Tractor Wiring Harness

for Agricultural Machines

WellPCB manufactures tractor wire harness solutions to withstand vibration, moisture and dust in heavy duty field conditions.

From lighting and ignition circuits to alternator, battery and cab controls, our harnesses deliver dependable electrical performance and long term reliability across all major tractor parts and systems.

Each custom built harness is produced to OEM wire harness specification, tested under strict quality control and delivered with fast turnaround.

- Heavy duty covered wire with abrasion resistant jacketing and cotton braid options

- ISO 9001 and IPC/WHMA-A-620 certified wire harness assemblies for guaranteed compliance

- Fast global delivery from prototype runs to full scale tractor wire harness manufacture

ISO9001 ISO13485

ISO14001

IATF

16949

IPC-A-610H International

Certification

Fully Automated

AOI Inspection

High Quality Tractor Wire Harnesses for Reliable Farm Machinery

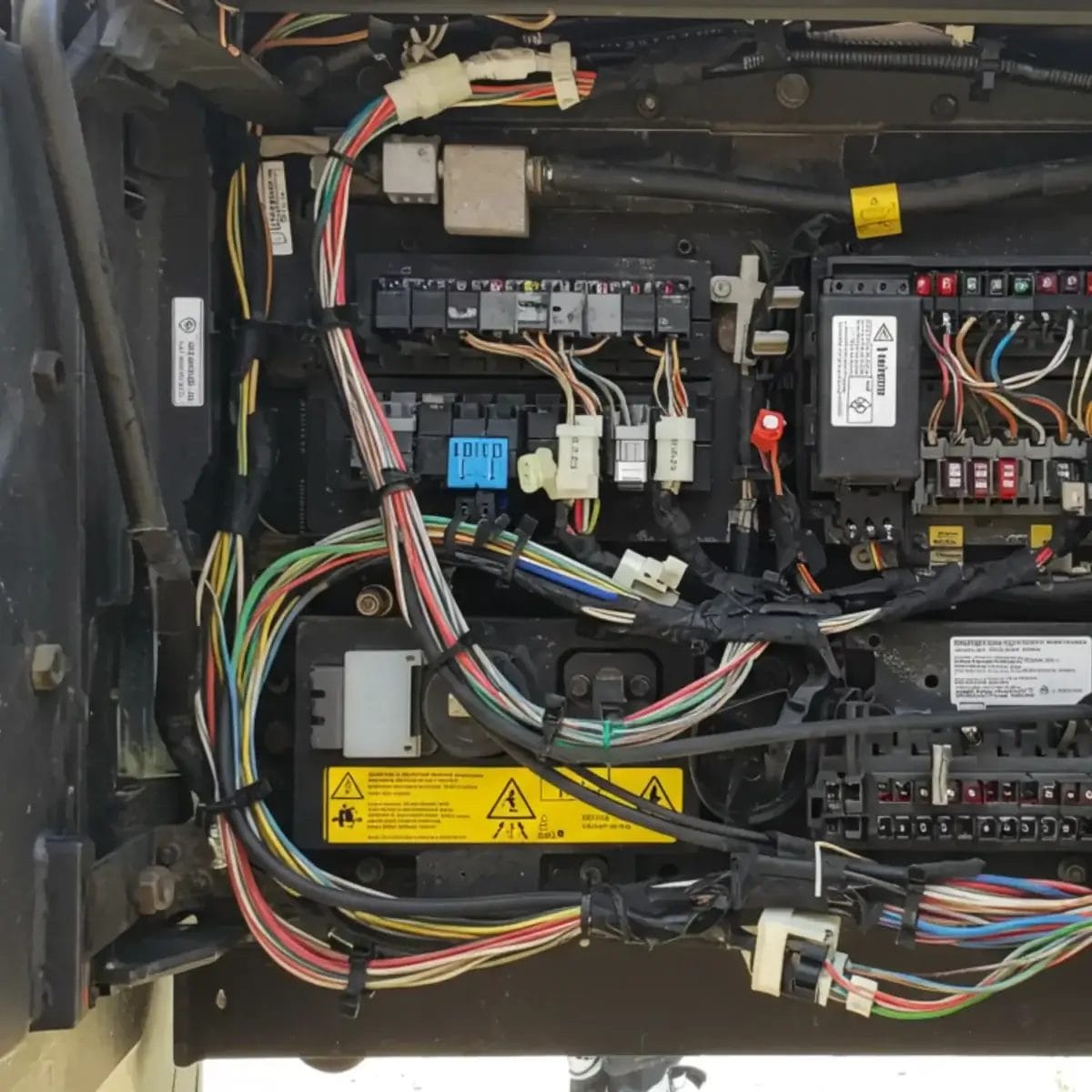

Tractor wire harnesses provide safe, organized routing of power and signal circuits across tractor parts including the alternator, battery, headlights, cab controls and dash instrumentation.

As tractors evolve with more electrical components and precision controls, demand is shifting toward high quality harness assembly solutions that balance durability with simplified installation. WellPCB supports this transformation with certified, tested tractor wire harness assembly solutions manufactured to international standards.

WellPCB manufactures agricultural wire harnesses using OEM-grade covered wire, sealed connectors, cotton braid jacketing and abrasion-resistant nylon sleeving. Harnesses are built to the correct gauge, include fuse and relay holders and are available as a complete kit or individual harness replacement.

With fast lead times and global delivery, WellPCB delivers custom-made, heavy duty harnesses that reduce on-site repair work while keeping tractors running in the field.

Our Tractor Wire Harness Capabilities

We manufacture tractor wire harnesses and agricultural cable assembly solutions using conductor sizes ranging from 12 to 22 AWG for signal and lighting circuits., and 4 to 0 AWG for battery, starter and alternator feeds, matching common tractor system requirements.

Harnesses are sized to the correct gauge for each circuit, with options for XLPE, PVC or Tefzel insulation. These materials support operation from -40°C to 105°C, with 125°C insulation options available for engine bay and alternator zones.

