OEM PCB Manufacturing

for Complex Electronics

WellPCB is a full service OEM PCB manufacturer trusted by OEMs in the medical, automotive, aerospace and industrial sectors.

We provide one stop PCB fabrication, PCB assembly, testing and global sourcing all under ISO 9001, IATF 16949, and UL-certified systems.

With two large advanced PCB manufacturing bases and two dedicated PCB assembly factories, we support fast prototyping, scalable production and full traceability across every stage of the manufacturing and assembly process.

- 100% in house fabrication, assembly, and testing

- Certified for IATF 16949, ISO 9001, UL, IPC Class 3

- Fast prototyping (2 weeks) and mass production (4 to 5 weeks)

ISO9001 ISO13485

ISO14001

IATF

16949

IPC-A-610H International

Certification

Fully Automated

AOI Inspection

OEM PCB Manufacturing for Supplied Netlists and Builds

WellPCB supports OEM programs that require stable stack-up control, exact impedance routing and component footprint precision across repeated production runs.

Global demand for OEM PCB manufacturing is expected to reach USD 84.24 billion by 2025, driven by the growth of 5G, IoT and AI-powered electronics.

As a production-focused OEM PCB manufacturer, we handle fabrication and PCB assembly for applications where trace alignment, via structures and solder mask tolerances directly impact product reliability.

We work with verified Gerber, ODB++, or IPC-2581 data, which includes defined net classes, layer usage, and test point accessibility, all of which have already been approved by your internal team.

Panelized outputs are matched to stencil apertures and reel configurations before being released to the line. Every step from CAM review to post-reflow AOI is structured to preserve BOM integrity and reduce variation between early prototypes and final mass production units.

Our OEM PCB Manufacturing Capabilities

WellPCB supports OEM PCB manufacturing with in-house capabilities for multilayer fabrication, high density PCB assembly, component sourcing, and final testing.

As a highly rated OEM PCB manufacturer, we build from locked stack-ups and verified netlists, applying traceable procedures to control tolerances, material usage, and inspection across every lot. From drill-to-plating registration to AOI alignment and stencil-to-reel matching, our workflow is engineered for repeatable output and product-level integration.

We support rigid and hybrid PCB fabrication from 1 to 64 layers using FR4, aluminum, ceramic, and high frequency PCB materials like Rogers.

The minimum trace/space is 3 mil, and finished copper weights range from 0.5 oz to 20 oz. Lamination, drilling and plating are controlled for via stability across multilayer structures.

We also support HDI PCBs with microvias, laser drilling, and embedded passive components for miniaturized OEM assemblies.

Surface mount lines place up to 600,000 components per hour with 0.2 mm BGA and 0.15 mm QFP support.

We handle mixed technology builds using SMT, selective soldering, and through-hole insertion with post-wave AOI. Each board is matched to stencil and reel files for reel-to-bin traceability.

We deliver expedited PCB prototype runs in as little as 2 weeks and support volume builds up to 10,000+ units.

Full panel setup, tooling and DRC locking are preserved during the transition from short-run to mass production to minimize variation and re-approval.

Our process aligns with Industry 4.0 initiatives, using automation and traceability systems to support smarter production.

We perform design for manufacturing (DFM) and DRC checks on all customer-supplied layout files before production.

Stack-up consistency, impedance target alignment and fabrication constraints are reviewed at the CAM stage.

Our role is to identify potential build issues and prepare clean data outputs for stable fabrication and assembly.

We support turnkey, consigned, or hybrid sourcing using verified distributors, including Mouser, Digi-Key, Arrow and Element14.

BOMs are checked for conflicts, lifecycle status, and alternates. Each part is confirmed before the order with authorized part numbers and procurement logs.

Inline inspection includes AOI, flying probe and 2D/3D X-ray. Boards are tested with ICT or functional testing based on the netlist and BOM.

First article inspection and statistical process control (SPC) reports are available for all staged builds.

We manufacture under ISO 9001, IATF 16949 and UL frameworks, with every assembly meeting IPC-A-610 Class 2 or 3 criteria.

