Contents

- 1 Things to Consider Before Buying Batch PCBs

- 2 What is a Batch PCB?

- 3 Batched PCBs–Benefits For SMALL BATCH PCBs

- 4 Batched PCBs–Batch PCB and Electronics Production

- 5 Batched PCBs–Why Choose Small Batch PCB Assembly?

- 6 Batched PCBs–What is the Best Place to Manufacture PCBs in Small Quantities?

- 7 Conclusion

Things to Consider Before Buying Batch PCBs

There are certain points that you need to keep in mind before ordering batch PCBs. We have listed down a few main points:

• First, finalize your circuit design and make its schematics. Many simulation tools are available, so creating a Custom PCB circuit board may be a tall order.

This article will walk you through five basic ways to land the best PCB board online that can be downloaded for this purpose.

• Next, develop at least one circuit prototype to ensure it works correctly. This way, you will not need to throw away your batch of PCBs, as they can no longer be

• faulty. Faulty circuits can never lead to successfully printed circuit boards. Figure 1 shows the printed circuit board of a defective car camera.

• After that, you need to make a PCB layout of your circuit. You can ask the manufacturer if they have any specific requirements for manufacturing PCBs.

There are high chances of layout failures, which can negatively affect the final product’s functionality. There are several PCB layouts.

• After the layout is ready, you can upload your Gerber file and order batch PCBs.

• Further, double-check your prototype, board layout, and circuit design before ordering. A mistake at this stage can cost a lot of money if your circuit is defective.

• You should also make sure that the manufacturing firm offers the production of batch PCBs. It will permit you to save money compared to a large batch of personalized boards.

• Therefore, you should consider the above points before purchasing Batch PCBs. The next section will explain what exactly a batch PCB is.

What is a Batch PCB?

In simplest terms, it means producing a particular part of one specific product and then allowing the production panel to begin manufacturing the subsequent product.

Technically, PCB batching involves pooling different printed circuit boards onto a single board.

This means that PCBs are made once a big single PCB is filled with many individual PCBs. Each PCB may belong to a different customer, so the costs are divided among the customers.

What does this imply?

It means that batched PCBs save your costs compared to manufacturing individual PCBs.

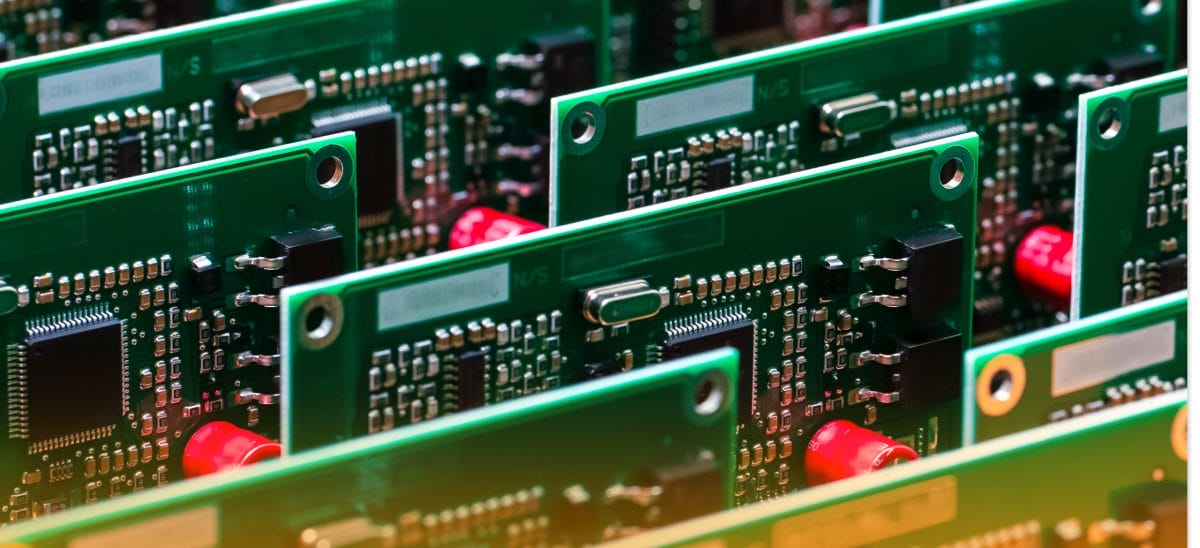

You will find them alluring if you are looking for low-volume and budget-sensitive circuit board works. Figure 2 demonstrates a batch of printed circuit boards (PCBs).

We here at WellPCB offer economical batched printed circuit boards.

You can contact us or place an order on our website. The next section will discuss their benefits.

Batched PCBs–Benefits For SMALL BATCH PCBs

• Cheap: You can greatly reduce your costs by ordering pooling technology. Manufacturing companies will not charge tooling costs, and there will be no minimum order limit.

