Polyimide PCB Manufacturer for High Performance Flexible PCBs

WellPCB is a leading polyimide PCB manufacturer trusted by OEMs in multiple sectors for high-performance flexible and rigid-flex PCBs.

We provide complete polyimide PCB manufacturing and assembly using advanced polyimide materials including pure polyimide, filled polyimide, and 3rd generation polyimide substrates for superior thermal and chemical resistance.

Our factories support prototyping, scalable polyimide PCB production and full traceability.

- Pure polyimide and filled polyimide materials with thermal stability up to 400°C.

- Flexible polyimide PCBs as well as rigid-flex PCBs.

- Advanced polyimide flex circuits made to client specifications.

ISO9001 ISO13485

ISO14001

IATF

16949

IPC-A-610H International

Certification

Fully Automated

AOI Inspection

- PCB Manufacturer

- Polyimide

Polyimide PCB Manufacturer for Flexible and Rigid Flex Circuit Boards

WellPCB makes PCBs for high performance applications that depend on flexible material properties, superior thermal resistance and reliable polyimide circuit boards across complex flexible and rigid flex PCB architectures.

As a production grade polyimide PCB manufacturer, we fabricate flexible PCBs using advanced polyimide materials and specialized lamination processes to provide exceptional flexibility while maintaining electrical integrity.

Every polyimide PCB uses high quality polyimide film and base material, ensuring mechanical and thermal reliability across all flexible circuit configurations. We process polyimide printed circuit boards from validated Gerber, ODB++, or IPC-2581 design inputs.

All polyimide flexible PCBs undergo comprehensive bend testing, thermal cycling, and electrical verification. Each polyimide circuit board meets IPC standards with full traceability maintained throughout the polyimide PCB production process.

Our Polyimide PCB Manufacturing Capabilities

We use high-performance polyimide film including pure polyimide for maximum flexibility and filled polyimide for enhanced dimensional stability and thermal conductivity.

Our polyimide material selection includes 3rd generation polyimide with superior chemical resistance, operating temperatures up to 400°C, and excellent dielectric properties.

Material thickness ranges from 12.5 to 125 µm, with controlled adhesive systems and copper foil bonding optimized for flexible and rigid flex PCB applications.

Our flexible PCBs are manufactured using specialized polyimide flex processing with controlled bend radius, flex-to-install ratios, and dynamic flexing capabilities.

Single sided, double sided, and multilayer polyimide flexible PCBs support intricate circuit designs with fine-pitch conductors down to 50 µm line/space.

Flexible polyimide PCBs undergo controlled lamination at 380°C with vacuum pressing to eliminate air entrapment and ensure reliable copper-to-polyimide adhesion.

Rigid-flex PCBs combine rigid polyimide PCB sections with flexible circuit areas using seamless transition zones and controlled impedance routing.

Our rigid-flex fabrication supports up to 12 rigid sections connected by polyimide flex circuits, enabling complex 3D packaging and space saving designs.

Transition areas are reinforced with polyimide stiffeners and controlled bend radii to prevent stress concentration during assembly and operation.

Advanced polyimide PCB production uses sequential lamination with precise temperature control, pressure distribution, and cure cycle optimization.

Our lamination process maintains polyimide material properties while achieving reliable interlayer bonding and dimensional stability across the circuit board.

Each polyimide PCB undergoes controlled cooling and stress relief to prevent warpage and ensure consistent electrical performance.

We fabricate polyimide circuit boards with higher circuit density, fine-pitch routing and complex geometries for demanding applications.

Our circuit design capabilities include impedance-controlled traces, via-in-pad structures, and multilayer polyimide PCB configurations up to 20 layers.

Design optimization ensures proper bend radius calculations, conductor pattern layouts and thermal management for reliable polyimide flexible PCB performance.

Our polyimide PCBs are designed for seamless integration with standard PCB assembly processes including SMT placement, reflow soldering and component attachment.

Flexible circuit board areas can be temporarily stiffened during assembly, then return to flexible operation after component placement and soldering.

Assembly-ready polyimide PCBs include proper solder mask application, surface finishes, and connector attachment zones optimized for automated assembly.

