Contents

What is a MOV

Various applications in the electronic world require protection from high currents or voltage. For instance, if your circuit requires a 3.3v supply but gets a 5.5v collection instead. The excess power could damage the electrical components.

This is where the MOV plays a role.

Though we say MOV, we don’t mean the MOV file extension for MOV videos and file format. We’re talking about the metal oxide varistor.

A metal oxide varistor is a common type of varistor used for circuit protection. It features a mixture of zinc oxide and other metal oxides (cobalt, manganese, etc.) components. Plus, these components stay between two electrodes – metal plates.

Also, MOVs are crucial components to protect a wide variety of heavy devices from short bursts of voltages.

In other words, an MOV is a collection of diodes connected parallel to each other. This collection of diodes creates diode border junctions. Also, Its parallel mode design allows it to handle energy better. However, if you want to provide a better voltage rating, then connect the diodes in series.

MOVs are also considered a type of variable resistor. It varies its resistance according to the amount of voltage you apply across your circuit.

The MOV decreases its resistance value when high currents pass through it. Plus, it also serves as a short circuit. Thus, you’ll find MOVs in parallel with a fuse to protect your course from voltage spikes.

How Does a MOV Work?

As said earlier, an MOV is a variable resistor type that varies its resistance according to the applied voltage. Unlike potentiometers, the resistance of the MOV decreases when the voltage across it increases and vice versa.

So, how does this surge protector work?

When operating normally, the MOV’s resistance would be high, so it only draws minimal current.

But, when a surge happens in the network, the MOV rises above the threshold voltage of the clamping voltage and draws more current.

For this reason, the MOV dissipates the surge and protects the other electronic components from damage.

But there’s a catch.

The MOV can only protect your circuit against short surges or voltage spikes. Sustained surges would damage both the MOV and the course. Also, exposing the MOV to repeated high-voltage spikes would degrade its properties.

How? Because the clamping voltage of the MOV goes lower whenever a surge happens. After a while, it can get destroyed.

Luckily, there’s an easy solution to this problem.

You will find a majority of MOVs connected in series with a fuse (thermal switch). The fuse activates whenever the MOV draws high current levels from the circuit. Once the transient voltage flows through the component, the MOV will prepare for the next one.

MOV Performance

This varistor mainly performs as a line voltage surge suppressor. It doesn’t conduct electricity when the voltage across it is lesser than the clamping voltage. However, the MOV won’t perform if it receives a surge spike rating higher than the varistor can handle. The result of this is a damaged MOV.

Also, the performance of the varistor will decrease as time goes on. You can find the lifespan of any MOV on the manufacturers’ chart. The manufacturers’ graph will give you detailed readings and diagrams of the time, current, and the number of transient pulses passing through the component.

Energy rating is another factor that affects the performance of a MOV. When the energy rating increases, it affects the life of the varistor. For this reason, the number of transient pulses the MOV can handle will change.

You can also increase performance by connecting more varistors in parallel. Increasing the rating also helps to improve the performance of the MOV.

Another great thing about the MOV’s performance is its response time. The MOV can short out spikes within nanoseconds. However, certain features like the inductance of component leads and mounting design method can affect the response time.

MOV Specifications

Here are some of the things you need to look out for when purchasing or making a MOV:

Maximum Working Voltage

It is the maximum steady-state DC voltage the MOV can handle. Typically, the value of the leakage current should be less than a specified value.

Varistor Voltage

When selecting a MOV for voltage, the maximum continuous RMS voltage should be a little bit above the predicted voltage supply. For instance, a 260v RMS for a 230 voltage supply.

Maximum Clamping Voltage

You can get this when you apply a specific pulse current to the component. It helps you achieve the maximum peak voltage. Also, it is the voltage that allows the MOV to dissipate and conduct surge current.

Surge Current

The surge current is the highest peak current a device can handle without getting damaged. It usually occurs for a given period. Your MOV must divert surge current while allowing the regular current to power up your circuit.

