Industrial Control PCB Assembly for Automation and Process Control

WellPCB provides industrial control PCB assembly for high reliability control systems used in manufacturing, energy and automation industries.

Our control PCBs are built with industrial-grade materials to withstand extreme temperatures, vibration and electrical noise, maintaining consistent performance in harsh environments.

We offer PCB assembly services from prototype PCB builds to volume PCB assembly, with IPC-A-610 Class 3 compliance for industrial control components.

- Industrial control PCB assembly with copper weights from 0.5 to 5 oz

- ISO, UL, and RoHS certified PCB assembly manufacturer facilities

- Advanced SMT and THT assembly process for complex control systems

ISO9001 ISO13485

ISO14001

IATF

16949

IPC-A-610H International

Certification

Fully Automated

AOI Inspection

- PCB Manufacturer

- PCB Assembly Service

- Industrial Control

Precision Industrial Control PCB Assembly for Demanding Applications

Industrial control PCB assembly supports the reliable operation of industrial control components in automation, process control and heavy duty manufacturing equipment.

These control PCBs combine high quality PCB material selection with IPC Class 3 workmanship, allowing for continuous operation in industrial settings that are exposed to vibration, electrical interference and extreme temperatures.

Our manufacturing and assembly process for industrial control PCBs includes SMT placement accuracy within ±30µm, 0.2 mm BGA pitch capability, and through-hole soldering for high-mechanical-strength components.

For each PCB assembly project, we use automated optical inspection, X-ray verification for hidden joints, and impedance control for stable signal integrity. All control PCBs undergo thermal shock testing, solderability assessment, and dimensional tolerance checks before shipping.

Our Industrial Control PCB Assembly Capabilities

WellPCB’s industrial control PCB assembly combines high precision placement, advanced quality control and robust material selection to deliver reliable industrial control PCBs for a variety of industrial control applications.

Our SMT lines achieve placement accuracy within ±30 µm and support components down to 01005 packages.

For industrial control components requiring high density layouts, we handle BGA pitches down to 0.2 mm and QFP spacing as fine as 0.25 mm.

Copper thickness from 0.5 oz to 5 oz is supported, with heavy copper up to 20 oz for high current control PCB designs.

We assemble embedded wireless modules for industrial control, including ESP32, ESP8266, Quectel, Fibocom and Simcom.

RF layouts follow 50 ohm antenna feed geometry with keep‑out, shield can footprints and low loss dielectrics where needed.

We validate radio paths with S11 checks, conduct power measurements, and connectorized test points for repeatable RF calibration.

Through-hole technology (THT) assembly is available for components demanding enhanced mechanical strength in industrial control systems often subjected to vibration, shock and thermal cycling.

Drilling capabilities include finished hole sizes down to 0.15 mm for boards ≤1.6 mm thick, with aspect ratios up to 12:1 for plated through-holes.

We offer HDI PCB structures with via-in-pad, stacked microvias, and blind/buried via configurations for compact industrial control board designs.

These support signal integrity and space optimization in complex industrial control equipment, especially where EMI control is necessary.

For space-constrained control enclosures, we assemble flexible PCB and rigid-flex PCB designs using polyimide and high Tg FR4 substrates.

Thickness ranges from 0.2 mm to 6.0 mm with warp and twist ≤0.7%, ensuring dimensional stability during the assembly process.

We integrate SMT and THT on the same control PCB when both miniaturization and mechanical robustness are required.

This approach is often used in process control systems and motion control applications where signal processing circuits and high power connectors must coexist.

Assemblies support CAN, RS485, Ethernet, Modbus and industrial Wi Fi or BLE for plant networks. Designs apply galvanic isolation, TVS protection, and common‑mode chokes to protect control equipment in noisy plants.

We route differential pairs to target impedance and specify transformer‑isolated magnetics for reliable links.

