Contents

The Electronic Manufacturing Industry: An Overview

Electronic circuit boards, microchips, and other general electronics demand a detailed process to create and manufacture.

The electronics manufacturing industry consists of the following operations to ensure the correct manufacture of electronic products. They are:

-Designing

-Testing

-Distribution

-Providing repairs and returns for original equipment manufacturers (aka OEMs)

All four make up the “manufacturing” of any given electronic item.

This has been the standard procedure since microchips and circuit boards became integral parts of electronic devices in the 1970s.

These four operations are the most relevant to electronics manufacturing.

They also possess their own set of processes and issues that anybody who is interested in succeeding in the field should know about.

Nearly every issue in the electronics manufacturing field will revolve around these four topics.

1.1 The Electronic manufacturing industry: An outlook

Because we live in a culture that considers technology an omnipresent factor in our daily lives, there are numerous opportunities in the electronic manufacturing industry.

Combine this with more and more information on a cheap and easily accessible subject, and it is easy to understand that there will always be opportunities in the electronic manufacturing industry.

The question is not whether the industry itself is growing or not but which operations within it are growing and which ones will become less relevant over the years.

Because many operations, not only in electronics manufacturing but also in physical labor workplaces at large, are being automated more and more, the design process could also be automated.

However, the designs often require reasoning that can only be possible with a human brain’s ability to be creative and make decisions on the fly, neither of which can be automated in the abstract.

Testing and production will be completely automated, at least on a grand scale, if they haven’t already.

Manual testers may be necessary on a smaller scale, but that is rare.

The days when the testing of any electronics that require many sets of human eyes are long gone, and there will be a massive decline in testers.

Another thing that will be automated will be distributed. In eras past, distribution was a long and complicated task that required many people to stock many vessels with completed electronic devices that were ready to be delivered.

Distribution has been almost wholly automated now, as the advent of assembly lines and larger vessels has allowed it to require fewer human hands than before.

Like testing, only a few individuals are necessary for the distribution field.

Repairing and returning OEM equipment depends on what the OEM wants and how complicated the repair is.

Returns can be automated, as returning equipment involves entering whatever needs to be returned into a spreadsheet.

The details of a repair determine whether it should be automated.

If the necessary repair is very complicated, it may require a workforce, but if the repair is simple, the chances are good that it can be automated and will not require as much workforce.

The Electronic Manufacturing Industry: An Analysis

Many other details and external factors can affect the decisions an electronics manufacturer should make.

However, certain things in the electronics manufacturing industry remain the same, and changing them is a significant risk for any electronics manufacturer.

When analyzing the electronic manufacturing industry as a whole, it is essential to understand the finite and rigid procedure that the manufacturing process is predicated on and the trends that affect it.

2.1 The Lifecycle of Electronic Product Development

At the expense of sounding cliche, technology moves very, very fast. The smartphone was in its infancy not even a decade ago, and few people in developed nations owned it.

Two decades ago, many homes used wired connections to connect to the Internet. Now, nearly everything is wireless.

Fifteen years ago, notebook computers and laptops were seen as super luxury items, relegated to only people who needed to use their computers while traveling.

It means that electronic product developments have a life cycle, and certain electronic products can be determined obsolete.

Even though the production of most electronics still contains the same kinds of materials as they did decades ago, there still is a life cycle for certain electronics, especially ones that can connect to networks.

The life cycle of any electronic product development refers to the time a particular electronic product has before alternatives that can perform better are available.

That’s why it’s a good idea to understand trends and other types of events and developments that may affect how electronic products are distributed and manufactured.

2.2 The electronics manufacturing process: An explanation

Why is manufacturing anything necessary in the first place, let alone electronics? Manufacturing is necessary when in demand and rather large amounts.

If the public thinks very confident about any given electronic device, there will be a massive demand for it as well as a need for all the parts for it.

Manufacturing is necessary to meet high demand from the public. Moreover, the core process of manufacturing is consistency.

No matter what kinds of trends develop, manufacturers always utilize the same process.

Here is how this process works.

A bill of materials (aka BOM) must be determined before anything can be considered for production, distribution, or manufacturing.

It should be determined before any design plans are made.

