Contents

- 1 What Is Rogers PCB?

- 2 What Is Fr-4 Material?

- 3 rogers pcb vs fr4-Price

- 4 Rogers pcb vs. fr4-High Frequencies

- 5 Df/Dissipation

- 6 Impedance Stability

- 7 Dielectric Constant

- 8 Space Applications

- 9 rogers pcb vs. fr4-Temperature Management

- 10 Rogers PCB Manufacturing Considerations

- 11 Rogers PCB Material Selection Guidelines

- 12 Conclusion

What Is Rogers PCB?

If you laminated several layers of specialized material to create a PCB substrate, you would technically have a Rogers PCB.

However, it must have a ceramic base as a high-frequency material.

Plus, you must ensure it doesn’t have fiberglass in the mid-section.

Manufacturers will use Rogers PCB in high-humidity, high-frequency, commercial microwave, and RF(radio frequency) equipment and applications.

Despite its premium, it beats FR-4 material in use-specific applications.

What Is Fr-4 Material?

Combine woven fiberglass cloth and epoxy resin binder then make the final product flame retardant. What do you get? FR-4. FR-4, in itself, is not a material.

Rather, manufacturers opt for a grade of a material because of its FR (flame retardant) property.

Usually, FR-4 material is used as a PCB base. Also, the FR-4 name could denote a rating for epoxy laminate sheets.

rogers pcb vs fr4-Price

When manufacturing printed circuit boards, the type of material used matters a lot, but price matters.

The FR-4 and Rogers materials differ in cost. FR-4 material is cheaper than Rogers material.

FR-4 is one of the low-cost materials used to manufacture printed circuit boards, preferred for minimal processing costs.

Although PCBs made of FR-4 materials are known for their low performance, they cost less than printed circuit boards made of Rogers material.

Considering the price of the content and its processing needs, it is possible to determine whether you get value for your money.

However, if you need a printed circuit board of cheap materials, you better go for FR-4 materials.

But if you are not on a budget and need high-performing PCBs made of the best materials, you are better off with Rogers materials.

However, you need to keep at the back of your mind that choosing Rogers materials may be the best option because cheap may be expensive in the end.

Rogers pcb vs. fr4-High Frequencies

Printed circuit boards made of FR-4 and Rogers materials –regardless of whether they consist of Rogers 4350 or Rogers 4350b materials- are highly popular due to a wide array of electronic applications, and again, for a good reason.

Printed circuit boards made of FR-4 materials are preferred for their low cost and for being reliable and well-understood for their electrical and mechanical characteristics.

They find use in everything from microwave designs to audio circuits.

Unfortunately, printed circuit boards made of FR-4 materials are unsuitable for high-frequency applications.

Rogers manufactured the most famous high-frequency-special laminates.

Its materials exhibit a nearly 20% reduction in dielectric constant compared to printed circuit boards made of FR-4.

The best way to decide whether your project will work better with high-frequency laminates is to size up the job’s mechanical and electrical requirements.

If you find that the electrical and mechanical variations are too broad, you are better off with Rogers is materials.

Df/Dissipation

When manufacturing printed circuit boards, the type of material matters the most, although substantial costs may be necessary.

However, it is not the only problem that knows the content value regarding the loss factor or Df.

Printed circuit boards made of FR-4 materials will be affected or reduced. The losses are more significant than those for printed circuit boards made of Rogers materials.

In other words, FR-4 materials have a higher dissipation factor than Rogers’s articles, especially at high frequencies.

Typical values for printed circuit boards made of FR-4 materials are about 0.020 and close to 0.004 for boards made of Rogers materials.

FR-4 materials are identifiable by dissipation, which increases when frequency increases. High-frequency laminates mainly exhibit a stable dissipation characteristic with frequency.

The low dissipation factor of FR-4 materials helps minimize signal losses, not forgetting that their compatibility with automated assembly and processing of FR-4 makes them very easy to manufacture.

Impedance Stability

Impedance is the obstruction or measure of the opposition of an electric current to the energy flow when a voltage is applied.

An apt impedance example is a resistance line on an electric current.

Stable impedance is essential to plenty of designs; this is an area where the FR-4 and Rogers materials differ.

Even though they are low in cost, FR-4 materials are highly susceptible to wide variations in the dielectric constant across the width and length of a substrate, as well as changes in temperature.

Overall, Rogers’s material has a more extensive range of dielectric constants compared to FR-4 content when it comes to impedance stability.

High-frequency laminates are better if a circuit needs to work with little variations over broad temperature changes.

Here, you may have to choose printed circuit boards made of Rogers materials instead of FR-4 materials, especially if a majority of your operations involve working in high-temperate environments.

