Contents

What are Fast-Acting Fuses?

Electrical Fuse

Fuses have one essential duty in any electric circuit–overcurrent protection.

In truth, they accomplish this by overheating to points that break a circuit’s connection, which stops excess voltage from reaching the system.

Further, fast-acting fuses burst immediately when they detect high power voltage passing through.

This quick reaction provides a prompt reaction that allows the home appliance to survive without damage to the electronic circuit.

So, it’s no surprise these fuses are widespread in most electrical devices.

Also, fast-blow fuses have sensitive designs that can’t withstand temporary overload currents often associated with most electrical loads.

Fast-Acting Fuses vs. Time-Delay Fuses: What’s the Difference?

Fuses with different ratings

Before we dive into the differences, let’s explore time-delay fuses.

These variants are more tolerant to temporary current surges.

As a result, they can withstand sudden voltage changes without bursting.

In addition, time-delay fuses give you enough time to switch off the power source–protecting the Fuse and circuit from overcurrent damage.

With that in mind, here are the differences between both fuses.

Usage

Usage is one factor that differentiates fast-acting fuses from their time-delay counterparts.

Usually, slow-blow fuses are widespread in the motor industry due to their current-holding properties.

For example, switching on a motor engine allows current to burst through the vehicle’s circuit.

As a result, it needs a fuse that can endure the force of high voltage without bursting–hence the use of a slow-blow fuse.

Also, it allows the vehicle to start without blowing a fuse.

In contrast, fast-blow fuses are more effective in small motors and home appliances.

Why?

Because most of these devices are sensitive to electric current changes.

Fuse Speed

As stated earlier, fast-acting fuses are incredibly sensitive to high current changes.

Hence, they blow instantly when the voltage exceeds the Fuse’s maximum rating.

On the other hand, time-delay variants won’t burst unless the current overload lasts for extended periods–usually ten seconds.

In addition, slow-blow fuses can withstand surges even when they exceed the maximum rating.

Interchangeability

You can replace fast-acting fuses with time-delay variants to enjoy enhanced anti-surge capability. However, it’s not possible to interchange slow-blow fuses for quick-blow ones.

Swapping slow-blow for fast-blow fuses would cause early breaking, which prevents the equipment from starting.

