Fast Prototype PCB Assembly

for Easy Iteration

WellPCB is a leading prototype PCB assembly manufacturer in the rapidly growing $147.5B PCBA market, specializing in prototype PCB board fabrication and assembly for engineers, startups, and established companies across high-growth sectors.

Our advanced PCB prototype assembly service delivers high-quality prototype PCBs with lead times as short as 2 weeks.

We provide comprehensive turnkey solutions including PCB fabrication, SMT assembly, through-hole assembly, and box build services all under ISO 9001 and IPC certified systems.

With our dedicated facilities, we support everything from single prototype boards to small run production with full traceability.

- Complete prototype PCB assembly and fabrication services in house.

- Certified for ISO 9001, IPC-A-610 Class 3, and UL manufacturing standards.

- Fast prototype PCB board assembly (2 week lead time).

ISO9001 ISO13485

ISO14001

IATF

16949

IPC-A-610H International

Certification

Fully Automated

AOI Inspection

- PCB Manufacturer

- PCB Assembly Service

- Prototype

Prototype PCB Assembly for Fast Product Development

WellPCB supports rapid product development cycles that depend on reliable prototype PCB assembly, precision component placement and high quality PCB board prototype fabrication across complex electronic designs.

As a production grade prototype PCB assembly service provider, we manufacture prototype PCBs using advanced SMT assembly, through-hole assembly, and full turnkey capabilities.

We process validated Gerber files, bill of materials, and design files from industry standard formats. Component sourcing, stencil fabrication and pick-and-place programming are optimized for prototype requirements and design changes.

Signal integrity, thermal management, and board edge constraints are evaluated to prevent assembly issues and support optimal performance. Each prototype PCB undergoes automated optical inspection (AOI), in-circuit testing, X-ray inspection, and functional verification before shipping.

Full traceability is maintained throughout the fabrication and assembly process from component procurement to final testing, with all work verified to IPC standards.

Our Prototype PCB Assembly Capabilities

Our prototype PCB assembly services are perfect for rapid prototyping with precision component placement, reliable solder joints and comprehensive testing. We support complex prototype PCB boards from single-sided to multi layer designs with full turnkey assembly capabilities and quick delivery times.

We use advanced pick and place equipment for SMT assembly, handling components from 0201 passives to complex BGAs and QFPs.

Our surface mount process includes automated stencil printing, reflow soldering and AOI inspection to ensure reliable prototype PCB assembly with minimal defects.

Our through-hole assembly capabilities support both selective soldering and wave soldering processes for prototype PCBs requiring conventional components.

We handle mixed technology boards combining SMT and through-hole components with precise assembly process control.

We provide comprehensive component sourcing services, managing your bill of materials from prototype to production.

Our supplier network ensures authentic electronic components with proper traceability, reducing lead times for your prototype PCB projects.

Custom stencil fabrication is performed in-house using laser-cut stainless steel or nickel electroform materials.

Solder paste application is optimized for each prototype PCB board design, ensuring consistent print quality and proper reflow characteristics.

Our fabrication and assembly services are fully integrated, supporting prototype PCBs from Gerber files through final testing.

This turnkey approach eliminates coordination delays and ensures compatibility between PCB manufacturing and assembly processes.

Every prototype PCB assembly undergoes rigorous testing including in-circuit testing, functional verification and X-ray inspection for hidden solder joints.

Our quality control process ensures each prototype board meets design specifications and IPC standards.

Beyond PCB assembly, we offer box build assembly services for complete prototype systems.

This includes mechanical assembly, cable harnessing, and final system testing to deliver fully functional prototype products.

Why Choose WellPCB for Your Prototype PCB Assembly?

Rapid Prototype PCB Assembly & Quick Delivery Time

ISO & IPC Certified Manufacturing

Advanced PCB Manufacturing Facilities

Global Component Sourcing Network

Full Turnkey Assembly Capabilities

Comprehensive Testing & Quality Assurance

What is a Prototype PCB Assembly?

A prototype PCB assembly is a testable version of your design before full-scale production. It’s a fully functional printed circuit board with electronic components mounted and soldered, a sample of the real thing. Unlike bare PCB fabrication, prototype assembly includes the complete process from component sourcing through final testing.

Prototype PCBs allow engineers to verify circuit functionality, test signal integrity, and identify design changes before committing to volume production. This prototype service reduces development costs and accelerates time-to-market by catching issues early in the design cycle.

For startups and established companies, prototype assembly bridges the gap between PCB design concepts and manufacturable products. Whether you need a single prototype board for initial testing or small run production for market validation, a professional pcb prototype fabrication service provides the precision required for successful product development.

What Types of Circuit Boards Can Prototype PCB Assembly Cover?

Single Sided & Double Sided PCBs

Multi Layer PCB Prototypes

HDI & High Density Interconnect Boards

Flexible & Rigid-Flex PCB Assembly

High Frequency & RF Circuit Boards

Custom PCB Shapes & Sizes

Why Choose Prototype PCB Assembly?