Dielectric Constant

The dielectric constant is a quantity that effectively measures the ability of a substance to store some electrical energy across an electrical field; when it comes to matters concerning dielectric constant, FR-4 features a dielectric constant of about 4.5, a figure much lower than Rogers material, whose dielectric constant stands at around 6.15 to 11.

Put, printed circuit boards made with materials that contain high dielectric constant values can yield some small circuits.

FR-4 materials have higher dielectric values than most plastics. Using FR-4 materials can save 25% or more on a printed circuit board made of such materials.

Other things that make FR-4 articles accessible because these redundant fire materials are lightweight, moisture resistant, and come with high dielectric strength.

Even though Rogers is materials are suitable, when it comes to dielectric constant, you are better off with FR-4 materials. R

ogers 4350 and Rogers 4350b materials follow the same manufacturing processes as FR-4 materials, though an FR-4 element can effectively store electrical energy compared to a Rogers PCB.

A high dielectric constant in itself is not as desirable as such.

Generally, printed circuit boards with high dielectric constant tend to break down quickly, especially when subjected to some of the most intense electrical fields.

Space Applications

Space exploration has increased lately, with many countries trying to send people to space.

When it comes to space applications, the materials used in manufacturing printed circuit boards matter a lot; not all the materials used in producing printed circuit boards meant for space exploration come with the promise of excellent functionality.

Some materials may fail to function as desired.

FR-4 and Rogers are materials that profoundly differ regarding their applicability or use in space.

Outgassing occurs in space when trapped gases are released into powder coating during curing.

Corrosive materials or moisture can penetrate the surface via the pinholes to destroy some parts.

Even though FR-4 materials deliver an excellent balance of electrical stability, manufacturability, durability, and cost,

Rogers’s materials are regarded as some of the best in the field regarding space applications.

In short, they are low outgassing for almost every space exploration or use.

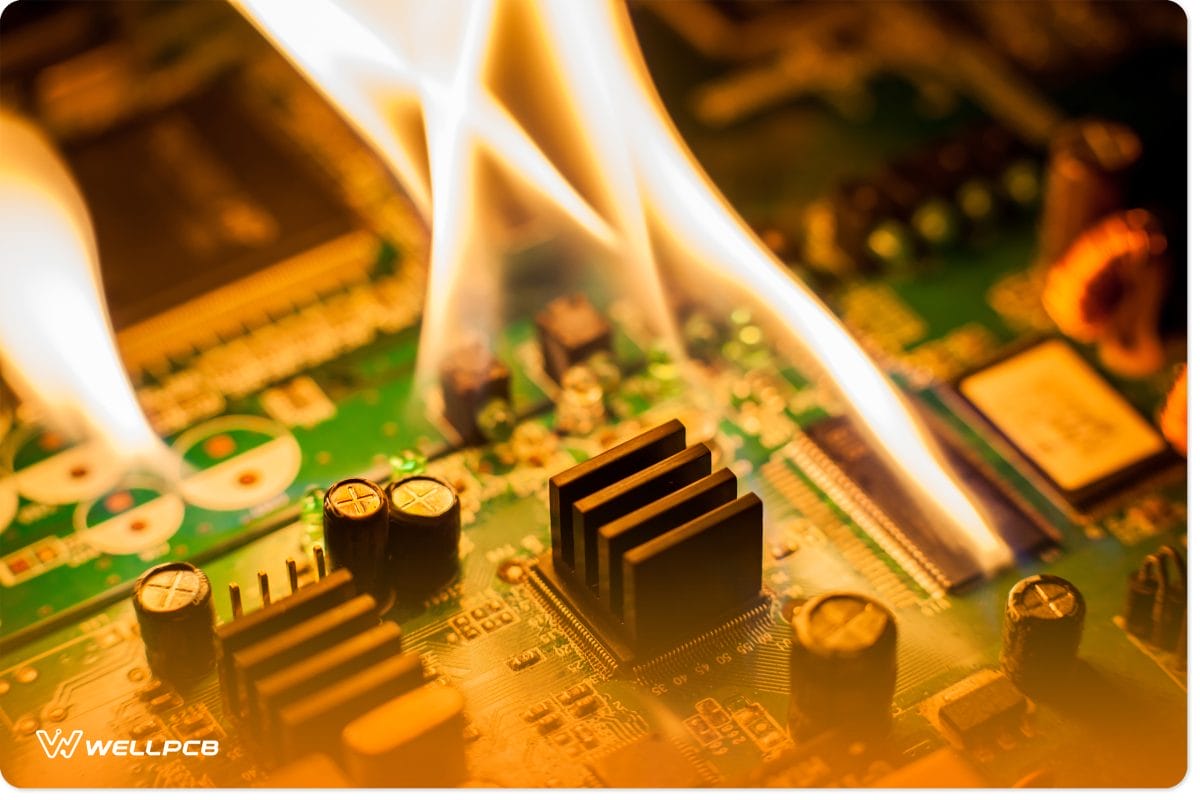

rogers pcb vs. fr4-Temperature Management

Heat management materials are essential for plenty of electrical devices.

