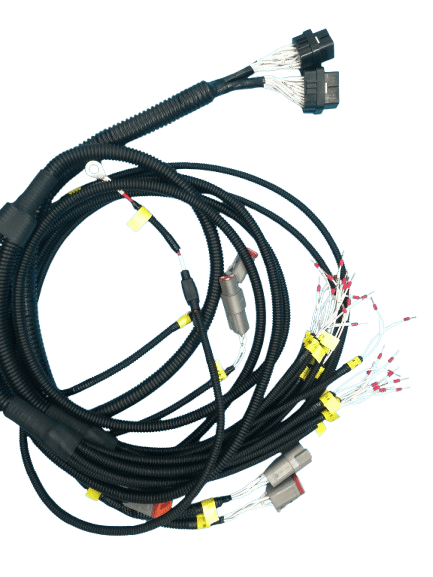

Custom Car Wire Harnesses for Power, Signal, and Vehicle System Integration

Modern vehicles contain over 40 harnesses, 700+ connectors, and more than 3,000 wires spanning up to 2.5 miles.

As a specialized automotive wiring harness manufacturer, WellPCB delivers electric power, signal routing, and automotive cable assembly solutions between ECUs, sensor networks, battery modules, and lighting systems in internal combustion, hybrid, and electric vehicles.

WellPCB is an automotive wiring harness manufacturer that produces custom wire harness assemblies in-house using RoHS-compliant automotive wire, flame-retardant cable sleeving, and sealed connectors for harsh automotive environments.

Production supports wire gauges from 40AWG to 120 mm², high-voltage routing for inverter and battery lines, and twisted-pair signal channels for CAN bus and data control.

- RoHS-compliant wire, flame-rated cable jackets, and sealed connectors.

- Automotive wiring harness assembly on form boards with crimped terminals and wire marking.

- 100% continuity and pull-force testing on all car wiring harness assemblies.

ISO9001 ISO13485

ISO14001

IATF

16949

IPC-A-610H International

Certification

Fully Automated

AOI Inspection

Automotive Wiring Harness Manufacturer for Routing Accuracy and Electrical Reliability

Automotive wiring harnesses manage the routing of power and data between Electronic Control Units (ECUs), control modules, lighting assemblies, and Electric Vehicle (EV) subsystems across combustion, hybrid, and electric vehicles.

These wiring systems support integrated signal paths and load-bearing conductors throughout the vehicle body and drivetrain.

WellPCB manufactures custom wire harness assemblies based on client-supplied schematics, pinout maps, and netlists.

Each wiring harness for car applications is fixture-assembled with length-matched conductors, grouped routing, and calibrated crimp terminations.

We use halogen-free automotive wire, flame-retardant sleeving, and moisture-resistant connector systems that are rated for thermal cycling, abrasion, and vibration.

IATF 16949 Certified Automotive Wiring Harness Manufacturer Capabilities

WellPCB manufactures automotive wiring harnesses in-house using calibrated equipment, fixture-based routing, and RoHS-compliant wire and cable. Our comprehensive wiring harness services cover every stage from conductor prep through final electrical testing. Each wire harness build is guided by OEM pinouts and BOMs, with process control covering conductor prep, terminal crimping, connector assembly, and electrical testing.

As an automotive wiring harness manufacturer, WellPCB processes automotive wire using programmable servo-controlled cut-and-strip machines. Conductor lengths from 50 mm to 2000 mm are prepared with insulation stripping tolerances of ±0.5 mm.

We support wire gauges from 40AWG to 120 mm² using XLPE, PVC, and silicone-jacketed types. Optical verification systems confirm cut length and strip depth before the wire is transferred to the automotive wiring harness assembly stations.

Closed-barrel, open-barrel, and flag-style terminals are crimped using pneumatic or hydraulic presses fitted with calibrated applicator dies.

Crimp height is checked using micrometer tools, and all crimps are validated to meet minimum pull-force values according to SAE J2030 and OEM-specific specs.

Connector types include sealed and unsealed housings, with HVIL-compatible terminals supported for high-voltage wire harnesses. Supported systems include Sumitomo, Yazaki Corporation, Deutsch, Molex, JST, and TE Connectivity.

