Precision 12 Layer PCB Manufacturer for High Density Multilayer Designs

At WellPCB, we manufacture 12 layer PCBs for complex layouts, dense routing and stable performance across every layer.

Each 12 layer PCB stack is engineered in house, fabricated to IPC standards, and supported with complete assembly services.

Turnaround starts at 2 weeks for prototypes, with standard production in 4 to 5 weeks.

- HDI stack ups, via-in-pad, and X-ray tested builds

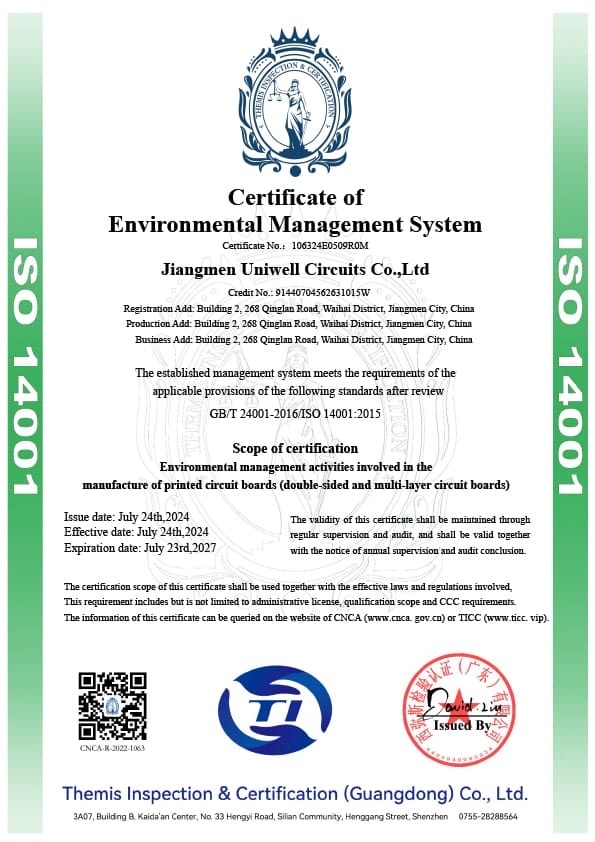

- Certified to ISO 9001, IATF 16949, and IPC-6012

- Controlled impedance with 3/3 mil trace/space routing

ISO9001 ISO13485

ISO14001

IATF

16949

IPC-A-610H International

Certification

Fully Automated

AOI Inspection

- PCB Manufacturer

- 12 Layer

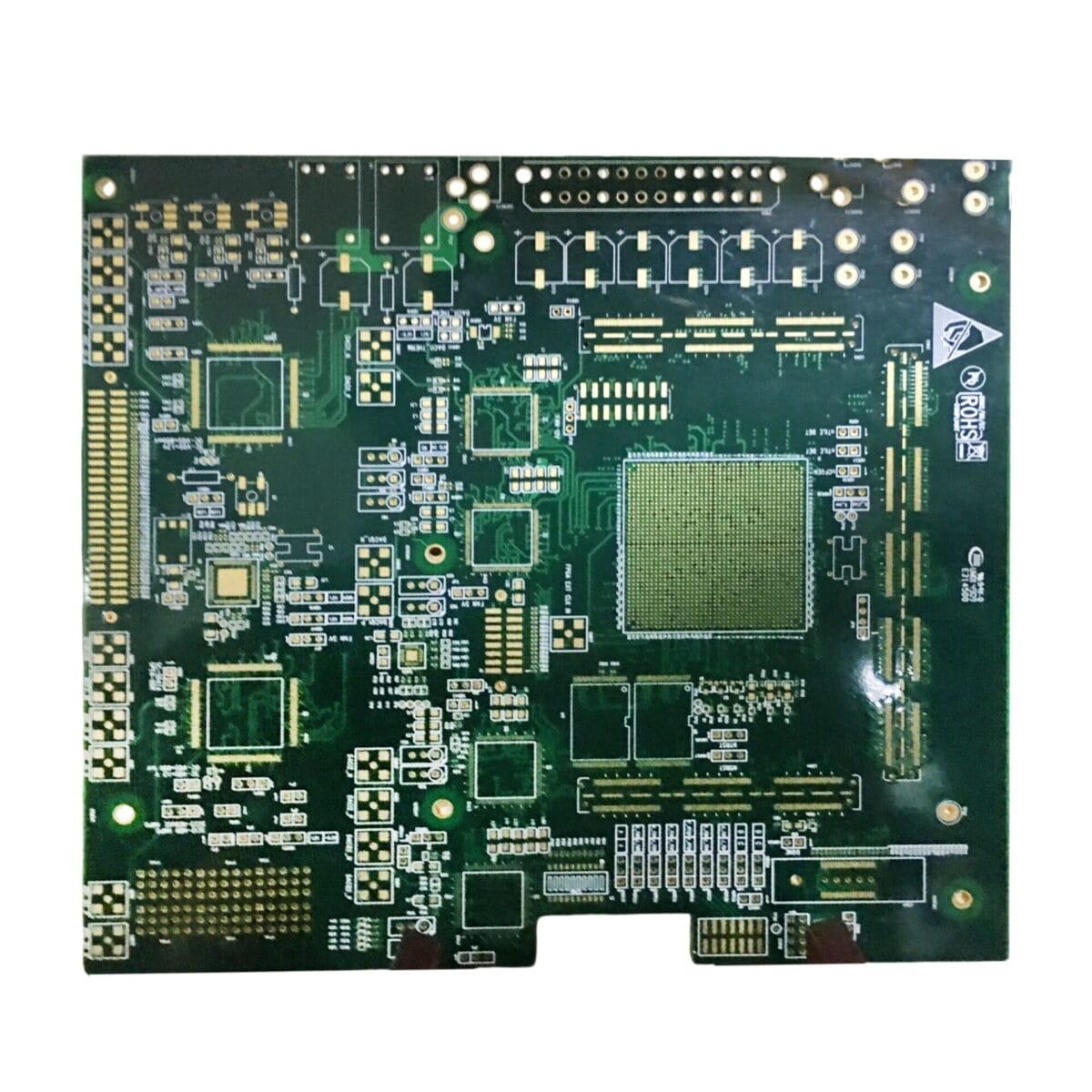

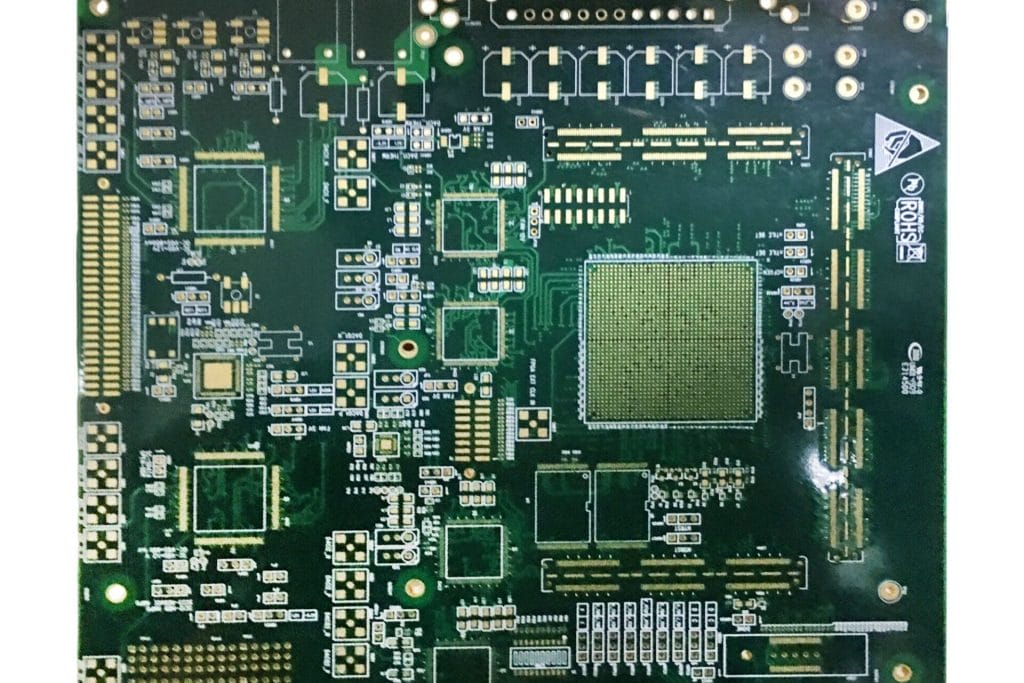

12 Layer PCB Manufacturer for High Density, High Speed Layer Stacks

12 layer PCBs are commonly used in RF front ends, BMS controllers, network processors and embedded systems with split analog/digital domains.

These stack ups allow precise routing across multiple signal layers without sacrificing EMI control, thermal stability or mechanical integrity in a confined enclosure.

WellPCB builds 12 layer PCB stacks with signal integrity, return path planning and assembly viability in mind, whether you’re finalizing a high speed prototype or preparing for scaled production.

Our team handles in house fabrication on FR4-TG170, hybrid, or high Tg materials with blind/buried vias, 3/3 mil routing, and controlled impedance trace modeling.

