Custom Truck Wiring Harnesses

for Power, Signal, and Trailer Systems

A truck wiring harness consolidates wire routing for power distribution, signal communication, and trailer control into a single durable assembly.

Each custom truck wiring harness is engineered to fit the platforms of heavy-duty vehicles, including semi trucks, pickup trucks and commercial trailer systems.

WellPCB is a wiring harness manufacturer specializing in OEM grade truck wiring solutions for lighting, accessory, switch and connector integration.

All truck harness assemblies are custom-made using high quality wire, vinyl sleeving, and in house cable processing with verified electrical inspection.

- Custom truck wiring harness builds for engine, trailer, cab, and rear lighting.

- Meets the necessary standards (IATF 16949, ISO 9001, UL)

- No-MOQ harness builds for OEM, fleet, and aftermarket.

ISO9001 ISO13485

ISO14001

IATF

16949

IPC-A-610H International

Certification

Fully Automated

AOI Inspection

Wiring Harnesses for Truck Applications

Truck wiring harnesses connect lighting, switches, and electrical components across the engine, cab, frame, and trailer.

These harness assemblies organize wire routing for power delivery, signal timing, and accessory operation in both pickup and semi platforms.

Modern truck wiring harness systems have evolved from simple ignition looms to multibranch assemblies supporting diagnostics, emissions control and ECU coordination.

Standards like ISO9001 and IATF16949 became necessary as vehicles adopted CAN-based systems, expanded electronic safety functions, and integrated real-time data sharing across the drivetrain and trailer interface.

WellPCB manufactures custom wiring harness to match the cable paths, mount points and wiring harness extension requirements of your truck’s operational needs.

Every harness is built with wire lengths, plug types and branch points aligned to certified fitment drawings and real world installation zones, reducing troubleshooting during service or installation.

We deliver custom-made wiring solutions for brake light hookups, trailer wiring harness connections, and component branch-outs without requiring third party modification or inventory adaptation.

Our Truck Wiring Harness Capabilities

WellPCB builds custom truck wiring harness assemblies based on client-supplied drawings and electrical specifications. Each wire harness supports power, signal, or lighting functions and is assembled, tested, and packaged for direct installation across truck engine, cab, chassis and trailer systems.

We manufacture custom truck wiring harness assemblies for engine circuits, including ignition, starter, and fuel systems.

Each wiring harness for trucks is built with TXL or GXL wire types rated to 257 °F (125 °C), XLPE insulation, and chemical resistant jacketing.

Thermal zones are isolated using split loom or braided sleeving, and connector seals meet IP67 ingress standards for oil and moisture protection.

Our truck wiring harness for transmissions is compatible with Allison, Spicer and Eaton platforms.

These builds include AMP, TE, or Delphi plug interfaces with support for signal grounding, power crossover and shielded logic wires.

Assemblies maintain torque route clearances and integrate strain relief boots at housing transitions to reduce flex damage under chassis-mounted conditions.

WellPCB builds custom wiring harnesses that carry brake control signals between ABS/EBS modules, trailer interlocks, and electronic valve control units.

We use color coded XLPE insulation for fast terminal identification and seal branch-outs, and use overmolded polyurethane. Branch circuits are crimped with force monitoring and pull-tested in accordance with IPC/WHMA-A-620 Class 3.

Compatible with WABCO and Bendix control modules for ABS and trailer brake interlocks.

WellPCB manufactures truck harness systems for dash interfaces, switch panels, HVAC wiring, and infotainment networks based on customer supplied schematics and fitment drawings.

Harness layouts are built using 26 to 20 AWG wire with flame-rated vinyl sleeving to accommodate tight interior routing. All branches are labeled, continuity-checked, and configured for straightforward plug fitment in cab assemblies.

Every truck wiring harness is built for lamp voltage delivery, grounding and lighting circuit protection.

Our lighting looms include trailer wiring harness systems with sealed lamp connectors, 7-way RV blade compatibility and accessory power takeoffs.

Rear harness runs are routed using corrugated conduit with heat-set retention clips and foam tape wrap. Every custom truck wiring harness includes labeled brake, reverse and tail lamp feeds.