• Convenient: Manufacturers will show you custom and standard price columns detailing myriad deliveries and quantities.

Furthermore, you will also be free to choose the type of material, mask and silkscreen colors, copper weights, etc.

• Time-saving: After selection, you can order your batched PCB online. Moreover, your full PCB records, such as running order status and quotations, will be available online.

• Quick Product Delivery: Many batch PCB assembly providers have a turnaround time of five days or less. Therefore, you will frequently receive a quick product delivery if you order a batched PCB.

• Economic Testing: If you order small batches of PCBs, you are also actually helping the production firms. They will have to spend less money throughout the initial stages of board testing. Figure 3 demonstrates a female engineer testing a printed circuit board.

• PCB Proto: Some companies also offer batch PCB prototype pooling services. Thus, they can provide your product super quickly and at a low price.

These are some of the advantages of Fabricated PCBs. In the next section, we will discuss their production phases.

Batched PCBs–Batch PCB and Electronics Production

Batch PCB is the most popular production process in the electronics production business.

You will see that electronics manufacturing is often distributed into separate, particular phases in the volume production method.

In every phase, various machines and even computer-operated ones are highly involved. If you are wondering about the production stages followed by batch PCB manufacturers, look no further.

We have listed them down for you:

- First of all, producers create printed circuit boards.

- Then, they bore holes in the PCB.

- After that, the electronic components will be added to the board. Figure 4 shows the placement of a microchip on the PCB.

4. Following this, they will solder these components into their locations.

5. Ultimately, they will do final checks on the board and prepare it for the end product.

In the coming section, we will explain why you should consider buying it.

Batched PCBs–Why Choose Small Batch PCB Assembly?

Before proceeding, we would like to ask why you would select a small batch Bill Of Materials (BOM) of a PCB to be fitted onto a board. PCB assembly.

Of course, your answer would involve one or more of the advantages mentioned in section 4.

That’s true, too.

In TodaToday’sld, when almost every everyday product has a PCB, one would want to manufacture them quickly. Industries are grasping the fact that they require quick PCB prototypes.