Inner layer alignment is verified optically before lamination and confirmed post-drill by X-ray. Features like via-in-pad and BGA pads are inspected for shift or breakout.

Our 12 Layer PCB Manufacturer Capabilities

Every 12 layer PCB stackup starts with verified dielectric constants and modeled trace impedance.

We simulate single-ended and differential pairs across each signal layer, using controlled Dk/Df values from FR4-TG170 or high frequency PCB laminates.

Our team builds for symmetry, matching inner layer copper distribution to reduce warp and signal skew. Each layer of the PCB is reviewed before fabrication to align with standards and your assembly constraints.

We support blind, buried and stacked vias with laser drilling down to 3 mil (0.075 mm) in thickness. Copper layer aspect ratios up to 25:1 are achievable on boards up to 6.0 mm thick.

Via-in-pad is standard, not a surcharge, and backdrill capability is available for 50Ω BGA breakout. Every via stack is validated during CAM, and depth is verified with cross sectional microsection analysis.

Our engineers simulate impedance across routed pairs with ±5% tolerance. We support 50Ω and 100Ω differential impedance routing across any layer in the stack, with clearance optimization to adjacent ground and power planes.

EMI suppression is built into every 12 layer PCB with tight return path control and layer separation. Each printed circuit board is fabricated to IPC electrical performance standards.