We manufacture shielded twisted pairs for CAN-based wire harness layouts.

Using foil wrap and drain wire grounding, these segments minimize EMI to ensure stable signal integrity between ECUs.

All CAN lines maintain differential impedance targets of 120 ohms with 250 kbps and 500 kbps standardized data rates and up to 30 ECUs on a 40-meter network.

Each high voltage truck wiring harness is built with XLPE-rated insulation for -40 °F to 302 °F (-40 °C to 150 °C) temperature range, 2.0 to 6.0 mm² copper conductors, and a dielectric rating of 1000 VDC or higher.

All HV terminals are crimped using hydraulic tooling and tested for dielectric resistance up to 1500 V.

Wire paths include heat shields and mount points that are compatible with electric vehicle (EV) architecture and battery enclosures. The rated continuous temperature is 302 °F (150 °C) in core zones.

Our custom truck assemblies include overmolding at connector transitions, jacket seams and exposed splice zones.

TPE and polyurethane boots are injected over mold cavities to create seamless sealing with cable jackets.

Pull-force and twist tests verify plug retention, while final inspection confirms moisture ingress protection.

Why Choose WellPCB for Your

Truck Wiring Harness?

WellPCB manufactures custom truck wiring harness assemblies with verified fitment, regulatory compliance, and full electrical testing.

Our in-house capability supports low volume builds, ruggedized wire harness construction, and reliable component sourcing for OEM and aftermarket truck systems.

Design-Verified Truck Harness Builds

Global Standard Compliance

Built for Harsh Operating Environments

Rapid Prototyping and Low-Volume Flexibility

Full Electrical and Mechanical Testing

Project Engineering and Technical Support

Industries We Serve With Custom Truck Wiring Harnesses

WellPCB supplies custom truck wiring harness assemblies to OEMs and service providers across commercial vehicle sectors. Each harness is built to match the operational needs, plug layouts, and mounting zones of heavy-duty trucks, trailers, or hybrid platforms.

Commercial Truck Manufacturers

Trailer and Body Equipment Suppliers

Electric and Hybrid Truck Platforms

Heavy-Duty Fleet Maintenance Services

Control System and Subsystem OEMs

Our Truck Wiring Harness Process?

WellPCB follows a controlled process to manufacture each custom truck wiring harness, ensuring accurate routing, verified component terminations, and a full functional inspection.

Our in-house team handles cutting, assembly, testing and packaging to deliver consistent harness builds that match client specifications and field installation needs.

Step 1: Review and Specification Matching

Step 2: Wire Preparation and Labeling

Step 3: Termination and Subassembly

Step 4: Assembly and Routing on Harness Board

Step 5: Final Testing and Inspection

Step 6: Packaging and Delivery

Troubleshooting and Maintenance

Common service issues include intermittent brake signals, trailer plug faults, or cracked insulation at flex points. All truck wiring harnesses include labeled plug maps and wire tags to support rapid troubleshooting during field repair. Routine inspection for abrasion, corrosion, or loose terminals is recommended during maintenance cycles or vehicle retrofits.

Submit Your Design

Send us your design details (Drawing or Detailed Specifications).

Get a Fast Quote

Once your design and specs are received, a fast quote will be sent to you within 24 hours.

Confirm Order & Make Payment

When the quotation is approved, please send the PO or order confirmation, we will proceed with the production after receiving your payment.

Arrange Production & Inspection

Before production, our technical team will review all details of the drawing/specs again. If everything is OK, the order will start. We'll keep you updated throughout the manufacturing process. After the production is completed, the products will be 100% inspected.

Packaging & Delivery

When completed, your order will be carefully packed and shipped to you, with shipping documents and tracking information provided.

WellPCB is trusted by millions of

businesses and innovators.

Why Choose WellPCB as Your Wire Harness Manufacturer?

WellPCB stands out among USA wire harness manufacturers by delivering superior quality, advanced solutions, and unmatched reliability. With years of experience serving global markets, WellPCB has earned a reputation as one of the top wire harness manufacturers in the USA.