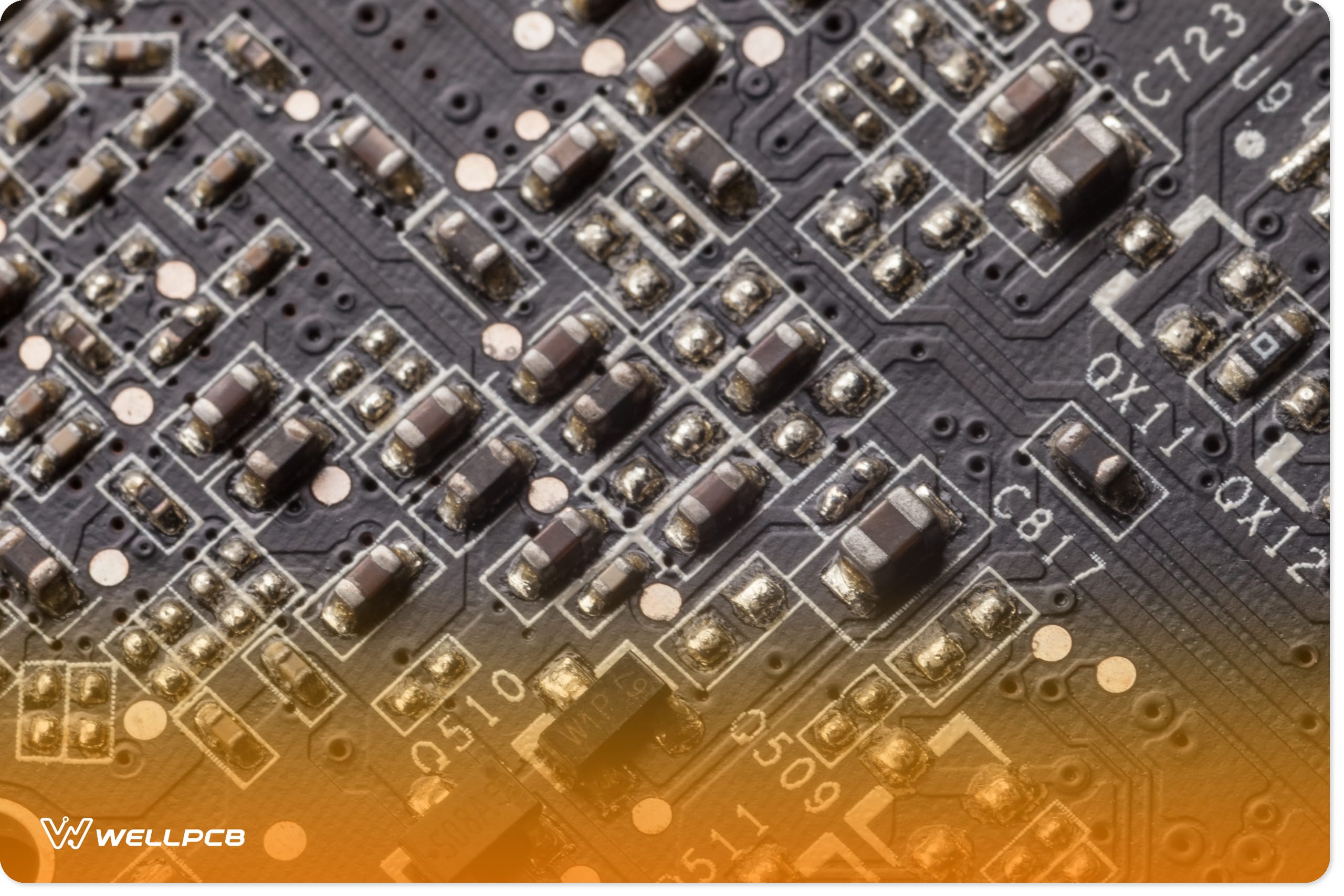

The most important part of anything involving electronics manufacturing is determining what kinds of materials to use and how much they will cost.

That is why it is determined first.

After building a BOM, the design is the next thing to consider.

If you don’t first create a blueprint for design and production, you can’t achieve any of the manufacturing goals.

Designing an electronic device entails some things.

Measurements must be made, as well as well as the kinds of components that will make up the materials for the electronic device. The goal of the design is to create a reliable blueprint that is perfect.

After designing comes testing. Testing is to be done before production, so anything that needs to be changed can be changed before mass production.

Although it sounds obvious, many manufacturers forget this and make the mistake of going through with production without finishing testing.

Distribution takes place after everything is designed and tested.

Before considering anything for distribution, it’s a good idea to run final tests to see if each manufactured electronics is ready for distribution.

Repairs and returns for OEMs are also part of the manufacturing process, as you are dealing with any faulty electronics that have been produced and distributed.

Like other electronics manufacturing processes, you should also have a dedicated system for repairs and returns.

2.3 The electronics manufacturing process: A flowchart

It is a general picture of manufacturing electronic products. One thing not included in this picture is what happens outside the manufacturing organization.

There are ways to address these, and they will be mentioned next.

Challenges In The Consumer Electronics Industry

Consumer electronics is an industry that will never stop growing, but that does not mean that the industry does not come with adversity.

Because the process of manufacturing electronics is very established, changes in anything that affects electronics, such as new regulations, guidelines, preferences from clients and the public, and even newer and more efficient methods of design, testing, and production, can all affect how electronics are manufactured.

One of these challenges is the pressure to make the materials necessary in building most electronics eco-friendly.

Since research on climate change and global warming is increasing, more regulations and guidelines are being created to ensure that the materials used in electronics are environmentally friendly.

Because carbon is a ubiquitous substance necessary for electronics production, this challenge will affect electronics manufacturing.

Manufacturers will need to adapt to any future regulations on carbon use.

