Contents

Can you Convert 24v to 12v

It is possible to convert 24v to a 12-volt battery in electrical devices. Often this happens when we use 24v in a device that requires the use of 12v. However, a DC-DC converter makes the conversion easier. A 24v voltage converter steps down the voltage from 24v to the 12v necessary to regulate the output voltage.

The table below explains the differences between the 24v system and the 12v system.

| Feature | 24v | 12v |

| Resistance | high | low |

| inverter efficiency | high | low |

| voltage produced | low | high |

| voltage drop | low | high |

| wiring system | cheaper | expensive |

| fire hazard | low | high |

A 12v system is double that of a 24v system with the exact power supply amounts, making this its downside. The 12v is less efficient than the 24v, and this is because, at each power draw, the 12v batteries use two times the amperage a 24v uses.

(example of a battery-powered device)

The number of batteries we use in a circuit is essential. Also, we refer to this as the battery bank, and it is because an appliance’s battery life depends on how frequently it charges. So, to get the correct number of batteries to use, we do the following calculations.

For example,

We have;

4x400watts=1600w/hr

And when we use it for five days, we’ll use a total of

1600×5=8000w/hr

Therefore, using a calculated DoD(depth of discharge) of 0.5% we get

8000/0.5=16000w/hr

Also, to quickly reduce the voltage loss, we have to use higher voltage. Thus, to use a 12, 24, or 48v, we need to divide the result with the required volts

16000/24=667Ah

Therefore, when using a 330Ah battery of 12v, you will need four batteries. At the same time, a 24v or 48v battery will require a simple average of 2 batteries.

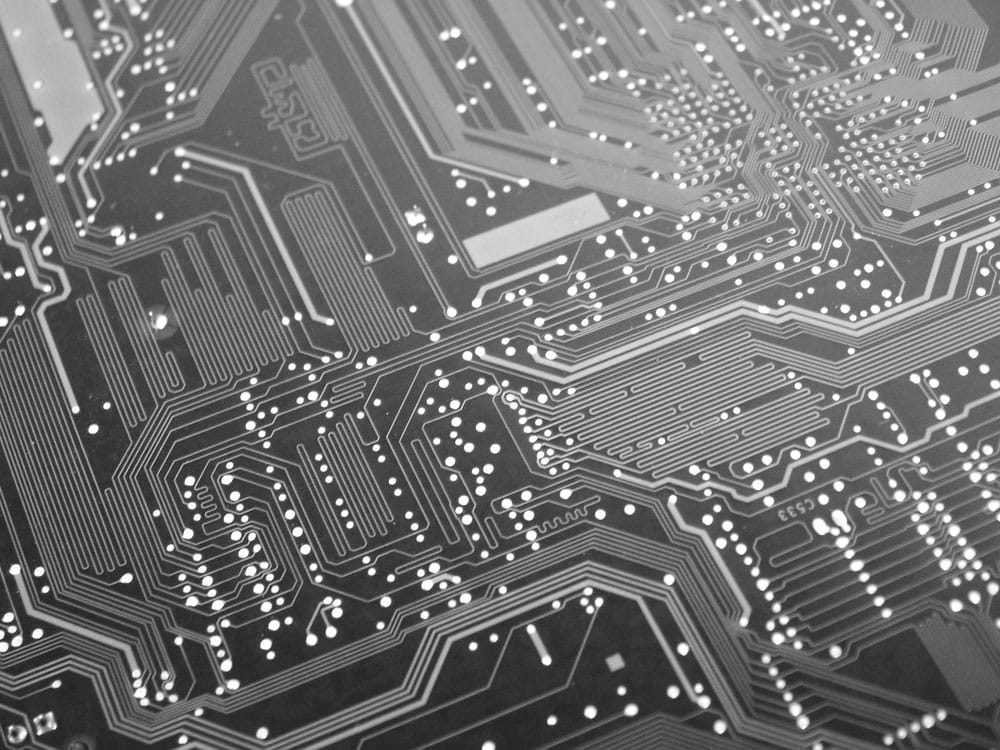

(Computer circuit)

