Heavy Copper PCB Manufacturer & Supplier

WellPCB manufactures heavy copper PCBs for power-dense, thermally demanding environments with superior thermal conductivity, structural integrity, and electrical performance under thermal cycling.

We produce high-performance copper circuit boards capable of sustaining continuous high current loads for power electronics, industrial automation, and electric vehicle applications.

- Advanced manufacturing for exceptional heat dissipation and reliability

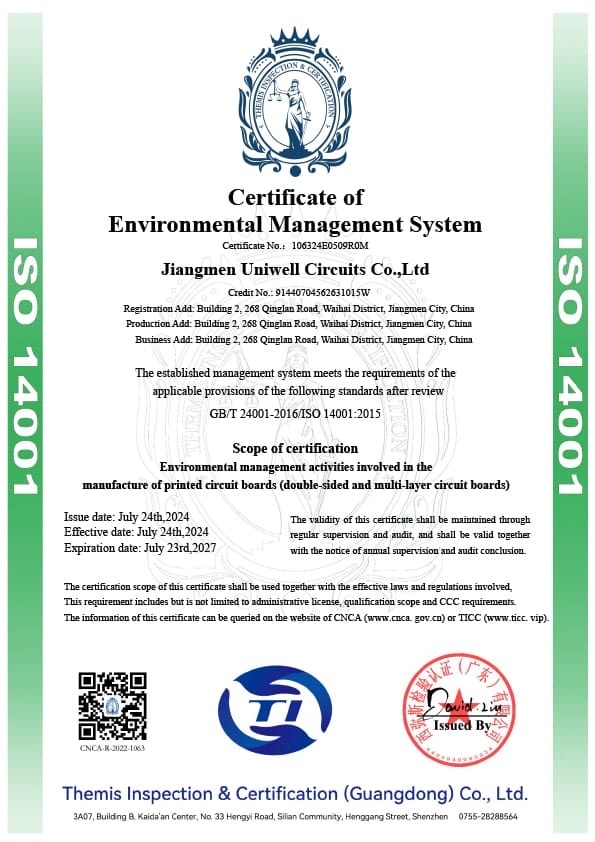

- Full compliance with IPC-6012 Class 2/3, RoHS, and ISO 9001/13485/14001 standards

- 18+ years of trusted multilayer circuit board expertise

ISO9001 ISO13485

ISO14001

IATF

16949

IPC-A-610H International

Certification

Fully Automated

AOI Inspection

- PCB Manufacturer

- Copper

- Heavy Copper

Introduction to Heavy Copper PCBs

WellPCB is a globally trusted heavy copper PCB manufacturer with over 18 years of experience in multilayer circuit board fabrication. We specialize in thick copper PCBs that support high current flow, advanced thermal dissipation, and rugged mechanical reliability.

Our heavy copper PCB manufacturing capabilities include copper thickness up to 1000 μm (≈28 oz) on inner and outer layers, precision etching, and step plating for controlled layer buildup. We utilize advanced step plating and differential etching techniques to achieve these thick copper layers while maintaining clean edge profiles.

We produce 2 to 16-layer copper circuit boards with comprehensive manufacturing processes including prepreg-bonded cores, copper foil lamination, high-speed copper plating, and deviation etching for optimal conductor formation.

Technical Specifications & Capabilities:

- Copper thickness options up to 1000 μm (≈28 oz)

- Up to 22.5 × 47.2 inch panel size and 40:1 aspect ratio support

- Substrate options include FR4, high Tg FR4, PTFE, aluminum, and ceramics for low CTE and high-temperature stability

We support a full range of substrates—including FR4, aluminum, ceramic, and PTFE—engineered for high-Tg stability, low dielectric loss, and minimal CTE mismatch.

Quality Control & Testing: Each copper PCB undergoes comprehensive validation including automated optical inspection (AOI), X-ray inspection for via and pad integrity, impedance control testing to verify signal performance across conductive copper layers, and electrical validation. All boards meet IPC-6012 Class 2/3, RoHS, and ISO 9001/13485/14001 requirements with full traceability.

