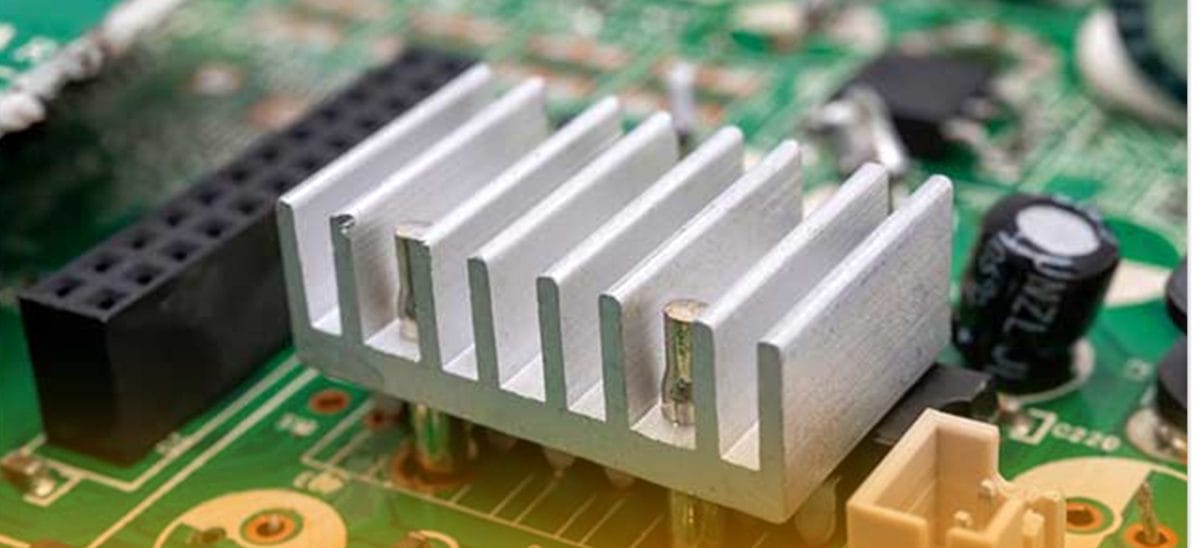

ic layer will perform as the conducive link between IC and heat sink. Unlike FR4. The copper and Aluminum PCBs are one of the best choice PCBs for engineering applications. Also, they are ideal for heat control and maintenance.

Contents

What are Aluminum PCBs?

So, let’s start with the definition of Aluminum PCBs.

So, what exactly are Aluminum PCBs?

An Aluminum PCB is a fine layer of the conductive dielectric component.

But that’s not all.

It also has an electrically insulating material. Plus, it lies between the aluminum metal and copper layer.

So, the copper foil adopts the chosen circuit pattern. In contrast, the metal component enables the heat loss. Plus, it gets support from the dielectric between the layers. Later in this article, we’ll talk about the various types of layers.

Besides, some engineers know it as Aluminum Clad, MCPCB, Aluminum bed, etc. They also have other names like Thermic Conductive PCBs, IMS, etc.

Generally, these aluminum PCBs first came into existence in the mid-70s. Afterward, they experienced a dramatic increase in the application. Hence, engineers first used Aluminum PCBs for Amplified Hybrid Integrated Circuits.

Today, a lot of engineers use aluminum PCBs on a large scale. And it’s due to its high conductivity.

Structure of Aluminum PCBs

So, here are the four basic structures of aluminum PCBs.

Copper Foil Layer

The circuit layer comes with a copper foil. Furthermore, the copper foils in the layer come in various weights. Typically, you can find them from 1 – 10 ounces. And PCB producers select them based on their needs.

Dielectric Layer

The dielectric layer of aluminum PCBs does one major thing. So, its function is to absorb heat while current flows through the PCB. Afterward, it moves to the aluminum layer, where the heat spreads.

Aluminum Base Layer

The aluminum Base layer of aluminum PCBs consists of aluminum substrates. Hence, this layer has two excellent properties. They are viscoelastic and have high thermal conductivity.

Aluminum Base Membrane

The layer has a substrate made from aluminum alloy. Also, it’s quite selective and protective. So, it keeps the surface of the aluminum from etching and scratching. Plus, it comes in two different types. And they are above 250 degrees and below 120 degrees.

But that’s not all.

