Custom Medical Cable Assemblies for Imaging, Monitoring, and Surgical Systems

Medical cable assembly solutions transmit power and signal between diagnostic machines, medical devices and patient monitoring systems in clinical environments.

WellPCB builds custom medical cable assemblies using TPU, silicone, and TPE jacketing, with EMI shielding and overmolded connectors designed for tight spaces and the flex they need.

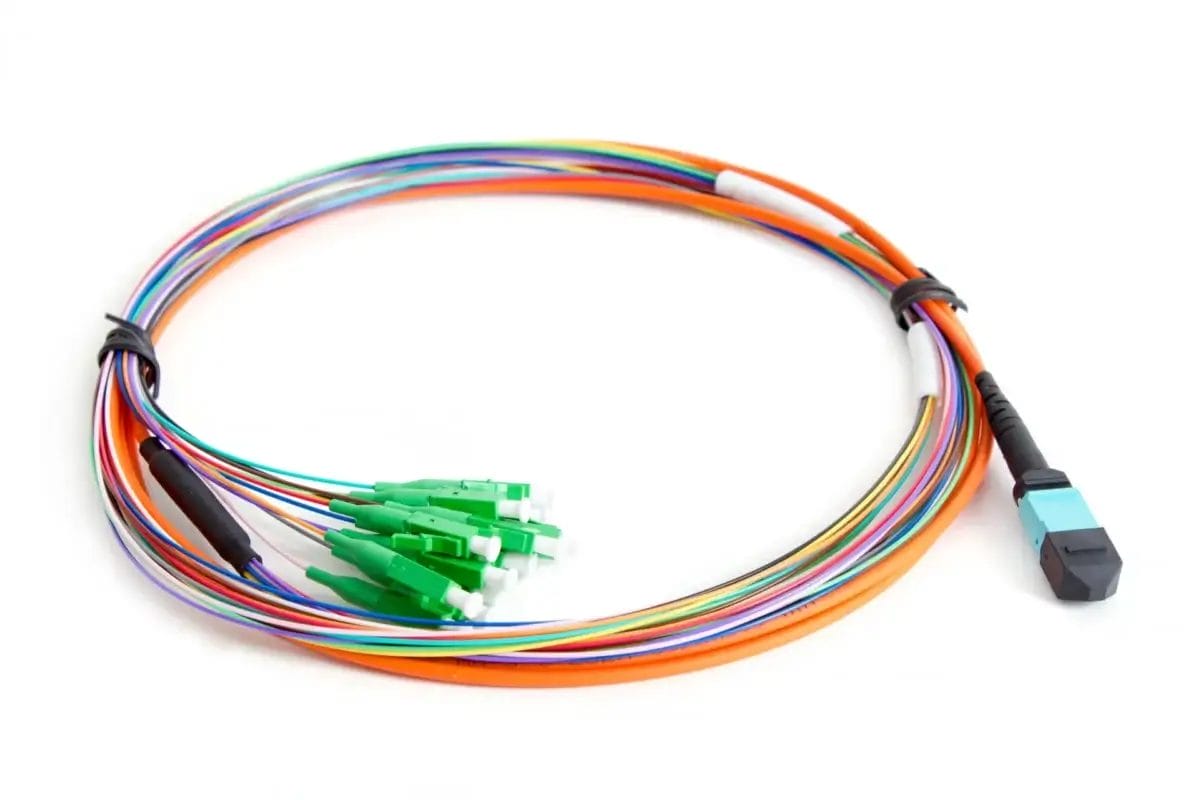

Our medical cable assembly manufacturing services can handle both single use and reusable builds, as well as hybrid fiber optic and signal formats, and are validated for compatibility with autoclave, ETO, and gamma disinfection methods.

- Custom assemblies for imaging, monitoring, and surgical platforms.

- TPU, silicone, and TPE jacketing with overmolded strain reliefs.

- Full test coverage: electrical, dimensional and mechanical.

ISO9001 ISO13485

ISO14001

IATF

16949

IPC-A-610H International

Certification

Fully Automated

AOI Inspection

Medical Cable Assembly Solutions for High-Density Systems

WellPCB manufactures custom medical cable assemblies based on the routing, signal, and pinout constraints that our clients request.

All assembly steps are handled in controlled environments using fixtures, strain-relief profiles and connector termination procedures that match the client’s specifications.

We also support multi-stage routing with inline breakouts, EMI braid wrapping, ferrule installation, and pin setting across staggered contact rows.

Our technicians follow strict electrical and mechanical documentation to maintain jacket orientation, pitch separation, and labeled routing per build instructions.

We verify the final assemblies are for wire mapping, physical alignment, and conformance to bend specifications before we ship them to our clients.