Each polyimide circuit board undergoes comprehensive testing including flexibility testing, thermal cycling, and electrical performance verification.

Our quality control includes bend testing to 100,000 cycles, thermal shock testing from -55°C to +125°C, and impedance verification across all circuit layers.

All polyimide PCBs meet IPC-2223 standards with full documentation and traceability maintained throughout the polyimide PCB production process.

Our polyimide PCB material expertise covers various polyimide types including thermoplastic polyimide, thermoset polyimide, and specialty formulations.

We support applications requiring chemical resistance, high temperature operation, and long-term reliability in aerospace, medical, and automotive sectors.

Each type of polyimide PCB is optimized for specific application requirements, ensuring the best polyimide PCB solution for every project.

Why Choose WellPCB?

Advanced Polyimide PCB Manufacturer Equipment

Superior Material Sourcing

Comprehensive Quality Assurance

18+ Years of Polyimide PCB Manufacturer Experience

Fast Turnaround Times

Expert Engineering Support

Features of Polyimide PCBs

Exceptional Thermal Stability

Superior Chemical Resistance

Outstanding Flexibility & Durability

High Electrical Performance

Excellent Dimensional Stability

Lightweight & Thin Profile

Which Materials Are Found in Polyimide-Based PCBs?

| Material Type | Operating Temperature | Dielectric Constant (Dk) | Dissipation Factor (Df) | Thermal Conductivity | Flexibility | Typical Applications |

|---|---|---|---|---|---|---|

| Pure Polyimide | -269°C to +400°C | 3.4 @ 1GHz | 0.002 @ 1GHz | 0.12 W/m·K | Excellent | Flexible circuits, dynamic flexing, medical devices |

| Filled Polyimide | -55°C to +300°C | 4.2 @ 1GHz | 0.008 @ 1GHz | 0.8 W/m·K | Good | Rigid flex PCBs, automotive, power electronics |

| 3rd Generation Polyimide | -200°C to +350°C | 3.2 @ 1GHz | 0.004 @ 1GHz | 0.15 W/m·K | Excellent | High frequency, aerospace, defense applications |

| Thermoplastic Polyimide | -40°C to +250°C | 3.6 @ 1GHz | 0.006 @ 1GHz | 0.2 W/m·K | Very Good | Consumer electronics, wearables, IoT devices |

| Thermoset Polyimide | -100°C to +400°C | 3.5 @ 1GHz | 0.003 @ 1GHz | 0.18 W/m·K | Good | High temperature applications, industrial controls |

| Polyimide Film (Kapton) | -269°C to +400°C | 3.4 @ 1MHz | 0.002 @ 1MHz | 0.12 W/m·K | Excellent | Flexible substrates, cable assemblies, sensors |

| Copper-Clad Polyimide | -55°C to +300°C | 3.8 @ 1GHz | 0.005 @ 1GHz | 0.25 W/m·K | Good | Single sided flex circuits, EMI shielding |

| Adhesiveless Polyimide | -200°C to +350°C | 3.3 @ 1GHz | 0.002 @ 1GHz | 0.14 W/m·K | Excellent | High density interconnects, fine-pitch applications |

How to Order Your Polyimide PCB

Submit Your PCB Design

Upload your Gerber files or use our easy online PCB design tool to create your board layout. Make sure your files are complete and correctly formatted to ensure smooth processing and production accuracy.

Select Your PCB Specifications

Customize your order by choosing the technical specifications—number of layers, board dimensions, thickness, copper weight, solder mask color, surface finish, and more. Our intuitive interface helps you configure everything based on your project’s needs.

Get an Instant Quote

Once your design and specs are in place, you'll receive a transparent, instant quote. Pricing updates in real time as you modify options, so you can adjust your selections to match your budget before placing the order.

Confirm Order & Make Payment

Review your entire order for accuracy, including file previews and selected specs. After confirmation, proceed to secure checkout and choose your preferred payment method. You’ll receive an email confirmation with order details.

Production & Delivery

Your PCB moves into production immediately. We’ll keep you updated throughout the manufacturing process. Once completed, your boards are carefully packed and shipped to your door, with tracking information provided for your convenience.