Aluminum PCBs make this layer an excellent component for through-hole systems. Plus, it happens because of the aluminum present in them. We’ll be talking more about through-hole technology later.

Different Types of Aluminum PCBs

Like we mentioned earlier, wne shall dive deep into the various aluminum PCBs.

There are four different types of Aluminum PCBs.

Through-hole Aluminum PCBs

A lot of things happen in through-hole aluminum PCBs. Hence, a single layer of aluminum gets pre-drilled and backfilled. Plus, it happens—when it comes to the most complex fabrications. Usually, the back-filling and pre-drilling happen before the lamination application. In the end, it forms a core of multilayer fabrications.

Afterward, thermal bonding components help to do something. Hence, they help to laminate the thermal materials on every side of the aluminum.

Next is the drilling after the lamination process is complete. And this drilling gets applied to the assembly.

So, to maintain the proper electrical insulation, something happens—the plated holes created from the drilling pass through the aluminum clearances.

Flexible Aluminum PCBs

This type of aluminum PCB is new to aluminum products. Hence, the materials contain polyimide resin. Plus, the resin gets integrated into ceramic filters that possess some features. Therefore, they are quality electrical insulation, thermal efficiency, and high flexibility.

So, these materials combine with aluminum materials. And then a result comes out. In short, they deliver a final product that removes the need for pricy connectors and cables.

But that’s not all.

The materials’ flexibility makes the products twist or fold. Plus, they take any shape or form before remaining stationary. As soon as the shape gets adopted, something happens. The shape can’t be altered like standard flexible PCBs.

Multilayer Aluminum PCBs

These layers are pretty popular with power supply products. Hence, they have multiple layers of thermally conductive dielectric materials.

So, these materials come in handy. Plus, they do better when combined with single or multiple layers of circuitry.

But there’s more.

When combined with layers of circuity, something happens. The thermic conductive dielectric materials get buried between layers. So, the layers get help from blind vias, which act as thermal or single vias.

However, we must warn you about something. The single-layer designs aren’t always practical. But they do well with intricate designs. Plus, they provide heat loss for tons of applications.

Hybrid Aluminum PCBs

For hybrid aluminum fabrication, one major thing happens. So, you’ll find non-thermal materials getting refined and processed separately. Afterward, it gets applied to the thermal components with an aluminum bed.

So, the most prevalent practice is developing two or 4-layer structures. These structures consist of FR4 components.

Also, the non-thermal material that bonds with thermal material and the aluminum bed provides something. So, it provides firmness. Plus, it helps to lose heat.

Furthermore, most engineers prefer non-thermal bonding to thermal materials. And it’s because of affordability. Plus, it has a more efficient thermal conductance than regular FR4 products.

Performance of Aluminum PCBs

Thermal Expansion

PCB substrates like CEM3 and FR4 have low thermal conductivity. So, if the high temperature of the electronic equipment doesn’t get distributed promptly, something happens. There will be a failure of high-temperature electronic components.

Also, aluminum substrates solve thermal dissipation issues.

Thermal Dissipation

Generally, the aluminum substrate PCB solves thermal dissipation issues. Hence, they do it effectively. With them, there are no thermal contraction and expansion issues on PCBs. Thus, it improves the sturdiness and quality of electronic appliances.

Significantly, aluminum substrates can also solve issues facing SMT. Plus, it does a great job when its thermal contraction and expansion issues.

Dimensional Stability

Most aluminum substrate PCBs have larger firmness than insulating materials. When their temperature rises from 30 °C to 140 ~ 150 °C, they still stay stable. Plus, the aluminum substrate’s dimensional change stays at only 2.5 ~ 3.0%.

Other Performance

So, aluminum substrate PCBs come with a shielding effect. Plus, they have other brittle ceramic substrates.

But that’s not all.

The substrate helps to boost tangible features and heat resistance. As a result, they reduce the cost of production and labor.

Aluminum PCB Applications

Using aluminum PCB for your products improves two things. Its performance and durability. Besides, it’s relatively cheap compared to copper. And it’s a lightweight material.

So, here are some examples of its applications:

LED Circuit Boards

When you combine aluminum with your LED PCB, one thing is sure. You’ll get the lowest possible operating temperature. Plus, it gives maximum life, color, and brightness. Also, it helps to save energy.

