Rigid Flex PCB Manufacturer,

Supplier & Assembly Services

Rigid-flex PCBs combine flexible and rigid substrates in a single integrated structure for complex mechanical and electrical designs.

WellPCB is a rigid-flex PCB manufacturer with 2 large manufacturing and 2 assembly facilities totaling over 25,000 m² of floor space. We provide end-to-end rigid flex PCB fabrication and assembly services from prototyping through production.

- Rigid flex PCB prototyping with 3 to 14 day lead times.

- Full surface finish options including ENIG, OSP, HASL, and hard gold.

- Up to 30-layer rigid-flex stack-ups with HDI and flex-in-core support.

ISO9001 ISO13485

ISO14001

IATF

16949

IPC-A-610H International

Certification

Fully Automated

AOI Inspection

- PCB Manufacturer

- PCB Assembly Service

- Rigid Flex

Rigid-Flex PCB Services

You Can Rely On

Our rigid-flex PCB services can handle demanding board designs requiring mechanical durability and layout flexibility across dynamic, space-limited environments.

WellPCB integrates design verification, fabrication, and assembly into one streamlined process. Our rigid flex PCB fabrication services are backed by strict process controls, configurable stack-up options, and an online quoting system that simplifies the transition from design to production.

All builds undergo comprehensive DRC checks and are manufactured to IPC-A-610H Class 3 standards, ensuring circuit reliability across medical, automotive, and industrial applications.

Our Rigid-Flex PCB Service Capabilities

We support 2 to 30 layer rigid flex PCB stack-ups, including configurations like 1F+2R, 2F+4R, and 6F+8R+6F.

Whether your design requires flex-in-core or flex-on-external structures, we accommodate complex builds with bookbinder and asymmetrical thickness options.

| Project Items | WellPCB Capabilities |

|---|---|

| FPC Base Material(Adhesive) | Shengyi SF305: PI = 0.5mil, 1mil, 2mil; Cu = 0.5oz, 1oz |

| FPC Base Material(Adhesiveless) |

|

| Cover Layer | Shengyi SF305C: 0515, 0525, 1025, 1035, 2030 |

| Pure Adhesive |

|

| PI Stiffener | Taihong MHK Series: PI = 3mil, 5mil, 7mil, 9mil |

| 3M Adhesives | 9077, 9460, 6677, 9458 |

| Low Flow Prepreg | EM-37B (L) |

| Flexible Solder Mask Ink | Taiyo: PSR-9000 FLX501 |

| Standard Rigid Materials |

|

| Special Rigid Materials |

|

| Layers (Flex Layers) | Standard: 26 layers (10 flex layers); Custom: 30 layers (18 flex layers) |

| Finished Board Thickness | 0.3–5.0mm |

| Size of Finished Products(Min) | 10mm × 15mm |

| Size of Finished Products(Max) | 16 inch × 29 inch |

| Impedance Control (Single-Ended) |

|

| Impedance Control (Differential) |

|

| HDI Board Types | Standard:2+n+2 (buried vias ≤0.4mm); Custom: 3+n+3 (buried vias ≤0.4mm) |

| Via Capabilities |

|

| Min. Warpage |

|

| Min. Trace Width |

|

| Surface Finish Types |

|

Our fabrication process enables ultra-fine features with 3/3 mil trace and spacing, laser-drilled vias down to 3 mil, and mechanical hole diameters as small as 0.1 mm.

We offer copper weights from 0.5 to 5 oz and maintain impedance control within a ±10% tolerance window.

We work with high-reliability board materials, including high-Tg FR4, polyimide, and adhesiveless base substrates.

Available surface finishes include ENIG, OSP, hard gold, and immersion silver, all manufactured to IPC-6013 Class 3 standards.

WellPCB provides complete assembly services for rigid flex circuits, supporting SMT, through-hole, and mixed technologies.

We handle fine-pitch components such as BGAs, QFNs, and CSPs with IPC-A-610 Class 3 quality standards, backed by AOI, X-ray, and ICT testing.

Our rigid-flex circuit boards are built to endure over 200,000 flex cycles. This makes them ideal for environments of constant vibration or mechanical stress, including automotive, industrial robotics, aerospace, and medical equipment.

We offer standard build times ranging from 3 to 14 days for rigid flex PCB fabrication. Our production lines are equipped to handle both prototype orders and small-to-medium batch volumes with consistent process control and delivery reliability.

