Reliable Through-Hole PCB Assembly

Solutions for Durable Electronic Applications

WellPCB provides through-hole PCB assembly for electronic products exposed to mechanical or environmental stress. We offer manual and automated through-hole assembly to support prototype, low-volume, and high-volume production.

- IPC 610, ISO 9001, RoHS compliance

- Full through-hole assembly services from prototype to high-volume production

- Manual and automated insertion for axial, radial, and large components

ISO9001 ISO13485

ISO14001

IATF

16949

IPC-A-610H International

Certification

Fully Automated

AOI Inspection

- PCB Manufacturer

- PCB Assembly Service

- Through-Hole

What is Through-Hole PCB

Assembly?

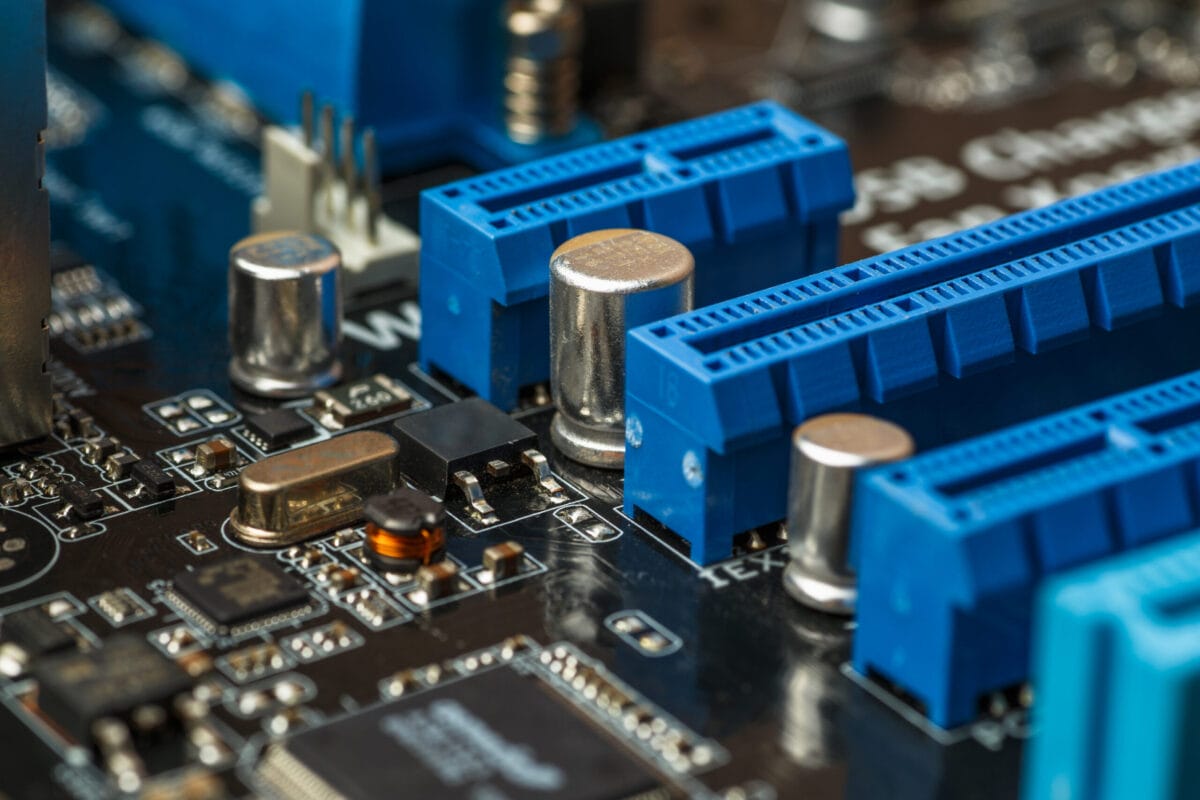

Through-hole PCB assembly is a process where components are inserted through holes drilled into the printed circuit board and soldered to pads on the opposite side. This technique forms strong mechanical and electrical bonds between the circuit and its components, providing high durability for applications subjected to vibration, heat, and high voltage.

Unlike surface mount technology, which mounts components directly onto the board surface, through-hole assembly secures component leads deep within the board structure. This makes it suitable for heavier components, such as transformers, capacitors, and connectors, where mechanical strength is required.

Our Through-Hole PCB

Assembly Capabilities

WellPCB supports axial components, radial components, and through-hole components, including transformers, inductors, and large connectors. We provide manual and automated insertion, with automated insertion for volume PCB assembly and manual soldering or selective soldering for prototypes and complex boards. This ensures accurate component placement and secure component leads for assemblies subjected to mechanical or environmental stress.