Files, components, and process controls are archived for traceability and audit reporting. Our processes reflect industry expectations from IPC, FDA, and EPA where applicable, particularly for medical, automotive and industrial builds.

Available finishes include ENIG, OSP, HASL (leaded or lead-free), ENEPIG, and immersion options like silver and tin.

All coatings meet RoHS and REACH directives and are applied under controlled line conditions using in house chemistry calibration and bake profiles.

Reasons to Work With WellPCB as

Your OEM PCB Manufacturer

One-Stop PCB Manufacturing and Assembly

Every OEM PCB project is managed within a single workflow, so there are no sourcing delays, traceability gaps or integration errors between suppliers.

Documented Anti-Counterfeit Component Policy

This protects customers from counterfeit parts, compliance problems, and traceability issues.

Advanced Impedance Control and Testing

Every controlled impedance circuit board is verified through advanced testing before shipment to ensure it meets the electrical design specifications.

Our OEM PCB manufacturer team applies modeling and measurement procedures throughout the fabrication process, as well as final in-line testing.

Multiple Factory Locations for Load Balancing

This allows us to balance large and small orders effectively so you get your order on time, regardless of our workload.

No Minimum Order Requirement for OEM Projects

We have no minimum and no maximum order size.

Responsive Post-Sale Support

Our team is available for support and advice even after your order has been processed.

We can also provide documentation after your order has been closed, if necessary.

Industries We Serve as an OEM Electronics Manufacturer

WellPCB delivers precise, scalable OEM PCB manufacturing and PCB assembly services to demanding sectors including aerospace, automotive, medical, telecommunications and industrial automation where durability, accuracy and production consistency are essential.

Aerospace

Automotive

Medical Devices

Consumer Electronics

Telecommunications

Energy

Our OEM PCB Manufacturing Process

Our OEM PCB manufacturing process covers PCB design review, fabrication, assembly, testing, and product integration all done in house for speed, traceability and cost control. As an OEM PCB manufacturer, we support scalable production from prototype PCB to full turnkey contract builds, using a tightly managed, end-to-end manufacturing process.

1. PCB Design Review & DFM Analysis

2. PCB Fabrication

3. Component Sourcing

4. Surface Mount and Through-Hole Capabilities

5. Testing, Inspection & Quality Management

6. Final Assembly & Box Build

What Materials and Surface Finishes Do We Offer?

We offer FR4, High Tg, halogen free, Rogers, CEM-3 and metal core substrates for OEM PCB manufacturer workflows. Surface finishes include ENIG, OSP, leaded and lead-free HASL, immersion silver and hard gold, each of which is tested for solderability, reliability, and compatibility with SMT and turnkey PCB assembly.

| PCB Materials | Material / Finish | Production Advantages |

|---|---|---|

| Substrate Types | FR4 | Widely supported by fabricators, stable performance and low cost across most stackups. |

| High Tg FR4 | Higher thermal reliability supports lead-free assembly and automotive grade cycles. | |

| Halogen-Free FR4 | Better environmental performance and enhanced product quality, especially in fire safety applications. | |

| Rogers | Low dielectric loss and tight impedance control for RF and high speed digital designs. | |

| CEM-3 | Lower density and cost benefit short-run and budget constrained builds. | |

| Metal-Core (Aluminum, Copper, Ceramic) | Enhances thermal conductivity while reducing layer count in power-dense OEM layouts. | |

| Surface Coating Options | ENIG (Electroless Nickel Immersion Gold) | Uniform plating and flat pads support BGA/QFN placement with minimal bridging. |

| OSP (Organic Solderability Preservative) | Reduces oxidation risks before assembly; compatible with high-mix PCB workflows. | |

| Lead-Free HASL / HASL | Proven wetting and joint integrity across wave and reflow soldering lines. | |

| Immersion Silver / Immersion Tin | Minimizes signal loss; preferred in OEM digital and RF mixed-signal layers. | |

| Hard Gold | Gold plated contacts ensure long insertion life for OEM products with interconnect cycles. |

What’s the Difference Between OEM and Standard Manufacturing?