WellPCB is trusted by millions of

businesses and innovators.

Why Choose WellPCB?

WellPCB stands out among USA PCB manufacturers by delivering superior quality, advanced solutions, and unmatched reliability. With years of experience serving global markets, WellPCB has earned a reputation as one of the top PCB manufacturers in USA.

WellPCB specializes in multilayer PCBs for advanced electronic applications. You can order these boards with $100 off using our special offer, providing high complexity at competitive rates for demanding projects.

Hommer Zhao

Founder and Chief Editor – Hommer Zhao

Welcome! I’m Hommer Zhao, the founder and Chief Editor of WellPCB. With years of experience in the PCB industry, I’m committed to making sure our content is both accurate and helpful. We’re proud to serve a growing community of over 4,000 customers worldwide, and our goal is to provide you with the best resources and support. Your satisfaction is our top priority, and we’re here to help you every step of the way!

Jesse Holland

Technical Manager – Jesse Holland

Hi, I’m Jesse Holland, an Engineer and Technical Manager at WellPCB. With years of experience in PCB design and engineering, I’m here to ensure that every project we work on meets the highest technical standards. I lead our team, focusing on precision and innovation, collaborating closely with clients to provide tailored solutions and expert guidance. Whether you’re facing a complex design challenge or need advice on technical aspects, I’m here to ensure your project is a success from start to finish.

Nathan Jensen

Purchasing Manager – Nathan Jensen

Hi, I’m Nathan Jenson, the Purchasing Manager at WellPCB. I’m responsible for sourcing the best materials and components to ensure our products meet the highest quality standards. With my extensive experience in procurement, I work closely with suppliers to secure reliable and cost-effective solutions while maintaining strong relationships to support our operations. I aim to ensure every project runs smoothly by providing the resources needed to deliver on time and to your satisfaction.

Emma

Sales Manager – Emma

Hey, I am Emma, sales manager at WellPCB. I studied electronic science and technology at university and have served customers for PCB and PCB Assembly service for several years.

I enjoy communicating with customers and our technicians to solve problems, and customers always say, "It's great to have you onboard".

It is my pleasure and honour to be helpful. Contact me now, and you'll know.

Bella and Cassiel

Sales Representatives – Bella and Cassiel

We’re Bella and Cassiel, your dedicated sales representatives at WellPCB. With our extensive knowledge of the PCB industry, we’re here to provide exceptional service and support. We take the time to understand your unique needs and are always ready to offer tailored solutions and advice. Whether you need product recommendations, assistance with your orders, or simply have a question, we’re here to ensure your experience is smooth and seamless at every step.

Mandy and Wendy

Sales Representatives – Mandy and Wendy

We’re Mandy and Wendy, your friendly sales representatives at WellPCB. Passionate about helping our customers, we bring a wealth of experience in the PCB industry to provide you with the best solutions and service. We take pride in building strong relationships with our clients, understanding their specific needs, and offering personalised support to ensure their satisfaction. Whether you’re looking for advice, product information, or assistance with any part of your order, we’re here to make your experience as smooth and efficient as possible.

Our Team

Our skilled engineers and technicians bring expertise and precision to every PCB assembly project. Committed to quality, efficiency, and innovation, our team ensures every order meets the highest UL, IPC, ROHS & REACH standards, delivering reliable solutions tailored to your needs.

- Founder and Chief Editor – Hommer Zhao

- Technical Manager – Jesse Holland

- Purchasing Manager – Nathan Jensen

- Sales Manager – Emma

- Sales Representatives – Bella and Cassiel

- Sales Representatives – Mandy and Wendy

Polyimide PCB Case Studies

PCB Assembly

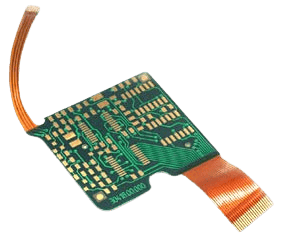

This project is a 6 layer Flex-Rigid PCB using the polyimide material for flex part.

