Custom Appliance Wire Harnesses for Reliable Performance

WellPCB is one of the leading appliance wire harness manufacturers, delivering high quality wire harness assemblies for major appliances and OEMs worldwide.

From home appliance wiring harnesses to industrial applications, our products meet ISO 9001 and IATF 16949 standards, supporting safe connections, durable wire and cable integration and reliable performance.

- Capable of handling wire gauges 10 to 30 AWG with ±0.1 mm precision

- 100% testing IPC/WHMA-A-620 workmanship standards

- Scalable builds from prototype lots of 50 harnesses to mass production runs exceeding 100,000 units for global OEM supply

ISO9001 ISO13485

ISO14001

IATF

16949

IPC-A-610H International

Certification

Fully Automated

AOI Inspection

Appliance Wire Harnesses for Home and Industrial Equipment

Appliance wire harnesses provide organized routing of electrical wire and cable, ensure safe connections across everyday and industrial appliances and reduce assembly time, improve reliability and allow OEMs to maintain consistent quality standards. As a leading provider of custom wiring harness solutions, WellPCB delivers precision-engineered assemblies for diverse applications.

The global appliance market is projected to exceed USD 600 billion by 2030 according to Grand View Research, driving demand for advanced wiring and custom wire harness solutions. WellPCB supports this growth by delivering precision engineered, tested and certified harnesses tailored to modern consumer electronics and heavy duty industrial applications.

WellPCB manufactures wire harness products for appliances using UL-certified electrical wire, flame retardant insulation and Molex or Amphenol connectors.

Each custom wire harness manufacturer build is validated with 100% continuity checks, insulation resistance measurements and pull-force testing. We provide wire harness assemblies that reduce in-field wiring errors and support both prototype evaluation and OEM scale deployment.

Appliance Wire Harness Manufacturer Capabilities

Automated machines cut and strip wire and cable with ±0.1 mm accuracy across gauges from 10 AWG to 30 AWG.

This precision guarantees consistent harness lengths, clean terminations and reduced rework during appliance assembly.

We apply monitored crimp forces between 20 to 200 N, ensuring every terminal connection meets IPC/WHMA-A-620 workmanship standards.

Harnesses integrate UL-listed connectors from leading suppliers such as Molex and Amphenol for high current appliance wire harnesses.

Injection overmolding enhances durability by sealing out moisture, oil and dust. Jackets are manufactured from PVC or XLPE compounds rated for operating temperatures between -40°C and +125°C.

These insulation systems extend the service life of wire harness products in home appliances and industrial environments.

We design custom wire harness solutions for HVAC units, induction cooktops and commercial appliances rated up to 600 V AC.

Clearances and creepage distances comply with ISO, UL and RoHS international quality standards.

Our engineering team can deliver prototype builds within 3 weeks, enabling rapid validation of new appliance models.

This service allows OEMs to evaluate form, fit and electrical integrity before scaling to volume production.

With automated assembly lines, we support production from 50 units to more than 100,000 harnesses.

Our flexible approach accommodates both custom batches and long term OEM contracts, backed by advanced manufacturing processes.

Every harness undergoes 100% electrical continuity checks, hipot testing up to 3 kV and pull-force validation.

For long term durability, we perform salt spray corrosion tests on terminals and connectors, ensuring reliable performance across industrial applications and consumer products.

We provide wire ID systems with barcoding, heat-shrink labeling and color coded conductors.

Packaging can be customized for streamlined assembly line use, supporting equipment manufacturers that require organized, ready-to-install wire harness assemblies.

Why Choose WellPCB?

One-Stop Manufacturing Services

Certified Quality Standards

Scalable Manufacturing Capabilities

Global OEM Partnerships

Proven Reliability

Completely Custom Wire Harnesses

Different Types of Appliance Wire Harnesses

Appliance wire harness manufacturers produce a wide range of harnesses to meet the diverse electrical needs of household and industrial equipment. Each type is engineered to optimize routing, safety and reliable performance within its application.

Power Supply Harnesses

Control Panel Harnesses

Signal and Data Harnesses

High-Temperature Harnesses

Battery Cable Assemblies

Custom Wire and Cable Configurations

Our Wire Harness Manufacturing Process

As dedicated wire harness manufacturers, WellPCB follows a structured process to deliver high quality wire harness products that meet strict international quality standards. Each stage is supported by automation, inspection and compliance testing to guarantee reliable wiring solutions for appliances and industrial applications.

