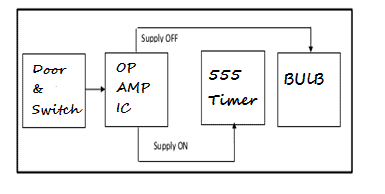

2. How To Design Automated Light For Bed Room—Simple Block Diagram

The following is the simple block diagram of the circuit.

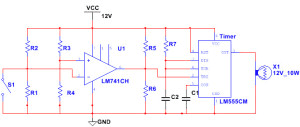

3. Working of the Circuit and Schematics

The IC of the operational amplifier has eight pins in which pin 2, 3 are for the inputs. In contrast, pin 3 is for the non-inverting information, and pin 2 is the inverting input terminal. Pin 3 is given with a fixed voltage with the help of a potential divider, whereas at pin two, the input voltage is provided through the switch. The button is being used in the closed position, i.e., the SPST switch is being used. The output of the operational amplifier is being fed to the IC of the timer, i.e., 555, which, when triggers, generates a very low voltage at the input terminal 2 and generates a high pulse at terminal 3 of the OP-AMP IC. Now the output of the operational amplifier is then connected to the lamp of 12 volts.

The basic circuitry or schematic diagram of the project is as follows.

As it is evident from the schematic diagram that the switch must be placed over the wall of the room.

The way such that when the door of the room is opened, the light gets ON automatically when the trigger of the switch is pushed. When the motivation of the button is made, the connection through the switch is completed, and it gets ON. The IC of the operational amplifier works as a comparator when the switch is opened, the inverting terminal of the OP-AMP IC is connected to the lamp, and voltages of almost 4 Volts are generated, which are generated fed into the non-inverting terminal of the OP-AMP IC.

Now at the non-inverting terminal of the OP-AMP IC, the voltage is lesser than that of the inverting terminal of the IC. Therefore a novel pulse is being generated at the output of the IC, which is fed into the 555 timer IC with the help of a potential divider arrangement. By this time, the IC of 555 timers is getting triggered with the help of low voltage signals at the input side, and in return, it generates a very high pulse at the output terminal. Now the timer is working in the mode known as the mono-stable mode. Here when the lamp is receiving a signal of 12 volts, it glows automatically.

When you come out of the room, you will close the door, and the entire process will reverse. The switch would get back into its original position and would get close. This is because the non-inverting terminal of the operational amplifier IC is getting higher voltages than the inverting terminal. This ends up failing the trigger to get ON, and the lights don’t get 12 volts and are made OFF.

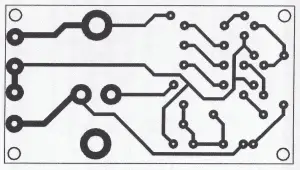

4. How To Design Automated Light For Bed Room—The PCB Design of the Circuit

The basic layout of the Printed Circuit Board for the project is given below. Numerous methods can be used for making the Printed Circuit Board for the project. However, LEDASK is a good choice for printed circuit board manufacturing.