Cotton braid or abrasion resistant nylon sleeving is available for additional protection against chafing and vibration.

Supported connector families include Delphi/Packard, Deutsch DT, TE Connectivity and OEM-specific sealed plugs.

Terminations are applied with validated crimp-force settings and pull testing, ensuring each terminal achieves proper conductivity and retention. Connectors are sealed to IP67/IP69K for mud and washdown exposure.

Overmolded interfaces and back shells can be supplied for heavy duty applications across tractor engine bays and cab controls.

We integrate inline junctions, splice points, fuse holders and relay sockets into tractor harness assemblies.

These are sealed with adhesive lined heat shrink or injection overmold, maintaining environmental protection.

Harnesses can incorporate blade fuses, mini relays and battery feed circuits to support ignition, dash controls and auxiliary tractor equipment.

Wire cutting, stripping and crimping is performed on semi automated machines with tight tolerances for accuracy across production runs.

Each harness is supplied with ID tags, heat-shrink markers or printed diagram references linked to customer specification sheets. This simplifies installation, replacement and harness repair in the field.

Custom wire harness assemblies can be supplied with molded boots, grommets or sealed junctions for IP68 protection.

Overmolded branch points prevent water ingress and protect against fertilizer, dust and diesel exposure.

Covered wire with over-braid and split-loom conduit options further extend service life in exposed tractor harness routing.

All harnesses are tested to strict environmental standards, covering vibration, thermal cycling, humidity and chemical exposure typical of agricultural operations. This aligns our production with the same durability benchmarks used by leading tractor and implement manufacturers.

We apply documented quality control protocols following IPC/WHMA-A-620 workmanship standards, with ISO 9001 certification and IATF 16949 alignment for automotive grade manufacture.

WellPCB also aligns with agricultural industry bodies such as the American Farm Bureau and the Agricultural Engineers Society, ensuring our solutions reflect practical farming needs and regulatory expectations.

Quantities range from 1-off prototype harness builds to 10,000+ harnesses/month.

Prototypes are typically delivered in 3 weeks, with full production runs in 4 to 5 weeks depending on complexity.