Validate Design Functionality Before Production

Reduce Development Costs & Time-to-Market

Test Component Compatibility & Sourcing

Optimize Assembly Process & Manufacturing

Demonstrate Proof of Concept to Stakeholders

Enable Design Iterations & Improvements

Design Considerations for Prototype PCB Assembly

Component Selection & Bill of Materials

Choose components that are readily available to avoid delays in prototype PCB assembly. Consider component package sizes, lead times and alternative parts in your bill of materials. Standard components reduce costs and assembly complexity, while obsolete or hard-to-source parts can impact your prototype delivery time.

PCB Layout & Assembly Constraints

Design your PCB layout with assembly processes in mind, ensuring adequate spacing between components for pick and place operations. Consider stencil design requirements for solder paste application, and avoid placing components too close to board edges where assembly tooling may interfere with the prototype assembly process.

Thermal Management & Heat Dissipation

Plan for thermal considerations early in your prototype PCB design, especially for power components and high speed circuits. Include thermal vias, copper pours and proper component spacing to prevent overheating during testing. Thermal issues discovered during prototype assembly can require design changes if not addressed initially.

Test Point Accessibility & Debug Features

Incorporate test points and debug features into your prototype PCB board design to facilitate testing and troubleshooting. Accessible test points enable efficient in-circuit testing and functional verification during the assembly process, making it easier to identify and resolve issues in your prototype.

Signal Integrity & Layer Stack-up

Consider signal integrity requirements when designing multi layer prototype PCBs, including proper impedance control and ground plane design. Work with your PCB manufacturer to optimize the layer stack up for your specific signal requirements, ensuring your prototype boards perform as expected.

Design for Manufacturing (DFM) Guidelines

Follow DFM best practices to ensure your prototype PCB can be efficiently assembled and tested. This includes proper via sizing, adequate copper spacing, and consideration of PCB fabrication tolerances.

Documentation & Design Files

Prepare comprehensive Gerber files, assembly drawings, and component placement files for your prototype PCB assembly. Clear documentation reduces assembly errors and ensures your prototype boards are built according to specifications, minimizing delays and revision cycles.

How to Order Your Prototype PCB Assembly

Submit Your PCB Design

Upload your Gerber files or use our easy online PCB design tool to create your board layout. Make sure your files are complete and correctly formatted to ensure smooth processing and production accuracy.

Select Your PCB Specifications

Customize your order by choosing the technical specifications—number of layers, board dimensions, thickness, copper weight, solder mask color, surface finish, and more. Our intuitive interface helps you configure everything based on your project’s needs.

Get an Instant Quote

Once your design and specs are in place, you'll receive a transparent, instant quote. Pricing updates in real time as you modify options, so you can adjust your selections to match your budget before placing the order.

Confirm Order & Make Payment

Review your entire order for accuracy, including file previews and selected specs. After confirmation, proceed to secure checkout and choose your preferred payment method. You’ll receive an email confirmation with order details.

Production & Delivery

Your PCB moves into production immediately. We’ll keep you updated throughout the manufacturing process. Once completed, your boards are carefully packed and shipped to your door, with tracking information provided for your convenience.

WellPCB is trusted by millions of

businesses and innovators.

Why Choose WellPCB?

WellPCB stands out among USA PCB manufacturers by delivering superior quality, advanced solutions, and unmatched reliability. With years of experience serving global markets, WellPCB has earned a reputation as one of the top PCB manufacturers in USA.

WellPCB specializes in multilayer PCBs for advanced electronic applications. You can order these boards with $100 off using our special offer, providing high complexity at competitive rates for demanding projects.

Hommer Zhao

Founder and Chief Editor – Hommer Zhao

Welcome! I’m Hommer Zhao, the founder and Chief Editor of WellPCB. With years of experience in the PCB industry, I’m committed to making sure our content is both accurate and helpful. We’re proud to serve a growing community of over 4,000 customers worldwide, and our goal is to provide you with the best resources and support. Your satisfaction is our top priority, and we’re here to help you every step of the way!

Jesse Holland

Technical Manager – Jesse Holland

Hi, I’m Jesse Holland, an Engineer and Technical Manager at WellPCB. With years of experience in PCB design and engineering, I’m here to ensure that every project we work on meets the highest technical standards. I lead our team, focusing on precision and innovation, collaborating closely with clients to provide tailored solutions and expert guidance. Whether you’re facing a complex design challenge or need advice on technical aspects, I’m here to ensure your project is a success from start to finish.

Nathan Jensen

Purchasing Manager – Nathan Jensen

Hi, I’m Nathan Jenson, the Purchasing Manager at WellPCB. I’m responsible for sourcing the best materials and components to ensure our products meet the highest quality standards. With my extensive experience in procurement, I work closely with suppliers to secure reliable and cost-effective solutions while maintaining strong relationships to support our operations. I aim to ensure every project runs smoothly by providing the resources needed to deliver on time and to your satisfaction.