Our Medical Cable Assemblies Capabilities

WellPCB’s medical cable assembly facility manufactures custom solutions with in house overmolding and electrical and mechanical testing for both prototypes and scaled production.

Each cable build follows routing and dimensional controls aligned to IATF16949:2016 and ISO9001:2015 requirements.

Our wire preparation supports stranded or solid copper conductors from AWG 40 to 120mm², cut and stripped using precision rotary blade equipment with insulation length control that meets IPC standards.

Terminations include crimped, tinned, or soldered ends using thermal stripping or mechanical separation, depending on the jacket type.

Operator workflows are controlled by assembly drawings and part-level routing sheets, with crimp height and pull strength measured at every 50 units per lot.

Conductor length tolerances are maintained within IPC rating standards.

We support extrusion and jacketing using TPU (with wear resistance 3 to 5x greater than natural rubber), TPE, PVC, and silicone with OD ranges between 1.5 mm and 9.0 mm, verified before the production process and staged in ESD-safe cable trays.

Jacket ends are stripped with careful control to protect underlying shielding or fillers. OD concentricity, jacket roundness, and sheath continuity are inspected visually and dimensionally using calipers and ring gauges.

Cut jackets are fitted during termination to preserve jacket edge integrity and ensure mechanical retention at crimp or overmold interfaces.

Overmolds are formed using aluminum or steel molds matched to cable geometry, with cavity fills for right angle, inline or multicore split configurations.

WellPCB uses elastomeric compounds rated Shore A65 to A90 and cured at 302 to 356 °F (150 to 180 °C), providing thermal integrity throughout sterilization cycles.

Molded joints undergo tensile validation in high strength test configurations and are visually checked for air gaps, flash, or shrink distortion. We also support ferrule encapsulation, boot flaring, and strain relief formation directly over split cable exits.

Cable terminations include 2 to 64-position connectors across circular, coaxial, and rectangular interfaces, including formats used by LEMO and ODU, with contact pitch support down to 0.635 mm and insulation diameter match up to 1.8 mm per lead.

Pinout maps are matched against customer schematics using continuity probes or automated connector testers.

Contact depth is verified using cavity inspection tools, with overinsertion or back-out limits kept to the smallest offset from the spec centerline.

Signal pairs are twisted, aligned, and jacketed before routing to final positions for panel mount or inline mating.

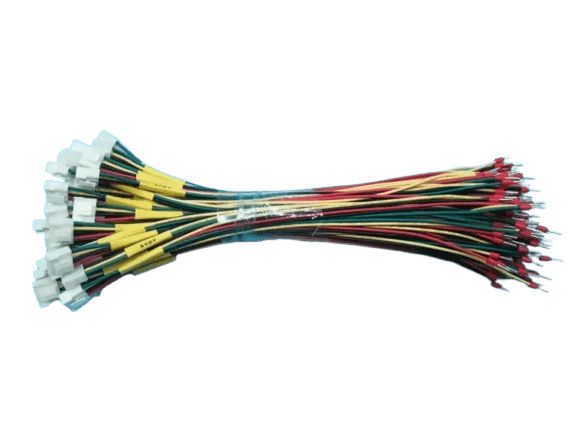

Harness assemblies are constructed on fixtured panels with split lengths, connector types, and bend radii controlled to within the IPC Standard of the routing layout.

All breakouts are labeled using heat-shrink tubing or laser marked ID bands placed at defined offset intervals.

Branches are sleeved with expandable braid or PVC tubing, with inner bundles secured using crimp collars, cable ties, or internal potting compounds.

Cable support includes routing across support saddles, strain-loop gaps, and anchor points used for robotic, diagnostic, and surgical medical equipment.

Electrical testing includes continuity measurement across all conductors, insulation resistance up to 500 MΩ, and hi-pot withstand testing at up to 1500 VDC, depending on the assembly rating.

Signal cables are evaluated using TDR for impedance consistency, return loss, and propagation delay.

Test logs are tagged to batch numbers and cross-referenced to routing drawings. Failures are documented by pin number, error type and corrective action to isolate mechanical or operator faults.

These test outcomes are important in applications where cable failure could disrupt patient monitoring or life support functions.

Assembly is conducted in electrostatic protected zones using grounded workstations, wrist straps, and ESD-rated trays for cable staging.

Incoming wire, terminals, and connector shells are tested for conductivity and surface resistance in accordance with ESD S20.20 guidelines. Tools and fixtures are cleaned and revalidated daily for contact wear, static buildup, and alignment drift.

Connectors are mated only once during test and final inspection to reduce insertion wear and preserve contact plating integrity in high cycle builds.

We support prototype builds starting at 1 unit through volume production exceeding 2.5 million assemblies per year, with documentation tracked per batch, operator ID, material code, and connector lot.

