Contents

What is an Air Core Inductor?

An air core inductor is an inductor that has no solid or ferromagnetic material in between the coiled wire.

Air core inductors operate on the basis that air has a relatively minimal electrical conductivity.

This means the air-core inductance is also low, thus producing a weak magnetic field.

Due to the air cores’ small magnetic field production, it can achieve a faster current rise while preventing signal loss. That mainly occurs when an inductor produces higher magnetic field strengths in an electric circuit.

Air Core in an Electrical Circuit

Therefore, experts prefer air-core inductors over their ferromagnetic core inductor counterparts, such as iron.

They (ferromagnetic core inductors) usually become saturated and experience current loss when faced with a higher frequency range than 100 MHz.

Air Core Inductor Design: Calculating Air core inductors

Also called inductance values or current values.

Air core inductors are in two groups:

1. Single-coil air core inductor

2. Multilayer-coil air core inductor

As their names suggest, a single air core inductor has only one coil, while a multilayer inductor has numerous coils wound up.

Let’s look at the calculations for each.

Single Coil inductor

To calculate the induction of a single-layer coil inductor, you can apply air core inductor equations.

Where:

L- Represents the length of the coil in Millimeters

n- Represents the number of turns taken by the coil.

D- Represents the coil’s diameter in millimeters.

Formula 2

Where:

N- represents the number of turns.

r- Coil radius in inches.

l- Length of winding coil in inches.

L – Refers to inductance in microhenries (uH).