Whether for power electronics, industrial automation, or electric vehicles, our heavy copper PCBs are designed to handle high current loads and deliver exceptional heat dissipation over extended thermal cycles.

Our Heavy Copper PCB Capabilities

WellPCB manufactures heavy copper PCBs with finished copper weights up to 28 oz/ft² on outer layers and 28 oz/ft² on inner layers, enabling continuous current flow beyond 50 to 100 A, depending on conductor geometry.

Our minimum trace width and spacing for 12 oz high copper weights are 8 mil, adjusted based on etch factor modeling to mitigate undercut and maintain dimensional fidelity.

Copper circuits are patterned using dry film photolithography and controlled differential etching, ensuring consistent copper thickness across dense routing regions.

Heavy copper PCBs are engineered with high-Tg materials (≥170°C), including FR4-TG180+, ceramic-filled PTFE, and polyimide composites, to handle high current loads with minimal CTE mismatch.

Thermal vias are deployed to route heat to copper planes or cold plates, supported by resin-coated or filled vias for mechanical stability. Our thermal modeling supports θJA reductions of up to 30% compared to standard PCBs.

Prepreg stacks are selected to balance Z-axis expansion and dielectric constant, with thermal performance validated through thermal shock cycling (eg. -40°C to +125°C, 1,000+ cycles).

We support 2 to 16 layer builds with sequential lamination and via structures, including stacked microvias (4 to 6 mil laser), blind and buried vias, and via-in-pad with copper fill.

Our plating achieves via wall copper thicknesses of ≥25 μm (1 mil), with aspect ratios up to 10:1 (eg. 0.008″ drill through 0.080″ board).

All via structures are thermally stress-tested per IPC-TM-650 standards to verify reliability under thermal expansion forces.

Material selections include aluminum-core for high-wattage thermal paths, copper-core for direct bonded copper PCBs, and PTFE for RF impedance control (Dk ~2.2, Df < 0.0015).

Standard FR4 (Tg130 to 180°C), polyimide, and ceramic substrates support diverse electrical, thermal, and mechanical demands.

These substrates are laminated using prepregs matched for glass transition temperature and CTE, ensuring cohesive bonding during multiple lamination cycles.

Copper deposition is executed using step plating and pulse plating techniques to manage uniformity across complex geometries.

In multi-thickness designs, deviation etching and panel-level thickness measurement (±10% tolerance) ensure consistent electrical characteristics.

For inner layer thick copper routing, we implement dual-pass plating to mitigate overetching, with plating bath control at 24 to 26°C and current densities between 20 and 30 ASF.

Each heavy copper PCB undergoes optical resolution verification (AOI, 5 μm resolution), X-ray cross-sectioning of vias and internal layers, E-testing for continuity/isolation, and impedance testing for transmission line verification.

Microsection analysis validates copper wall adhesion, plating thickness, and dielectric integrity, following IPC-6012 Class 2/3 performance classes.

Surface treatments include HASL (Sn63/Pb37, RoHS-compliant lead-free variants), ENIG (0.05 to 0.10 μm Au over 3 to 6 μm Ni), OSP, Immersion Tin (0.8 to 1.2 μm), Immersion Silver (0.15 to 0.35 μm), and ENEPIG.

Surface finish is matched to final assembly method (eg. reflow vs. wave solder) and environmental exposure constraints, including sulfur resistance for outdoor electronics.

Production supports rapid prototyping (as short as 72 hours for ≤ 12-layer builds) and batch runs up to 10,000+ units.

Each job includes full traceability (material lot, plating records, test logs), and is tracked under ISO 9001:2015 and IPC-A-610H standards.

Statistical process control (SPC) ensures consistency in copper thickness, drill registration, and solder mask alignment across all builds.

Why Choose WellPCB for Your Heavy Copper PCBs?