We provide DFM and DRC checks at no cost and support Gerber, Altium, and IPC-2581 file formats.

Our team helps evaluate layer stack-up options, bend radius constraints, and key manufacturability concerns to ensure your rigid-flex PCB fabrication is production-ready.

Why Choose WellPCB as

Your Rigid-Flex PCB Manufacturer?

Competitive Pricing

Our pricing is transparent and free of hidden charges, whether you’re producing a rigid flex prototype or moving into full production.

We accept flexible payment methods, including T/T, PayPal, bank transfers, credit card, and cash, to make global transactions seamless.

On-Time and Safe Delivery

Orders are packaged in anti-static, moisture-proof, and vibration-resistant materials.

Quality Assurance

Every build is subject to 100% X-ray inspection, AOI, aqueous cleaning, and final PCB testing.

We consistently deliver flexible circuit performance with a 98% customer satisfaction rate.

Guaranteed Reliability

If any issue arises due to fabrication or handling, our compensation policy includes rework, refund, or re-fabrication at no additional cost.

Proven Track Record

Our end-to-end process makes us a trusted rigid-flex PCB manufacturer for high-performance circuit board solutions.

Scalable Global Support

Your printed circuit board builds are delivered with consistent quality, manufactured to spec, and prepared for direct integration into your application.

What Types of Rigid-Flex PCB Stack-Ups and

Structures are Available?

Rigid-flex PCB structures are classified by how the flexible layers and rigid sections are combined. Options include single- or double-sided flex, multilayer rigid-flex, and laminated or non-laminated configurations, each designed to meet specific routing, bending, and space requirements.

Single-Sided Rigid-Flex

This configuration features a single copper layer on the flexible circuit portion, bonded to one or more rigid sections.

It’s commonly used for low-complexity interconnects such as sensor modules, camera assemblies, or display connections.

These flex PCBs are easy to manufacture and offer good mechanical bend performance, especially in dynamic applications with limited routing paths.

Double-Sided Rigid-Flex

Two conductive layers are routed on the flexible portion, allowing signal layers or ground planes to run in parallel.

This enhances circuit density while preserving flexibility. Plated through-holes are used to connect both copper layers.

Applications include flex and rigid-flex PCBs in consumer devices, medical diagnostics, and industrial sensors requiring greater layout complexity.

Multilayer Rigid-Flex

These rigid-flex printed circuit boards support high-density routing, controlled impedance, and advanced grounding schemes.

Microvia and HDI-compatible structures can be integrated to meet demanding PCB design needs. Used in aerospace, automotive ADAS, and high-end wearables.

Non-Lamination Flex & Rigid Board

The flex section typically consists of polyimide or polyester, while the rigid section uses FR-4 or CEM-1.

This design allows for simplified rework or replacement but lacks the electrical reliability and mechanical stability of laminated rigid-flex circuit boards.

Laminated Rigid-Flex PCB Structures

Flex Layer in Inner Layer: The flex layer is embedded between rigid layers, protected from external stress.

Flex Layer on Outer Layer: Flex layers are positioned outside the rigid core for applications requiring repeated bending.

What Materials are used in Rigid-Flex PCBs?

Rigid-flex PCBs are made from four core material groups: conductors, adhesives, insulators, and surface finishes.

| Material Type | Example / Subtype | Function |

|---|---|---|

| Conductors | Rolled Annealed (RA) Copper | Used in flexible circuits requiring repeated bending. It offers superior ductility, a grain structure aligned with the bend axis, and a reduced risk of micro-cracking. |

| Electro-Deposited (ED) Copper | Preferred in rigid sections and some static flex zones. Provides high conductivity and fine trace definition but lower flex fatigue performance than RA copper. | |

| Adhesives | Epoxy | Strong adhesion with low moisture absorption. Tg typically ≥135 °C. Commonly used between copper and dielectric layers in rigid zones. |

| Acrylic | High peel strength, chemical resistance, and thermal stability (Tg ~150 to 200 °C). Often selected for rigid-flex bonding interfaces. | |

| Pressure Sensitive Adhesive (PSA) | Low-temperature bonding layer is used to attach stiffeners or mount flex circuits. Limited to non-electrically active zones. | |

| Polyimide (as adhesive) | Extreme thermal resistance (>250 °C) and chemical durability. Used in aerospace-grade flexible PCB assemblies exposed to harsh environments. | |

