Telecom PCB Assembly Services

WellPCB is one of the top telecom PCB assembly providers. We deliver high performance custom PCBs for communication systems in various different sectors.

Our telecom PCBs have specific properties that make them successful. These include controlled impedance routing, HDI structures and advanced material options. These features help maintain signal integrity in challenging environments.

Our in house manufacturing facilities handle every stage of production. It doesn’t matter if you need small batch prototypes or large scale manufacturing. Our team is ready to help.

- High frequency RF and millimeter-wave up to 77 GHz

- Surface mount for ultra small parts, fine-pitch BGAs, HDI boards and microvias

- ISO 9001, IPC-A-610 Class 3, RoHS

ISO9001 ISO13485

ISO14001

IATF

16949

IPC-A-610H International

Certification

Fully Automated

AOI Inspection

- PCB Manufacturer

- PCB Assembly Service

- Telecom

Telecom PCB Assembly Built for Next-Generation Communication

You can find telecom printed circuit boards inside communication devices, networking gear, and satellite systems. Their purpose is to keep high-speed data transmission stable.

They come with advanced built-in features. Smart layer structures and specialized substrate materials help them to operate with minimal signal loss, no matter what environment they’re in.

Our telecom PCB assembly process uses innovative technology. Automated surface mount placement, through-hole soldering and HDI fabrication make it possible for us to handle fine-pitch components (down to 0.35 mm) and copper weights up to 10 oz.

Every production process includes a range of testing. Our team does optical inspection, X-ray verification and full electrical continuity testing. These help us make sure the circuit integrity and dimensional accuracy are on point.

As a PCB assembly manufacturer, we work to IPC-A-610 Class 3 and IPC-6012 standards.

Our Telecom PCB Assembly Capabilities

WellPCB’s high frequency telecom assemblies achieve an insertion loss of <0.5 dB/inch at 28 GHz. We use Rogers RO4350B (Dk=3.48 ±0.05, Df=0.0037) and Taconic TLY-5A substrates.

The power amplifier chain gain flatness is held within ±0.3 dB across operational bandwidth. This ensures long-term signal integrity.

We maintain ±15 μm component placement tolerances to ensure as close to a perfect fit as possible. Ground via stitching patterns keep the spacing under λ/10 with via diameters of 0.15 mm (at a minimum).

We manufacture single-ended 50Ω traces to ±5% tolerance using 1 oz copper on FR-4 with Er=4.2 (±0.1) at 1 GHz.

Our team builds differential 100Ω pairs to ±7% impedance control with 0.1 mm minimum coupling gaps and length matching within 0.1 mm over 50 mm trace runs.

Via backdrilling removes stubs up to 0.5mm deep, keeping the quality and reliability above 10 GHz.

Edge-coupled microstrip designs meet 0.075 mm minimum width and spacing. These precise measurements are a must for PCB assembly solutions in telecommunications equipment.

Our team fabricates microvia diameters to 0.1 mm finished size with a 1:1 aspect ratio through 0.1 mm dielectric layers. We also offer the option for stacked microvias, which allows up to four via-on-via builds with ±25 μm positional accuracy between layers.

Via-in-pad processes support 0.4mm pitch BGAs (with copper fill protrusion under 10 μm after planarization). Buried via designs connect layer pairs 2 to 11 with capture pad diameters of at least 0.15 mm. WellPCB’s any-layer HDI constructions extend to 12 layers.

Our SMT lines achieve a placement accuracy of ±30 micrometres for 0201 passive components (0.6 mm by 0.3 mm).

We assemble ball grid arrays with a 0.35 mm pitch to withstand more than 1,000 thermal cycles from minus 40°C to plus 125°C.

We use a stencil printing process that maintains a 75% area ratio for 0.35 mm pitch apertures. Reflow profiles peak at 245°C (±5°C) with 60 to 90 seconds above the solder alloy liquidus temperature.

We integrate SMT and through-hole processes. Within these processes, we use selective wave soldering in nitrogen, keeping void content under 5% in solder joints.

Our team maintains wave solder parameters at 260°C (±5°C) contact temperature with a 3 to 4 second dwell.