Each automotive harness is assembled on mechanical form boards designed from customer routing diagrams. Harness routes are laid using spot taping, branching fixtures, and sleeving paths.

Grouped wires are bundled using PVC or braided cable sleeving, with concentric layup applied to twisted pairs for EMI-sensitive subsystems. Final layout is verified against drawing overlay sheets or digital inspection systems.

WellPCB’s automotive wiring harness manufacturer expertise extends to high-voltage EV systems using orange XLPE-jacketed cable rated for 600 V, with conductor sizes from 2.5 mm² to 6 mm².

Insulation resistance is tested to 100 MΩ at 500 VDC, and dielectric withstand testing is conducted at up to 1500 VDC for critical battery and inverter paths.

Protective sleeving includes fiberglass, silicone, and PET braided options. Cable routing incorporates bend radius validation and shielding continuity for charge and BMS modules.

Each automotive harness undergoes 100% continuity testing using computer-controlled test benches matched to the harness pinout table. Isolation tests use hi-pot equipment at 500–1500 VDC, depending on the harness type.

Visual inspections include terminal seating, insulation stripping quality, and wire marking legibility, performed at 5x to 10x magnification.

Pull-test and crimp-height logs are recorded for each harness group and linked to serialized QC reports.

All automotive wiring harnesses are serialized with barcoded labels, heat-shrink IDs, and batch metadata.

Labeling options include UV-rated inkjet, laser etch, or printed tags, depending on environmental class.

All wire and cable lots are tracked to supplier documentation and RoHS certificates. Operator IDs, timestamps, and final test logs are attached to each production record for traceable release.

WellPCB supports low-volume runs starting from a single unit, with scalable production for over 10,000 harnesses per part number.

Prototypes are built in 2 to 3 weeks, depending on connector availability and BOM complexity. We source wire, cable, and terminal materials through global cable suppliers, including Digi-Key, Mouser, and Avnet, with full material traceability and component substitution support.

Why Choose WellPCB as Your

Automotive Wiring Harness Manufacturer?

WellPCB is an assembly and wire harness manufacturer that builds all automotive wiring harnesses in-house using fixture-based routing, calibrated press crimping, and 100% test coverage.

Our process control supports high-volume builds with consistent conductor layout, verified terminal compression, and RoHS-traceable wire and cable materials, following IATF 16949 and IPC/WHMA-A-620 Class 3 standards.

In-House Production, No Outsourcing

10 Years of Experience in Harness Manufacturing

Sourcing Partnerships with Global Cable Suppliers

High-Quality Wire Harness Assembly Standards

Flexible Volumes from Prototype to Mass Production

Full Support for Automotive Cable Assemblies

What Types of Vehicles and Harness Builds does WellPCB Support?

WellPCB supplies automotive OEM wire harness solutions to OEMs, Tier 1 suppliers, and aftermarket manufacturers building for electric, hybrid, combustion, and specialty vehicle platforms.

We manufacture to your specifications across full production volumes, including builds for EV drivetrains, combustion engines, off-road equipment, ADAS systems, and low-volume service replacement harnesses.

Passenger Vehicles and Fleet Cars

Electric Vehicles and Hybrid Platforms

Heavy-Duty, Off-Road, and Agricultural Equipment

Autonomous and ADAS-Capable Platforms

Aftermarket and Service Replacement Automotive Harnesses

Our Automotive Wiring Harness Process

WellPCB manufactures every wiring harness for car applications using a defined technical workflow that begins with customer-supplied drawings and ends with serialized, test-validated harnesses ready for integration.

Our process supports wire harness drawing reviews, BOM traceability, in-line inspection, and scalable transition from prototype to final product manufacturing.

OEM Drawing & BOM Review

Routing Diagram and Pinout Mapping

DFM Feedback and Material Confirmation

Prototyping and Initial Sample Testing

Full-Scale Wire Harness Manufacturing

Electrical, Mechanical, and Visual Testing

Packaging, Documentation & Shipment

What Types of Wire and Insulation Materials do You Use?

In every wiring harness for car purposes, WellPCB uses stranded copper automotive wire with RoHS-compliant insulation systems including XLPE, PVC, silicone, and fiberglass.

All wire and cable are specified by conductor class, strand count, and voltage rating, supporting high-voltage systems, engine compartments, and interior harness builds across EV, hybrid, and combustion vehicle types.

