Contents

Resistor Color Code

A resistor color code refers to using colored bands to spot chip resistors’ percentage tolerance and resistive value. That said, there are various types of resistors you can use for electronic component values and electrical circuits.

With this, you can either create a voltage drop in different ways or control the rate of current flows.

But how do you pull it off?

First off, you have to ensure that your actual resistor has a value (resistance or resistive).

Typically, most resistors come in a span of resistance values (fraction to multiple ohms).

No doubt, it’s not practical to have tons of resistors for each value.

For instance, 1Ω, 2Ω, 3Ω, etc., since tons of resistors are present to deliver possible values.

So, resistors come in preferred values, and the resistance values have colored ink prints for each.

Resistor with Value and Colour code fixed Resistor

You can also find other values on the resistor’s body, like wattage rating, component tolerance, component names, numbers, and component positions when the resistor is larger.

But, if it’s a small resistor like a one-quarter film or watt carbon type, the specifications are represented in other ways as the text may be too tiny to see.

How to Solve Color Coding for Small Resistors?

So, how do you overcome this problem with a small choice of resistors?

You can use colored painted bands. These bands generate a system of identification called Resistor Color code.

Therefore, you can use the bands to display wattage ratings, resistive value, the combination of resistors, and tolerance on small resistors.

The idea of the colored bands resulted in the development of an international and globally received color scheme.

The goal was to know a resistor’s ohmic value quickly—regardless of its condition or size.

So, the scheme comprises a bundle of individual colored bands in visionary order—to represent each of the resistor’s value digits.

Ideally, you should read the color code signs from left to right—for a single band per time.

Then, you can find the resistor’s tolerance on the right side (with the bigger width tolerance band).

Thus, when you pair the number one band along with the linked number at the digit column of the color chart, it gives you the number one figure of the resistance value.

Also, you can pair the color of the number t band with its connected number at the digit column of the color chart—to grab the number two digit of the resistance value and more.

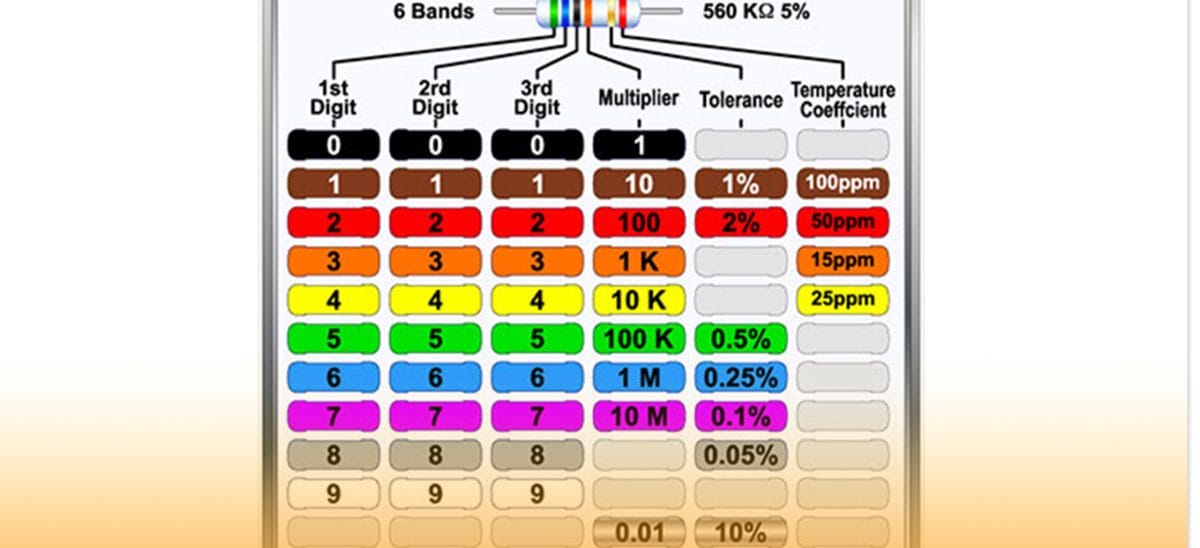

Resistor Color Code Chart

Before we dive into the resistor color code chat, let’s look at the code table to understand better.

four-band resistor color code

Resistor Color Code Arranged in a Tabular Form

| Color | Multiplier | Digit | Tolerance |

| Red | 100 | 2 | ±2% |

| Blue | 1,000,000 | 6 | ±0.25% |

| Orange | 1,000 | 3 | – |

| Yellow | 10,000 | 4 | – |

| Violet | 10,000,000 | 7 | ±0.1% |

| White | – | 9 | – |

| Green | 100,000 | 5 | ±0.5% |

| Silver | 0.01 | – | ±10% |

| Grey | – | 8 | ±0.05% |

| Black | 1 | 0 | – |

| Brown | 10 | 1 | ±1% |

| None | – | – | ±20% |

| Gold | 0.1 | – | ±5% |

Table showing the resistor color code and their values

Now that you know the color code, it’s time to see a summary of various weighted positions of each colored Band that makes the resistor color code above.

Table showing the various weighted positions of each color band

How Do You Calculate Resistor Values?

No doubt, the color code function is good—but you must know how to utilize it to achieve an accurate resistor value.