Deep Manufacturing Expertise

Advanced Test Infrastructure

<span data-metadata=""><span data-buffer="">Industrial Control Systems

Certified Quality & Compliance

Advanced Thermal Management

Competitive Pricing with Engineering Value

What is a Heavy Copper PCB?

A heavy copper PCB is a printed circuit board fabricated with copper thicknesses ranging from 4 oz/ft² to 20 oz/ft² (equivalent to 140 μm to 700 μm of finished copper). This exceeds the standard 1 oz/ft² (~35 μm) copper used in most PCBs and allows the board to handle continuous current loads up to and beyond 100 A, depending on trace width and temperature rise constraints.

These PCBs require specialized plating processes, including step plating to incrementally build up copper layers and differential etching to ensure edge definition on thick copper features.

What are the Characteristics of Heavy Copper PCBs?

Thick Conductive Copper Layers

These enable low-resistance current paths. The amount of current a copper circuit can safely carry depends on its cross-sectional area and allowable temperature rise, guided by IPC-2221 standards.

For example, a 200 μm copper trace at 5 mm width can safely carry over 60 A with a 20°C temperature rise in open air.

Support For Multi-Functional Integration

Heavy copper layers allow designers to route high-power and low-voltage control signals on the same PCB.

The result is reduced parasitic impedance, simplified interconnection, and enhanced system density, especially in DC-DC converters, EV battery systems, and industrial power control modules.

Superior Mechanical Performance

The thicker copper and reinforced via barrels significantly improve the mechanical fatigue resistance of plated through holes (PTHs) under thermal cycling.

WellPCB typically plates via walls to ≥25 μm thickness to support expansion-contraction from -40°C to +125°C environments.

Cost And Longevity Trade-Offs

While heavy copper PCBs involve higher fabrication costs due to extended plating time, increased copper consumption, and tighter etching controls, they eliminate the need for external busbars, thermal shields, or oversized traces.

This results in a more compact, reliable, and serviceable product with lower lifetime system cost.

PCB Copper Thickness Calculator

Determining the right copper thickness is important to optimize the current-carrying capacity and thermal dissipation of your heavy copper PCB. WellPCB’s copper thickness calculator uses IPC-2221 trace width formulas to correlate current, trace width, and temperature rise, helping engineers select the optimal copper weight, from 4 oz to 28 oz, for each layer.

Use this tool to:

- Calculate safe current flow through copper traces based on width, layer type, and ambient temperature.

- Estimate copper usage and cost per square foot for accurate project budgeting.

- Tailor copper selection to the electrical and thermal demands of your specific application.

What are the Design Considerations

for Heavy Copper PCBs?

Heavy copper PCB design demands precision across electrical, thermal, and mechanical domains due to the unique challenges presented by copper thicknesses ranging from 105 μm to 700 μm. Proper planning ensures reliability under high current loads and aggressive thermal cycling while maintaining manufacturability.

Trace Spacing and Width

Minimum spacing starts at 6 mils for 105 μm copper, increasing with thickness to avoid dielectric breakdown and shorting. For 210 μm copper, spacing may need to exceed 27 mils, with minimum trace widths of 12–25 mils based on the required current capacity and IPC-2221 guidelines.

Substrate Material and Thermal Stability

Select high-Tg base materials (>130°C) such as FR4-TG170+, PTFE, or ceramic for stability under thermal load. These materials must also exhibit low coefficients of thermal expansion (<17 ppm/°C) to prevent trace fracture or delamination from expansion mismatch during soldering and operation.

Copper Distribution and Fill Levels

Maintain even copper fill across layers to reduce mechanical stress and prevent Z-axis warping or void-induced delamination during press cycles. Use copper balancing techniques and avoid large open areas or highly localized trace clusters.

Prepreg and Laminate Selection

Use resin flow-optimized prepregs matched to copper volume to ensure void-free lamination and interlayer adhesion, especially in stackups with 6 oz+ copper. Simulation tools can assist in calculating optimal resin content and press cycle parameters.

Plating Process Control

Adjust galvanic plating parameters such as dwell time and current density to achieve uniform copper buildup on thick inner and outer layers. Step plating or pulse plating is recommended for builds with >4 oz copper per layer.