OEM PCB manufacturing is designed for companies that need consistent, repeatable production with locked specifications, while standard manufacturing is project based with more flexibility for changes.

| OEM PCB Manufacturing | Standard Manufacturing |

|---|---|

| Locked specifications: Once approved, there are no changes for reliable PCB assembly. | Flexible designs: Changes allowed between orders for varied assembly projects. |

| Dedicated project manager: Single point of contact from our Shenzhen PCB factory | Shared support team: Various contacts per project across manufacturing services. |

| Volume commitments: Planned production schedules with turnkey contract manufacturing. | Order-by-order: No volume commitments for individual assembly services. |

| Consistent pricing: Contracted rates for OEM PCB assembly and manufacturing services | Quote-per-project: Pricing varies by order from printed circuit board manufacturers |

| Long-term partnership: Multi-year agreements with top OEM PCB manufacturers. | Transactional: Project-based relationships with a contract manufacturer. |

When Should You Use an OEM PCB Manufacturer?

You should use an OEM PCB manufacturer when you need high-volume production, fast scaling or you’re looking to reduce your overhead costs.

They handle component sourcing, manage your supply chain, and optimize your PCB design through DFM. With advanced tools and expert teams, they maintain strict quality control throughout the entire production process, from prototype to mass production.

Choose OEM PCB assembly when consistency, speed, and cost matter. It gives you access to specialized electronics manufacturing without owning the process. You get tested, production ready printed circuit board assemblies built to locked specs, fast. For growing companies, it’s how you ship more, without building more.

How to Order from WellPCB OEM PCB Manufacturer

Submit Your PCB Design

Upload your Gerber files or use our easy online PCB design tool to create your board layout. Make sure your files are complete and correctly formatted to ensure smooth processing and production accuracy.

Select Your PCB Specifications

Customize your order by choosing the technical specifications—number of layers, board dimensions, thickness, copper weight, solder mask color, surface finish, and more. Our intuitive interface helps you configure everything based on your project’s needs.

Get an Instant Quote

Once your design and specs are in place, you'll receive a transparent, instant quote. Pricing updates in real time as you modify options, so you can adjust your selections to match your budget before placing the order.

Confirm Order & Make Payment

Review your entire order for accuracy, including file previews and selected specs. After confirmation, proceed to secure checkout and choose your preferred payment method. You’ll receive an email confirmation with order details.

Production & Delivery

Your PCB moves into production immediately. We’ll keep you updated throughout the manufacturing process. Once completed, your boards are carefully packed and shipped to your door, with tracking information provided for your convenience.

WellPCB is trusted by millions of

businesses and innovators.

Why Choose WellPCB?

WellPCB stands out among USA PCB manufacturers by delivering superior quality, advanced solutions, and unmatched reliability. With years of experience serving global markets, WellPCB has earned a reputation as one of the top PCB manufacturers in USA.

WellPCB specializes in multilayer PCBs for advanced electronic applications. You can order these boards with $100 off using our special offer, providing high complexity at competitive rates for demanding projects.

Hommer Zhao

Founder and Chief Editor – Hommer Zhao

Welcome! I’m Hommer Zhao, the founder and Chief Editor of WellPCB. With years of experience in the PCB industry, I’m committed to making sure our content is both accurate and helpful. We’re proud to serve a growing community of over 4,000 customers worldwide, and our goal is to provide you with the best resources and support. Your satisfaction is our top priority, and we’re here to help you every step of the way!

Jesse Holland

Technical Manager – Jesse Holland

Hi, I’m Jesse Holland, an Engineer and Technical Manager at WellPCB. With years of experience in PCB design and engineering, I’m here to ensure that every project we work on meets the highest technical standards. I lead our team, focusing on precision and innovation, collaborating closely with clients to provide tailored solutions and expert guidance. Whether you’re facing a complex design challenge or need advice on technical aspects, I’m here to ensure your project is a success from start to finish.