Surge Shift

The surge shift is the variation in voltage after the surge current passes through the MOV. So, when a surge happens, it reduces the rated clamping voltage and creates a voltage variation after the wave.

Energy Absorption

The energy absorption is the maximum energy a specific waveform dissipates without having many problems.

To run all your devices, you can determine this value by using a specific controlled circuit with predetermined values.

Also, you can express the energy in standard transient x/y. Here, y is the duration required to reach half the peak value, while x is the quick rise.

Capacitance

Due to the MOV being two metal plates with a dielectric in between, it acts as a capacitor in the nF range. Thus, the bigger the size, the more the capacitance. However, this doesn’t affect the AC or DC power feeds until a surge event takes place.

Leakage Current

The current that flows from the AC or DC circuit in any equipment to the ground is the leakage current. It also refers to the amount of current the varistor draws when operating below the clamping voltage.

Response Time

The response time refers to the time the MOV starts conducting after the surge event. The standard response time of MOVs is 500 picoseconds. However, it’s not necessary to compare response speeds because most transient voltages have slower rise times. Similarly, the circuit directly affects the response time of a leaded MOV.

Maximum AC Voltage

The maximum AC voltage is the maximum RMS voltage you can constantly transfer to the varistor. When choosing your maximum RMS value, it should be a little bit above the actual RMS voltage.