Emma

Sales Manager – Emma

Hey, I am Emma, sales manager at WellPCB. I studied electronic science and technology at university and have served customers for PCB and PCB Assembly service for several years.

I enjoy communicating with customers and our technicians to solve problems, and customers always say, "It's great to have you onboard".

It is my pleasure and honour to be helpful. Contact me now, and you'll know.

Bella and Cassiel

Sales Representatives – Bella and Cassiel

We’re Bella and Cassiel, your dedicated sales representatives at WellPCB. With our extensive knowledge of the PCB industry, we’re here to provide exceptional service and support. We take the time to understand your unique needs and are always ready to offer tailored solutions and advice. Whether you need product recommendations, assistance with your orders, or simply have a question, we’re here to ensure your experience is smooth and seamless at every step.

Mandy and Wendy

Sales Representatives – Mandy and Wendy

We’re Mandy and Wendy, your friendly sales representatives at WellPCB. Passionate about helping our customers, we bring a wealth of experience in the PCB industry to provide you with the best solutions and service. We take pride in building strong relationships with our clients, understanding their specific needs, and offering personalised support to ensure their satisfaction. Whether you’re looking for advice, product information, or assistance with any part of your order, we’re here to make your experience as smooth and efficient as possible.

Our Team

Our skilled engineers and technicians bring expertise and precision to every PCB assembly project. Committed to quality, efficiency, and innovation, our team ensures every order meets the highest UL, IPC, ROHS & REACH standards, delivering reliable solutions tailored to your needs.

- Founder and Chief Editor – Hommer Zhao

- Technical Manager – Jesse Holland

- Purchasing Manager – Nathan Jensen

- Sales Manager – Emma

- Sales Representatives – Bella and Cassiel

- Sales Representatives – Mandy and Wendy

Prototype PCB Assembly Case Studies

PCB Assembly

Used for device networking and data transmission, such as in smart hardware systems, to achieve communication between devices and networks, devices and peripherals, and may also be used for data interaction scenarios of small industrial control equipment

Features:

- •Function: Network communication, data interaction, device expansion, etc.

- •Application: Internet of Things

PCB Assembly

Suitable for scenarios requiring complex connections and controls, in line with industrial standards

Features:

- •Diverse interfaces, strong scalability

- •Application: industrial control or network communication

PCB Assembly

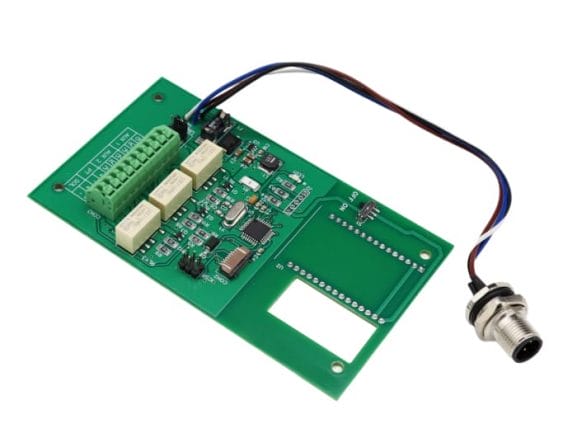

Electronic prototype assembly with relay modules & wiring harnesses. Designed for smart device control units to enable signal interaction & action execution.

Features:

- •Relay module and wiring harness assembly

- •Application: Control unit for smart devices to realize signal interaction and action execution

Prototype PCB Assembly Client Feedback

As an R&D manager, I have had an outstanding experience working with WELL-PCB. For many years, our company has entrusted them with the production, assembly, and programming of the boards developed in our R&D unit, and they have consistently exceeded our expectations.

Hamid Reza Moshayedi

R&D Manager

Their work is very impressively perfect. Today, when they check our company PCB board after assemble. They found a fake short point which many engineers has never found in the past years. But that is just designed so. The PCB board quality is excellent. Their service is also excellent.

MikeZ

My friend introduced WellPCB to me, the first try, a little look forward to. I ordered a 47*72 10ps PCB, and I can’t wait to receive my PCB. So I used expedited service and received my PCB in three days. I tested and soldered the PCB, Quality is really good, silkscreen, plating also great.

Warren Cliton

Prototype PCB Assembly FAQs

What file formats do you need for prototype PCB assembly?

Can you source components that are out of stock or obsolete?

What is the minimum order quantity for prototype PCB assembly?

What happens if my prototype PCB assembly fails testing?

Start On Your Prototype PCB Assembly Today

Get $100 Off Your First Order!

Our experienced team delivers high-quality prototype PCB assembly with fast turnaround times, comprehensive testing, and full turnkey solutions. From single prototype boards to small run production.