Surface finishes include leaded HASL, lead-free HASL, ENIG (0.05 to 0.2 µm Au over 3 to 6 µm Ni), OSP, immersion tin, and immersion silver.

These are selected according to industrial processes and corrosion resistance needs. Conformal coatings protect against dust, moisture, and chemicals in harsh industrial settings.

Every industrial control PCBA undergoes 100% automated optical inspection (AOI), X-ray inspection for hidden joints and either flying probe or in-circuit testing.

Extra tests include thermal shock, solderability, impedance verification and microsection analysis to confirm copper plating quality.

For connected control PCB assemblies, we add RF and protocol tests. That includes over the air checks, conducted sensitivity sweeps, link margin assessments, and network stack validation for CAN, RS485, and Ethernet. We provide log files and pass criteria with each batch.

Our team can handle complete PCB assembly solutions, from fabrication to sourcing components, to final assembly and packaging.

Our production capacity of 600,000 components per hour supports both prototype PCB assembly and high volume PCB assembly manufacturing with consistent quality control.

Why Choose WellPCB for Your Industrial Control PCB Assembly?

Manufacturing and Assembly Services Under One Roof

IPC Class 3 and ISO-Certified Quality Control

Industrial-Grade Material and Component Sourcing

Fast Turnaround for Prototypes and Volume PCB Assembly

Advanced Testing and Inspection Capabilities

Responsive Technical Support

What Is Industrial Control PCB Assembly?

Industrial control PCB assembly is the process of building printed circuit board assemblies specifically designed for industrial control systems and automation equipment. Unlike consumer-grade PCBs, teams engineer these control PCBs to operate reliably in harsh industrial settings, withstanding vibration, extreme temperatures, dust, moisture and electromagnetic interference.

This type of PCB assembly integrates industrial control components like microcontrollers, communication modules, power regulation circuits and sensor interfaces into a single, high-reliability control PCB.

Features of Industrial Control PCBs

Industrial control PCBs are engineered for reliability, safety and performance in industrial control systems often operating in harsh environments. These features ensure stable operation, long service life and support Industry 4.0 programs.

Extended Temperature Range Components (-40°C to +125°C)

High Copper Weights for Power Handling

Polyimide, PTFE & Metal-Core Substrate Options

Long Lifecycle Component Strategies

Vibration-Resistant Mounting Techniques

Industries We Serve with Industrial Control PCB Assembly

WellPCB delivers industrial control PCB assembly solutions for a variety of industrial control applications, each requiring specific design features, PCB materials and assembly processes to ensure reliability in demanding environments.

Industrial Automation & Robotics

Control PCBs for industrial automation integrate motion control drivers, feedback loop processing, and network interfaces such as CAN bus or EtherCAT.

These assemblies often use heavy copper layers for high current motor outputs and rigid-flex PCB designs to fit within robotic joints or compact housings.

Process Control Systems

PCBs for process control manage temperature, pressure, and flow monitoring equipment in chemical, petrochemical and food processing plants.

These designs often require conformal coating for moisture resistance, controlled impedance for sensor communication lines, and through-hole mounted connectors for high strength terminations.

Power Conversion & Distribution Equipment

Industrial control boards for power systems use copper weights up to 20 oz for current handling and thermal dissipation.

Applications include inverters, converters, and distribution switchgear, where IPC Class 3 solder joints and polyimide substrates support high voltage insulation requirements.

Human-Machine Interfaces (HMIs)

HMI control PCBs integrate touchscreens, display drivers, and input controllers.

Flexible PCB sections may be used for ergonomic panel layouts, while surface finishes like ENIG provide long term contact reliability for user input areas.

Renewable Energy Control Systems

For solar, wind, and energy storage applications, industrial control PCB assemblies must handle variable power conditions and environmental extremes.

Designs often include metal-core PCB substrates for heat dissipation, robust surge protection components, and industrial grade connectors.