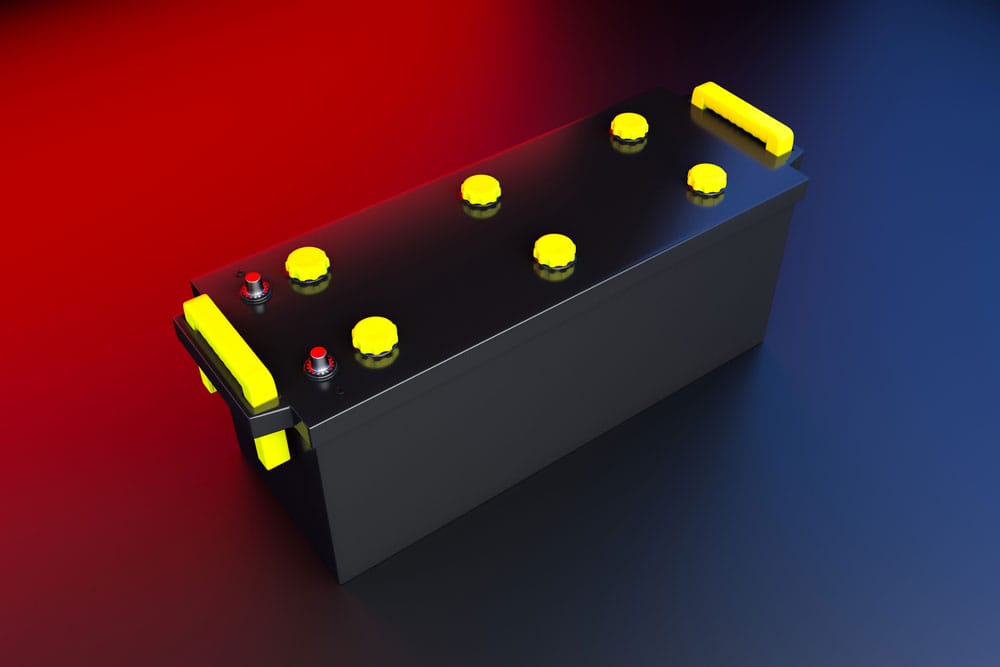

For example, when powering a 12v DC device, you have a 24v lorry battery or a 24v truck battery. There is an abundance of step-down transformers to use in the market. We have several lorry drivers who use 12v kettles, radios, or televisions in a car that wires at 24v.

The critical thing to look for in such a case is the power converter’s max current. Also, the efficiency of the converter is essential. Most importantly, the maximum load current tells you how much the 12v-rated appliance can draw at a time. Nonetheless, efficiency ensures there is no wasted stored battery charge as heat, and it only explains that you need to purchase the correct DC-DC converter.

(a 24v lorry battery)

How to Design a 24v to 12v Converter Circuit

When designing voltage converter circuits, quality power bank PCB assembly plays a crucial role in ensuring reliable performance and safety.

The following are some of the hardware components to use;

- Integrated Circuit

- Diode

- DC supply

- Capacitors

- Heat sink with IC

From this first simple circuit diagram, we have the following hardware components to use;

(Circuit diagram 1)

An integrated circuit of LM7812, a diode of 1N4002, and a DC supply of 24v. Also, we use two capacitors, each of 330 uF and 100 uF, and a heat sink.

We use two resistors and two capacitors in the second circuit example;

(Circuit diagram 2)

The IC is of the LM317T value, a 1N4002 diode, 24v DC supply, and two capacitors of 0.1uF and 1uF. Finally, use two resistors of 2.1K and 240 ohms and a heat sink.

We have the number of capacitors and resistors similar to the second circuit for the third circuit example. However, there are two diodes.

(Circuit diagram 3)

The IC is of a value of LM338, two diodes of 1N4002, and a 24v input voltage. Use capacitors of 0.1uF and 1uF and two resistors of 1.3K and 150 ohms. Finally, use a heat sink.

These circuits show that you can step down a 24v to a 12v with the help of voltage regulator ICs. In these circuits, we use the LM7812 IC, LM317T IC, and LM338 IC.