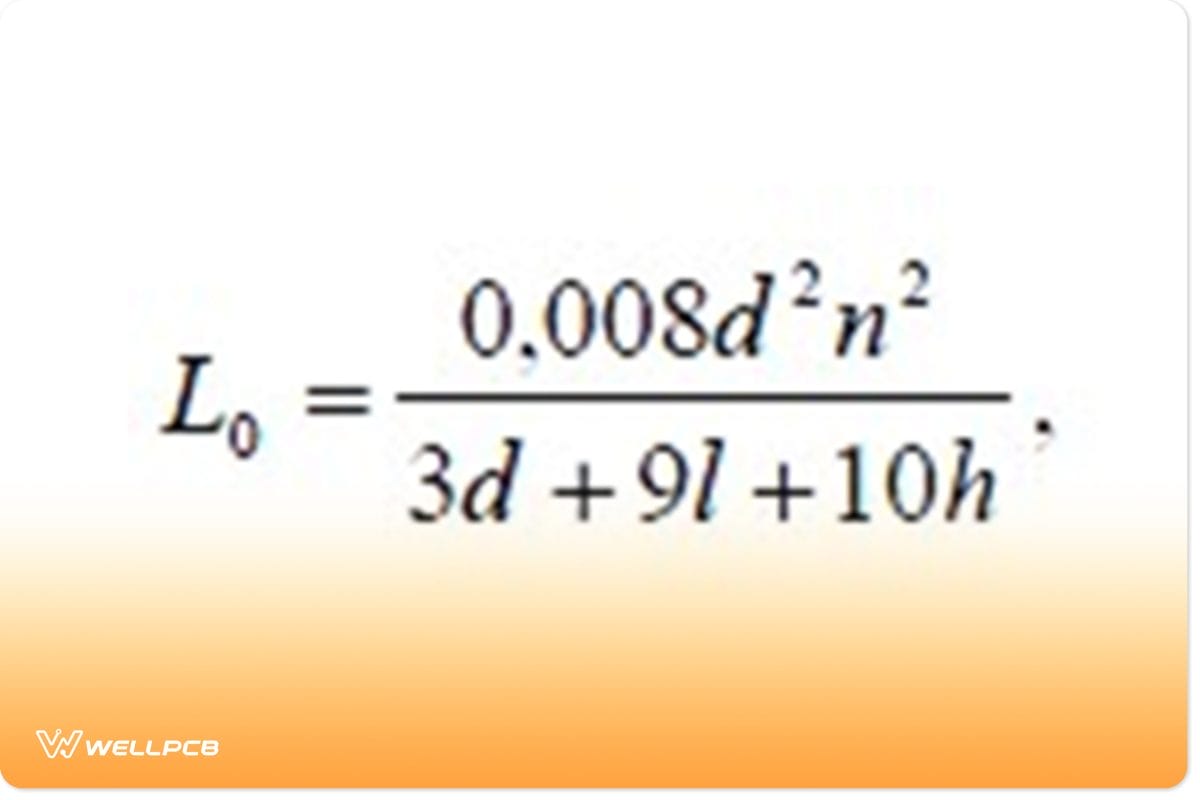

Multilayer Coil Inductor

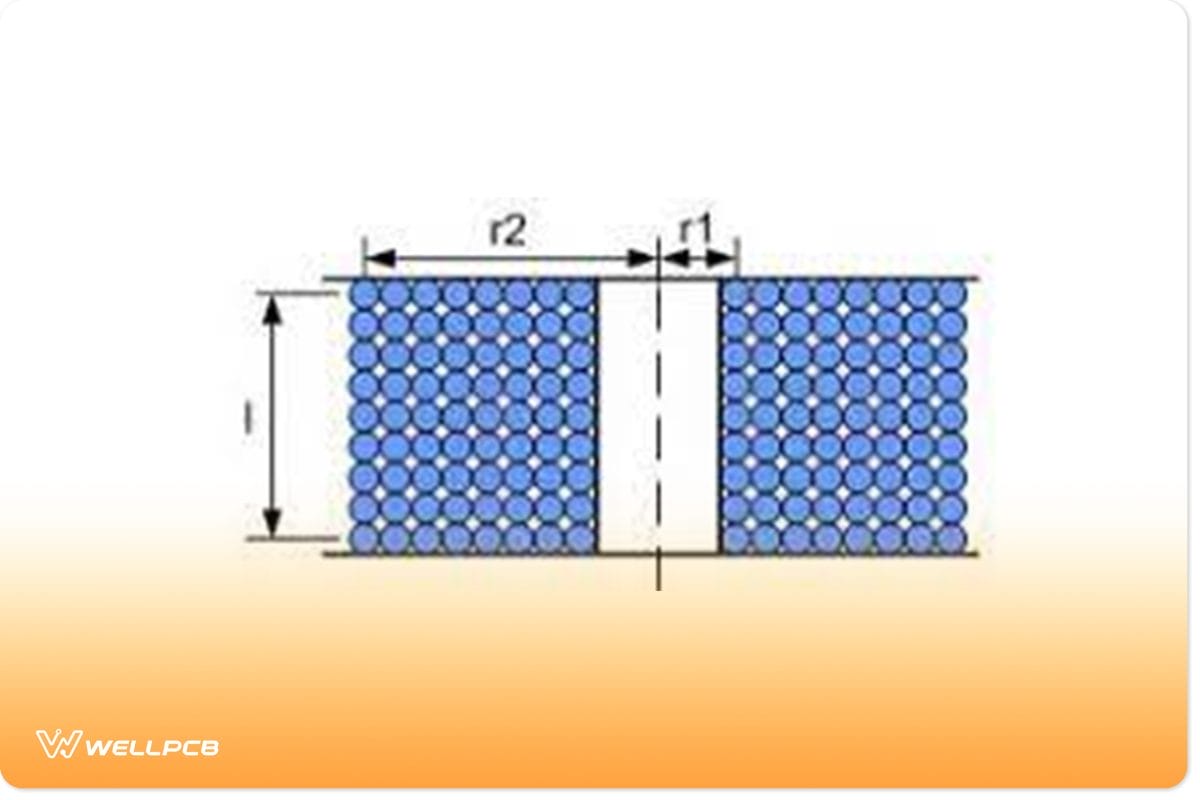

Multilayer coil Inductor

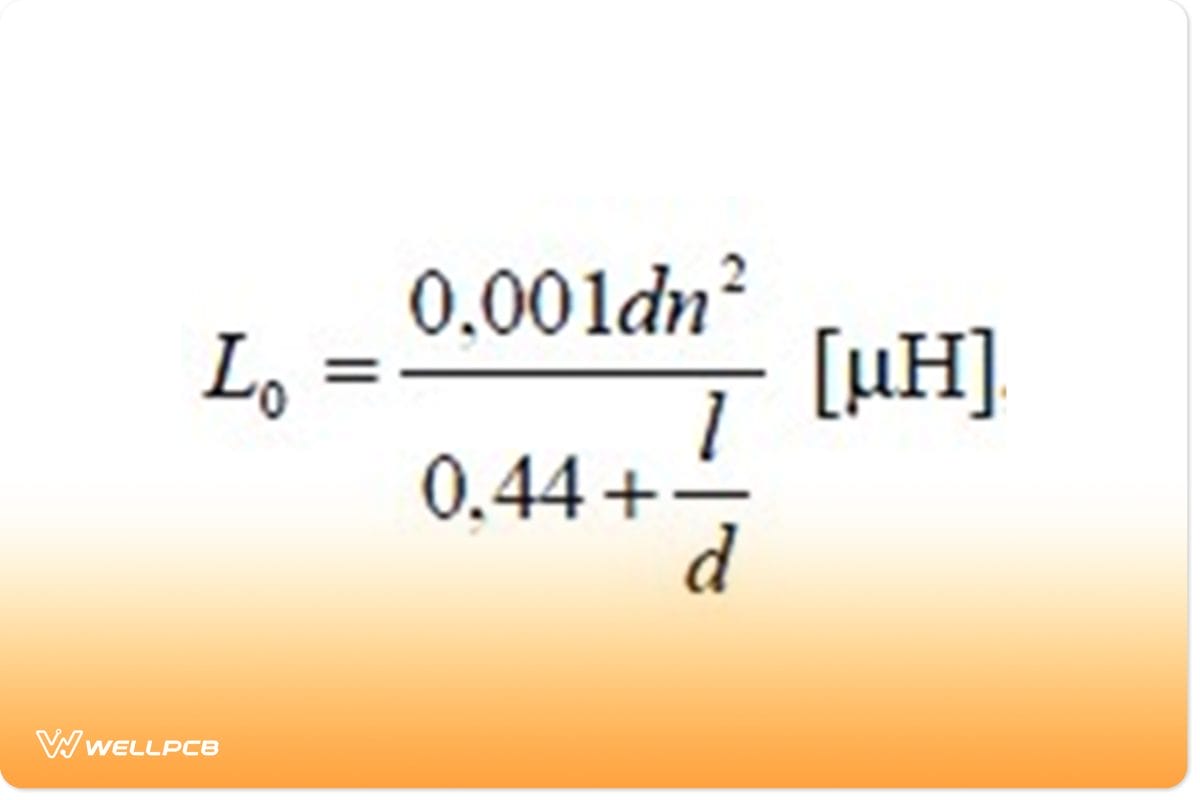

Here, you can use Wheeler’s formula:

Where

h- Refers to coil height in Millimeters.

n- Number of coil turns.

d- Coil diameter in Millimeters or half the radius of the coil.

Experts argue that a multilayer coil has a higher coil current. You can also calculate the magnetic flux density of the air core coil.

Homebrew Your Air Core Inductors

Sometimes you may be looking for a specific air-core inductor(axial component) only to realize they are hard to find.

Your luck worsens if you are seeking an inductor that works well in an Rf electric circuit.

However, when you do find a suitable air core inductor, it’s highly priced.

Small Inductors

Well, you are in luck, for outlined below are steps you can take to make quality air-core inductors or air core coils with magnificent Q.

Materials you will need

- Coil Form

- A spacing Block and electrical steel

- Flathead nylon Bolts

- Glue or Epoxy

- A wire, also called a spacing line

- Copper Aluminium wire- core material

Procedure

Making the Coil Form

- Cut slots into a PVC pipe 9.5 millimeters wide.

- Make two small holes on the Coil form (PVC) pipe. One at both ends of the coil form.

- To make a larger coil to produce a higher magnetic field and electric charge, you will need to make a larger coil form to wind the coil.

- Tap out the block in the middle of the coil using a dowel and a hammer.

Dowel and hammer

Wind the coil

Since our coil form is circular, we will wind a cylindrical coil.

Cylindrical coil

- Use a spacing cord or coil winding wire.

- Also, use a nylon monofilament line for closer spacing and speaker wire for wider spacing.

- Make it a point to use a wire length similar to the coil length.

- Space the coils at least one and a half diameters apart to balance inductance and efficiency.

- If you seek a neater coil, ensure it remains tightened throughout. You can achieve the tightness by passing the wire through a vise.