Transportation & Material Handling Equipment

Control boards for elevators, conveyor systems, and automated guided vehicles (AGVs) require shock and vibration resistance, redundant safety circuit paths and environmental sealing.

Rigid-flex PCB designs enable integration into moving assemblies without compromising signal integrity.

How to Order Your Industrial Control PCB Assembly

Submit Your PCB Design

Upload your Gerber files or use our easy online PCB design tool to create your board layout. Make sure your files are complete and correctly formatted to ensure smooth processing and production accuracy.

Select Your PCB Specifications

Customize your order by choosing the technical specifications—number of layers, board dimensions, thickness, copper weight, solder mask color, surface finish, and more. Our intuitive interface helps you configure everything based on your project’s needs.

Get an Instant Quote

Once your design and specs are in place, you'll receive a transparent, instant quote. Pricing updates in real time as you modify options, so you can adjust your selections to match your budget before placing the order.

Confirm Order & Make Payment

Review your entire order for accuracy, including file previews and selected specs. After confirmation, proceed to secure checkout and choose your preferred payment method. You’ll receive an email confirmation with order details.

Production & Delivery

Your PCB moves into production immediately. We’ll keep you updated throughout the manufacturing process. Once completed, your boards are carefully packed and shipped to your door, with tracking information provided for your convenience.

WellPCB is trusted by millions of

businesses and innovators.

Why Choose WellPCB?

WellPCB stands out among USA PCB manufacturers by delivering superior quality, advanced solutions, and unmatched reliability. With years of experience serving global markets, WellPCB has earned a reputation as one of the top PCB manufacturers in USA.

WellPCB specializes in multilayer PCBs for advanced electronic applications. You can order these boards with $100 off using our special offer, providing high complexity at competitive rates for demanding projects.

Hommer Zhao

Founder and Chief Editor – Hommer Zhao

Welcome! I’m Hommer Zhao, the founder and Chief Editor of WellPCB. With years of experience in the PCB industry, I’m committed to making sure our content is both accurate and helpful. We’re proud to serve a growing community of over 4,000 customers worldwide, and our goal is to provide you with the best resources and support. Your satisfaction is our top priority, and we’re here to help you every step of the way!

Jesse Holland

Technical Manager – Jesse Holland

Hi, I’m Jesse Holland, an Engineer and Technical Manager at WellPCB. With years of experience in PCB design and engineering, I’m here to ensure that every project we work on meets the highest technical standards. I lead our team, focusing on precision and innovation, collaborating closely with clients to provide tailored solutions and expert guidance. Whether you’re facing a complex design challenge or need advice on technical aspects, I’m here to ensure your project is a success from start to finish.

Nathan Jensen

Purchasing Manager – Nathan Jensen

Hi, I’m Nathan Jenson, the Purchasing Manager at WellPCB. I’m responsible for sourcing the best materials and components to ensure our products meet the highest quality standards. With my extensive experience in procurement, I work closely with suppliers to secure reliable and cost-effective solutions while maintaining strong relationships to support our operations. I aim to ensure every project runs smoothly by providing the resources needed to deliver on time and to your satisfaction.

Emma

Sales Manager – Emma

Hey, I am Emma, sales manager at WellPCB. I studied electronic science and technology at university and have served customers for PCB and PCB Assembly service for several years.

I enjoy communicating with customers and our technicians to solve problems, and customers always say, "It's great to have you onboard".

It is my pleasure and honour to be helpful. Contact me now, and you'll know.

Bella and Cassiel

Sales Representatives – Bella and Cassiel

We’re Bella and Cassiel, your dedicated sales representatives at WellPCB. With our extensive knowledge of the PCB industry, we’re here to provide exceptional service and support. We take the time to understand your unique needs and are always ready to offer tailored solutions and advice. Whether you need product recommendations, assistance with your orders, or simply have a question, we’re here to ensure your experience is smooth and seamless at every step.