Examples of products in this category are pendant lights, flashlights, etc.

Computer

Generally, computers release a lot of heat. And continuous heating results in damage. But, when you use aluminum PCBs, it reduces the heat effectively.

Examples of computer devices that use aluminum PCBs are the motherboard, floppy disk drive, etc.

Power Converters

Aluminum PCBs are suitable for power converters. And it’s all thanks to the variety of thermal performances they offer. Besides, the aluminum-clad is highly reliable and compatible with mechanical fasteners.

Examples of power converters are DC-AC adapters, stabilizers, etc.

Audio Equipment

No doubt, aluminum boards are quite useful as thermal conductive options. In other words, they are the most suitable solution to tight tolerance and high-power applications. So, it helps to move heat away from vital components.

Consequently, it reduces the harmful effect it could have on the circuit boards. Examples of this audio equipment are power amp, preamplifiers, etc.

Automobile

When it comes to automobiles, you can find aluminum substrates on the LED boards. And it’s because the boards need heat loss. So, you’ll find aluminum PCBs for parts like brake lights, headlights, etc.

Benefits of Aluminum PCB

Now, you know its applications. Let’s dive into the benefits of the aluminum PCB.

Lightweight

Aluminum is a lightweight metal. And this is one of the essential benefits of this PCB. After all, it adds extra flexibility and strength to the PCB.

Environment-friendly

It’s relatively easy to assemble aluminum. As a result, it assists to conserve energy. Also, aluminum is non-toxic and recyclable. In summary, aluminum PCBs are environmentally friendly. So, it contributes to protecting the planet.

It Enhances Heat Loss

Most times, vital components on circuit boards get exposed to high temperatures. As a result, the parts get damaged. So, it’s crucial to protect them from damage. And you can do this by using aluminum PCBs. After all, it enhances heat loss.

It’s Economical

The production process of aluminum is cheaper compared to other metals. And it’s because you can find it in most climatic conditions. Plus, it’s easy to mine and refine.

Sturdiness

Aluminum has high durability. And it’s due to the material’s sturdiness. So, using aluminum circuit boards reduces the risk of accidental breakage during everyday use. Also, it provides remarkable strength.

Production Bottlenecks of Aluminum PCBs

There’s a lot of similarity in the production process of almost every aluminum PCB. And there are difficulties involved. They are:

Copper Etching

Copper foil is vital in the production of aluminum PCBs. And the foil is relatively chunkier. No doubt, copper etching requires some width compensation. But it happens when you go overboard.

Or you don’t follow the design’s demand. The trace width usually goes out of forbearance after the process. So, it’s crucial to design the trace width redress accurately.

Solder Mask Printing

You may face issues when it comes to solder mask printing for aluminum PCBs. And it’s because of the thick copper foil. That is when the trace copper is very chunky, the etched image will face an issue.

The problem is a big difference between the baseboard and trace surface. So, it’s best to use a two-sided solder mask. Also, it’s vital to use good-quality oil for the solder mask. Or better still, do the resin filling before the solder mask.

Mechanical Manufacturing

Some of the processes involved in mechanical production are v-scoring, molding, and mechanical drilling, etc. And these processes could lessen electrical strength. So, it’s best to use professional and electric milling for producing low-volume products.

Also, you should adjust the drilling framework. That way, you’ll avoid generating a rough edge.