Standard copper layer options range from 0.5 oz to 5 oz, with heavy copper builds available up to 20 oz on request.

Power plane 1 signal layer separation is maintained for thermal dissipation, while arrays of plated thermal vias allow hotspot routing away from critical components.

The top layer and bottom layer copper balance is modeled to reduce warping in reflow. We validate each 12 layer board for thickness, tolerance, and current capacity.

As a quality 12 layer PCB manufacturer, we offer ENIG, immersion silver, immersion tin, OSP, and lead free HASL, all of which are RoHS and REACH compliant.

We support a range of soldermask colors such as green, red, blue, black, and white. Legends are printed using white or yellow ink. The final copper finish is chosen to match your PCB assembly process (eg. ENIG for BGA, HASL for test PCBs).

Every printed circuit goes through 100% AOI, final visual, and ionic cleanliness checks.

We support full PCB manufacturing and assembly services, including SMT, THT, and PCB assembly with fine-pitch BGA, QFN, DFN and CSP. BOMs are sourced from Digi-Key, Mouser, Arrow or Avnet.

Whether you’re ordering a PCB prototype or a pilot run, we provide traceability for lots, batch verification, and inline testing. We also support box builds, cable integration, and conformal coating under one supplier chain.

WellPCB is a certified 12 layer circuit board manufacturer. All builds follow IPC-6012 Class 3 for reliability, ISO 9001, and IATF 16949 for automotive electronics.