Features:

- •4 layer Rigid+2 layer Flex PCB

- •Total Thickness: 1.6mm

- •Min. Trace Width / Space: 4 mil / 3 mil (0.1 mm / 0.075 mm)

- •Stack-Up: Special/customized (for signal + power + flex optimization)

- •Bendability: High flexibility in dynamic areas; rigid sections for connectors or ICs

PCB Assembly

Polyimide is the main material for Flexible PCB manufacture.This project is using for LED strip.

Structural reliability is validated through X-ray inspection, micro-section analysis, peel strength testing, and thermal shock simulation.

PCB Assembly

Polyimide is known for its excellent thermal stability, flexibility, and high strength, making it suitable for demanding applications.

Features:

- •Positional Accuracy (Male Component): ±0.03 mm tolerance

- •Thickness: 0.15 mm

- •Reinforcement: Front and back reinforced with 0.15 mm steel sheets

- •Copper Thickness: 35 µm (1 oz)

Manufacturing Processes:

- •Solder coating

- •Plug plating

- •Covering layer application

Polyimide PCB Manufacturer Client Feedback

As an R&D manager, I have had an outstanding experience working with WELL-PCB. For many years, our company has entrusted them with the production, assembly, and programming of the boards developed in our R&D unit, and they have consistently exceeded our expectations.

Hamid Reza Moshayedi

R&D Manager

Their work is very impressively perfect. Today, when they check our company PCB board after assemble. They found a fake short point which many engineers has never found in the past years. But that is just designed so. The PCB board quality is excellent. Their service is also excellent.

MikeZ

My friend introduced WellPCB to me, the first try, a little look forward to. I ordered a 47*72 10ps PCB, and I can’t wait to receive my PCB. So I used expedited service and received my PCB in three days. I tested and soldered the PCB, Quality is really good, silkscreen, plating also great.

Warren Cliton

Polyimide PCB Manufacturer FAQs

Why are polyimide PCBs better than traditional FR4 material?

Polyimide PCBs offer superior thermal stability (up to 400°C vs 130°C for FR4 material), exceptional flexibility for dynamic applications, and excellent chemical resistance. The advantages of polyimide include lightweight construction, higher circuit density capabilities and reliable performance in extreme environments.

Pure polyimide and filled polyimide materials maintain electrical properties across wide temperature ranges, making polyimide flexible PCBs ideal for aerospace, medical, and automotive applications where FR4 material would fail.

Can polyimide PCBs be used with standard SMT assembly processes?

Yes, polyimide PCBs are fully compatible with standard PCB assembly processes including SMT placement, reflow soldering, and wave soldering. During PCB assembly, flexible circuit areas can be temporarily stiffened using polyimide stiffeners or temporary support materials to prevent movement during component placement.

Our polyimide PCB design includes proper solder mask application and surface finishes optimized for automated assembly equipment. The key is controlling temperature profiles during reflow to stay within polyimide material limits while achieving reliable solder joints.

What is the minimum bend radius achievable with polyimide flexible PCBs?

The minimum bend radius for polyimide flexible PCBs depends on the polyimide material thickness, copper weight, and circuit design. Generally, pure polyimide supports bend radii as low as 1mm for dynamic flexing applications, while filled polyimide requires slightly larger radii.

Our circuit design guidelines recommend minimum bend radius calculations based on material thickness, typically 6x to 10x the total stackup thickness for reliable flex life. We optimize conductor patterns and use of flexible material to achieve the tightest possible bend radius for each polyimide PCB application.

What are the design considerations for successful polyimide PCB fabrication?

Critical design considerations include proper bend radius calculations, conductor routing patterns, and polyimide material selection. Circuit design must account for stress relief areas, avoid sharp corners in flexible sections, and include adequate copper-to-edge spacing.

The polyimide PCB design should specify appropriate via placement away from bend areas and include strain relief features. Our engineering team reviews each polyimide circuit board design for manufacturability, ensuring optimal trace routing, layer stackup design, and component placement for reliable polyimide PCB performance.

Ready to Work With a Reliable Polyimide PCB Manufacturer?

Get $100 Off Your First Order!

Partner with WellPCB, your trusted polyimide PCB manufacturer and supplier in China, for reliable polyimide flexible PCBs, rigid flex solutions and expert engineering support.