Custom built options such as custom wire routing, color coding, pinout logic and modular harness kit packaging are available for OEM tractor suppliers.

WellPCB acts as a trusted supplier of tractor harnesses worldwide, shipping to North America, Europe and Australia.

We support OEM builds, aftermarket replacements and repair applications, ensuring every harness meets the durability and reliability requirements of modern agricultural machinery.

Why Choose WellPCB?

One-Stop Manufacturing

Certified Compliance

Durability in the Field

Fast Global Delivery

U.S. Market Alignment

Dedicated Customer Support

What Is a Tractor Wire Harness?

Features of Tractor Wire Harnesses

Heavy Duty Construction

Assemblies use covered wire with abrasion resistant jacketing, cotton braid or nylon sleeving. These materials withstand vibration, mud, UV and diesel exposure in the field.

Integrated Protection

Harnesses incorporate fuse and relay holder assemblies, protecting tractor parts such as ignition, lighting and cab controls from overload or short circuits.

OEM Compatibility

Each tractor wire harness assembly is manufactured to OEM standard specification, enabling direct replacement and plug-and-play installation with factory connectors.

Custom-Built Options

We offer custom tractor wire harness solutions and custom built harness kits for prototype runs, aftermarket replacements or specialized agricultural machinery. Options include correct gauge selection, branch routing and custom made terminations.

Other Applications of Tractor Wiring Harnesses

Modern tractors rely on electrical connectivity not just within the vehicle itself, but across a wide range of implements and attachments used throughout seasonal farming operations. From planting to harvesting, harnesses must support quick connection, reliable power and environmental sealing for mobile and often removable agricultural equipment.

WellPCB manufactures specialized tractor wire harness assemblies designed for full implement integration:

Planters & Seeders

Harnesses route power to vacuum pumps, seed metering systems and GPS-based row sensors. EMI-shielded wire harnesses protect data lines for variable-rate application and precision farming automation.

Fertilizer Spreaders & Manure Tanks

Corrosive materials and heavy washdowns demand sealed connectors and covered wire with overmolded splices. Assemblies integrate moisture sensors, gate actuators and load monitors, ensuring uptime across spring and fall seasons.

Balers & Crop Bins

Baler harnesses carry power to twine cutters, bale counters and ejection sensors. Connectors must withstand dust, vibration and impact from field use, while maintaining signal continuity under movement.

Post-Hole Diggers & Tillage Attachments

Implements with hydraulic control or rotational movement require flexible, durable looms with abrasion resistance and mechanical strain relief. Harnesses support actuator circuits, depth sensors and safety interlocks.

Agricultural Challenges and Harness Solutions

Agricultural harnesses face harsher conditions than many other industries. Tractors and implements run in mud, rain, dust and chemical exposure, while vibration and shock loads can cause loose terminals or broken wires if assemblies aren’t built correctly. Seasonal cycles also add stress: freezing winters (-40°C) and hot summers (40°C+) demand wide temperature performance.

Seasonal Operations

Precision Farming Equipment

Field Vibration & Shock

Downtime Reduction

Design Considerations for Tractor Wire Harnesses

When manufacturing a tractor wire harness, several engineering factors determine long term performance. Harnesses must survive heat, vibration and moisture while delivering stable electrical connections across all circuits.

Vibration Resistance

Thermal Protection

Water & Dust Sealing

Power Distribution

Ease of Service & Repair

How to Order Your Tractor Wire Harness

Submit Your Design

Send us your design details (Drawing or Detailed Specifications).

Get a Fast Quote

Once your design and specs are received, a fast quote will be sent to you within 24 hours.

Confirm Order & Make Payment

When the quotation is approved, please send the PO or order confirmation, we will proceed with the production after receiving your payment.

Arrange Production & Inspection

Before production, our technical team will review all details of the drawing/specs again. If everything is OK, the order will start. We'll keep you updated throughout the manufacturing process. After the production is completed, the products will be 100% inspected.

Packaging & Delivery

When completed, your order will be carefully packed and shipped to you, with shipping documents and tracking information provided.

WellPCB is trusted by millions of

businesses and innovators.