We provide full traceability, batch-level testing, and final QA documents for every run.

Our PCB capabilities include test coupon validation, netlist verification, solderability testing and 5x optical inspection of finished holes and pads.

12 layer PCBs are available with 2-week prototype fabrication or 4 to 5 week standard builds, depending on the stackup.

Completed boards are vacuum-sealed with humidity control, ESD bagged, and shipped via FedEx, DHL, or UPS. All logistics are tracked in-house, with no third party brokers.

Standard packaging includes desiccant, moisture barrier, and lot labeling with serialization.

Why Choose WellPCB as Your 12 Layer PCB Manufacturer?

In House 12 Layer PCB Manufacturing with HDI

The 12 layer PCB manufacturer process includes press registration, plating depth control, and image alignment across the full layer stack up.

No part of the fabrication is outsourced or subcontracted.

Stackup Simulation and Pre-CAM Review

If the signal layer order causes reflection or violates spacing rules, the stack up is rejected. We document all review actions as part of the build approval.

Regulatory Compliance for Medical and Automotive Builds

As a 12 layer PCB manufacturer WellPCB is certified to ISO 9001:2008, ISO 14001:2004, and ISO/TS 16949:2009.

We support regulated industry requirements by providing lot traceability, moisture sensitive labeling, shelf-life control, and batch-level serialization.

These practices are integrated into our PCB manufacturing workflow for medical and automotive customers that require documented quality protocols, even without formal device-level certification.

Class 3 Process Control for Multi-Layer Boards

Plated vias are sectioned during process validation and measured for depth, wall thickness, and fill consistency.

Visual inspection and X-ray are performed during final lot release.

Prototype and Production Consistency

This eliminates requalification and maintains mechanical performance across scale.

Turnkey Assembly and Final Integration

We provide full PCB assembly services with stencil prep, solder paste control, SMT placement, X-ray alignment, and post-process cleaning.

Final builds can include firmware flashing, connector installation, and coating for protection or insulation.

If the order requires a completed 12-layer board, our team delivers a unit that is tested, packed and ready for integration.

What Is a 12-Layer PCB?

A 12-layer PCB is a type of multilayer board built from twelve stacked and laminated copper layers, separated by insulating dielectric material. These layers are arranged in a specific sequence called a 12 layer PCB stack up, which defines the position of signal layers, power planes, and ground layers.

The structure is chosen to support dense routing, impedance-controlled signals, and reliable power distribution without increasing the board’s physical footprint. Most designs use the outer layers for component routing, while inner layers manage cross-sheet signals, voltage rails and shielding.

Vias connect specific layers based on routing constraints, allowing data and power to move vertically through the board. The result is a layout that can support compact, high speed, and EMI-sensitive circuits in a format that balances electrical performance and mechanical stability. Choose a dedicated 12 layer PCB manufacturer for best results.

Where Are 12-Layer PCBs Used In Real-World Systems?

A 12-layer PCB is used when signal complexity, isolation requirements, and routing density exceed the limits of simpler boards. These stack ups allow engineers to combine high speed digital signals, sensitive analog domains, and power delivery in a tightly controlled footprint.

Telecommunications and Networking

Medical Electronics

Automotive Systems

Industrial Control Systems

Aerospace

High-End Computing Devices

Benefits of Using a 12-Layer PCB

A 12-layer PCB offers structure, routing freedom, and electrical consistency that simpler boards cannot support. These stack ups are used to control impedance, reduce EMI, and isolate high-speed or analog signals within a compact footprint.

The added layers enable engineers to separate logic domains, stabilize power delivery and prevent congestion near BGA or fine-pitch components.

Higher Circuit Density

Improved Signal Integrity

Enhanced Power Distribution

Better EMI Shielding

What Materials Are Used in 12-Layer PCB Manufacturing?

12-layer PCBs are constructed from alternating layers of copper foil, glass reinforced epoxy cores and dielectric prepregs selected for electrical consistency and thermal durability. The material system used depends on impedance targets, layer count, and reflow cycle exposure.