WellPCB specializes in custom wire harnesses for complex electronic and industrial applications. You can order these assemblies with $100 off using our special offer—delivering high-quality, tailor-made harnesses at competitive rates for your most demanding projects.

Hommer Zhao

Founder and Chief Editor – Hommer Zhao

Welcome! I’m Hommer Zhao, the founder and Chief Editor of WellPCB. With years of experience in the PCB industry, I’m committed to making sure our content is both accurate and helpful. We’re proud to serve a growing community of over 4,000 customers worldwide, and our goal is to provide you with the best resources and support. Your satisfaction is our top priority, and we’re here to help you every step of the way!

Jesse Holland

Technical Manager – Jesse Holland

Hi, I’m Jesse Holland, an Engineer and Technical Manager at WellPCB. With years of experience in PCB design and engineering, I’m here to ensure that every project we work on meets the highest technical standards. I lead our team, focusing on precision and innovation, collaborating closely with clients to provide tailored solutions and expert guidance. Whether you’re facing a complex design challenge or need advice on technical aspects, I’m here to ensure your project is a success from start to finish.

Nathan Jensen

Purchasing Manager – Nathan Jensen

Hi, I’m Nathan Jenson, the Purchasing Manager at WellPCB. I’m responsible for sourcing the best materials and components to ensure our products meet the highest quality standards. With my extensive experience in procurement, I work closely with suppliers to secure reliable and cost-effective solutions while maintaining strong relationships to support our operations. I aim to ensure every project runs smoothly by providing the resources needed to deliver on time and to your satisfaction.

Emma

Sales Manager – Emma

Hey, I am Emma, sales manager at WellPCB. I studied electronic science and technology at university and have served customers for PCB and PCB Assembly service for several years.

I enjoy communicating with customers and our technicians to solve problems, and customers always say, "It's great to have you onboard".

It is my pleasure and honour to be helpful. Contact me now, and you'll know.

Bella and Cassiel

Sales Representatives – Bella and Cassiel

We’re Bella and Cassiel, your dedicated sales representatives at WellPCB. With our extensive knowledge of the PCB industry, we’re here to provide exceptional service and support. We take the time to understand your unique needs and are always ready to offer tailored solutions and advice. Whether you need product recommendations, assistance with your orders, or simply have a question, we’re here to ensure your experience is smooth and seamless at every step.

Mandy and Wendy

Sales Representatives – Mandy and Wendy

We’re Mandy and Wendy, your friendly sales representatives at WellPCB. Passionate about helping our customers, we bring a wealth of experience in the PCB industry to provide you with the best solutions and service. We take pride in building strong relationships with our clients, understanding their specific needs, and offering personalised support to ensure their satisfaction. Whether you’re looking for advice, product information, or assistance with any part of your order, we’re here to make your experience as smooth and efficient as possible.

Our Team

Our skilled engineers and technicians bring expertise and precision to every PCB assembly project. Committed to quality, efficiency, and innovation, our team ensures every order meets the highest UL, IPC, ROHS & REACH standards, delivering reliable solutions tailored to your needs.

- Founder and Chief Editor – Hommer Zhao

- Technical Manager – Jesse Holland

- Purchasing Manager – Nathan Jensen

- Sales Manager – Emma

- Sales Representatives – Bella and Cassiel

- Sales Representatives – Mandy and Wendy

Wire Harness

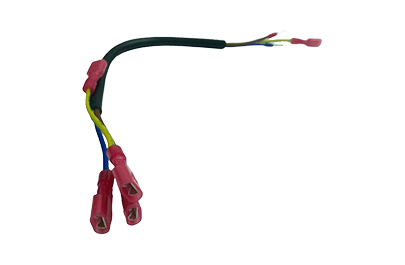

Various electronic control units (ECUs), sensors, actuators, etc. inside the truck need to be connected through wiring harnesses and crimping terminals are responsible for connecting various electrical components to ensure the normal operation of the car system.

