Contents

LED PCB Materials

When selecting an LED PCB substrate, it’s crucial to carefully consider the thermal performance of the material. Other factors like weight, size, and cost are also significant.

Here are some common substrate options:

- FR4 PCB Raw Material

- CEM-1 PCB Raw Material

- CEM-3 PCB Raw Material

- Copper Core PCB Material

- Ceramic Base PCB Material

Each material used in PCBs has its advantages and drawbacks. Metal and ceramic substrates provide superior thermal performance compared to laminate but are often more expensive.

For example, CEM-1 boards are a low-cost choice but tend to be more fragile than FR4 and CEM-3 substrates. Ceramic-based PCBs, often made from materials like Alumina, deliver excellent thermal management but come with a higher price tag.

A similar trade-off applies to metal-core PCB materials, such as aluminum PCB and copper, which offer high thermal conductivity. Although they come at a premium, aluminum PCBs are a popular choice for LED applications due to their effective heat dissipation and reliability.

When considering circuit board manufacturing, understanding these material trade-offs can help you select the best option for both performance and budget.

The Benefits Of LED PCB & The LED Lighting Industry

LED PCBs have many advantages over traditional lighting. These include:

- Lower power consumption

- Longer Lifespan

- Very Compact

- Mercury Free

You can shape lighting boards and change the color of LEDs to create interesting lighting effects.

The Application Of LED PCB

The recognition of the benefits of an LED circuit board is increasing. Hence, the number of applications is also rising. Some examples are:

- Automotive.

- Medical.

- Computer.

- Telecom.

- Military.

- Traffic and signal lights.

- Signs.

- LED lights for indoor farming.

Various market forces are increasing demand. These include Improving LED technology, green energy demand, and lower cost. As a result, the forecast compound annual growth rate for the LED circuit board lighting market between 2021 and 2026 is (CAGR) 14.25%.