High speed designs often require low loss laminates, while power dense layouts demand stable Tg, matched CTE, and minimal resin shrinkage. Each selection impacts how the board performs during drilling, plating, lamination, and system-level operation.

| Material Category | Material Type | Properties | Uses / Applications |

|---|---|---|---|

| Substrate | FR-4 | Flame-retardant, good insulation, and cost-effective. | Standard 12-layer PCBs. |

| Rogers Materials | Low loss, controlled dielectric, high-frequency performance. | RF and microwave applications. | |

| Conductor | Copper Foil (0.5 to 2 oz) | Standard conductivity, various thicknesses. | Signal layers and power planes. |

| Bonding | Prepreg | Adhesive properties, dielectric insulation. | Layer bonding in the stack up. |

| Core Materials | Structural support, copper-clad. | Inner layer pairs. | |

| Finishing | ENIG (Ni/Au) | Excellent solderability, corrosion protection. | Surface mount pads. |

| HASL | Cost-effective, good solderability. | General purpose finish. | |

| Protection | Solder Mask | Electrical insulation, protection. | Circuit protection. |

| Silkscreen | Durable printing, component identification. | Assembly markings. |

How Are 12-Layer PCBs Manufactured?

A 12 layer PCB is manufactured by imaging copper layers, laminating them under heat and pressure, drilling vias, plating interconnects, and finishing the surface.

Each step is aligned to preserve stack registration, trace geometry, and plating consistency. We build every 12-layer PCB in a defined 10 step process that controls impedance, board flatness, and electrical performance.

1. Engineering Review and Stackup Validation

Our team confirms the 12-layer PCB stack-up layout, dielectric assignments, and copper layer symmetry against production tolerances.

DRC and netlist comparisons are used to catch shorts, spacing violations, or mismatched pad sizes before tooling. We simulate impedance if specified and confirm materials based on Tg, CTE, and resin flow.

2. Inner Layer Imaging and Etching

We chemically etch copper to isolate circuit paths, then strip resist, clean the surface, and apply oxide or brown oxide to promote bonding.

Imaging tolerances are held to ±25 µm to prevent misalignment during multilayer registration. Every finished layer is scanned for trace defects before lamination.

3. Layup and Multilayer Lamination

The 12-layer printed circuit board stack up is compressed in a vacuum-assisted press using defined time, temperature, and pressure profiles.

We monitor resin flow, squeeze-out, and dielectric thickness across all zones. Proper stack registration is maintained using tooling pins or optical targets depending on the stack class.

4. Drilling

Drill diameter, aspect ratio, and layer access are based on your PCB design constraints and plating requirements.

Deviation from the pad center must stay within ±2 mils, and hole wall roughness is checked for smear, tear-out, or resin damage. Every drilled panel is verified for pad registration before plating.

5. Hole Desmear and Electroless Plating

We apply a thin conductive seed layer of copper using electroless plating to prepare for electroplating. Wall coverage must be continuous with no voids or breakouts, especially in high aspect ratio designs.

This step ensures electrical contact between the PCB layers and the mechanical integrity of every via.

6. Electroplating and Copper Build-Up

Plating thickness on hole walls is typically 20 to 25 µm, and surface copper is plated to match finished weight. The goal is uniform coverage with minimal nodulation or thickness variation.

7. Outer Layer Imaging and Etching

Etching removes exposed copper, leaving behind the circuit pattern. We confirm pad-to-trace spacing and feature size against design rules and run AOI after etch.

This defines the topmost routing layer and the final footprint of the 12-layer board.

8. Solder Mask and Silkscreen

Silkscreen is printed with component outlines, part numbers, or polarity marks. Mask thickness and alignment are checked before thermal curing.

This protects the PCB board from solder bridging and environmental damage during the PCB assembly process.

9. Surface Finish

Finish thickness, solderability, and thermal robustness are verified after deposition. Gold pads are measured for flatness and nickel barrier thickness using XRF.

This step ensures long term pad protection and good wetting during reflow or hand soldering.