Since the temperature of these products needs to be maintained at certain levels, thermal management materials are necessary when producing printed circuit boards.

Printed circuit board materials are characterized or gauged by the thermal coefficient of the dielectric constant.

For FR-4 materials, this is almost 200 parts per million per degree Celsius change.

If a printed circuit board must work with little variations over a high-temperature range, then those made of Rogers material could be better than those made of FR-4 materials.

In short, regarding temperature management, Rogers’s materials perform better because they have less variation than FR-4 content. High-frequency thermoset-based laminates such as

Rogers’s materials are highly robust compared to FR-4 materials and are known for their excellent handling of high temperatures.

Rogers PCB Manufacturing Considerations

Rogers PCB manufacturing has specific considerations that ensure a near-perfect final product.

Preparing the Surface

The manufacturer will opt for a chemical process that involves cleaning, micro-etching, and water rinsing. After, they will dry the prepared surface.

However, this chemical process applies mainly to thin core material.

Otherwise, materials with a core thickness above 60 mils undergo a mechanical scrub.

The other consideration manufacturers make during surface preparation is lowering the pressure.

Minimal pressure ensures the laminate remains possibly scratch-free to maximize the spacing between traces.

Bonding Multiple Layers

Manufacturers use oxides in the preparation processes of Rogers cores to bond multiple layers.

They bake the inner layer cores on a rack at 225-250 degrees Fahrenheit for 30 minutes before any layups.

Drilling Considerations

When possible, i.e. with correct aspect ratios, they use CO2, UV, or a laser combination of both to drill vias and through-holes.

They apply alkaline permanganate to clean up after the post-laser procedure. Alternatively, they might use CF4/O2 plasma. The clean-up and the clean-up material preferences ensure the copper base establishes a firm electrical connection at the vias’ base.

They might consider pressed phenolic entry/exit material or standard aluminum when they choose mechanical drilling.

Copper Plating/Outer Layer Processing

Rogers PCBs work well with electrolytic tin plating and acid copper for panel and pattern processing.

Afterward, manufacturers treat the material with strip-etch-strip procedures after plating.

Etching should establish a solid bond between the surface and direct screen and photo-imageable solder masks. Still, a follow-up bake is needed to dry the surface.

The bake can take 30 minutes or 60 minutes between 230°F and 257°F.

Rogers PCB Material Selection Guidelines

Rogers materials come in many variations, each suitable for specific applications.

Knowing important properties can help you choose the ideal Rogers PCB material for your avionics, communication, or antenna systems applications.

Dielectric Constant

In Rogers PCB, low DK material is used in higher frequency RF applications with more impedance control.

However, it will cost you a demand in larger trace width. Select a Rogers PCB material with higher DK if you want higher circuit density and miniaturized components.

However, a higher DK will limit frequency range and impedance control.

The trick here is to use a Rogers PCB material that has balanced features.

Board Thickness

Sure, in some instances, thicker is better. However, thinner Rogers PCB materials have lower dielectric effects.

Lower DK boosts high-frequency performance. Manufacturers will often pick boards thicker than 0.031” when they want better fabrication, less risk of physical and handling damage, less wrinkling, and higher power distribution.

Loss Tangent

Loss tangent is simply the Rogers PCB’s signal loss. Less loss tangent means less signal attenuation.

Therefore less loss tangent guarantees a stronger signal.

Still lower loss tangent Rogers PCB comes at a premium cost.

If a manufacturer can use a higher-loss tangent material, they can use it to make significant budget savings. Still on loss, select material with low conductor loss.

When operating at high frequency, this quality is found in thick copper and materials with low dielectric loss tangents.

Cumulatively, this combination reduces instances of signal loss.

Operating Frequency

Since every application has an ideal operating frequency, manufacturers often pick the Rogers PCB with a matching operating frequency.

A perfect material-to-application frequency match ensures minimal signal loss.

Thermal Design

Overheating is an ever-present concern in many PCB operations and applications.

Therefore, materials with good thermal conductivity are needed for heat dissipation to avoid overheating and heat damage.

High thermal conductivity Rogers PCB materials dissipate heat better than other materials, such as FR-4.

Certification and Compliance

Aside from the physical selection requirements, you also need a material that passes various certifications.

Some materials have military specifications, while others have an IPC 6012 automotive specification.

And since heat makes up a large part of most PCB applications, look out for materials with a UL 94-0 flammability rating.