Conductor Materials and Sizes

Primary Insulation Types

Secondary Sleeving and Shielding

Color Coding and Wire Marking

What are the Design Considerations for Automotive Wire Harnesses?

Designing automotive wiring harnesses requires optimization for electrical performance, packaging constraints, signal integrity, and mechanical durability. Each wiring harness for car applications must maintain reliable function under voltage load, EMI exposure, and mechanical stress throughout its installed service life.

Electrical Performance and Safety

Electromagnetic Compatibility (EMI/EMC) and Grounding

Strain Relief

Physical Design and Routing

Routing Difficulty

Length, Tolerance, and Outer Covering

Submit Your Design

Send us your design details (Drawing or Detailed Specifications).

Get a Fast Quote

Once your design and specs are received, a fast quote will be sent to you within 24 hours.

Confirm Order & Make Payment

When the quotation is approved, please send the PO or order confirmation, we will proceed with the production after receiving your payment.

Arrange Production & Inspection

Before production, our technical team will review all details of the drawing/specs again. If everything is OK, the order will start. We'll keep you updated throughout the manufacturing process. After the production is completed, the products will be 100% inspected.

Packaging & Delivery

When completed, your order will be carefully packed and shipped to you, with shipping documents and tracking information provided.

WellPCB is trusted by millions of

businesses and innovators.

Why Choose WellPCB as Your Wire Harness Manufacturer?

WellPCB stands out among USA wire harness manufacturers by delivering superior quality, advanced solutions, and unmatched reliability. With years of experience serving global markets, WellPCB has earned a reputation as one of the top wire harness manufacturers in the USA.

WellPCB specializes in custom wire harnesses for complex electronic and industrial applications. You can order these assemblies with $100 off using our special offer—delivering high-quality, tailor-made harnesses at competitive rates for your most demanding projects.

Hommer Zhao

Founder and Chief Editor – Hommer Zhao

Welcome! I’m Hommer Zhao, the founder and Chief Editor of WellPCB. With years of experience in the PCB industry, I’m committed to making sure our content is both accurate and helpful. We’re proud to serve a growing community of over 4,000 customers worldwide, and our goal is to provide you with the best resources and support. Your satisfaction is our top priority, and we’re here to help you every step of the way!

Jesse Holland

Technical Manager – Jesse Holland

Hi, I’m Jesse Holland, an Engineer and Technical Manager at WellPCB. With years of experience in PCB design and engineering, I’m here to ensure that every project we work on meets the highest technical standards. I lead our team, focusing on precision and innovation, collaborating closely with clients to provide tailored solutions and expert guidance. Whether you’re facing a complex design challenge or need advice on technical aspects, I’m here to ensure your project is a success from start to finish.

Nathan Jensen

Purchasing Manager – Nathan Jensen

Hi, I’m Nathan Jenson, the Purchasing Manager at WellPCB. I’m responsible for sourcing the best materials and components to ensure our products meet the highest quality standards. With my extensive experience in procurement, I work closely with suppliers to secure reliable and cost-effective solutions while maintaining strong relationships to support our operations. I aim to ensure every project runs smoothly by providing the resources needed to deliver on time and to your satisfaction.

Emma

Sales Manager – Emma

Hey, I am Emma, sales manager at WellPCB. I studied electronic science and technology at university and have served customers for PCB and PCB Assembly service for several years.

I enjoy communicating with customers and our technicians to solve problems, and customers always say, "It's great to have you onboard".

It is my pleasure and honour to be helpful. Contact me now, and you'll know.

Bella and Cassiel

Sales Representatives – Bella and Cassiel

We’re Bella and Cassiel, your dedicated sales representatives at WellPCB. With our extensive knowledge of the PCB industry, we’re here to provide exceptional service and support. We take the time to understand your unique needs and are always ready to offer tailored solutions and advice. Whether you need product recommendations, assistance with your orders, or simply have a question, we’re here to ensure your experience is smooth and seamless at every step.

Mandy and Wendy

Sales Representatives – Mandy and Wendy

We’re Mandy and Wendy, your friendly sales representatives at WellPCB. Passionate about helping our customers, we bring a wealth of experience in the PCB industry to provide you with the best solutions and service. We take pride in building strong relationships with our clients, understanding their specific needs, and offering personalised support to ensure their satisfaction. Whether you’re looking for advice, product information, or assistance with any part of your order, we’re here to make your experience as smooth and efficient as possible.