Specifications:

- •Terminal Types: Ring, spade, blade, bullet, or custom

- •Crimp Type: Insulated / non-insulated; open / closed barrel

- •Wire Size: AWG 10–30

- •Pull Test Strength: Per UL 486A/B standards

- •Insulation: PVC, Teflon, Silicone

- •Marking: Color-coded or labeled wires

- •Certifications: UL, ISO 9001, IPC/WHMA-A-620, RoHS

PCB Assembly

Mainly through accurate temperature monitoring, real-time battery protection and optimization of the battery management system, ultimately improving battery performance, extending battery life, and ensuring safe and reliable operation of the truck system.

Specifications:

- •Type: NTC thermistor

- •Temp Range: -40°C to +125°C (up to +150°C optional)

- •Resistance @25°C: 10kΩ (customizable)

- •Tolerance: ±1% to ±5%

- •Response Time: Fast (<10s in still air)

- •Mounting: Inline, surface mount, or embedded

- •Applications: EV battery packs, UPS, medical devices

- •Standards: AEC-Q200, RoHS, ISO 9001

Wire Harness

A wiring harness that can block interference signals.

In automobile circuit communications, there is always interference from interference signals such as electromagnetic waves, which causes signal distortion and errors.

Specifications:

- •Signal Types: CAN, Ethernet, RS-232, USB, LVDS

- •Voltage Rating: Up to 300V

- •Temp Range: -40°C to +125°C

- •Shielding: Foil and/or braided for EMI protection

- •Connector Types: Circular, D-sub, M12, custom

- •Jacket: UV, oil, and abrasion-resistant (PVC, TPE, or PUR)

- •Sealing: IP67/IP68 rated for outdoor use

- •Certifications: ISO 9001, IPC/WHMA-A-620, RoHS

Client Feedback On Our Truck Wiring Harnesses

As an R&D manager, I have had an outstanding experience working with WELL-PCB. For many years, our company has entrusted them with the production, assembly, and programming of the boards developed in our R&D unit, and they have consistently exceeded our expectations.

Hamid Reza Moshayedi

R&D Manager

Their work is very impressively perfect. Today, when they check our company PCB board after assemble. They found a fake short point which many engineers has never found in the past years. But that is just designed so. The PCB board quality is excellent. Their service is also excellent.

MikeZ

My friend introduced WellPCB to me, the first try, a little look forward to. I ordered a 47*72 10ps PCB, and I can’t wait to receive my PCB. So I used expedited service and received my PCB in three days. I tested and soldered the PCB, Quality is really good, silkscreen, plating also great.

Warren Cliton

Truck Wiring Harness FAQs

What is a truck wiring harness?

A truck wiring harness is a bundled cable assembly that routes power and signal between the engine, brakes, lighting, and cab systems. These assemblies reduce connection faults and improve service access across commercial truck platforms.

What are the truck harness regulatory standards you build to?

We build truck wiring harness assemblies to meet ISO 9001, IATF 16949, UL, RoHS and IPC/WHMA-A-620 standards. Each wiring harness for truck systems is tested for mechanical pull strength, insulation resistance, plug continuity, and overall circuit integrity.

What voltage ratings can you build truck harnesses for?

We build custom truck wiring harness assemblies for 12V, 24V, and 48V systems. Each wire size is selected based on allowable voltage drop, current draw, and route length. Load zones are isolated by branch circuits, with XLPE or flame-rated vinyl insulation applied for thermal and abrasion resistance.

Can you build wiring harnesses for hybrid or electric trucks?

Yes, we build custom wiring harnesses for hybrid and electric vehicle (EV) applications, featuring dielectric withstand testing and heat-rated jacketing. Each high-voltage truck wiring harness includes XLPE or TPE insulation, sealed plugs, and routing support for controller zones, battery enclosures, and high-current paths.

Do you build truck trailer interface wiring systems?

Yes, we build trailer wiring harness assemblies with 7-way RV blade or sealed round connector types. Each plug includes pin-mapped circuits for brake, signal, and marker lamps. We also offer wiring extension options for pickup and truck bed installations requiring branch-outs or lighting upgrades.

Truck Wiring Harnesses That You Can Count On

Get $100 Off Your First Order!

Our custom truck wiring harnesses are built to withstand the punishment of heavy-duty operations, from engine heat and road vibration to chemical exposure and extreme weather.