Conformal coating thickness stays between 25 and 75 μm using acrylic, silicone or urethane formulations. Coverage exceeds 95% with a masking accuracy of ±0.1 mm for connectors and test points.

Through-hole insertion maintains a clinch length of at least 0.8 mm, verified by automated optical inspection, supporting assembly services for telecom and environmental conditions often found in telecom networks.

Rigid-flex assemblies combine 25-micrometer polyimide flex with FR-4 rigid sections.

These transitions maintain single-ended impedance within ±3 ohms (for targets at or below 50 ohms) and ±5% for targets above 50 ohms.

We rate dynamic flex designs for more than 100,000 bend cycles on four-layer builds. Stiffener bonding uses 50 micrometer PSA with peel strength over 2 N/mm.

WellPCB’s flex placement achieves ±50 micrometer accuracy with vacuum tooling on 0.1 mm substrates. This enables miniaturization of electronic devices and custom builds in telecommunication PCBs.

We manufacture heavy copper PCB power layers with finished copper thicknesses up to 20 oz, enabling high current and thermal-load telecom PCB assembly. These builds support reliable power distribution.

WellPCB’s heavy copper fabrication process maintains layer adhesion during multi stage lamination. This makes sure the PCB remains durable in common telecom networks environments.

Reinforced plated vias increase the current handling, and copper pours with large thermal pads improve the heat spreading in high-power RF and amplifier circuits.

Each heavy copper design undergoes a PCB DFM review early on. This step helps to optimize conductor geometry, spacing, and thermal management.

WellPCB conducts vector network analyzer testing from DC to 50 GHz with reference planes calibrated to ≤0.1 dB magnitude and ≤2° phase uncertainty.

Time-domain reflectometry identifies impedance deviations over ±5Ω with 10 ps resolution. We also run functional RF tests to confirm that gain, noise figure, and P1dB compression points meet customer specifications.

Boundary scan testing covers more than 95% of digital circuits. We use IEEE 1149.1 JTAG vectors to validate dependable operation in the telecommunications industry.

Why Choose WellPCB?

High-Frequency Expertise

Advanced Manufacturing Processes

Quality & Compliance

Turnkey Sourcing

Fast Turnarounds

Excellent Support

What is Telecom PCB Assembly?

Telecom PCB assembly is the process of manufacturing and assembling printed circuit boards designed for telecommunication devices and communication systems. It uses specialized materials, controlled impedance routing, and RF testing to ensure signal integrity and reliability in applications such as base stations, networking equipment, and satellite systems within the telecommunications industry.

Which Telecom Applications Require PCB Assembly?

Telecommunications Infrastructure (Cell Towers & Satellites)

You’ll find telecom PCBs in tower modules and satellite communication systems, built to endure outdoor conditions and support high-frequency signal handling.

Networking & Office Communications Equipment

PCBs power routers, modems, VoIP devices, and switching systems. They serve as the electronic backbone for office and enterprise-level communications.

Wireless Access & Antenna Systems

Specialized PCB boards support wireless base stations, signal boosters and custom antenna modules, enabling seamless high speed data transmission.

LED Displays & Indicators in Telecom Gear

Printed circuit boards form the basis of control and interface panels, including status indicators and LED displays used in telecommunications devices.

Telecom PCB Assembly vs. Standard PCB Assembly

High Frequency

Tighter Tolerances

Specialized Materials

RF Testing

How to Order Your Telecom PCB Assembly

Submit Your PCB Design

Upload your Gerber files or use our easy online PCB design tool to create your board layout. Make sure your files are complete and correctly formatted to ensure smooth processing and production accuracy.

Select Your PCB Specifications

Customize your order by choosing the technical specifications—number of layers, board dimensions, thickness, copper weight, solder mask color, surface finish, and more. Our intuitive interface helps you configure everything based on your project’s needs.

Get an Instant Quote

Once your design and specs are in place, you'll receive a transparent, instant quote. Pricing updates in real time as you modify options, so you can adjust your selections to match your budget before placing the order.

Confirm Order & Make Payment

Review your entire order for accuracy, including file previews and selected specs. After confirmation, proceed to secure checkout and choose your preferred payment method. You’ll receive an email confirmation with order details.