Why Choose WellPCB as Your Wire Harness Manufacturer?

WellPCB stands out among USA wire harness manufacturers by delivering superior quality, advanced solutions, and unmatched reliability. With years of experience serving global markets, WellPCB has earned a reputation as one of the top wire harness manufacturers in the USA.

WellPCB specializes in custom wire harnesses for complex electronic and industrial applications. You can order these assemblies with $100 off using our special offer—delivering high-quality, tailor-made harnesses at competitive rates for your most demanding projects.

Hommer Zhao

Founder and Chief Editor – Hommer Zhao

Welcome! I’m Hommer Zhao, the founder and Chief Editor of WellPCB. With years of experience in the PCB industry, I’m committed to making sure our content is both accurate and helpful. We’re proud to serve a growing community of over 4,000 customers worldwide, and our goal is to provide you with the best resources and support. Your satisfaction is our top priority, and we’re here to help you every step of the way!

Jesse Holland

Technical Manager – Jesse Holland

Hi, I’m Jesse Holland, an Engineer and Technical Manager at WellPCB. With years of experience in PCB design and engineering, I’m here to ensure that every project we work on meets the highest technical standards. I lead our team, focusing on precision and innovation, collaborating closely with clients to provide tailored solutions and expert guidance. Whether you’re facing a complex design challenge or need advice on technical aspects, I’m here to ensure your project is a success from start to finish.

Nathan Jensen

Purchasing Manager – Nathan Jensen

Hi, I’m Nathan Jenson, the Purchasing Manager at WellPCB. I’m responsible for sourcing the best materials and components to ensure our products meet the highest quality standards. With my extensive experience in procurement, I work closely with suppliers to secure reliable and cost-effective solutions while maintaining strong relationships to support our operations. I aim to ensure every project runs smoothly by providing the resources needed to deliver on time and to your satisfaction.

Emma

Sales Manager – Emma

Hey, I am Emma, sales manager at WellPCB. I studied electronic science and technology at university and have served customers for PCB and PCB Assembly service for several years.

I enjoy communicating with customers and our technicians to solve problems, and customers always say, "It's great to have you onboard".

It is my pleasure and honour to be helpful. Contact me now, and you'll know.

Bella and Cassiel

Sales Representatives – Bella and Cassiel

We’re Bella and Cassiel, your dedicated sales representatives at WellPCB. With our extensive knowledge of the PCB industry, we’re here to provide exceptional service and support. We take the time to understand your unique needs and are always ready to offer tailored solutions and advice. Whether you need product recommendations, assistance with your orders, or simply have a question, we’re here to ensure your experience is smooth and seamless at every step.

Mandy and Wendy

Sales Representatives – Mandy and Wendy

We’re Mandy and Wendy, your friendly sales representatives at WellPCB. Passionate about helping our customers, we bring a wealth of experience in the PCB industry to provide you with the best solutions and service. We take pride in building strong relationships with our clients, understanding their specific needs, and offering personalised support to ensure their satisfaction. Whether you’re looking for advice, product information, or assistance with any part of your order, we’re here to make your experience as smooth and efficient as possible.

Our Team

Our skilled engineers and technicians bring expertise and precision to every PCB assembly project. Committed to quality, efficiency, and innovation, our team ensures every order meets the highest UL, IPC, ROHS & REACH standards, delivering reliable solutions tailored to your needs.

- Founder and Chief Editor – Hommer Zhao

- Technical Manager – Jesse Holland

- Purchasing Manager – Nathan Jensen

- Sales Manager – Emma

- Sales Representatives – Bella and Cassiel

- Sales Representatives – Mandy and Wendy

Train Wire Harness Case Studies

PCB Assembly

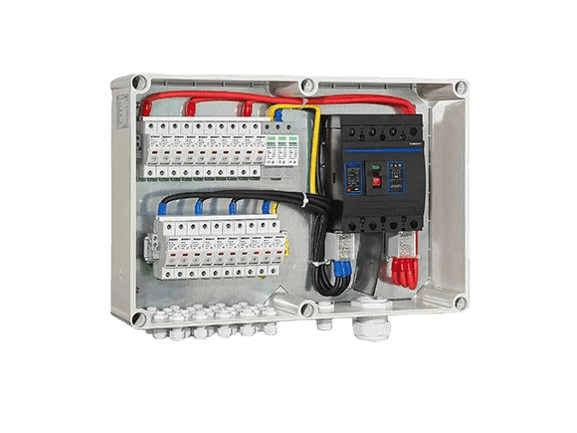

This case study showcases a high-performance solar panel wiring harness for outdoor photovoltaic systems, requiring high and low temperature resistance, UV resistance, and efficient electrical conductivity.