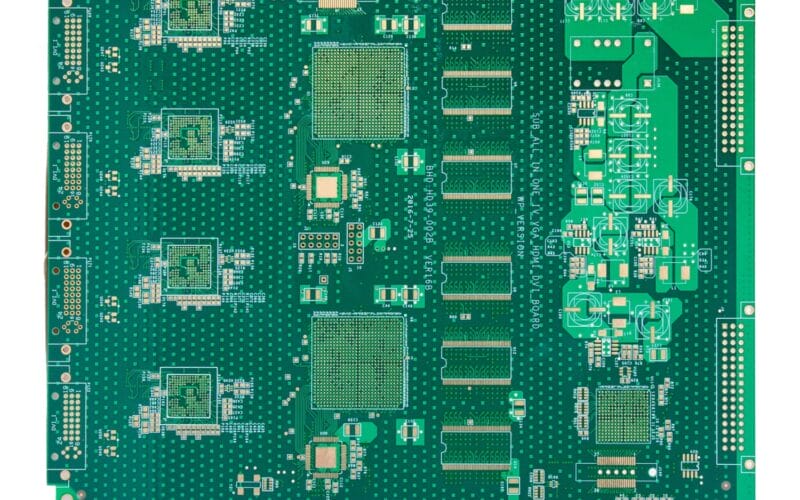

We assemble single-sided, double-sided, and multilayer printed circuit boards with up to 64 layers. Designs can integrate through holes with SMT components for hybrid circuit board assembly, combining mechanical strength with space efficiency. Our construction supports PCB through-hole designs for high voltage, thermal cycling, and vibration durability.

Surface finishes include ENIG, HASL, OSP, immersion silver, and immersion tin, selected based on PCB assembly requirements and assembly techniques. We work with substrates such as FR4, high TG FR4, halogen-free laminates, and Rogers HF materials, offering heat tolerance and mechanical stability under environmental stress and high power conditions.

Our assembly process supports copper thicknesses ranging up to 1000 μm. This flexibility increases current-carrying capacity and heat tolerance, especially in high-voltage power supplies, industrial control systems, and automotive electronics. The heavier copper also provides stronger bonds between the circuit and components, improving mechanical resilience.

We source electronic components from trusted distributors such as Mouser, Digi-Key, Future Electronics, and WPG Holdings. Our PCB assembly process includes component placement, insertion through holes drilled in the board, manual and automated soldering, optical inspection, functional testing, and final quality verification. We offer full PCB assembly capabilities, covering prototype through volume production.

Our testing protocols include functional testing, optical inspection, and electrical testing using oscilloscopes, signal generators, programmable digital power supplies, and high-voltage testers. We also apply automated optical inspection (AOI), X-ray inspection, and assembly testing. All work is performed to IPC 610 Class 2 and Class 3 standards.

Where is Through-Hole Assembly Used?

Power Supplies and High Voltage Circuits

<span data-metadata=""><span data-buffer="">Automotive Control Modules

<span data-metadata=""><span data-buffer="">Industrial Control Systems

<span data-metadata=""><span data-buffer="">Medical Electronics

<span data-metadata=""><span data-buffer="">Aerospace and Defense Systems

What are the Benefits of Through-Hole

PCB Assembly?

Through-hole PCB assembly offers several advantages compared with other assembly techniques, especially in applications where mechanical durability, electrical reliability, and long-term performance are serious requirements. These benefits make through-hole technology a preferred choice for industries requiring robust solutions for demanding operating environments.

Stronger Mechanical Bonds

Higher Heat and Power Tolerance

Support for Large and Heavy Components

<span data-metadata=""><span data-buffer="">Improved Durability Under Environmental Stress

<span data-metadata=""><span data-buffer="">Compatibility with Mixed Technology Designs

Our Through-Hole PCB

Testing Process

WellPCB applies a comprehensive testing and inspection process to confirm electrical performance, mechanical reliability, and solder joint integrity in every through-hole PCB assembly. We apply testing protocols based on the IPC 610 Class 2 and Class 3 workmanship standards, which specify acceptance criteria for solder joint quality, component placement accuracy, and mechanical durability.

Functional Testing

Optical Inspection

Electrical Testing

X-ray Inspection

At WellPCB, we use X-ray inspection to examine hidden solder joints, internal vias, and plated through holes. This non-destructive technique identifies voids, bridging, or cold solder joints that may not be visible externally but can impact long-term reliability.

Assembly Testing

Assembly testing confirms the integrity of the assembly process, validating that components are inserted through holes drilled accurately and soldered to meet mechanical strength requirements.