Production & Delivery

Your PCB moves into production immediately. We’ll keep you updated throughout the manufacturing process. Once completed, your boards are carefully packed and shipped to your door, with tracking information provided for your convenience.

WellPCB is trusted by millions of

businesses and innovators.

Why Choose WellPCB?

WellPCB stands out among USA PCB manufacturers by delivering superior quality, advanced solutions, and unmatched reliability. With years of experience serving global markets, WellPCB has earned a reputation as one of the top PCB manufacturers in USA.

WellPCB specializes in multilayer PCBs for advanced electronic applications. You can order these boards with $100 off using our special offer, providing high complexity at competitive rates for demanding projects.

Hommer Zhao

Founder and Chief Editor – Hommer Zhao

Welcome! I’m Hommer Zhao, the founder and Chief Editor of WellPCB. With years of experience in the PCB industry, I’m committed to making sure our content is both accurate and helpful. We’re proud to serve a growing community of over 4,000 customers worldwide, and our goal is to provide you with the best resources and support. Your satisfaction is our top priority, and we’re here to help you every step of the way!

Jesse Holland

Technical Manager – Jesse Holland

Hi, I’m Jesse Holland, an Engineer and Technical Manager at WellPCB. With years of experience in PCB design and engineering, I’m here to ensure that every project we work on meets the highest technical standards. I lead our team, focusing on precision and innovation, collaborating closely with clients to provide tailored solutions and expert guidance. Whether you’re facing a complex design challenge or need advice on technical aspects, I’m here to ensure your project is a success from start to finish.

Nathan Jensen

Purchasing Manager – Nathan Jensen

Hi, I’m Nathan Jenson, the Purchasing Manager at WellPCB. I’m responsible for sourcing the best materials and components to ensure our products meet the highest quality standards. With my extensive experience in procurement, I work closely with suppliers to secure reliable and cost-effective solutions while maintaining strong relationships to support our operations. I aim to ensure every project runs smoothly by providing the resources needed to deliver on time and to your satisfaction.

Emma

Sales Manager – Emma

Hey, I am Emma, sales manager at WellPCB. I studied electronic science and technology at university and have served customers for PCB and PCB Assembly service for several years.

I enjoy communicating with customers and our technicians to solve problems, and customers always say, "It's great to have you onboard".

It is my pleasure and honour to be helpful. Contact me now, and you'll know.

Bella and Cassiel

Sales Representatives – Bella and Cassiel

We’re Bella and Cassiel, your dedicated sales representatives at WellPCB. With our extensive knowledge of the PCB industry, we’re here to provide exceptional service and support. We take the time to understand your unique needs and are always ready to offer tailored solutions and advice. Whether you need product recommendations, assistance with your orders, or simply have a question, we’re here to ensure your experience is smooth and seamless at every step.

Mandy and Wendy

Sales Representatives – Mandy and Wendy

We’re Mandy and Wendy, your friendly sales representatives at WellPCB. Passionate about helping our customers, we bring a wealth of experience in the PCB industry to provide you with the best solutions and service. We take pride in building strong relationships with our clients, understanding their specific needs, and offering personalised support to ensure their satisfaction. Whether you’re looking for advice, product information, or assistance with any part of your order, we’re here to make your experience as smooth and efficient as possible.

Our Team

Our skilled engineers and technicians bring expertise and precision to every PCB assembly project. Committed to quality, efficiency, and innovation, our team ensures every order meets the highest UL, IPC, ROHS & REACH standards, delivering reliable solutions tailored to your needs.