It also consumes less energy when it comes to manufacturing electronics.

While this will get manufacturers to cut costs, the methods of cutting these costs will probably take testers and producers out of their comfort zone as they will need to consider other methods that they may be new to.

These are just a couple of challenges that the electronics manufacturing industry is set to face.

The above two challenges perfectly represent outside forces that are beyond the control of many electronics manufacturers.

The Top 10 Electronics Companies In 2018

10. China Electronics Corporation

Since 2007, China Electronics has mainly manufactured mobile phones and smartphones.

If your electronics manufacturing organization manufactures phones and other mobile devices, you should look at what China Electronics is doing.

9. Mitsubishi Electric

Since the Fortune 500 started ranking its organizations by revenue in 1995, Mitsubishi has been on the list.

It is more than just an automobile company, as it also manufactures architectural equipment and photovoltaic panels. It is one of the oldest companies on this list, founded in 1921.

8. Honeywell International

Known best for its thermostats, Honeywell has grown steadily since its 1999 merger with AlliedSignal.

It allowed the organization to rebrand, which led to it becoming a Fortune 500 company.

7. LG Electronics

One of the most popular mobile device manufacturers, LG Electronics, manufactures much more than mobile devices.

Also specializing in home entertainment, air solutions, and even vehicle components, LG has all the bases covered.

6. Amer International Group

A lesser-known company on this list but still very profitable, Amer has an exciting history. Initially, it was a small business that produced copper rods.

After a Chinese billionaire took over the company with the idea to operate in mines and factories, it began growing quickly.

5. Panasonic

One of the most well-known electronics companies for decades, Panasonic began by producing light sockets and now produces almost every form of electronic device.

4. Sony

Over the last few decades, Sony has grown into much more than an electronics company; it has roots in producing and manufacturing electronics.

Sony has done everything from starting with transistor televisions to producing the Walkman to now owning its own record company and movie studio.

3. Hitachi

The single best thing that a business can do is diversify what it sells and the services it provides.

Since it began as a manufacturing company, Hitachi made this decision and now has nearly a dozen segments.

2. Hon Hai Precision Industry (aka Foxconn)

Foxconn specializes in contract electronics and has dozens of customers who manufacture, develop, and manufacture electronic products. It has led to their revenue of well over 100 billion dollars.

1. Samsung

There was never a question about Samsung being first on this list. Being one of the very first companies to produce smartphones,

Samsung is where they are today because they were willing to take risks and be innovative at all costs.

Electronic Manufacturing Services Marketing Sizes

The marketing size of any given electronic manufacturing organization is typically separated into tiers and is highly dependent on the organization’s budget. Certain tiers have more marketing opportunities than others.

A tier 1 organization has a budget of over five billion dollars. An organization like this is likely very diversified and has many marketing prospects.

Tier 1 organizations can spend anything they need to on marketing.

A tier 2 organization has a budget of 500 million to 5 billion.

Tier 2 organizations are likely getting ready to diversify and should spend a bit more on marketing to reach the tier 1 level because most secondary organizations have a budget that can reach many customers.

Tier 3 organizations have budgets ranging from 100 to 500 million dollars.

Any organization in this range should continue specializing in the electronics it manufactures but also spend a small percentage of its budget on marketing to expand.

Organizations with the least to spend are in the fourth tier at under 100 million dollars in the budget. If anyone in this tier wishes to do any marketing, it must be entirely in the word-of-mouth variety. Spending money on marketing would be too significant a risk for an organization in the fourth tier.

Trends In Electronics Manufacturing

Electronics are an industry that changes continuously, and the manufacturing behind them is no different.

One of the best things anybody in electronics manufacturing should look for is trends that can help them find more customers and clients.

One electronic device always in demand is smart devices that can connect to a network.

Ever since the advent of the smartphone, other devices, from televisions to even the electronic components in most automobiles, have been exploring the kind of technology that can connect those particular devices to wireless networks.

This presents a clear opportunity for electronics manufacturing.

Another trend in technology that presents an opportunity for electronics manufacturing is medical device technology.

With healthcare becoming increasingly accessible to more people, the need for better technology in the healthcare field is excellent, and this presents a significant opportunity for anybody interested in electronics manufacturing.

6.1 An outlook of the electronics manufacturing field in 2018

It is not a question of whether or not the electronics manufacturing field will grow. It always will because the demand for better technology, in general, will always exist.

The question is how much the electronics manufacturing field will grow.

Although it has grown very fast in recent years, it has been slowing down over the last couple of years.

However, the chances are good that electronics manufacturing will experience a turnaround and become very profitable again.

No matter what, electronics manufacturing will grow and will be profitable.

Conclusion

Stay updated on trends and other happenings in the electronics manufacturing industry. This will help you make good decisions about your manufacturing firm.

The PCB Manufacturing and assembly industry is one of the most important parts of electronics manufacturing.

Contact us to learn more about what WellPCB PCB manufacturing and assembly do in electronic development.