1. Design & Engineering Review

2. Material Sourcing

3. Precision Cutting & Crimping

4. Assembly & Overmolding

5. Testing & Validation

6. Packaging & Delivery

Standards We Meet As Appliance Wire Harness Manufacturers

| Standard | Application | WellPCB Implementation |

|---|---|---|

| IPC/WHMA-A-620 | Workmanship | All crimp, solder, assembly work |

| UL 94 | Fire Safety/Flammability | Flame-retardant materials and insulation |

| ISO 9001, IATF 16949 | Quality Management | Manufacturing operations |

| RoHS/REACH | Environmental | Lead free, compliant insulation |

How to Order from Appliance Wire Harness Manufacturers

Submit Your Design

Send us your design details (Drawing or Detailed Specifications).

Get a Fast Quote

Once your design and specs are received, a fast quote will be sent to you within 24 hours.

Confirm Order & Make Payment

When the quotation is approved, please send the PO or order confirmation, we will proceed with the production after receiving your payment.

Arrange Production & Inspection

Before production, our technical team will review all details of the drawing/specs again. If everything is OK, the order will start. We'll keep you updated throughout the manufacturing process. After the production is completed, the products will be 100% inspected.

Packaging & Delivery

When completed, your order will be carefully packed and shipped to you, with shipping documents and tracking information provided.

WellPCB is trusted by millions of

businesses and innovators.

Why Choose WellPCB as Your Wire Harness Manufacturer?

WellPCB stands out among USA wire harness manufacturers by delivering superior quality, advanced solutions, and unmatched reliability. With years of experience serving global markets, WellPCB has earned a reputation as one of the top wire harness manufacturers in the USA.

WellPCB specializes in custom wire harnesses for complex electronic and industrial applications. You can order these assemblies with $100 off using our special offer—delivering high-quality, tailor-made harnesses at competitive rates for your most demanding projects.

Hommer Zhao

Founder and Chief Editor – Hommer Zhao

Welcome! I’m Hommer Zhao, the founder and Chief Editor of WellPCB. With years of experience in the PCB industry, I’m committed to making sure our content is both accurate and helpful. We’re proud to serve a growing community of over 4,000 customers worldwide, and our goal is to provide you with the best resources and support. Your satisfaction is our top priority, and we’re here to help you every step of the way!

Jesse Holland

Technical Manager – Jesse Holland

Hi, I’m Jesse Holland, an Engineer and Technical Manager at WellPCB. With years of experience in PCB design and engineering, I’m here to ensure that every project we work on meets the highest technical standards. I lead our team, focusing on precision and innovation, collaborating closely with clients to provide tailored solutions and expert guidance. Whether you’re facing a complex design challenge or need advice on technical aspects, I’m here to ensure your project is a success from start to finish.

Nathan Jensen

Purchasing Manager – Nathan Jensen

Hi, I’m Nathan Jenson, the Purchasing Manager at WellPCB. I’m responsible for sourcing the best materials and components to ensure our products meet the highest quality standards. With my extensive experience in procurement, I work closely with suppliers to secure reliable and cost-effective solutions while maintaining strong relationships to support our operations. I aim to ensure every project runs smoothly by providing the resources needed to deliver on time and to your satisfaction.

Emma

Sales Manager – Emma

Hey, I am Emma, sales manager at WellPCB. I studied electronic science and technology at university and have served customers for PCB and PCB Assembly service for several years.

I enjoy communicating with customers and our technicians to solve problems, and customers always say, "It's great to have you onboard".

It is my pleasure and honour to be helpful. Contact me now, and you'll know.

Bella and Cassiel

Sales Representatives – Bella and Cassiel

We’re Bella and Cassiel, your dedicated sales representatives at WellPCB. With our extensive knowledge of the PCB industry, we’re here to provide exceptional service and support. We take the time to understand your unique needs and are always ready to offer tailored solutions and advice. Whether you need product recommendations, assistance with your orders, or simply have a question, we’re here to ensure your experience is smooth and seamless at every step.

Mandy and Wendy

Sales Representatives – Mandy and Wendy

We’re Mandy and Wendy, your friendly sales representatives at WellPCB. Passionate about helping our customers, we bring a wealth of experience in the PCB industry to provide you with the best solutions and service. We take pride in building strong relationships with our clients, understanding their specific needs, and offering personalised support to ensure their satisfaction. Whether you’re looking for advice, product information, or assistance with any part of your order, we’re here to make your experience as smooth and efficient as possible.

Our Team

Our skilled engineers and technicians bring expertise and precision to every PCB assembly project. Committed to quality, efficiency, and innovation, our team ensures every order meets the highest UL, IPC, ROHS & REACH standards, delivering reliable solutions tailored to your needs.

- Founder and Chief Editor – Hommer Zhao

- Technical Manager – Jesse Holland

- Purchasing Manager – Nathan Jensen

- Sales Manager – Emma

- Sales Representatives – Bella and Cassiel

- Sales Representatives – Mandy and Wendy

Appliance Wire Harness Manufacturers Case Studies

PCB Assembly

The picture shows an HDMI-to-DVI cable with USB power. It can be used to connect HDMI-enabled devices (such as laptops and TV boxes) to DVI-equipped monitors and other home appliances.