10. Electrical Test and Final Inspection

We inspect for short circuits or open nets via voids and registration defects. AOI and X-ray are used on BGA and fine-pitch packages, and microsection analysis is performed on a per-lot basis.

Boards are cleaned, bagged, and packed per order specifications before release.

How to Order Your 12-Layer PCB

Submit Your PCB Design

Upload your Gerber files or use our easy online PCB design tool to create your board layout. Make sure your files are complete and correctly formatted to ensure smooth processing and production accuracy.

Select Your PCB Specifications

Customize your order by choosing the technical specifications—number of layers, board dimensions, thickness, copper weight, solder mask color, surface finish, and more. Our intuitive interface helps you configure everything based on your project’s needs.

Get an Instant Quote

Once your design and specs are in place, you'll receive a transparent, instant quote. Pricing updates in real time as you modify options, so you can adjust your selections to match your budget before placing the order.

Confirm Order & Make Payment

Review your entire order for accuracy, including file previews and selected specs. After confirmation, proceed to secure checkout and choose your preferred payment method. You’ll receive an email confirmation with order details.

Production & Delivery

Your PCB moves into production immediately. We’ll keep you updated throughout the manufacturing process. Once completed, your boards are carefully packed and shipped to your door, with tracking information provided for your convenience.

WellPCB is trusted by millions of

businesses and innovators.

Why Choose WellPCB?

WellPCB stands out among USA PCB manufacturers by delivering superior quality, advanced solutions, and unmatched reliability. With years of experience serving global markets, WellPCB has earned a reputation as one of the top PCB manufacturers in USA.

WellPCB specializes in multilayer PCBs for advanced electronic applications. You can order these boards with $100 off using our special offer, providing high complexity at competitive rates for demanding projects.

Hommer Zhao

Founder and Chief Editor – Hommer Zhao

Welcome! I’m Hommer Zhao, the founder and Chief Editor of WellPCB. With years of experience in the PCB industry, I’m committed to making sure our content is both accurate and helpful. We’re proud to serve a growing community of over 4,000 customers worldwide, and our goal is to provide you with the best resources and support. Your satisfaction is our top priority, and we’re here to help you every step of the way!

Jesse Holland

Technical Manager – Jesse Holland

Hi, I’m Jesse Holland, an Engineer and Technical Manager at WellPCB. With years of experience in PCB design and engineering, I’m here to ensure that every project we work on meets the highest technical standards. I lead our team, focusing on precision and innovation, collaborating closely with clients to provide tailored solutions and expert guidance. Whether you’re facing a complex design challenge or need advice on technical aspects, I’m here to ensure your project is a success from start to finish.

Nathan Jensen

Purchasing Manager – Nathan Jensen

Hi, I’m Nathan Jenson, the Purchasing Manager at WellPCB. I’m responsible for sourcing the best materials and components to ensure our products meet the highest quality standards. With my extensive experience in procurement, I work closely with suppliers to secure reliable and cost-effective solutions while maintaining strong relationships to support our operations. I aim to ensure every project runs smoothly by providing the resources needed to deliver on time and to your satisfaction.

Emma

Sales Manager – Emma

Hey, I am Emma, sales manager at WellPCB. I studied electronic science and technology at university and have served customers for PCB and PCB Assembly service for several years.

I enjoy communicating with customers and our technicians to solve problems, and customers always say, "It's great to have you onboard".

It is my pleasure and honour to be helpful. Contact me now, and you'll know.

Bella and Cassiel

Sales Representatives – Bella and Cassiel

We’re Bella and Cassiel, your dedicated sales representatives at WellPCB. With our extensive knowledge of the PCB industry, we’re here to provide exceptional service and support. We take the time to understand your unique needs and are always ready to offer tailored solutions and advice. Whether you need product recommendations, assistance with your orders, or simply have a question, we’re here to ensure your experience is smooth and seamless at every step.