| Adhesiveless Base Material | Polyimide is cast directly onto copper foil. Eliminates adhesive interface, improves flexibility, reduces Z-axis expansion, and enhances thermal reliability in dynamic flex circuits. | |

| Pre-preg (Resin-coated Glass) | Dielectric bonding sheet used during multilayer lamination in rigid areas. Properties depend on the resin system (Tg, flow, Dk/Df). | |

| Insulators / Dielectrics | FR-4 | Standard rigid PCB core. Tg typically 135 to 170 °C. It provides mechanical support and a routing platform for rigid flex boards. |

| Polyimide | High-flex, high-temperature material (Tg >250 °C). Used in flexible sections due to superior bend endurance and dimensional stability. | |

| CEM-1 | Cellulose-based composite alternative to FR-4. Used in cost-sensitive rigid sections with low mechanical stress. | |

| Polyester (PET) | Flexible and thermally stable (~120 to 150 °C), lower cost than polyimide. Used in basic flexible PCB assemblies. |

What is the Manufacturing Process for Rigid-Flex PCBs?

Rigid-flex PCBs are manufactured through a controlled, multistep process that combines rigid boards and flexible circuits into a single structure. Each stage, from imaging to final inspection, is optimized to maintain alignment, prevent damage to flexible sections, and meet strict reliability standards.

Design, Layout, and Stack-Up Configuration

Your PCB design files are reviewed to verify DRC compliance, via structure, and bend zone layout. The stack-up is assessed for proper placement of flexible materials, controlled impedance, and layer balance. This step confirms that the build meets rigid flex PCB fabrication requirements for manufacturability and mechanical integrity.

Material Selection

Material selection is based on application-specific thermal, mechanical, and electrical requirements. Options include polyimide flex materials, high-Tg FR4, and adhesiveless copper laminates. Choosing the correct board materials minimizes delamination, enhances durability, and supports complex rigid-flex circuit boards.

Imaging and Etching

Copper layers are photo-imaged and etched to form signal traces. In flex PCB fabrication, precise alignment is critical high-Tg FR4, and adhesiveless copper laminates. Choosing the correct board materials minimizes delamination, enhances durability, and supports complex rigid-flex circuit boards.

Lamination

Rigid and flex layers are bonded using heat, pressure, and resin systems. This step integrates rigid parts and flexible circuits into a unified structure. Proper lamination controls Z-axis expansion and ensures mechanical integrity in flex and rigid-flex PCB builds.

Drilling and Plating

Via holes and pad sites are drilled using mechanical and laser systems. Through-hole plating forms electrical connections across layers. Care is taken to protect the flex circuit areas during drill-through to maintain mechanical and electrical reliability.

Solder Mask Application

A flexible solder mask is applied to exposed copper to prevent oxidation and solder bridging. Rigid board zones use standard epoxy masks; flex areas require masks that withstand dynamic bending. Accurate registration preserves pad exposure and edge clearance.

Surface Finishing

Surface finishes improve solderability and protect exposed pads. Available options include ENIG, OSP, and immersion silver. These coatings are chosen based on end-use environment, assembly process, and component compatibility in rigid-flex printed circuit boards.

Electrical Testing

All boards are tested for electrical continuity and isolation in accordance with IPC-6013 Class 3 performance criteria, covering via integrity, netlist conformance, and impedance requirements.

Final Inspection and Packaging

Finished boards are inspected visually and via AOI, with optional X-ray and cross-section analysis. Rigid-flex PCBs are packaged in anti-static, moisture-resistant, and vibration-proof materials, accompanied by inspection certificates for traceability.

What are the Benefits of Rigid-Flex PCBs?

Rigid-flex PCBs reduce size and weight by combining flexible and rigid layers in a single structure. They simplify assembly, improve signal performance by eliminating connectors, and maintain reliability under vibration, bending, and other mechanical stress.

Design Flexibility

The combination of rigid sections and flexible areas within a single PCB reduces the overall size and weight of the assembly.

This makes rigid-flex technology well-suited for compact applications such as wearables, smartphones, and portable diagnostic equipment, where standard rigid PCBs are too bulky or limited in mechanical versatility.

Enhanced Reliability

Rigid-flex designs eliminate connectors and wiring between rigid sections, removing common failure points.