Mandy and Wendy

Sales Representatives – Mandy and Wendy

We’re Mandy and Wendy, your friendly sales representatives at WellPCB. Passionate about helping our customers, we bring a wealth of experience in the PCB industry to provide you with the best solutions and service. We take pride in building strong relationships with our clients, understanding their specific needs, and offering personalised support to ensure their satisfaction. Whether you’re looking for advice, product information, or assistance with any part of your order, we’re here to make your experience as smooth and efficient as possible.

Our Team

Our skilled engineers and technicians bring expertise and precision to every PCB assembly project. Committed to quality, efficiency, and innovation, our team ensures every order meets the highest UL, IPC, ROHS & REACH standards, delivering reliable solutions tailored to your needs.

- Founder and Chief Editor – Hommer Zhao

- Technical Manager – Jesse Holland

- Purchasing Manager – Nathan Jensen

- Sales Manager – Emma

- Sales Representatives – Bella and Cassiel

- Sales Representatives – Mandy and Wendy

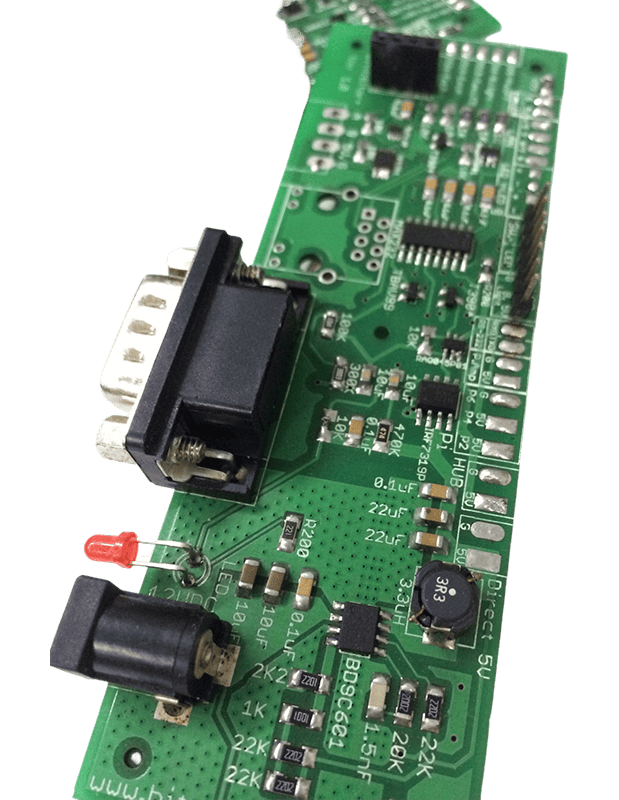

Industrial Control PCB Assembly Case Studies

PCB Assembly

This case shows the BGA&QFN Assembly, which is equipped with a variety of chips, capacitors, resistors, and other components.

It has functions such as signal processing, power management, and interface communication, and can adapt to the needs of data acquisition, device driving, communication interconnection, etc. in industrial control

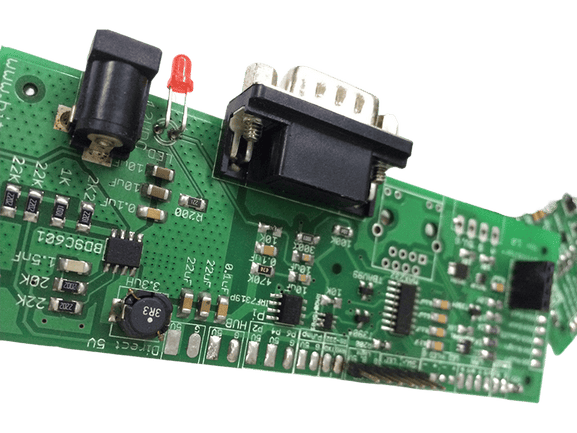

PCB Assembly

The high-quality multi-layer PCB effectively optimizes wiring space, reduces signal interference, and meets the complex signal transmission requirements of industrial control.