Each build includes revision controlled drawing, inspection signoff, and post-test report stored by work order number. Assembly aids include custom crimp blocks, overmold tooling, bend fixtures, and connector jigs, all tailored to each part number.

Scaling to production includes staged fixture storage, mold duplication, and documented lot-to-lot consistency control.

Why Get Your Medical Cable Assemblies

from WellPCB?

WellPCB provides certified medical cable assembly with in house tooling, controlled routing, and validated testing. We support prototype and high production volumes with traceability, overmolding, and compliance with IATF16949:2016 and ISO9001:2015 protocols. Our technical practices align with those used by global manufacturers such as Amphenol and TE Connectivity.

One-Stop Medical Cable Assembly Services

Certified Manufacturing for Medical Devices

Flexible Volumes and Fast Prototyping

Shielding and Signal Integrity Control

Overmolding and Strain Relief Integration

Process Testing and Production Traceability

Applications of Medical Cable Assemblies

WellPCB manufactures medical cable assemblies used across diagnostics, surgery, monitoring and embedded support systems. Each cable is built to match the environmental, mechanical and signal demands of its target system.

Diagnostic Imaging Systems

Patient Monitoring Equipment

Surgical Robotics and Endoscopes

Life Support Devices

Disposable Interfaces

Hospital Communication Systems

What are the Design Considerations

for Medical Cable Assemblies?

Every medical cable assembly must be configured to match sterilization demands, shielding layout, connector spacing and movement conditions.

These factors affect safety, routing reliability and long term cable performance. WellPCB supports these design choices with material selection, test validation, and process control across a broad range of medical systems.

Sterilization Method Compatibility

EMI/RFI Shielding Architecture

Connector Selection & MOOP/MOPP Rating

Flex & Torsion Durability

Biocompatibility and Surface Treatment

Submit Your Design

Send us your design details (Drawing or Detailed Specifications).

Get a Fast Quote

Once your design and specs are received, a fast quote will be sent to you within 24 hours.

Confirm Order & Make Payment

When the quotation is approved, please send the PO or order confirmation, we will proceed with the production after receiving your payment.

Arrange Production & Inspection

Before production, our technical team will review all details of the drawing/specs again. If everything is OK, the order will start. We'll keep you updated throughout the manufacturing process. After the production is completed, the products will be 100% inspected.

Packaging & Delivery

When completed, your order will be carefully packed and shipped to you, with shipping documents and tracking information provided.

WellPCB is trusted by millions of

businesses and innovators.

Why Choose WellPCB as Your Wire Harness Manufacturer?

WellPCB stands out among USA wire harness manufacturers by delivering superior quality, advanced solutions, and unmatched reliability. With years of experience serving global markets, WellPCB has earned a reputation as one of the top wire harness manufacturers in the USA.

WellPCB specializes in custom wire harnesses for complex electronic and industrial applications. You can order these assemblies with $100 off using our special offer—delivering high-quality, tailor-made harnesses at competitive rates for your most demanding projects.

Hommer Zhao

Founder and Chief Editor – Hommer Zhao

Welcome! I’m Hommer Zhao, the founder and Chief Editor of WellPCB. With years of experience in the PCB industry, I’m committed to making sure our content is both accurate and helpful. We’re proud to serve a growing community of over 4,000 customers worldwide, and our goal is to provide you with the best resources and support. Your satisfaction is our top priority, and we’re here to help you every step of the way!

Jesse Holland

Technical Manager – Jesse Holland

Hi, I’m Jesse Holland, an Engineer and Technical Manager at WellPCB. With years of experience in PCB design and engineering, I’m here to ensure that every project we work on meets the highest technical standards. I lead our team, focusing on precision and innovation, collaborating closely with clients to provide tailored solutions and expert guidance. Whether you’re facing a complex design challenge or need advice on technical aspects, I’m here to ensure your project is a success from start to finish.

Nathan Jensen

Purchasing Manager – Nathan Jensen

Hi, I’m Nathan Jenson, the Purchasing Manager at WellPCB. I’m responsible for sourcing the best materials and components to ensure our products meet the highest quality standards. With my extensive experience in procurement, I work closely with suppliers to secure reliable and cost-effective solutions while maintaining strong relationships to support our operations. I aim to ensure every project runs smoothly by providing the resources needed to deliver on time and to your satisfaction.

Emma

Sales Manager – Emma

Hey, I am Emma, sales manager at WellPCB. I studied electronic science and technology at university and have served customers for PCB and PCB Assembly service for several years.

I enjoy communicating with customers and our technicians to solve problems, and customers always say, "It's great to have you onboard".

It is my pleasure and honour to be helpful. Contact me now, and you'll know.