The flex sections also resist moisture and chemicals, making them dependable for long-term reliability in harsh or sealed environments.

Thermal Stability

Every build is subject to 100% X-ray inspection, AOI, aqueous cleaning, and final PCB testing.

We consistently deliver flexible circuit performance with a 98% customer satisfaction rate.

Durability

Improved Signal Integrity

Replacing cables with flex PCBs reduces impedance discontinuities and limits signal reflection. Controlled trace geometry within the rigid flex PCB stack-up improves performance for high-speed digital and analog signals.

Dual-Sided Mounting

Components can be mounted on both sides of the rigid sections, improving electrical routing efficiency and supporting high-density circuit board designs with limited space.

System Cost Savings

While rigid flex PCB fabrication may have higher unit costs, it reduces total cost of ownership by eliminating connectors, cables, and associated labor. It also lowers failure rates during assembly and field use.

Reduced Assembly Time

With no need to manually join rigid segments or insert cabling, rigid flex PCB assembly simplifies the production flow. This shortens lead times and reduces process variation in volume builds.

What are the Applications and Industries

that use Rigid-Flex PCBs?

Rigid-flex PCBs are used in electronic assemblies that require mechanical flexibility, compact form factors, and long-term reliability. Their structure supports both static and dynamic applications across multiple sectors, from embedded medical devices to aerospace instrumentation.

Aerospace and Defense

Applications include aerospace instrumentation, conformal routing inside airframes, and compact sensor platforms designed to fit complex 3D enclosures.

Medical Devices

Rigid-flex PCBs are found in internal and external medical electronics due to their compact size, chemical resistance, and mechanical stability.

They are commonly used in diagnostic systems, medical implants, surgical probes, and handheld diagnostic tools where reliable interconnects are required in limited space.

Consumer Electronics

Smartphones, tablets, foldable displays, cameras, fitness trackers, and smartwatches use Rigid-flex PCBs to support slim form factors and repeated bending.

These assemblies reduce the need for internal connectors while maintaining mechanical durability in tight, high-use enclosures.

Automotive Electronics

Their ability to tolerate vibration and temperature cycling makes them suitable for space-constrained automotive environments with continuous mechanical stress.

Industrial Equipment

Telecommunications

How to Order Your Rigid-Flex

PCB in 5 Easy Steps

Submit Your PCB Design

Upload your Gerber files or use our easy online PCB design tool to create your board layout. Make sure your files are complete and correctly formatted to ensure smooth processing and production accuracy.

Select Your PCB Specifications

Customize your order by choosing the technical specifications—number of layers, board dimensions, thickness, copper weight, solder mask color, surface finish, and more. Our intuitive interface helps you configure everything based on your project’s needs.

Get an Instant Quote

Once your design and specs are in place, you'll receive a transparent, instant quote. Pricing updates in real time as you modify options, so you can adjust your selections to match your budget before placing the order.

Confirm Order & Make Payment

Review your entire order for accuracy, including file previews and selected specs. After confirmation, proceed to secure checkout and choose your preferred payment method. You’ll receive an email confirmation with order details.

Production & Delivery

Your PCB moves into production immediately. We’ll keep you updated throughout the manufacturing process. Once completed, your boards are carefully packed and shipped to your door, with tracking information provided for your convenience.

WellPCB is trusted by millions of

businesses and innovators.

Why Choose WellPCB?

WellPCB stands out among USA PCB manufacturers by delivering superior quality, advanced solutions, and unmatched reliability. With years of experience serving global markets, WellPCB has earned a reputation as one of the top PCB manufacturers in USA.

WellPCB specializes in multilayer PCBs for advanced electronic applications. You can order these boards with $100 off using our special offer, providing high complexity at competitive rates for demanding projects.

Hommer Zhao

Founder and Chief Editor – Hommer Zhao

Welcome! I’m Hommer Zhao, the founder and Chief Editor of WellPCB. With years of experience in the PCB industry, I’m committed to making sure our content is both accurate and helpful. We’re proud to serve a growing community of over 4,000 customers worldwide, and our goal is to provide you with the best resources and support. Your satisfaction is our top priority, and we’re here to help you every step of the way!

Jesse Holland

Technical Manager – Jesse Holland

Hi, I’m Jesse Holland, an Engineer and Technical Manager at WellPCB. With years of experience in PCB design and engineering, I’m here to ensure that every project we work on meets the highest technical standards. I lead our team, focusing on precision and innovation, collaborating closely with clients to provide tailored solutions and expert guidance. Whether you’re facing a complex design challenge or need advice on technical aspects, I’m here to ensure your project is a success from start to finish.