Our Team

Our skilled engineers and technicians bring expertise and precision to every PCB assembly project. Committed to quality, efficiency, and innovation, our team ensures every order meets the highest UL, IPC, ROHS & REACH standards, delivering reliable solutions tailored to your needs.

- Founder and Chief Editor – Hommer Zhao

- Technical Manager – Jesse Holland

- Purchasing Manager – Nathan Jensen

- Sales Manager – Emma

- Sales Representatives – Bella and Cassiel

- Sales Representatives – Mandy and Wendy

Wiring Harness

Integrated wiring harness assemblies streamline power and signal distribution in sanitation vehicles, offering robust performance in harsh outdoor and washdown environments.

Specifications:

- •Voltage: Up to 600V

- •Temp Range: -40°C to +125°C

- •Conductor: Stranded copper

- •Insulation: XLPE or TPE

- •Protection: Braided sleeving or corrugated tubing

- •Sealing: IP67-rated connectors

- •Standards: ISO 9001, RoHS, SAE J1128

Wiring Harness

Connects engine, dashboard, lights, A/C, audio, airbags, and more—forming a reliable, complete electrical system for vehicle performance and safety.

Specifications:

- •Voltage: 12V / 24V systems

- •Temp Range: -40°C to +125°C

- •Conductor: Stranded copper

- •Insulation: PVC/XLPE

- •Sheathing: Corrugated or braided

- •Connectors: OEM-specific, sealed or unsealed

- •Standards: ISO/TS 16949, SAE J1939, RoHS

PCB Assembly

Used in autonomous driving systems, infotainment, and advanced vehicle electronics, our cable assemblies ensure fast, stable signal and power transmission under demanding conditions.

Specifications:

- •Voltage: 12V / 48V

- •Signal Types: CAN, LVDS, USB, Ethernet

- •Temp Range: -40°C to +125°C

- •Conductor: Stranded copper

- •Shielding: Foil/braid for EMI protection

- •Jacket: TPE or XLPE

- •Standards: IATF 16949, ISO 26262, RoHS

Client Feedback On Our Automotive Wiring Harnesses

As an R&D manager, I have had an outstanding experience working with WELL-PCB. For many years, our company has entrusted them with the production, assembly, and programming of the boards developed in our R&D unit, and they have consistently exceeded our expectations.

Hamid Reza Moshayedi

R&D Manager

Their work is very impressively perfect. Today, when they check our company PCB board after assemble. They found a fake short point which many engineers has never found in the past years. But that is just designed so. The PCB board quality is excellent. Their service is also excellent.

MikeZ

My friend introduced WellPCB to me, the first try, a little look forward to. I ordered a 47*72 10ps PCB, and I can’t wait to receive my PCB. So I used expedited service and received my PCB in three days. I tested and soldered the PCB, Quality is really good, silkscreen, plating also great.

Warren Cliton

Automotive Wiring Harness FAQs

What certified flame-retardant insulation do you offer?

We offer IATF 16949:2016, ISO 9001:2015, UL, and ROHS-certified flame-retardant insulation for interior harness applications.

Do you support CAN bus wiring with EMI shielding?

Yes, we support CAN bus wiring if it’s clearly indicated on the provided customer drawings. This includes EMI shielding, including twisted pair layout, foil wrap, and defined shield termination paths.

How is dielectric withstand testing performed on high-voltage EV harnesses?

We apply high-voltage DC between conductors and shielding to verify insulation performance and detect breakdown or leakage. This test is typically performed up to 1500 VDC, depending on the harness specification, and confirms compliance with required dielectric strength before release to final product manufacturing.

Do you supply temperature-rated insulation for exhaust-adjacent harnesses?

Yes, we offer high-temperature wire and cable with XLPE, silicone, or fiberglass jackets rated up to 150 °C for routing near engine and exhaust components.

Automotive Wiring Harness Manufacturers You Can Trust

Get $100 Off Your First Order! Custom automotive wiring harnesses manufactured to your provided specifications. Fast turnaround, quality materials, industry-certified.