The LM7812 IC is a 12v 1.5A fixed output voltage regulator IC.

On the other hand, the LM317T is a 12v 1.5A adjustable output voltage regulator IC.

There is a slight difference with the LM338 IC in that it’s a 12v 5A adjustable voltage regulator. Moreover, its uses are in appliances that require more current.

We use a suitable resistor to obtain the correct output voltage by placing it at R1. Although we need an output voltage of 12v while using the LM317, we use a 2.1K resistor at R1, as shown in circuit 2.

We either use a resistor or connect the batteries in series to get a 12v from a 24v system. Notably, the produced electrical energy by this resistor will convert to thermal energy, which is equivalent to the utilized electrical power.

We connect batteries in series such that the charge flows in only one path. It will significantly help to control the current circuit flow while reducing the voltage of the resistor.

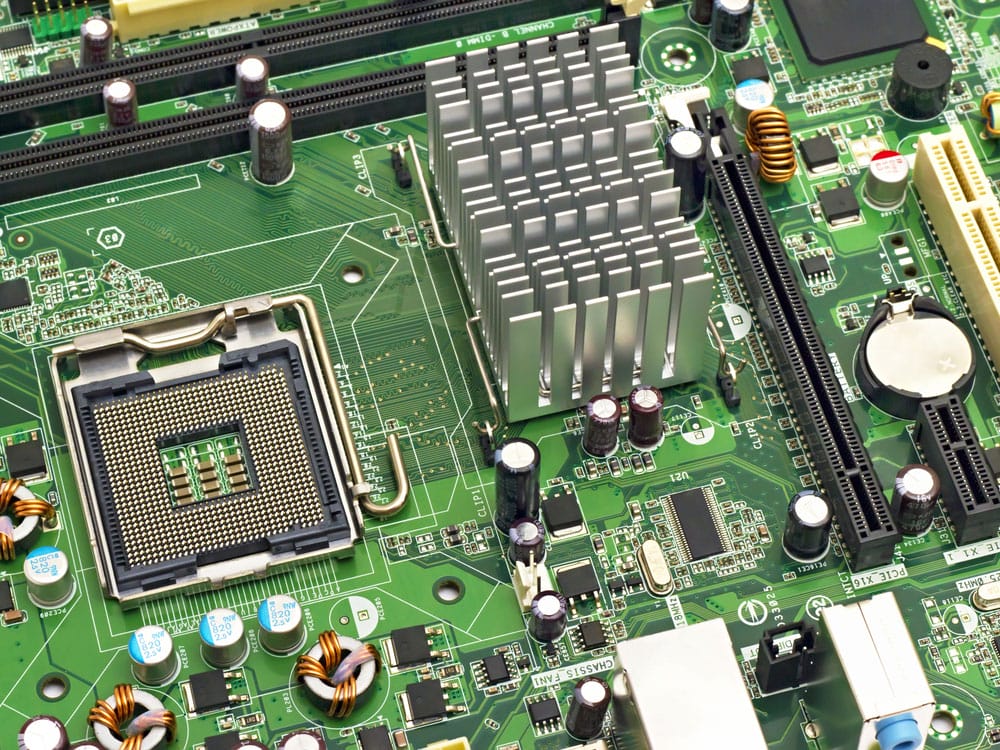

(picture of a motherboard with a heat sink.)

24v to 12v Converter Circuit Applications

- First, utilized in devices that run on batteries, including computers and cell phones.

- Secondly, wheelchair accessories such as laptops, radios, or seat pumps use this circuit.

- Also, the use of this voltage converter is in a car cigarette lighter.

- Furthermore, 24v lorry vehicles use these DC/DC step-down converters.

- Lastly, you can use a converter DC in an audio amplifier.

Summary

The 24v to 12v converter circuit is the most commonly used DC-DC converter in most home appliances. They’re straightforward to use and understand!

We hope this article is of great use to you and you learned how to use a 24v to 12v circuit converter. For any questions or comments about this or other circuits, don’t hesitate to contact us.