Through Hole vs SMT Assembly

| Feature | Through-Hole Assembly | Surface Mount Technology (SMT) |

|---|---|---|

| Component Mounting | Components are inserted through holes drilled into the board and soldered to pads. | Components are placed directly onto the PCB surface and soldered to surface pads. |

| Mechanical Strength | High. Leads create stronger bonds between the circuit and component leads, suited for mechanical or environmental stress. | Lower. Reliant on surface solder joints, which may be weaker under vibration or stress. |

| Component Types | Supports axial and radial components, large components, and those with high voltage or heat tolerance needs. | Best for smaller, lighter components where space savings and automation are priorities. |

| Assembly Process | Manual and automated insertion, manual soldering, or selective soldering. | Fully automated placement and SMT PCB assembly with reflow soldering. |

| Applications | Power electronics, automotive, medical, aerospace, industrial control systems. | Consumer electronics, compact devices, high-speed digital circuits. |

Why Choose WellPCB as Your Through-Hole

PCB Assembly Service Provider?

Proven Track Record and Industry Experience

Certifications and Quality Compliance

Original Component Sourcing for Reliability

Production Flexibility and Fast Lead Times

Engineering Support and Design Assistance

Full-Service Manufacturing Under One Roof

How to Order Your Through-Hole PCB

in 5 Easy Steps

PCB Manufacturing and Order Review Process

Submit Your PCB Design

Upload your Gerber files or use our easy online PCB design tool to create your board layout. Make sure your files are complete and correctly formatted to ensure smooth processing and production accuracy.

Select Your PCB Specifications

Customize your order by choosing the technical specifications—number of layers, board dimensions, thickness, copper weight, solder mask color, surface finish, and more. Our intuitive interface helps you configure everything based on your project’s needs.

Get an Instant Quote

Once your design and specs are in place, you'll receive a transparent, instant quote. Pricing updates in real time as you modify options, so you can adjust your selections to match your budget before placing the order.

Confirm Order & Make Payment

Review your entire order for accuracy, including file previews and selected specs. After confirmation, proceed to secure checkout and choose your preferred payment method. You’ll receive an email confirmation with order details.

Production & Delivery

Your PCB moves into production immediately. We’ll keep you updated throughout the manufacturing process. Once completed, your boards are carefully packed and shipped to your door, with tracking information provided for your convenience.

WellPCB is trusted by millions of

businesses and innovators.

Why Choose WellPCB?

WellPCB stands out among USA PCB manufacturers by delivering superior quality, advanced solutions, and unmatched reliability. With years of experience serving global markets, WellPCB has earned a reputation as one of the top PCB manufacturers in USA.

WellPCB specializes in multilayer PCBs for advanced electronic applications. You can order these boards with $100 off using our special offer, providing high complexity at competitive rates for demanding projects.

Hommer Zhao

Founder and Chief Editor – Hommer Zhao

Welcome! I’m Hommer Zhao, the founder and Chief Editor of WellPCB. With years of experience in the PCB industry, I’m committed to making sure our content is both accurate and helpful. We’re proud to serve a growing community of over 4,000 customers worldwide, and our goal is to provide you with the best resources and support. Your satisfaction is our top priority, and we’re here to help you every step of the way!

Jesse Holland

Technical Manager – Jesse Holland

Hi, I’m Jesse Holland, an Engineer and Technical Manager at WellPCB. With years of experience in PCB design and engineering, I’m here to ensure that every project we work on meets the highest technical standards. I lead our team, focusing on precision and innovation, collaborating closely with clients to provide tailored solutions and expert guidance. Whether you’re facing a complex design challenge or need advice on technical aspects, I’m here to ensure your project is a success from start to finish.

Nathan Jensen

Purchasing Manager – Nathan Jensen

Hi, I’m Nathan Jenson, the Purchasing Manager at WellPCB. I’m responsible for sourcing the best materials and components to ensure our products meet the highest quality standards. With my extensive experience in procurement, I work closely with suppliers to secure reliable and cost-effective solutions while maintaining strong relationships to support our operations. I aim to ensure every project runs smoothly by providing the resources needed to deliver on time and to your satisfaction.

Emma

Sales Manager – Emma

Hey, I am Emma, sales manager at WellPCB. I studied electronic science and technology at university and have served customers for PCB and PCB Assembly service for several years.

I enjoy communicating with customers and our technicians to solve problems, and customers always say, "It's great to have you onboard".

It is my pleasure and honour to be helpful. Contact me now, and you'll know.

Bella and Cassiel

Sales Representatives – Bella and Cassiel

We’re Bella and Cassiel, your dedicated sales representatives at WellPCB. With our extensive knowledge of the PCB industry, we’re here to provide exceptional service and support. We take the time to understand your unique needs and are always ready to offer tailored solutions and advice. Whether you need product recommendations, assistance with your orders, or simply have a question, we’re here to ensure your experience is smooth and seamless at every step.