Nathan Jensen

Purchasing Manager – Nathan Jensen

Hi, I’m Nathan Jenson, the Purchasing Manager at WellPCB. I’m responsible for sourcing the best materials and components to ensure our products meet the highest quality standards. With my extensive experience in procurement, I work closely with suppliers to secure reliable and cost-effective solutions while maintaining strong relationships to support our operations. I aim to ensure every project runs smoothly by providing the resources needed to deliver on time and to your satisfaction.

Emma

Sales Manager – Emma

Hey, I am Emma, sales manager at WellPCB. I studied electronic science and technology at university and have served customers for PCB and PCB Assembly service for several years.

I enjoy communicating with customers and our technicians to solve problems, and customers always say, "It's great to have you onboard".

It is my pleasure and honour to be helpful. Contact me now, and you'll know.

Bella and Cassiel

Sales Representatives – Bella and Cassiel

We’re Bella and Cassiel, your dedicated sales representatives at WellPCB. With our extensive knowledge of the PCB industry, we’re here to provide exceptional service and support. We take the time to understand your unique needs and are always ready to offer tailored solutions and advice. Whether you need product recommendations, assistance with your orders, or simply have a question, we’re here to ensure your experience is smooth and seamless at every step.

Mandy and Wendy

Sales Representatives – Mandy and Wendy

We’re Mandy and Wendy, your friendly sales representatives at WellPCB. Passionate about helping our customers, we bring a wealth of experience in the PCB industry to provide you with the best solutions and service. We take pride in building strong relationships with our clients, understanding their specific needs, and offering personalised support to ensure their satisfaction. Whether you’re looking for advice, product information, or assistance with any part of your order, we’re here to make your experience as smooth and efficient as possible.

Our Team

Our skilled engineers and technicians bring expertise and precision to every PCB assembly project. Committed to quality, efficiency, and innovation, our team ensures every order meets the highest UL, IPC, ROHS & REACH standards, delivering reliable solutions tailored to your needs.

- Founder and Chief Editor – Hommer Zhao

- Technical Manager – Jesse Holland

- Purchasing Manager – Nathan Jensen

- Sales Manager – Emma

- Sales Representatives – Bella and Cassiel

- Sales Representatives – Mandy and Wendy

Case Studies

Case Study

This 4-layer rigid-flex PCB is engineered for automotive door electronics, where signal reliability, space efficiency, and flex durability are paramount. It incorporates advanced features like blind vias and a customized layer stack-up to support dense BGA components and withstand the mechanical stress typical of vehicle door assemblies.

Product Specifications:

- Board Type: 4-layer rigid-flex PCB

- Min. Trace Width / Space: 4 mil / 3 mil (0.1 mm / 0.075 mm)

- Minimum BGA Pad Size: 7.8 mil (≈ 0.2 mm)

- Via Type: Blind via (laser or mechanical)

- Stack-Up: Special/customized (for signal + power + flex optimization)

- Application: Automotive door control unit / actuator systems

- Bendability: High flexibility in dynamic areas; rigid sections for connectors or ICs

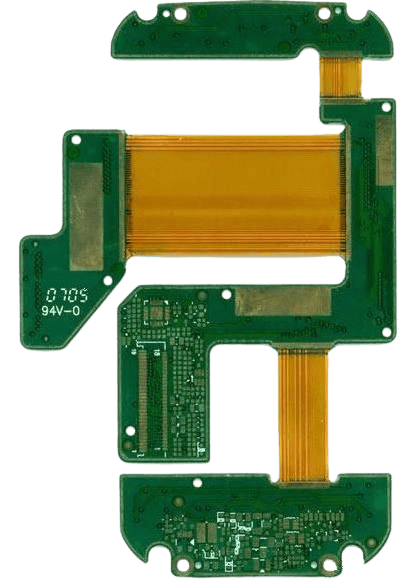

Case Study

This 2-layer rigid-flex PCB is designed specifically for compact GPS tracking devices, where size, weight, and reliability are critical. The board integrates rigid and flexible sections, allowing for efficient space utilization in small enclosures while ensuring consistent electrical performance under dynamic conditions.