Nathan Jensen

Purchasing Manager – Nathan Jensen

Hi, I’m Nathan Jenson, the Purchasing Manager at WellPCB. I’m responsible for sourcing the best materials and components to ensure our products meet the highest quality standards. With my extensive experience in procurement, I work closely with suppliers to secure reliable and cost-effective solutions while maintaining strong relationships to support our operations. I aim to ensure every project runs smoothly by providing the resources needed to deliver on time and to your satisfaction.

Emma

Sales Manager – Emma

Hey, I am Emma, sales manager at WellPCB. I studied electronic science and technology at university and have served customers for PCB and PCB Assembly service for several years.

I enjoy communicating with customers and our technicians to solve problems, and customers always say, "It's great to have you onboard".

It is my pleasure and honour to be helpful. Contact me now, and you'll know.

Bella and Cassiel

Sales Representatives – Bella and Cassiel

We’re Bella and Cassiel, your dedicated sales representatives at WellPCB. With our extensive knowledge of the PCB industry, we’re here to provide exceptional service and support. We take the time to understand your unique needs and are always ready to offer tailored solutions and advice. Whether you need product recommendations, assistance with your orders, or simply have a question, we’re here to ensure your experience is smooth and seamless at every step.

Mandy and Wendy

Sales Representatives – Mandy and Wendy

We’re Mandy and Wendy, your friendly sales representatives at WellPCB. Passionate about helping our customers, we bring a wealth of experience in the PCB industry to provide you with the best solutions and service. We take pride in building strong relationships with our clients, understanding their specific needs, and offering personalised support to ensure their satisfaction. Whether you’re looking for advice, product information, or assistance with any part of your order, we’re here to make your experience as smooth and efficient as possible.

Our Team

Our skilled engineers and technicians bring expertise and precision to every PCB assembly project. Committed to quality, efficiency, and innovation, our team ensures every order meets the highest UL, IPC, ROHS & REACH standards, delivering reliable solutions tailored to your needs.

- Founder and Chief Editor – Hommer Zhao

- Technical Manager – Jesse Holland

- Purchasing Manager – Nathan Jensen

- Sales Manager – Emma

- Sales Representatives – Bella and Cassiel

- Sales Representatives – Mandy and Wendy

OEM PCB Manufacturer Case Studies

PCB Assembly

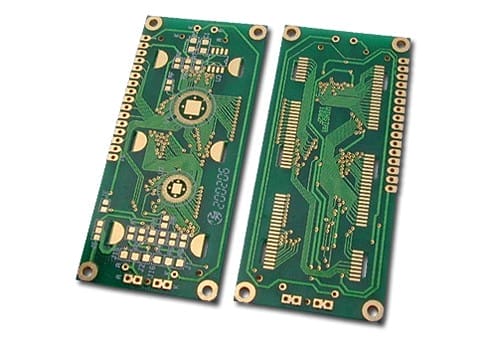

This project is a flex PCB, widely used in mobile phones (connecting screens, cameras and other modules), tablets, smart wearable devices, etc.

Features:

- •Material: ThinFlex PI

- •Board thickness: 0.3mm

- •Warpage:<1.5%

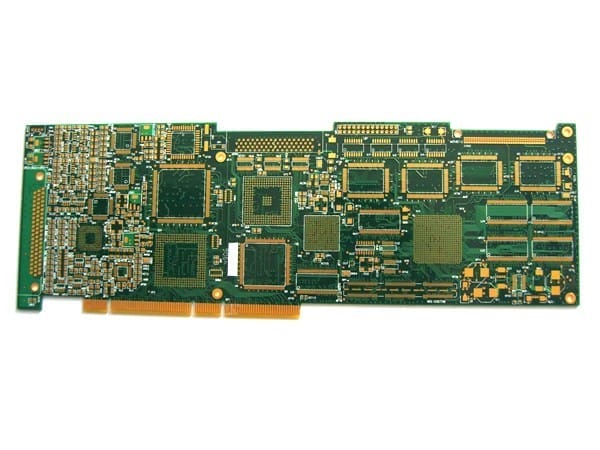

PCB Assembly

OEM PCB manufacturing with simple and fast delivery. Can be completed in 24 hours at the fastest

Features:

- •Material: FR4

- •Board thickness:0.8-1.6mm

- •Surface Finish: ENIG / OSP / Immersion Silver (varies by application)

PCB Assembly

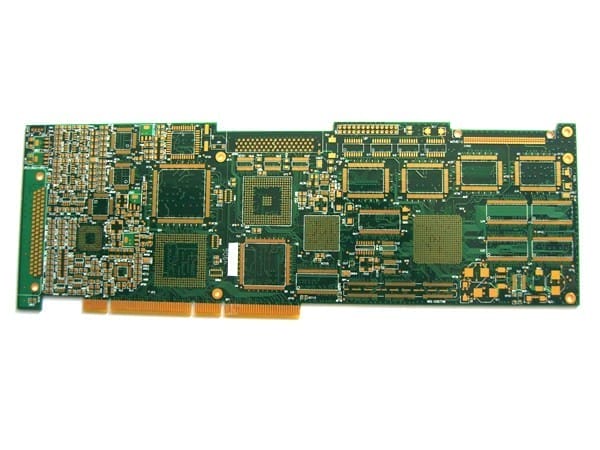

In aerospace test instruments, it is responsible for high-speed data acquisition, accurate signal analysis, and supports high-precision detection and control.

Features:

- •High-density multi-layer printed circuit boards

- •Special process: gold finger BGA packaging

OEM PCB Manufacturer Client Feedback

As an R&D manager, I have had an outstanding experience working with WELL-PCB. For many years, our company has entrusted them with the production, assembly, and programming of the boards developed in our R&D unit, and they have consistently exceeded our expectations.

Hamid Reza Moshayedi

R&D Manager

Their work is very impressively perfect. Today, when they check our company PCB board after assemble. They found a fake short point which many engineers has never found in the past years. But that is just designed so. The PCB board quality is excellent. Their service is also excellent.

MikeZ

My friend introduced WellPCB to me, the first try, a little look forward to. I ordered a 47*72 10ps PCB, and I can’t wait to receive my PCB. So I used expedited service and received my PCB in three days. I tested and soldered the PCB, Quality is really good, silkscreen, plating also great.

Warren Cliton

OEM PCB Manufacturer FAQs

How long does it take to set up OEM manufacturing for my project?

Setup time depends on your files, BOM and production scope. For a typical OEM PCB manufacturer project, we complete DFM, sourcing checks, and tooling setup in 2 to 5 business days.

Complex builds with tight tolerances or custom parts may require more extended validation and procurement times. We fast-track OEM PCB assembly runs with ready-to-go data and confirmed components.

What happens if components go end-of-life during production?

We monitor BOM lifecycle status throughout every OEM PCB assembly run. If a part is flagged as EOL, our sourcing team immediately recommends verified alternates or approved equivalents that match footprint, function, and spec.

All changes are reviewed with you before any substitutions are made. This ensures continuity in manufacturing and assembly without compromising the design.

How do you ensure quality consistency across multiple production runs?

We lock in production parameters after the first build, including approved files, DFM rules, soldering profiles, and stencil data. Every new run follows the same validated setup, with traceable serialization and logged inspection results.

Our team monitors variation at each step using IPC standards and internal benchmarks. This provides you with predictable, certified output, ensuring no surprises between lots.

Can I supply my own components for OEM PCB assembly?

Yes, we support consigned, partial, or full turnkey sourcing models. If you provide parts, we verify quantity, label, and condition before kitting. Supplied components must meet our inbound inspection standards to avoid delays during PCB assembly.

What’s included in your full turnkey OEM PCB manufacturer service?

We handle everything from PCB fabrication and sourcing to SMT assembly, testing, and final product assembly. You send us the design and we manage the rest.

This includes DFM, supply chain, process control, and outbound logistics. It’s designed for companies that want end-to-end support from a single OEM PCB manufacturer.

OEM PCB Manufacturer for Prototype and Full Scale Manufacturing Projects

Get $100 Off Your First Order!

Verified by our engineers, certified for the industry, and fastest turnaround times in the industry. Partner with a reliable OEM PCB manufacturer: WellPCB.