- Founder and Chief Editor – Hommer Zhao

- Technical Manager – Jesse Holland

- Purchasing Manager – Nathan Jensen

- Sales Manager – Emma

- Sales Representatives – Bella and Cassiel

- Sales Representatives – Mandy and Wendy

Telecom PCB Assembly Case Studies

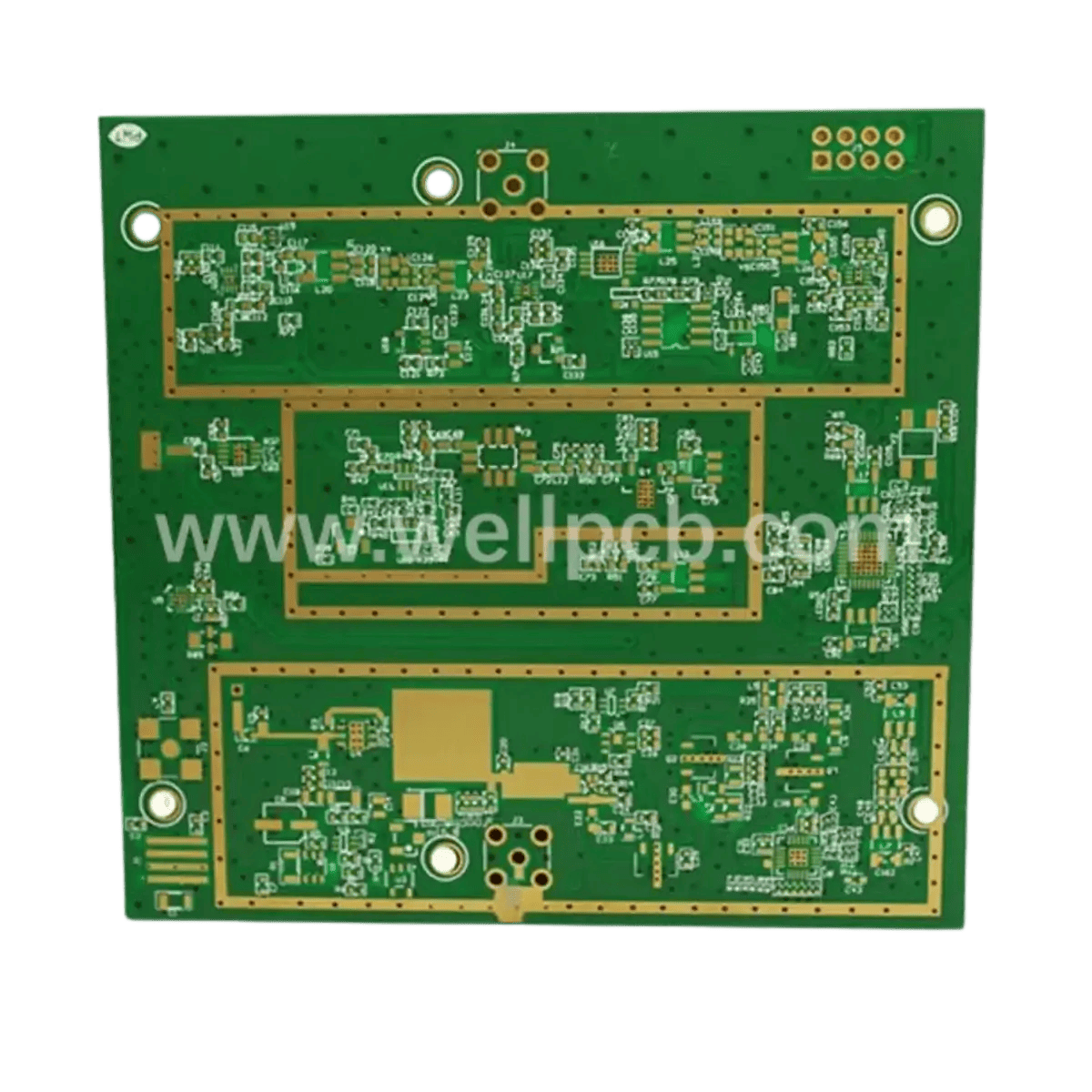

PCB Assembly

PCB assembly plays a vital role in telecommunications infrastructure. For example, as a key component of core network equipment, it facilitates data transmission, switching, and signal processing.

Assembly Process:

Soldering: Small components such as capacitors and resistors are precisely soldered using SMT to ensure reliable electrical connections. Interfaces, heat sinks, and other components are soldered using plug-in soldering to ensure a secure physical connection, ensuring proper signal transmission and heat dissipation.

Cable Connections: Connections such as ribbon cables and power cables must strictly adhere to pinout definitions and insertion and removal force standards. Loose ribbon cables, such as those shown in the image, can disrupt signal transmission and cause display anomalies.