The best solution is to check whether the material meets most compliance and certification requirements.

Function against Environmental Factors

Aside from budgetary concerns, a more important guideline is checking how different Rogers PCB materials respond to environmental changes.

Check these environmental factors that play out differently in different Rogers PCB materials.

- Shock

- UV-light and radiation response

- Moisture absorption

- Glass transition temperatures

- Adhesion

- Humidity

- Outgassing

- Vibration

Rogers 5880 has low moisture absorption, outgassing, and loss tangent.

How Many Layers

Multiple layers translate to thin dielectrics between the layers.

Therefore, manufacturers choose Rogers PCB material with low Dielectric constant and loss tangent. These two qualities ensure minimal interlayer signal degradation.

Fewer layers mean manufacturers can use high DK loss and loss tangent material.

For instance, Rogers 4835T is designed for multilayering.

Scaling

In this case, scaling is the possibility of future design changes or additions.

If there are plans in the future that might involve higher-quality Rogers PCB material, it would be a good idea to opt for high-quality material from the start.

Conclusion

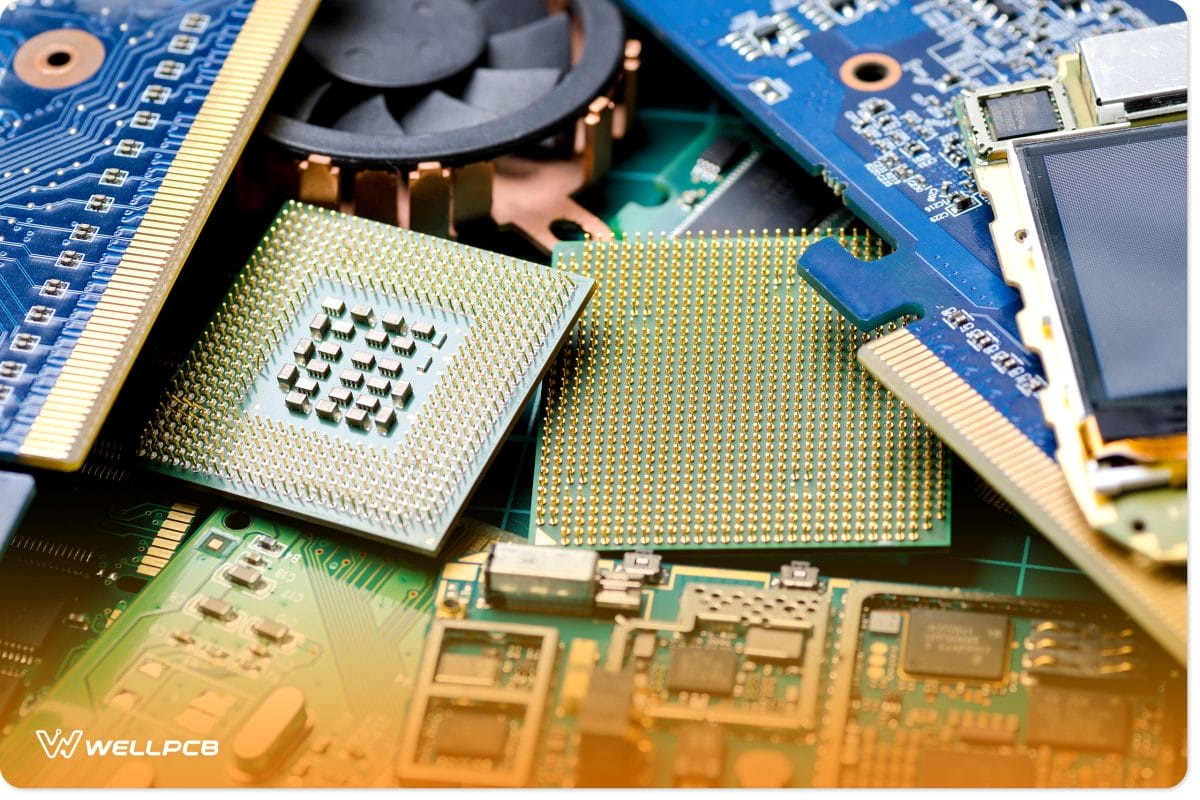

The type of material on your printed circuit board matters a lot.

When selecting a printed circuit board, you need to go for the one made of the best articles that guarantee you quality results and long-lasting effects.

Here at WellPCB is the best place to find excellent PCB production and manufacturing services. Depending on the type of materials that you need, rest assured of finding them at WellPCB.

We have a team of experts who can guarantee an unforgettable manufacturing experience using Rogers and FR-4 materials, which are popular in the industry.

For more details concerning PCB materials, contact our support team at your earliest convenience at sales@wellpcb.net.