Winding coil

- Place the block in the coil form and spacing line and coil wire in the holes.

- Next, start winding by rotating the coil form horizontally.

- Keep doing so until;

you have filled it up (single layer coil),

the coil is up to your required size (multilayer air coil),

and you reach the needed depth of coil.

- You can set a target diameter of coil winding for direction and improved coil performance.

Building coil ribs

- Place the coils on separate strips.

- Position a mold in the inner part to prevent the adhesive from dripping onto the other parts.

- Afterward, insert an electrical tape into the inner coil part.

- In case your coil form is small and there is a tight working space. You can use craft sticks, but first, you must cover them with a bit of tape.

Precautions you should take while using adhesive include.

- Use regular setting glue.

- Apply a small amount of glue and allow it to sink into the other coil wires.

- Avoid getting epoxy on the form.

Only apply epoxy on one side at a time; avoid using double-sided tape.

Remove the Coil Form

- Give the adhesive enough setting time—at least eight hours, then remove the spacer block.

- Cut the combination of wires passing through the coil form next to your air-cored coil.

- Your coil will quickly come off and have mechanical stability, a perfect circular coil.

Connect the Coil

- Before strapping wires onto the inductance coil, first remove the plastic coating on the coil surface.

- Finally, you can solder the wires to the ends of the air core inductor to connect it to the electric circuit.

Soldering wires

Mounting Your Coil

- Cut off the heads of the nylon bolts, and then push in one turn at the end of the coil on both sides.

- Complete the mounting by fixing the nylon posts at the pushed positions and adding adhesive for firmness on the cylindrical coil.

Your air core inductor is now complete.

Air core inductor applications

Air core inductors have a wide variety of applications. They include:

- Used in circuits of radio transmitters and Television receivers.

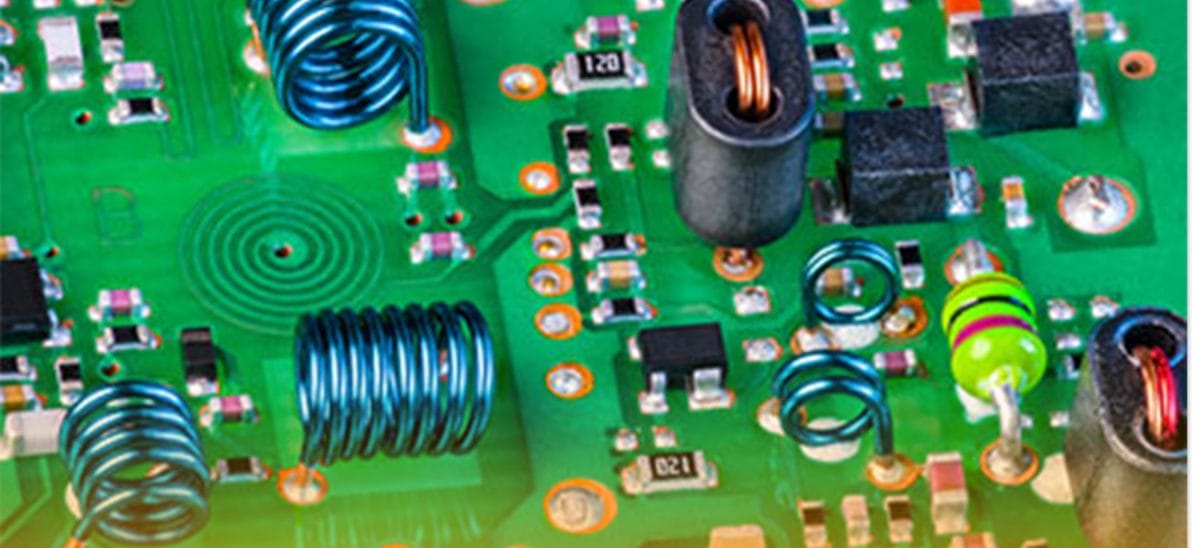

Air core coils in an Analog circuit

- In making snubber circuits.

- It is used to enhance bottom peak inductance.

- Making filter circuits.

Summary

Air core inductors on a circuit

Of all the types of inductors, you can see why air-core inductors rank higher compared to those made of ferromagnetic material. Well, that finalizes the article, but do remember to contact us for any inquiries you might have.