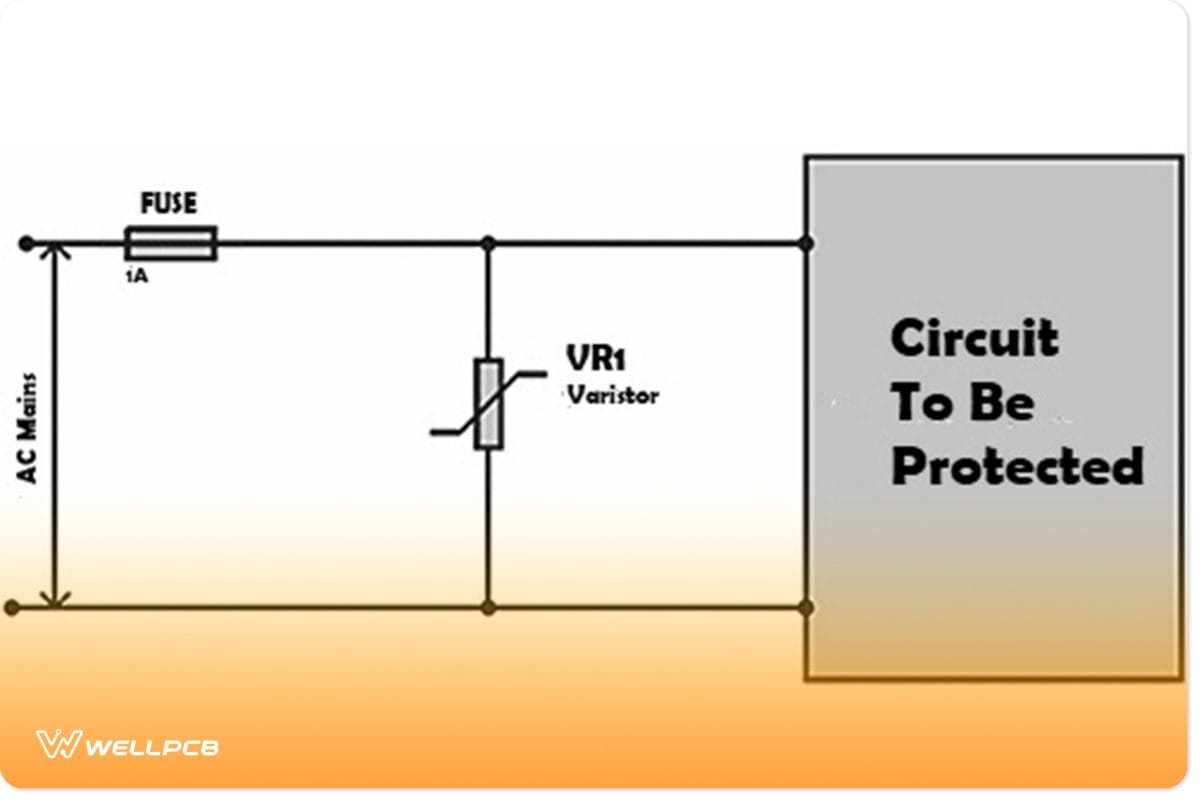

MOV Circuit

You’ll mostly find MOVs connected in parallel to a fuse. Here’s a diagram of a circuit to show you have the MOV works in an electronic circuit.

MOV circuit diagram

When the voltage of the circuit is within the rated limits, the MOV would have high resistance. Use, however, when a voltage spike happens, it moves across the MOV and reduces the resistance of the MOV to a low value. Thus, the current passes through the circuit and not the MOV. Therefore, it becomes a short circuit.

For this reason, the big spike of voltage passes through the MOV instead. Thus, the fuse blows up and disconnects the circuit from the main voltage.

However, in the case of transient voltage, the high voltage will always return to normal. Plus, the duration of the high current will not be enough to damage the fuse. Thus, the circuit resumes its regular operation when the voltage normalizes.

So, if you find a damaged MOV in your circuit, it might be the result of multiple high extra voltage spikes.

How to Build One

You can make a metal oxide varistor with ceramic powders of metal oxides and other metal oxides like oxides of bismuth and manganese. Most importantly, the MOV consists of zinc oxide (90%) and small amounts of other metal oxides. It would help if you kept the ceramic powders of the metal oxide intact between two electrodes (metal plates).

Furthermore, the metal oxide grains create a diode junction between each diode. Hence, a MOV is several diodes connected in series. So, you can cause a reverse leakage current that happens across all connections when you apply a small voltage to the metal plates.