The soldering process utilizes a combination of reflow and wave soldering. Through rigorous manufacturing processes and quality inspections, this PCBA can operate stably in complex and harsh industrial environments. It maintains accurate signal transmission and proper operation despite high and low temperatures, vibration, and electromagnetic interference. This PCBA is compatible with numerous standard-compliant industrial control software and hardware devices on the market, providing a solid foundation for industrial automation control.

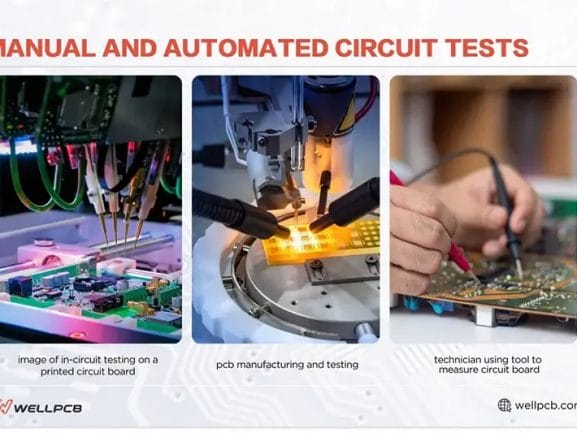

PCB Assembly

During the manufacturing process, WellPCB undergoes multiple inspection processes, such as automatic optical inspection (AOI), which uses optical cameras to check component mounting position, soldering quality, etc.; solder paste inspection and ICT inspection to evaluate component performance and connection status.

Flying probe testing is used to detect electrical performance problems such as circuit open circuit and short circuit to ensure the quality and reliability of PCBA.

Industrial Control PCB Assembly Client Feedback

As an R&D manager, I have had an outstanding experience working with WELL-PCB. For many years, our company has entrusted them with the production, assembly, and programming of the boards developed in our R&D unit, and they have consistently exceeded our expectations.

Hamid Reza Moshayedi

R&D Manager

Their work is very impressively perfect. Today, when they check our company PCB board after assemble. They found a fake short point which many engineers has never found in the past years. But that is just designed so. The PCB board quality is excellent. Their service is also excellent.

MikeZ

My friend introduced WellPCB to me, the first try, a little look forward to. I ordered a 47*72 10ps PCB, and I can’t wait to receive my PCB. So I used expedited service and received my PCB in three days. I tested and soldered the PCB, Quality is really good, silkscreen, plating also great.

Warren Cliton

Industrial Control PCB Assembly FAQs

Can you assemble both SMT and THT on the same board?

Yes, we offer mixed technology PCB assembly for industrial control PCBs, combining SMT for compact, high-density circuits with THT for mechanically robust industrial control components such as connectors, relays and transformers.

What testing methods are used for industrial control boards?

Every industrial control PCB assembly undergoes 100% automated optical inspection (AOI), X-ray for hidden joints, and either flying probe or in-circuit testing. Our team also performs functional testing under simulated operating conditions to verify performance in industrial control applications.

Do you provide component sourcing for industrial projects?

Yes, we source all electronic components from authorized distributors, focusing on industrial-grade parts rated for extended temperature ranges, vibration resistance, and long lifecycle availability to match the demands of industrial control systems.

Do you support Industry 4.0 and digital transformation initiatives?

Yes, we provide industrial control PCB assembly solutions that integrate into smart factory environments. Designs can support predictive maintenance sensors, real-time data analytics and secure network protocols for remote monitoring. For advanced applications, we can incorporate interfaces for digital twin connectivity, enabling synchronized virtual models of your control systems.

Partner with WellPCB for Reliable Industrial Control PCB Assembly

Get $100 Off Your First Order!

WellPCB delivers industrial control PCB assembly solutions that meet the highest IPC Class 3 standards for performance and reliability in demanding industrial control applications.