Mandy and Wendy

Sales Representatives – Mandy and Wendy

We’re Mandy and Wendy, your friendly sales representatives at WellPCB. Passionate about helping our customers, we bring a wealth of experience in the PCB industry to provide you with the best solutions and service. We take pride in building strong relationships with our clients, understanding their specific needs, and offering personalised support to ensure their satisfaction. Whether you’re looking for advice, product information, or assistance with any part of your order, we’re here to make your experience as smooth and efficient as possible.

Our Team

Our skilled engineers and technicians bring expertise and precision to every PCB assembly project. Committed to quality, efficiency, and innovation, our team ensures every order meets the highest UL, IPC, ROHS & REACH standards, delivering reliable solutions tailored to your needs.

- Founder and Chief Editor – Hommer Zhao

- Technical Manager – Jesse Holland

- Purchasing Manager – Nathan Jensen

- Sales Manager – Emma

- Sales Representatives – Bella and Cassiel

- Sales Representatives – Mandy and Wendy

12-Layer PCB Case Studies

.png?lossy=1&resize=433%2C577&ssl=1)

PCB Assembly

Professional 12-layer HDI (2+8+2) PCB with fine-pitch 2.5mil routing delivering exceptional signal integrity and density.

Features:

- •Material: R5775G (HVLP)

- •Line width/line spacing: 2.5/2.5mil

- •Inner layer space 5mil

- •Electrified gold 50U"

PCB Assembly

High-performance 12-layer PCB featuring immersion gold finish and 0.2mm minimum holes for precision electronic applications.

Features:

- •Number of layers: 12 layers

- •Surface treatment: Immersion gold(ENIG)

- •Minimum hole diameter: 0.2mm

- •Hole copper thickness: 20um

PCB Assembly

Professional 12-layer PCB designed for telecommunications with Panasonic material and 4mil traces for reliable connectivity.

Features:

- •Product application: Telecommunications

- •Number of layers: 12 layers

- •Board Thickness: 1.8mm

- •Material: Panasonic material

- •Min. Line width/space: 4/4mil

12 Layer PCB Manufacturer Client Feedback

As an R&D manager, I have had an outstanding experience working with WELL-PCB. For many years, our company has entrusted them with the production, assembly, and programming of the boards developed in our R&D unit, and they have consistently exceeded our expectations.

Hamid Reza Moshayedi

R&D Manager

Their work is very impressively perfect. Today, when they check our company PCB board after assemble. They found a fake short point which many engineers has never found in the past years. But that is just designed so. The PCB board quality is excellent. Their service is also excellent.

MikeZ

My friend introduced WellPCB to me, the first try, a little look forward to. I ordered a 47*72 10ps PCB, and I can’t wait to receive my PCB. So I used expedited service and received my PCB in three days. I tested and soldered the PCB, Quality is really good, silkscreen, plating also great.

Warren Cliton

12 Layer PCB Manufacturer FAQs

What is the minimum trace width and spacing for a 12-layer PCB?

We support 3.5 mil trace width and 4.0 mil spacing as standard on 1 oz copper builds. For finer geometries, please consult with us during the quote process to determine available tolerances based on your 12-layer PCB stack up.

What’s your maximum copper weight for inner layers?

Our standard capability for inner layer copper is up to 3 oz. However, we support up to 20 oz under special fabrication conditions. These builds are reviewed for plating thickness, thermal expansion, and PCB design feasibility.

Do you support 1+n+1 HDI stackups in 12-layer PCBs?

Yes, as a high quality 12 layer PCB manufacturer, we fabricate full HDI structures, including 1+n+1 through 8+2+8 with stacked microvias and any-layer interconnects. Stack validation includes drill offset, layer-to-layer registration, and via fill integrity during lamination.

Can you do via-in-pad and backdrill on a 12-layer board?

Yes. We support via-in-pad with filling, capping, or plating over, and we also offer mechanical backdrilling to eliminate unused stubs. These features improve high-speed signal quality and reduce parasitic effects in dense PCB layers.

12 Layer PCB Manufacturer for High Density Circuit Board Projects

Get $100 Off Your First Order!

For circuit boards you can trust with industry certifications, your exact specs, and professional factory processes from prototype to mass production.