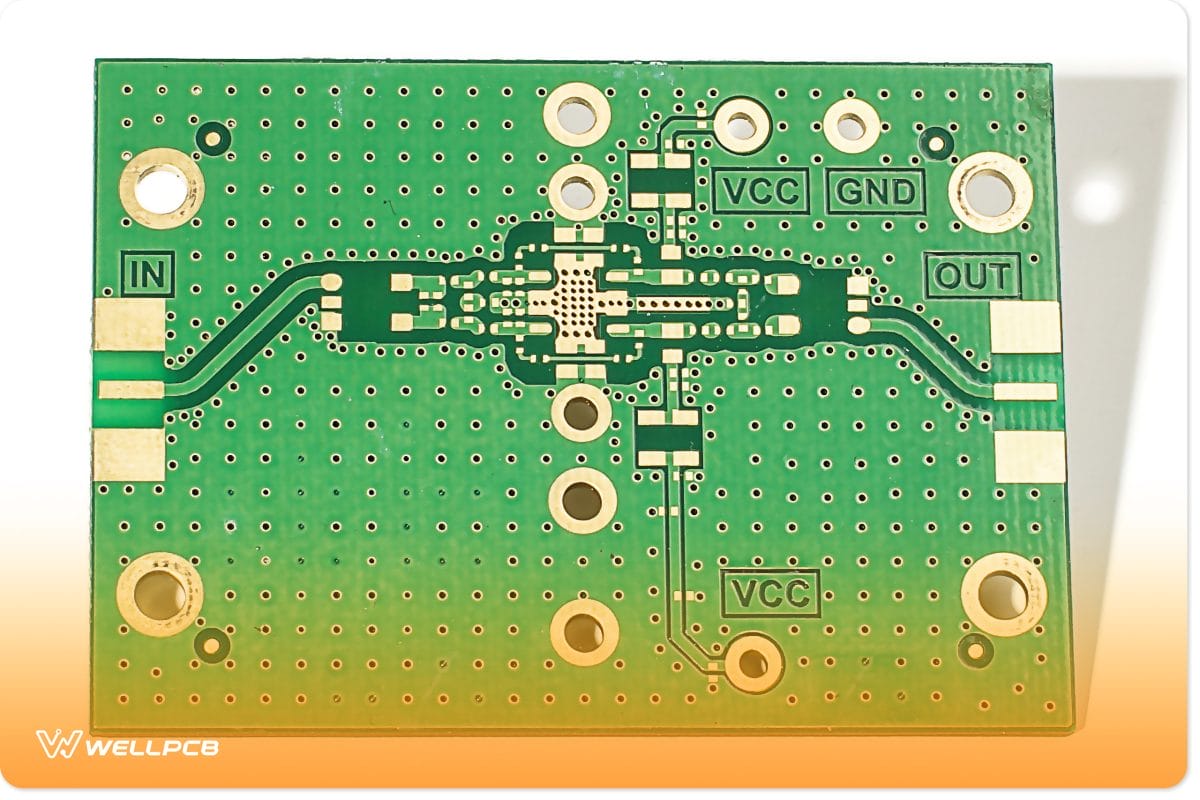

Figure 5 illustrates an isolated Electromagnetic Interference (EMI) is responsible for many cases of circuit board failure. EMI causes about 50% of PCB prototypes.

Companies must advance their products and develop new products to keep up with the evolving technology kingdom.

They need better PCBs for these accomplishments. However, full production of a fresh PCB design is not without risks.

Thus, all firms should go for a small batch Bill Of Materials (BOM) of a PCB fitted onto a board. PCB assembly.

They will need to realize sooner or later all the good it can do for them.

The next chapter will tell you about the best PCB batch manufacturers.

Batched PCBs–What is the Best Place to Manufacture PCBs in Small Quantities?

After spending hours researching the internet, I have listed down the three best batch PCB manufacturers:

- OurPCB

- WellPCB

- PCB

I have not numbered them as I consider all of them equally good. You can also help me decide which one is the best based on your own experiences.

I have found them better than others because of the customer reviews. I scoured the internet and came across some customer reviews that seemed rather positive.

OurPCB

OurPCB has been in the market since 2007. It is based in Belgium and has expertise in providing small-series PCBs and prototypes.

It has ISO9001:2008-approved production units in China. According to them, its employers have over 13 years of nonstop PCB experience.

In the previous 12 years, they have developed an embedded web-based commerce platform that ensures reliable, low-cost, and fast delivery of PCB technologies.

Furthermore, they provide many value-added services to their customers. You can visit their website for more information.

WellPCB

WellPCB PTY LTD Company is the daughter firm of Uniwell Circuits. It is registered in Australia. Their engineers and staff are highly qualified and have years of experience in PCB.

They mainly focus on SMT, which will allow a pick-and-place machine to easily place the components on the PCB (PCB Assembly, Fabrication, and Turn-key services).

Trusting need to know about ordering custom PCB Circuit boards online. For the PCB board you need, you can contact us at WellPCB.

You will get fast delivery, high quality, easy ordering, and low-cost PCBs. They deliver and take orders from users worldwide and can deliver more than 10,000 PCBs in a month.

They have a special service called Express PCB for batched PCBs. It would be best if you mentioned in your order that you want to use this service. After that, your order will be prioritized, and you can get your PCB even in five days.

It is not; they have all the value-added services available. Visit their website for more information.

PCB Assembly Technology

Assembly Technology has expertise in providing personalized batched SMT.

This will allow a pick-and-place machine to easily place the components on the PCB (PCB assembly services).

They claim that they have what it takes to tackle the hardest jobs. Moreover, they have advanced manufacturing facilities that will meet your expected quality of the PCB.

If you choose them, you can also get turn-key SMT).

This will make it easy for a pick-and-place machine to easily pick and place the components on the PCB (PCB assembly facilities for batched boards.

They will especially supervise the whole SMT).

This will make it easy for a pick-and-place machine to pick and place the components on the PCB (PCB assembly process), from parts attaining, PCB fabrication, to final product delivery.

They have earned a market reputation because they produce low-volume SMT.

This will make it easy for a pick-and-place machine to place the components on the PCB (PCB assembly services).

Can you guess the other name for low-volume PCB?

Furthermore, they make sure that your SMT.

This will make it easy for a pick-and-place machine to pick and place the components on the PCB (the PCB assembly job is safe and can be delivered quickly).

Customer Reviews

In this section, we have posted photos of one customer review about each company.

Conclusion

In conclusion, we would say that small-batch PCB assemblies come with certain benefits.

A lot of firms do not have the space requirements or money to assemble their personal printed circuit boards.

You will discover that subcontracting PCB production will save lots of your business expenses involved in overhead.

You will also frequently get your small-batch PCB orders in a short period. Did you know every great product comes after endless testing hours?

So, small-batch PCB orders also permit firms to test your product design with fewer expenses.

It doesn’t matter which project you are working on. Small-batch PCB should be your choice. It would be best if you preferred this SMT).

This will make it easy for a pick-and-place machine to pick and place the components on the PCB (PCB assembly production technique over others.

When you are circuit board shopping, various things might get you confused.

Whether you are looking for a single-sided, double-sided, or any other type of PCB, contact us today to learn more about how we can help you.