As we mentioned earlier, you arranged from one side to another.

As a result, the most vital band is closest to a merging lead alongside the color bands arranged from the left side to the right side like the example below:

Digit, Digit, Multiplier = Color, Color x 10color (Ω)

For instance, if a resistor comprises colored markings like:

Green Orange Red = 5 3 6 = 53 x 102 = 5300Ω

If you want to know the resistor’s tolerance, use the fifth and fourth bands. The resistor tolerance refers to measuring resistor variation.

six-band resistor color code

And you can do this by measuring the variation of resistors starting from the particular resistive value. That said, you can express tolerance as a percentage of its preferred or nominal value.

You should expect a tolerance range of 1 to 10 percent—if you’re dealing with film resistors. But if you’re handling carbon resistors, you should expect a tolerance of up to 20%.

five-band resistor code

The more expensive examples of resistors, called precision resistors, have tolerances of less than 2%. In other words, the lower the tolerance, the more expensive the sense resistor.

Furthermore, if you’re an electrical engineer, then you should be aware that most precision resistors include five-band resistors with 1% or 2% tolerance. On the other hand, four-band resistors have 5, 10, and 20 percent tolerance.

Hence, the color code you can use to indicate the tolerance rating of a resistor is:

Gold = 5 percent, Silver = 10 percent, Brown = 1 percent, Red = 2 percent

But what if the dependent resistor doesn’t have a 4th tolerance band resistor color?

In this case, you can use the normal tolerance, which is 20 percent. That said, it may be difficult to remember all the colors.

But you can use a shortcode in the form of phrases, expressions, and rhymes called acrostic—with each word representing the colors.

For instance, Buster Brown Races Our Young Girls But Vicky Generally Wins (this code shows the position of Brown).

BS 1852 (British Standard) Code

When you’re dealing with large current power resistors, it’s a different ball game in the sense that you don’t need resistor color code systems.

After all, you can easily print the specifications on the body of the main resistor.

But one major issue is that you may misread the specification when the resistor is dirty or discolored.

Hence, the idea of the BS1852 code was born to ease the process of writing and printing resistance values.

In this coding system, you replace decimal points with the suffix “M ” for megaohms or millions,” R” for the multiplier value that’s similar or lower than one, and” K” for kilohms or thousands.

Here’s the BS1852 Code for Resistor Values:

- 1MΩ = 1MO

- 470KΩ = 0M47 or 470K

- 47KΩ = 47K

- 4.7KΩ = 4K7

- 1.0KΩ = 1K0

- 0.47Ω = 0R47 or R47

- 1.0Ω = 1R0

- 47Ω = 47R

- 470Ω = 0K47 or 470R

It’s vital to note that some manufacturers may put an additional letter after the resistance value to indicate the tolerance, like 47K J.

Resistor color code for 4.7K Ohm

To understand these letters after the resistance value, you must know the tolerance letter coding for the axial resistors.

They include the following:

- B = 0.1%

- C = 0.25%

- D = 0.5%

- F = 1%

- G = 2%

- J = 5%

- K = 10%

- M = 20%

While you’re at it, ensure that you don’t mix up the tolerance values with the resistance values. For instance, confusing tolerance letter K = 10% fork = kilohms.

Resistor color code for 10K Ohm

Preferred Values, Bleeder Resistor Tolerance & E-series

As we mentioned earlier, preferred values are what manufacturers use to produce resistors.

The tolerance refers to the maximum difference between its exact value and the required value.

So, if you have 2kΩ±10%,

The maximum resistance value is 2kΩ or 2000Ω + 10% = 2400Ω

The minimum resistance value is 2kΩ or 2000Ω – 10% = 1600Ω

Resistor color code for 220 Ohm

From the example above, if you get the difference between the maximum and minimum values, you’ll have 800Ω—for the same value resistor.

E12 and E24 series are the most common resistors, and they represent twelve resistance and 24 resistance per decade, respectively.

The decade shows multiples of ten. You can refer to the resistor tolerance and E-series table for more detailed values.

Surface Mount Resistors

An SMD resistor is one with a rectangular-shaped metal oxide film. So, the design involves soldering electrical components directly on the PCB surface.

Plus, it usually has a ceramic substrate body with a thick layer of metal oxide resistance.

SMD resistor on a PCB

Also, you control the resistive value by increasing the type of deposited film, thickness, or length.

That said, you can print the SMD resistors in a three or four-digit numerical code to show the resistive value. The first two digits indicate the resistance value—while the third digit is the multiplier.

Resistor color code for 330 Ohms

For example: “482” = 48 x 100 ohms = 4.8 kiloΩ

If the resistors have values less than 100Ω, you can write it as:

“480” = 48 x 100 (which is equivalent to 1) = 48 x 1Ω = 48Ω or 48RΩ

Resistor color code for 100 Ohms

Resistor Color Code Calculator

This tool is quite useful for gaining information on axial lead and color-banded resistors.

All you need to do is pick the number of bands and colors—to know the tolerance and value of resistors.

Rounding Up

Identifying Resistor values isn’t rocket science. All you need to do is understand the resistor color code and calculate the values based on the bands.

Tolerance is another part to consider—since it’s critical to design performance.

Do you have questions or concerns on this topic? Feel free to contact us; we’ll be happy to help.