Mandy and Wendy

Sales Representatives – Mandy and Wendy

We’re Mandy and Wendy, your friendly sales representatives at WellPCB. Passionate about helping our customers, we bring a wealth of experience in the PCB industry to provide you with the best solutions and service. We take pride in building strong relationships with our clients, understanding their specific needs, and offering personalised support to ensure their satisfaction. Whether you’re looking for advice, product information, or assistance with any part of your order, we’re here to make your experience as smooth and efficient as possible.

Our Team

Our skilled engineers and technicians bring expertise and precision to every PCB assembly project. Committed to quality, efficiency, and innovation, our team ensures every order meets the highest UL, IPC, ROHS & REACH standards, delivering reliable solutions tailored to your needs.

- Founder and Chief Editor – Hommer Zhao

- Technical Manager – Jesse Holland

- Purchasing Manager – Nathan Jensen

- Sales Manager – Emma

- Sales Representatives – Bella and Cassiel

- Sales Representatives – Mandy and Wendy

Case Studies

PCB Specifications

- Layers: 8

- Board Thickness: 1.8mm

- Min. Line Width/Space: 3/3.5 mil

- Min. Hole Size: 0.2mm

- Min. Distance from Hole to Line: 0.13mm

- Inner Layer Copper: Hoz

- Outer Layer Copper: 1oz

- Surface Finish: Immersion Gold

The final board met all mechanical and electrical tolerances and passed electrical testing with 100% yield. This project shows our capabilities to handle complex, high-density multilayer PCBs with tight tolerances and strict quality standards.

Project Details

- Service Type: PCB Assembly

- Location: Italy

- Client Type: PCB Design Company

- Total Units: 20

- Lead Time: Rapid turnaround for prototyping

- Assembly Type: SMT+THT mixture assembly

Our experienced production team worked closely with the client to verify the BOM, optimize the stencil and the board’s layout design. We completed and delivered 20 fully assembled units within the expected lead time, allowing the client to avoid delays and meet their customers’ delivery window. This case highlights our capabilities to support global clients with flexible, low-volume PCB assembly solutions.

Project Details

- Service Type: Custom Automotive Wire Harness

- Location: New York, USA

- Client Type: Auto Repair Shop

- Quantity: 10,000 Units

Our team followed strict quality guidelines throughout production, using automotive-grade connectors and insulation materials. The order was completed on schedule with no reported defects, supporting the client’s rollout without interruption. This case shows our comprehensive capabilities in large-scale production, customized solutions, quality control and efficient delivery.

Through-Hole PCB Service: Client Feedback

As an R&D manager, I have had an outstanding experience working with WELL-PCB. For many years, our company has entrusted them with the production, assembly, and programming of the boards developed in our R&D unit, and they have consistently exceeded our expectations.

Hamid Reza Moshayedi

R&D Manager

Their work is very impressively perfect. Today, when they check our company PCB board after assemble. They found a fake short point which many engineers has never found in the past years. But that is just designed so. The PCB board quality is excellent. Their service is also excellent.

MikeZ

My friend introduced WellPCB to me, the first try, a little look forward to. I ordered a 47*72 10ps PCB, and I can’t wait to receive my PCB. So I used expedited service and received my PCB in three days. I tested and soldered the PCB, Quality is really good, silkscreen, plating also great.

Warren Cliton

Through-Hole PCB Assembly | FAQs

When should I choose through-hole assembly over SMT?

Choose through-hole assembly when the design involves heavier components, high heat tolerance, or when the circuit and its components face vibration, thermal cycling, or environmental stress. It is also preferred for high-voltage circuits and assemblies requiring stronger bonds between the circuit and the components.

Can through-hole assembly be combined with SMT?

Yes. Through-hole technology and surface mount technology are often combined in mixed-technology designs. This approach allows through-hole components to provide mechanical strength while SMT components save space and support automated assembly for lighter parts.

How does selective soldering improve through-hole assembly quality?

Selective soldering applies solder precisely to through-hole components without exposing the entire circuit board to high temperatures. This reduces thermal stress, prevents solder bridging, and improves joint consistency, especially when working with automated through-hole PCB assembly or boards combining through holes and SMT components.

What is the role of automated insertion in high-volume through-hole assembly?

Automated insertion uses precision machinery to place axial and radial components into pre-drilled holes at high speed. This increases placement accuracy, reduces manual handling, and shortens the assembly process for volume PCB assembly, improving production efficiency without sacrificing mechanical strength.

Comprehensive Through-Hole PCB Assembly Services You Can Trust

WellPCB delivers through-hole PCB assembly services with manual and automated insertion, component sourcing, assembly testing, and full production capabilities for prototypes and high-volume orders, supporting industrial, automotive, medical, and aerospace applications with IPC 610 Class 2 and Class 3 compliance.