We select high-quality, weather-resistant cables, precisely process terminals and connectors, and rigorously control insulation and sealing processes. This product can stably transmit power even in extreme environments, enabling efficient power generation in photovoltaic systems and fully demonstrates our expertise in solar panel wiring harness and photovoltaic cable manufacturing.

PCB Assembly

This project shows a solar wire harness specifically designed for DC combiner boxes in photovoltaic systems. The harness integrates multiple input strings from solar panels and safely channels the combined current toward the inverter.

High Current Capacity: Built with thick, tinned copper conductors to handle the combined output of multiple PV strings without overheating.

Safety and Protection: Incorporates fuse holders and ring terminals for secure grounding, reducing the risk of short circuits and electrical faults.

Easy Installation: Pre-terminated connectors allow for quick assembly on-site, lowering labor costs and installation time.

PCB Assembly

This case study highlights a customized wire harness developed for solar tracking systems that adjust panel angles throughout the day. The harness carries both control signals and power, ensuring the motorized trackers operate smoothly in outdoor environments.

Advantages:

- •Uses UV-resistant, flexible cables that withstand constant movement and bending without damage.

- •Multi-core design keeps power and data transmission reliable, even under continuous rotation.

- •Robust insulation and sealed connectors provide protection against dust, moisture, and temperature fluctuations.

Tractor Wire Harness Client Feedback

As an R&D manager, I have had an outstanding experience working with WELL-PCB. For many years, our company has entrusted them with the production, assembly, and programming of the boards developed in our R&D unit, and they have consistently exceeded our expectations.

Hamid Reza Moshayedi

R&D Manager

Their work is very impressively perfect. Today, when they check our company PCB board after assemble. They found a fake short point which many engineers has never found in the past years. But that is just designed so. The PCB board quality is excellent. Their service is also excellent.

MikeZ

My friend introduced WellPCB to me, the first try, a little look forward to. I ordered a 47*72 10ps PCB, and I can’t wait to receive my PCB. So I used expedited service and received my PCB in three days. I tested and soldered the PCB, Quality is really good, silkscreen, plating also great.

Warren Cliton

Tractor Wire Harness FAQs

What’s included in a typical tractor wire harness kit?

A complete custom tractor wire harness kit may include battery feeds, ignition wiring, headlight wiring, fuse and relay holders and labeled connections for cab and dash systems. Each harness is produced with correct gauge conductors and validated terminals for safe operation.

What standards and certifications do your tractor wire harnesses meet?

All tractor wire harness assemblies are built under ISO 9001 certified systems and follow IPC/WHMA-A-620 workmanship requirements. For automotive grade and agricultural wire harnesses, we align with IATF 16949 practices to support OEM customers. These certifications demonstrate documented expertise and commitment to consistent, high quality manufacturing.

Do you manufacture harnesses for aftermarket suppliers serving John Deere, Cub Cadet, and similar equipment brands?

Yes, we partner with aftermarket suppliers and distributors who serve major equipment brands including John Deere, Cub Cadet and Case IH (formerly Farmall). Our harnesses meet or exceed OEM specifications while providing cost-effective alternatives for replacement parts and upgrade applications. As long as you can provide a technical drawing, we can create a tractor wire harness to the exact specifications.

Choose WellPCB and Save On Your First Tractor Wire Harness Order!

Get $100 Off Your First Order!

Order your tractor wire harness today and benefit from WellPCB’s certified manufacturing, strict quality control and fast delivery worldwide. $100 off your first order of tested solutions with proven reliability.