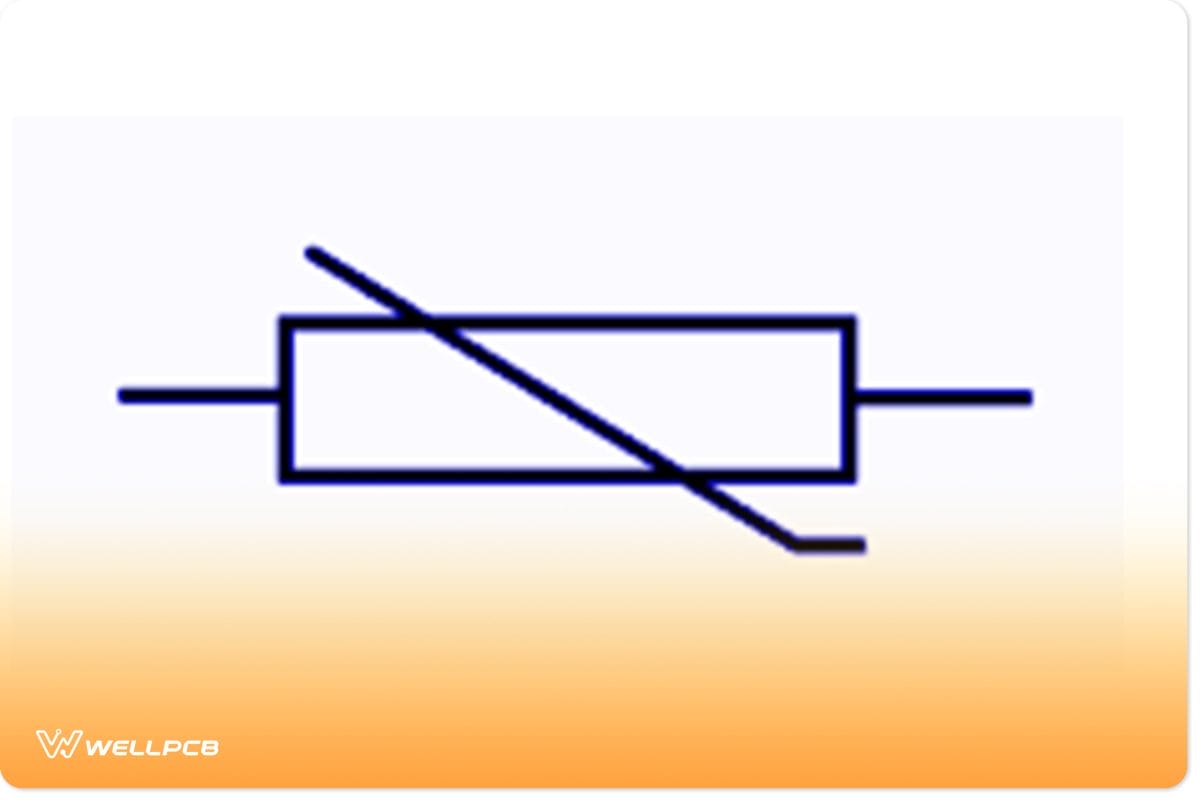

MOV Symbol

The varistor symbol is quite similar to the character of the thermistor. It has a primary resistor symbol of a rectangle with a diagonal line through it. Also, it features a small added section parallel to the body of the varistor symbol. This shows the varistor’s no-linear nature. Here’s what the character looks like:

MOV symbol

Choosing the Right MOV for Protection

Now that we know what a Metal Oxide Varistor is and how it protects your circuit from transient voltage. Let’s look at a few tips to help you choose the right Metal Oxide Varistor for circuit protection.

- The first thing you need to do when choosing a Metal Oxide Varistor is to determine the continuous working voltage. This is the voltage you will provide across the varistor. Thus, you should select the varistor with a maximum DC or AC voltage that’s slightly higher than the applied voltage.

Usually, people choose varistors with a maximum rated voltage of 10-15% higher than the actual line voltage.

So, if you’re aiming for a low leakage current, you can use your varistor with a higher operating voltage.

- Know the amount of energy the varistor can absorb in the event of a surge spike. You can determine this with a simple experiment. Use the varistor’s maximum load during a surge with the specifications on the datasheet.

Once your experiment is complete, choose the Metal Oxide Varistor that dissipates more energy that’s either equal to or slightly higher than the required energy dissipation during a surge.

- Calculate the surge current that passes through the varistor. Make sure you select the varistor with a surge current equivalent or slightly higher than the required current rating in any event.

- Similarly, you should also find the required power dissipation. So, ensure you select the varistor with a power rating equal to or exceeds the power handling required by the circuit in any event.

- If you’re unsure about what power, surge current, and energy rating to select, always choose a device with a higher power, energy rating, and surge current.

- Lastly, select the correct model to provide the right clamping voltage you can choose based on the allowed maximum voltage value for your input or output. Make sure your circuit can handle the allowed voltage.

MOV Application

You can use the Metal Oxide Varistor for a variety of applications. You can use MOVs in circuits that have risks of voltage spikes. Surge protection and strips are more common applications of MOVs.

Plus, you can find MOVs in power supplies connected to mains, various communication lines, data systems, digital cameras, computers, power systems, personal digital assistants, and MP3 players.

Less common applications of MOVs include microwave mixers for detection, modulation, and frequency conversion.

Rounding Up

Selecting the right Metal Oxide Varistor for protection isn’t rocket science. All you need to do is understand how the MOV works and how to choose your values.

The work of a varistor in sensitive electronic circuits is to prevent the voltage from exceeding a set value. This allows the varistor to become a short circuit that shuts off the current flow and prevents any damage from extra voltage.

Do you have questions or concerns about the MOV? Feel free to contact us; we’ll be happy to help.