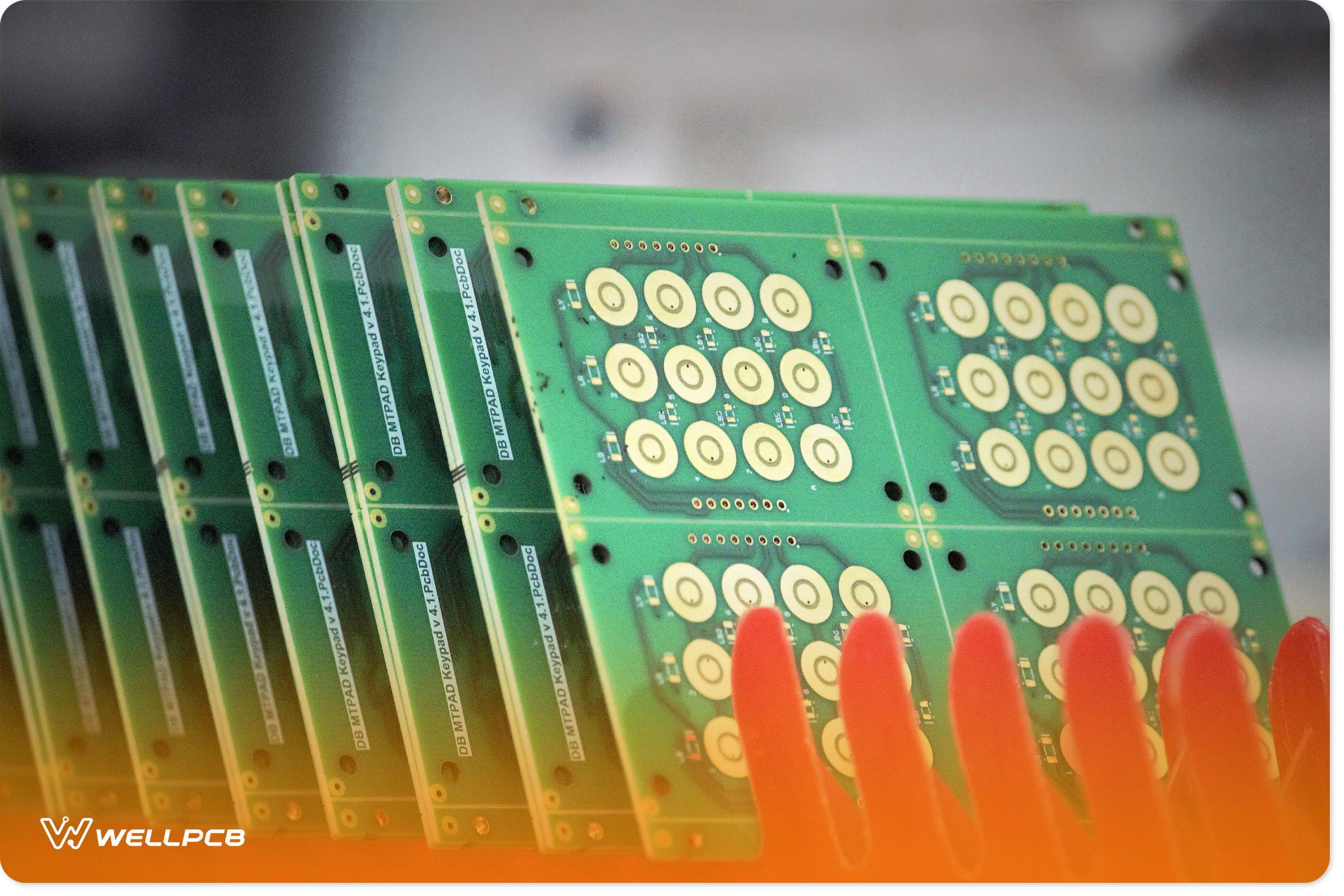

Key Factors to Consider When Choosing an Aluminum PCB Manufacturer

Selecting the best aluminum PCB producer is crucial. And it’s because suppliers use a different automation level in their process. So, before you choose one, you should look out for things like:

Dedicated Imaging Device

Most of the aluminum PCBs are lengthier than the regular ones. So, the best way to register and cheaply produce the parts is for the producer to have two things.

- A setup that can screen print an image at a single instance or a custom piece.

- The custom piece should be 60-inch-wide UV light imaging equipment.

Specialized Scoring Equipment

V scoring is one of the most effective ways to rout the parts out mechanically. And without it, there will be an increased cost.

So, it’s necessary to look out for a producer with loads of experience. With that, you can trust that you’ll get designs that are cost-effective to remove its panel.

In-Line Hi-Pot Test

Most customers are particular about their aluminum PCB passing a hi-pot test. So, if you’re one of them, look out for PCB producers that can produce a hi-pot test. After all, it’s an entirely different process that isn’t in the electrical examination. Plus, it reduces costs for customers.

In Conclusion

Aluminum PCBs are a thing these days, and it’s no surprise. After all, we can find them in different industries and consumer electronics.

Plus, it’s cost-effective, environmentally friendly, sturdy, lightweight, etc.

It’s easy to get a reliable aluminum PCB producer as long as you consider this post’s requirements.

If you have questions or suggestions on this topic, please contact us. We’ll be more than happy to help.