How to Detect a Fast-Acting Fuse

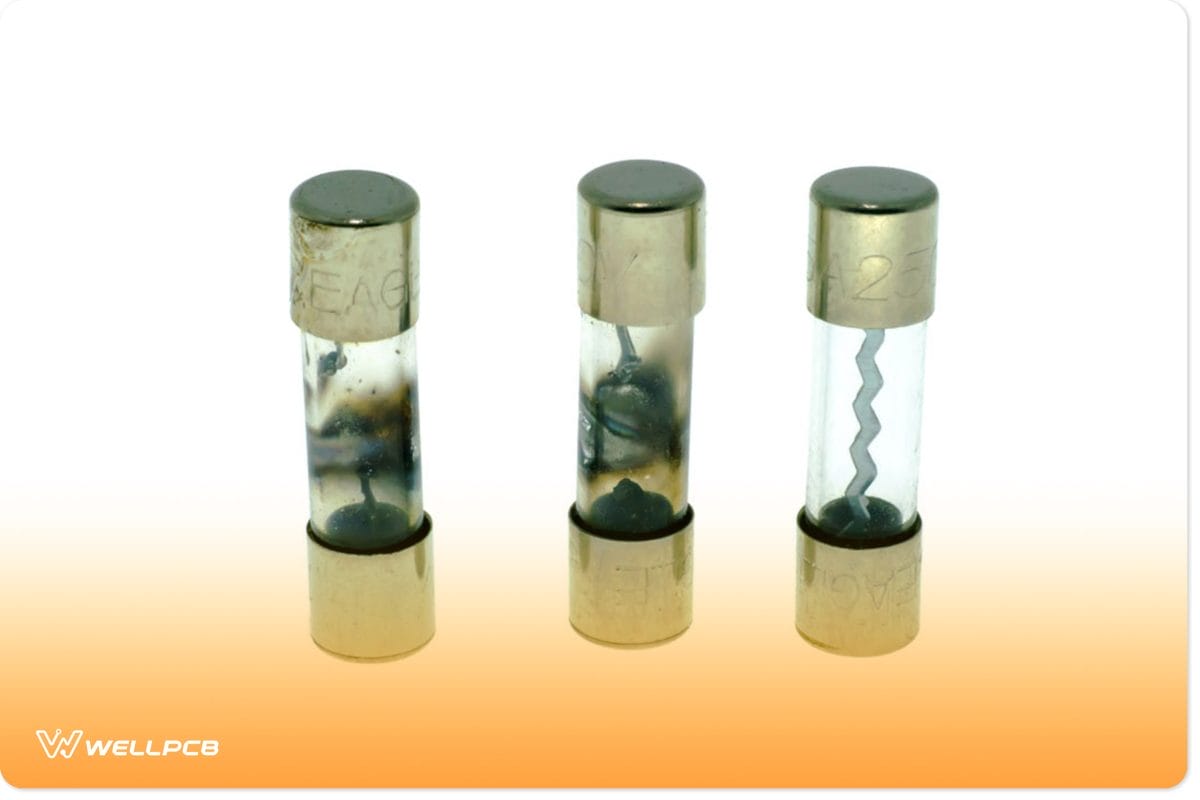

Fuse without spring

Here’s how to determine a fuse’s type in five simple steps.

- First, look for a sticker on the Fuse’s body. It’s the manufacturer’s label that shows the Fuse’s speed.

- The manufacturer’s label should indicate either fast or slow with markings and other letters unique to your equipment. Here’s a chart showing the different markings and their meanings.

| Fuse Marking | Marking Description |

| TT | Very slow-acting fuse (Trage Trage) |

| T | Very slow-acting Fuse (Trage Trage) |

| M | Slow-acting Fuse (Trage) |

| F | Medium-acting Fuse (Mitteltrage) |

| FF | Fast-acting Fuse (Flink) |

Note: If you see any “Shell-looking” symbol, it indicates a slow-acting fuse.

- After checking the speed, you can feel the fuse cap for raised lettering. Sometimes, it could be on the Fuse’s body. This method will be useful if the label’s lettering and marking are not legible.

- If the above steps don’t work, it’s time to grab a magnifying lens. You can check the Fuse for brand or extra manufacturer details.

- Lastly, you can identify the metal through the Fuse’s glass tubing. Examine the wire filament–you have a fast-acting fuse if there’s a thin filament.

Note: Thicker filaments with springs indicate slow-blow fuses

Fuse with spring

How Do You Choose the Correct Fuse for Your Devices?

Here are five steps that show how to select a suitable fuse for your equipment.

Step 1: Identify your Type of Voltage

AC fuses with voltage ratings

First, determine the voltage type you want to avoid entering your circuit.

Typically, most manufacturers specify a fuse’s voltage and use AC or DC to identify the Fuse’s current type.

Also, some fuses feature dual rates, which allows them to work as AC and DC.

Regardless, each Fuse comes with different ratings for overall power use.

Note: Choosing a fuse that doesn’t meet your circuit’s voltage requirements can cause serious issues.

Step 2: Examine the Circuit’s Amperage

After ensuring you have the correct voltage, observe your circuit’s amperage.

Then, you can select a fuse that matches your circuit.

Otherwise, it won’t protect the equipment from voltage surges.

Step 3: Choose a Proper Size

Size is the next thing to consider after sorting out voltage and amperage.

So, you must ensure that the selected Fuse fits your device’s holder.

Note: Your holder should also be specific to your selected Fuse.

Step 4: Check if your Fuse has Replaceable Components

Burnt out and new Fuse

In truth, some fuses allow you to replace the burnt-out parts without the hassle of fixing the whole component.

So, confirm if your Fuse offers such features before opting for a new one.

Note: Although most conductive elements in fuses are replaceable, you must be careful when swapping them to avoid damaging the cartridge.

Step 5: Get Fuses with Inspection Windows

Opt for fuses with inspection windows allowing you to see when a short circuit occurs.

These observation points can also help indicate if a circuit has other issues.

Rounding Up

Fuses are essential items in a circuit. They either endure the force of voltage surges or burn out.

Although it’s easy to ignore fuses, you’ll be disadvantaged if your circuit doesn’t have one.

In addition, fuses are circuit protectors, making them essential for most PCB designs.

Also, they ensure your devices and appliances stay safe from current overloads.

Do you need more information on this topic?

Don’t hesitate to contact us; we’ll gladly help.