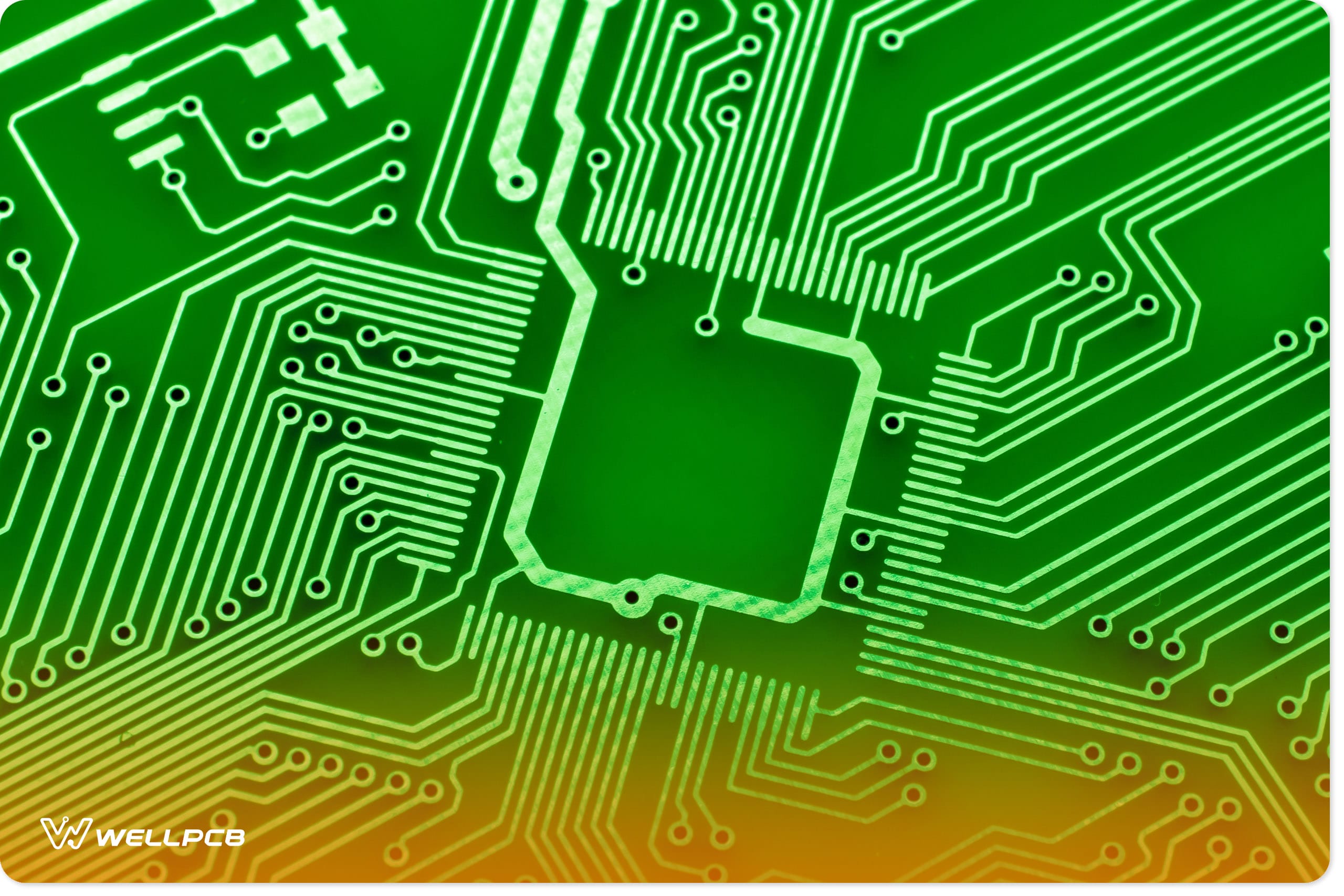

Using SMD Components on LED PCBs

LEDs are available in surface mount and leaded packages. As Surface mount devices (SMD) are small and low profile, they are the first choice for multi-device applications.

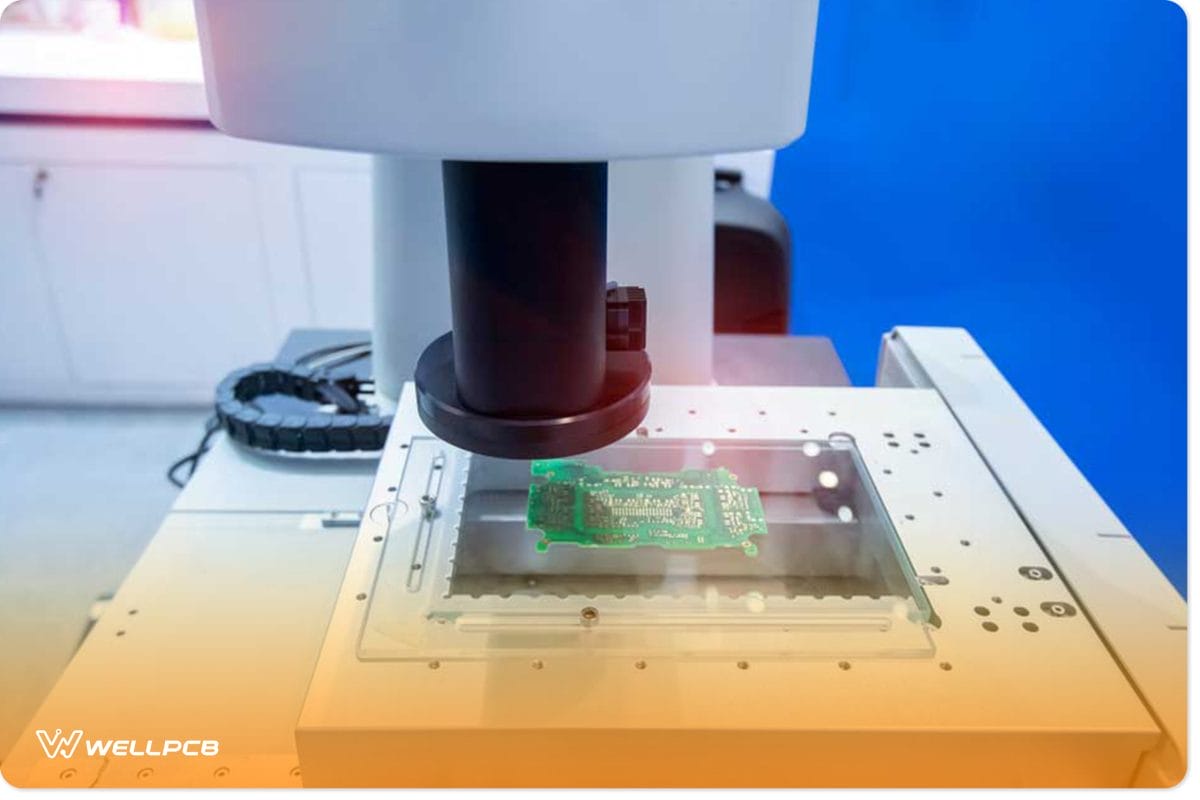

SMD LED assembly requires a high level of manufacturing skill. Manufacturers must fit LED circuits and circuit board accessories on a small PCB. Hence, LED lighting board production requires picking and placing equipment.