Bella and Cassiel

Sales Representatives – Bella and Cassiel

We’re Bella and Cassiel, your dedicated sales representatives at WellPCB. With our extensive knowledge of the PCB industry, we’re here to provide exceptional service and support. We take the time to understand your unique needs and are always ready to offer tailored solutions and advice. Whether you need product recommendations, assistance with your orders, or simply have a question, we’re here to ensure your experience is smooth and seamless at every step.

Mandy and Wendy

Sales Representatives – Mandy and Wendy

We’re Mandy and Wendy, your friendly sales representatives at WellPCB. Passionate about helping our customers, we bring a wealth of experience in the PCB industry to provide you with the best solutions and service. We take pride in building strong relationships with our clients, understanding their specific needs, and offering personalised support to ensure their satisfaction. Whether you’re looking for advice, product information, or assistance with any part of your order, we’re here to make your experience as smooth and efficient as possible.

Our Team

Our skilled engineers and technicians bring expertise and precision to every PCB assembly project. Committed to quality, efficiency, and innovation, our team ensures every order meets the highest UL, IPC, ROHS & REACH standards, delivering reliable solutions tailored to your needs.

- Founder and Chief Editor – Hommer Zhao

- Technical Manager – Jesse Holland

- Purchasing Manager – Nathan Jensen

- Sales Manager – Emma

- Sales Representatives – Bella and Cassiel

- Sales Representatives – Mandy and Wendy

Medical Cable Assemblies Case Studies

Case Study

Features:

Modern medical imaging and monitoring equipment, such as MRI systems, electrocardiographs, and patient telemetry devices, rely on precise signal transmission. RF cables help transmit diagnostic data clearly, enabling accurate results and real-time feedback in critical healthcare environments.

Case Study

Features:

- Excellent flex life performance

- Fast transmission

- Reduces vibration and shock, and reduces wear

Case Study

Features:

- Strong anti-interference ability

- Easy to install and manage

- Corrosion and heat resistance

Client Feedback On Our Medical Cable Assemblies

As an R&D manager, I have had an outstanding experience working with WELL-PCB. For many years, our company has entrusted them with the production, assembly, and programming of the boards developed in our R&D unit, and they have consistently exceeded our expectations.

Hamid Reza Moshayedi

R&D Manager

Their work is very impressively perfect. Today, when they check our company PCB board after assemble. They found a fake short point which many engineers has never found in the past years. But that is just designed so. The PCB board quality is excellent. Their service is also excellent.

MikeZ

My friend introduced WellPCB to me, the first try, a little look forward to. I ordered a 47*72 10ps PCB, and I can’t wait to receive my PCB. So I used expedited service and received my PCB in three days. I tested and soldered the PCB, Quality is really good, silkscreen, plating also great.

Warren Cliton

Medical Cable Assembly FAQs

What cable types are supported in your medical assemblies?

We support a wide range of cable types, including RF cables, twisted pair, ribbon, multicore, and hybrid combinations of signal and power conductors. These options are configured based on electrical rating, routing geometry, and jacketing requirements for the target application.

Can your assemblies withstand autoclave sterilization?

WellPCB offers cable assemblies for medical use, constructed with materials rated for continuous operation from -80 °C to 105 °C, including thermal cycling tolerance. TPU and silicone jackets are compatible with high temperature cleaning processes, supporting assemblies used in systems requiring repeated sterilization.

Do you provide compliance documentation and traceability?

We provide comprehensive compliance packages, including RoHS, REACH, and ISO certificates, as well as batch-level traceability. Our documentation includes wire ID, routing spec, jacket material, and all testing to ensure electrical and mechanical conformity.

Do you support medical cable assembly manufacturing for embedded diagnostic systems?

Yes, our medical cable assembly manufacturing services support embedded platforms in imaging, patient monitoring, and surgical control systems. These assemblies are configured with branch harnessing, label ID and pin mapping that match internal system layouts.

Can your team manufacture reusable and disposable medical cable assemblies?

Yes, we manufacture custom medical cable assemblies for both reusable and single use systems, using materials and connector finishes selected for ETO, gamma, or autoclave compatibility. Disposable builds are optimized for short-cycle sterilization and cost-sensitive manufacturing.

Do you support small-batch prototyping?

Yes, we support prototyping from 1 unit, including custom cut lengths, multi-pin harness assemblies, and overmolded terminations. All early builds follow the same quality control processes and material tracking used in production runs.

What testing protocols do you follow?

Our medical cable assembly manufacturing process includes testing for high voltage insulation, conductor resistance, flex life, and mechanical retention. Dimensional accuracy, label compliance, and cable traceability are verified to support assemblies used across various industries.

Get Custom Medical Cable Assemblies for Your Medical Industry Needs

Get $100 Off Your First Order!

WellPCB’s ISO 9001-certified facility delivers custom medical cable assemblies with overmolded strain reliefs, EMI shielding and full FDA documentation.