Product Specifications:

- Board Type: 2-layer rigid-flex PCB

- Rigid Layer Thickness: 0.5 mm

- Flexible Layer Thickness: 0.12 mm

- Solder Bridge Width: 4 mil (0.1 mm)

- Flex Core Material: Polyimide (PI) with adhesive or adhesive-free

- Copper Thickness: Typically 1 oz (35 μm) for both rigid and flex

- Application: GPS trackers, IoT devices, wearables

Case Study

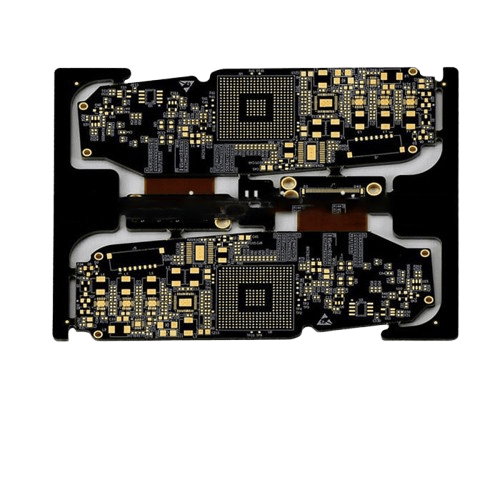

This 10-layer rigid-flex PCB is engineered for smartphone motherboards, integrating high-density routing, multiple interconnects, and flexible sections for space-saving, compact, and lightweight device architecture. Designed for advanced mobile electronics, it offers excellent signal integrity, fine-line capabilities, and durability under thermal and mechanical stress.

Product Specifications:

- Board Type: 10-layer rigid-flex PCB

- Total Thickness: 1.5 mm

- Line Width / Line Space: 3 mil / 4 mil (≈75 μm / 100 μm)

- Solder Bridge Width: 5 mil (≈125 μm)

- Flexible Layers: Polyimide (PI) with rolled annealed copper

- Rigid Layers: FR-4 (high Tg, halogen-free optional)

- Via Type: Blind and buried via (optional for HDI)

- Application: Smartphone motherboards, display drivers, power modules

Rigid-Flex PCB Manufacturer Client Feedback

As an R&D manager, I have had an outstanding experience working with WELL-PCB. For many years, our company has entrusted them with the production, assembly, and programming of the boards developed in our R&D unit, and they have consistently exceeded our expectations.

Hamid Reza Moshayedi

R&D Manager

Their work is very impressively perfect. Today, when they check our company PCB board after assemble. They found a fake short point which many engineers has never found in the past years. But that is just designed so. The PCB board quality is excellent. Their service is also excellent.

MikeZ

My friend introduced WellPCB to me, the first try, a little look forward to. I ordered a 47*72 10ps PCB, and I can’t wait to receive my PCB. So I used expedited service and received my PCB in three days. I tested and soldered the PCB, Quality is really good, silkscreen, plating also great.

Warren Cliton

Rigid-Flex PCB Manufacturer FAQs

What IPC standards do your rigid-flex boards meet?

All rigid-flex PCBs are manufactured following IPC-6013 Class 3. On request, we also support IPC-A-610 and IPC-1791 requirements for medical and military applications.

What's the minimum bend radius for flex sections?

Bend radius depends on the number of layers and overall stack-up thickness. For most builds, the minimum is 6 to 10× the board thickness for single- and double-layer flex, and 10 to 15× for multilayer rigid flex PCB stack-ups.

Can I receive custom stack-up diagrams for approval?

Yes. We provide standard reference stack-ups and custom diagrams based on your required impedance control, flexible material thickness, and mechanical layout constraints.

What is the minimum annular ring for vias in flex-rigid technology?

Annular ring requirements vary by Via type and class. Mechanically drilled vias typically require a 3 mil ring, while laser-drilled microvias require 2 mils. All via structures follow the guidelines outlined in IPC-6013.

Do you support Altium/IPC-2581 files?

Yes. We accept Altium, Gerber, and IPC-2581 file formats, including .PcbDoc and Pcb, for all rigid-flex PCB fabrication projects.

The Rigid-Flex PCB Manufacturer You Need for Your Next Project

With over 18 years of manufacturing experience and a 98% customer satisfaction rate, WellPCB is trusted by engineers in over 30 countries. Contact us, get an expert team for your rigid-flex PCB project, AND save $100 on your first order with us.