The process involves printing solder paste onto solder pads on the PCB. The next step is to place surface-mount LEDs on the solder pads. Heat is then applied to form a solder joint.

The placement accuracy of the LED component is important. Also, the solder paste must be level and within a specified thickness. To prevent damage to the LED device, control of the heat applied is critical.

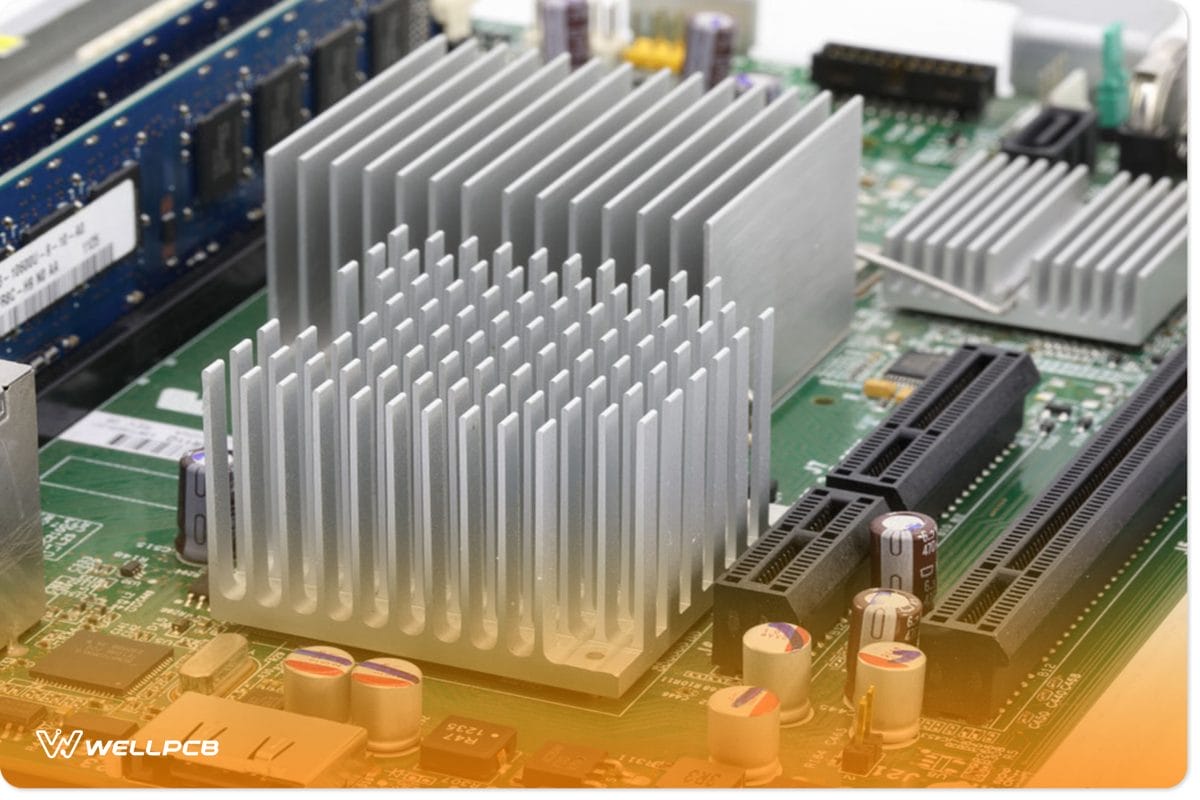

Aluminium LED Circuit Boards

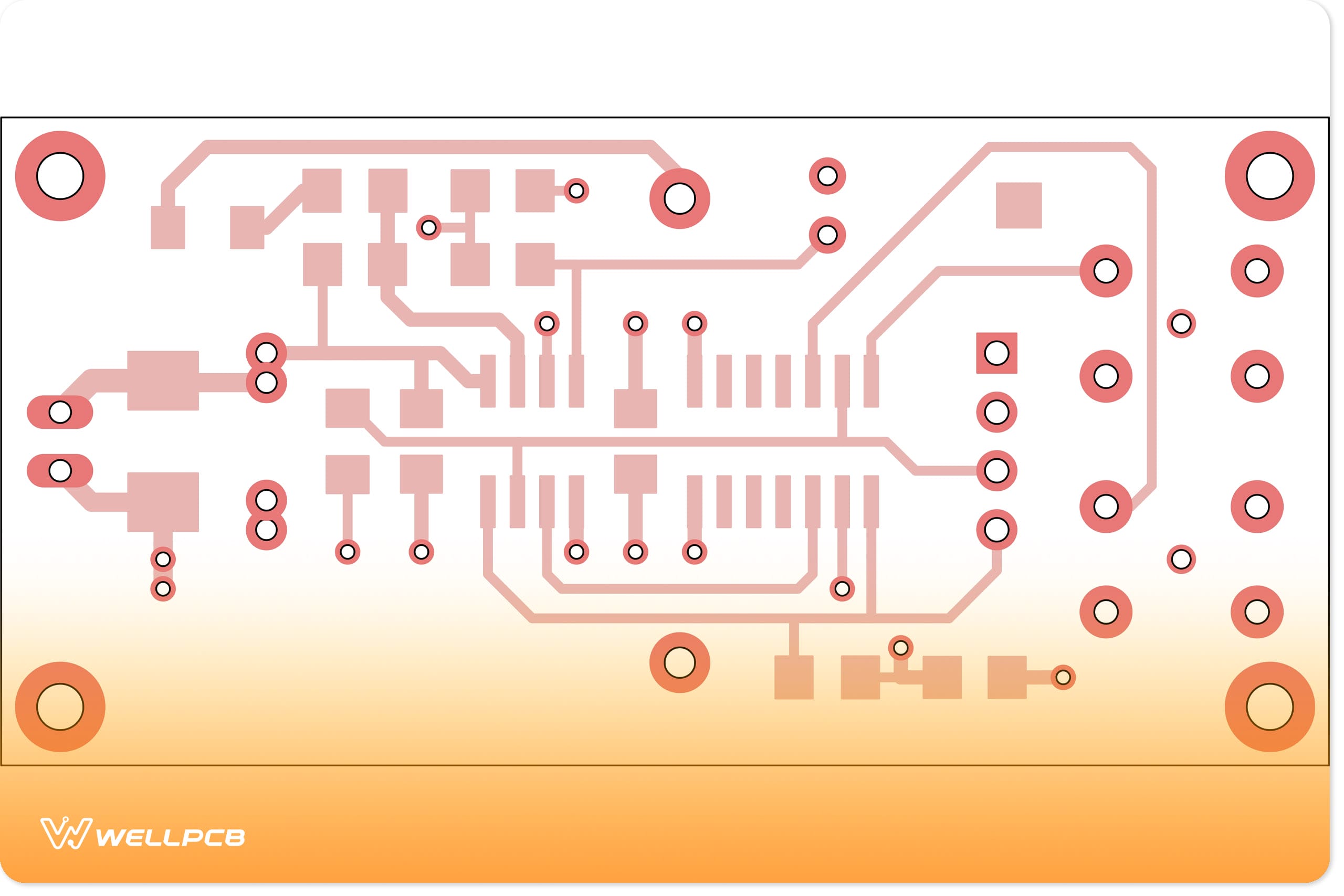

Printed circuit boards involve laminating four layers of material. They are a silkscreen, solder mask, copper layer, and substrate.

Manufacturers attach SMD LEDs to the surface of a PCB. As they pack many SMD devices into a small area, this increases the heat. Therefore, an LED PCB board uses a metal substrate to transfer heat away from heat-sensitive LEDs. This substrate is electrically insulated from the circuit by a dielectric material.

things that you need to consider when determining the best layout. Options such as Aluminum is a common choice for the metal substrate. It is durable, and its dimensions do not change when exposed to stress. Although Copper core PCB, or a mixture of specific metal alloys.

However, the Aluminum is not as thermally conductive as Copper, it is cheaper.

Choosing A LED PCB Manufacturer

When choosing a manufacturer, it is important to ensure they have relevant experience. The manufacture of LED PCBs is difficult. It requires surface mount processing knowledge and equipment.

- Ability To Meet Your Requirements

Make sure the LED PCB supplier can meet your production volumes and delivery requirements. Their costs should be reasonable given the specification and quality levels.

- A Customer/Supplier Partnership

The supplier should respond to your demands. Firstly, they should work with you to improve your LED PCB light products. And then, they should also help you drive down costs.

- A Quality Manufacturer

There is a lot to consider, including the type of LED. It is important to choose your manufacturer carefully to ensure the ongoing delivery of quality products.

Conclusion:

The advantages of LED lighting are clear and more applications are likely to switch to using LED PCBs in the future. When LED circuit boards are the right choice for your application, choose your manufacturer carefully.

Heat management is important, so select the right circuit board technology. Aluminum LED circuit boards have many advantages and are a common solution.

Find a manufacturer capable of overcoming the circuit board manufacturing challenges. They should be able to deliver a reliable product on time and at an acceptable cost.

If you have any questions, please get in touch.