Advantages:

- •Strong Compatibility: Allows connection between devices with different interface standards, expanding their use cases.

- •Stable Transmission: Provides stable video signal transmission, minimizing interference and loss during signal transmission.

- •Convenient Power Supply: No need to find a separate power source, making it more convenient to use.

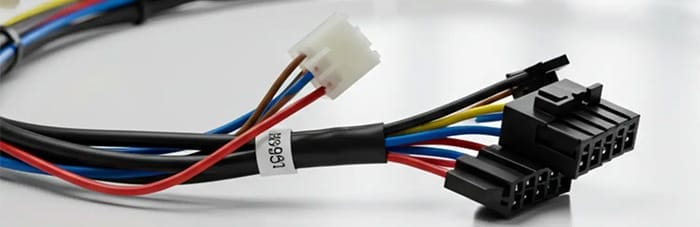

PCB Assembly

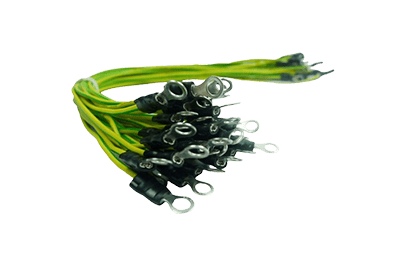

This project shows the wire harness with ring terminal--A kind of typical grounding harness.

Commonly used in large or metal-cased household appliances such as refrigerators, washing machines, air conditioners, and electric water heaters.

Its functions include grounding protection and static discharge, providing greater safety and stability.

PCB Assembly

This is a multicore ribbon cable harness that represent different circuit functions, facilitating wiring and maintenance. Equipped with a white multi-pin connector, this connector allows for centralized connection of multiple signals or power sources, providing a compact and convenient connection.

This allows for efficient transmission of power and control signals, enhancing the reliability and convenience of home appliance use.

Appliance Wire Harness Manufacturers Client Feedback

As an R&D manager, I have had an outstanding experience working with WELL-PCB. For many years, our company has entrusted them with the production, assembly, and programming of the boards developed in our R&D unit, and they have consistently exceeded our expectations.

Hamid Reza Moshayedi

R&D Manager

Their work is very impressively perfect. Today, when they check our company PCB board after assemble. They found a fake short point which many engineers has never found in the past years. But that is just designed so. The PCB board quality is excellent. Their service is also excellent.

MikeZ

My friend introduced WellPCB to me, the first try, a little look forward to. I ordered a 47*72 10ps PCB, and I can’t wait to receive my PCB. So I used expedited service and received my PCB in three days. I tested and soldered the PCB, Quality is really good, silkscreen, plating also great.

Warren Cliton

Appliance Wire Harness Manufacturers FAQs

Can wire harnesses support smart appliances and IoT integration?

Yes. As a modern appliance wire harness manufacturer supporting the shift toward smart technology, WellPCB designs harnesses that integrate with Wi-Fi, Bluetooth and IoT modules in connected appliances.

Our custom wire harness solutions include shielded wire and cable for EMI protection, dedicated signal lines for sensors and labeled connectors for seamless PCB integration. These wire harness products enable reliable communication in smart refrigerators, HVAC systems and washing machines, aligning with Industry 4.0 trends in wire harness manufacturing.

Are you a member of industry associations like WHMA?

Yes, WellPCB aligns with the Wire Harness Manufacturers Association (WHMA), following IPC/WHMA-A-620 workmanship standards. Membership signals compliance with global harness practices and access to the latest updates in the wire harness industry.

Do you meet international compliance and certification standards?

Every harness is built under ISO 9001 and IATF 16949 certification, with workmanship validated against IPC/WHMA-A-620. We also work with wire harness companies like Molex and Amphenol to guarantee that all components meet UL/CSA ratings.

What industries use appliance wire harnesses beyond home appliances?

WellPCB doesn’t just supply wiring harnesses for household equipment but also for medical devices, consumer electronics, control panels and the automotive industry. This makes us a versatile appliance wire harness manufacturer with cross-sector experience.

Can you support both wire harness and cable assemblies?

Yes, WellPCB offers cable assemblies and wire harness production under one roof. As a manufacturer of high quality assemblies, we deliver both custom cable assemblies and cable harness builds, ensuring OEMs receive complete assembly solutions without managing multiple suppliers.

Appliance Wire Harness Manufacturers Delivering Reliable Wiring Solutions

Get $100 Off Your First Order!

Partner with WellPCB, one of the trusted appliance wire harness manufacturers, for custom wiring solutions built to meet global quality standards.