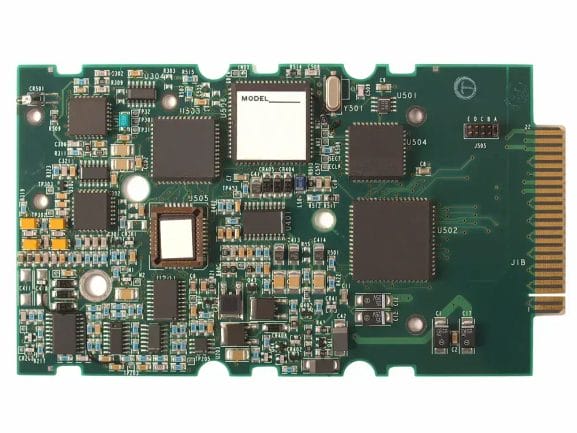

PCB Assembly

The board in the picture is a main control board manufactured according to customer requirements, and has relatively wide applicability in the telecommunications field. For example, server storage and cloud computing services, data transmission of network devices and communication base stations, etc.

Special Process:

- •High-precision SMT processing: Extremely small pin pitch and high assembly accuracy requirements.

- •Multi-layer PCB design and manufacturing: Multiple complex processes and extremely high inter-layer alignment requirements to ensure accurate signal transmission.

- •Packaging technology and reliability testing: To ensure the reliable operation of PCBA in various complex environments, a series of strict reliability tests needs to be carried out after the manufacturing is completed.

PCB Assembly

This case study focuses on a PCBA used in the telecommunications sector.

The board carries multiple types of chips (such as signal processing chips and memory chips) to support functions such as signal modulation and demodulation, data caching, and forwarding in telecommunications equipment.

Telecommunications networks place stringent demands on signal integrity and interference immunity. This circuit board utilizes a multi-layer PCB design to effectively isolate signals of different frequency bands and reduce electromagnetic interference (EMI). This ensures accurate signal transmission in the complex electromagnetic environment of telecommunications base stations, preventing problems such as call noise and data packet loss caused by signal crosstalk.

Telecom PCB Assembly Client Feedback

As an R&D manager, I have had an outstanding experience working with WELL-PCB. For many years, our company has entrusted them with the production, assembly, and programming of the boards developed in our R&D unit, and they have consistently exceeded our expectations.

Hamid Reza Moshayedi

R&D Manager

Their work is very impressively perfect. Today, when they check our company PCB board after assemble. They found a fake short point which many engineers has never found in the past years. But that is just designed so. The PCB board quality is excellent. Their service is also excellent.

MikeZ

My friend introduced WellPCB to me, the first try, a little look forward to. I ordered a 47*72 10ps PCB, and I can’t wait to receive my PCB. So I used expedited service and received my PCB in three days. I tested and soldered the PCB, Quality is really good, silkscreen, plating also great.

Warren Cliton

Telecom PCB Assembly FAQs

What is your minimum order quantity?

WellPCB accepts telecom PCB assembly orders starting from a single prototype unit. This means customers can validate their telecommunication PCB designs before committing to a full production run.

When you’re ready for full production, volume manufacturing can scale to tens of thousands of boards for large telecom applications.

What testing and validation methods do you use in your telecom PCB assembly?

We perform 100% automated optical inspection, electrical testing via flying probe or dedicated fixtures, and RF-specific checks such as vector network analyzer measurements and time-domain reflectometry. Functional testing verifies gain, noise figure, and other signal integrity parameters to meet specific requirements in the telecommunications industry.

Can you supply components for my telecom project?

Yes, WellPCB sources all components from authorized distributors including Mouser, Digi-Key, Arrow and Avnet. This ensures full traceability and eliminates counterfeit risk for PCB assembly for telecom, guaranteeing reliable supply for telecommunication devices and telecommunications equipment.

How do you control impedance for RF designs?

We use PCB stack-up modeling, trace geometry optimization, and precise dielectric material selection to achieve target impedance values. Controlled impedance in telecom PCBs is verified with TDR measurements, ensuring signal integrity in high-frequency communication systems.

Get In Touch Today to Start Your Telecom PCB Assembly Project

Get $100 Off Your First Order!

Partner with WellPCB for telecom PCB assembly that meets the quality and reliability demands of the telecommunications industry.