Solder Mask Application

Employ thick solder resist (>25 μm dry film) to reinforce mosaic edges, reduce flux ingress, and prevent mechanical erosion at the boundaries of copper features—especially critical on boards with high vibration exposure.

Thermal Path Optimization

Implement thermal vias, copper planes, and heat-spreading cores to manage ΔT under continuous current loads. Proper copper layer selection and thermal via density can significantly reduce junction-to-ambient thermal resistance.

Heavy Copper PCB Design Guidelines

Before finalizing a layout, match your baseline copper thickness to your application’s current and thermal requirements. These are reference values for spacing, path width, and material loss associated with different copper thicknesses.

| Criteria | 105 μm | 140 μm | 175 μm | 210 μm |

|---|---|---|---|---|

| Loss (mils/mm) | 3 / 0.08 | 5 / 0.13 | 6 / 0.15 | 7 / 0.18 |

| Minimum Spacing (mils) | 13 | 15 | 20 | 27 |

| Minimum Trace Width (mils) | 12 | 14 | 18 | 25 |

What is the Heavy Copper PCB

Manufacturing Process?

The fabrication of heavy copper PCBs involves specialized techniques beyond standard PCB manufacturing due to the challenges of etching and plating thick copper layers (≥105 μm) while preserving dimensional accuracy and electrical integrity.

Differential Etching

Enables the controlled removal of copper from areas with varying thicknesses on the same panel, important for boards combining 4 oz and 10 oz copper layers.

This prevents trace over-etching in thinner regions while preserving heavy copper features.

Step Plating

A sequential electroplating process that incrementally builds copper thickness in layers.

This method improves layer uniformity, reduces internal stress, and achieves consistent via wall copper ≥25 μm, even in high-aspect-ratio designs.

Deviation Etching

Utilizes tightly calibrated etch-back profiles to preserve trace geometry and sidewall quality, minimizing undercut on thick copper traces and maintaining signal fidelity for high-speed or impedance-controlled paths.

High-Speed Plating

Employs optimized bath agitation and controlled current density (20 to 30 ASF) to deposit thick copper layers efficiently while maintaining homogenous grain structure and adhesion across the PCB surface.

WellPCB’s Quality Assurance Protocols

AOI (Automated Optical Inspection)

High-resolution camera systems (≤5 μm accuracy) scan each board for conductor misalignment, open circuits, and surface defects post-etch and post-solder mask.

E-Test (Electrical Testing)

Validates 100% net continuity and insulation integrity across inner and outer layers using either flying probe or dedicated fixtures, depending on lot size.

X-Ray Inspection

Non-destructive imaging is used to confirm via fill consistency, inner-layer alignment, and solder joint voiding, especially important for boards using via-in-pad or heavy copper-filled structures.

Impedance Control Testing

Boards with controlled impedance features are tested to maintain ±10% tolerance, with adjustments in dielectric thickness, copper width, and resin content based on field solver simulations and in-line test feedback.

How to Order Your Heavy Copper PCB

in 5 Easy Steps

PCB Manufacturing and Order Review Process

Submit Your PCB Design

Upload your Gerber files or use our easy online PCB design tool to create your board layout. Make sure your files are complete and correctly formatted to ensure smooth processing and production accuracy.

Select Your PCB Specifications

Customize your order by choosing the technical specifications—number of layers, board dimensions, thickness, copper weight, solder mask color, surface finish, and more. Our intuitive interface helps you configure everything based on your project’s needs.

Get an Instant Quote

Once your design and specs are in place, you'll receive a transparent, instant quote. Pricing updates in real time as you modify options, so you can adjust your selections to match your budget before placing the order.

Confirm Order & Make Payment

Review your entire order for accuracy, including file previews and selected specs. After confirmation, proceed to secure checkout and choose your preferred payment method. You’ll receive an email confirmation with order details.

Production & Delivery

Your PCB moves into production immediately. We’ll keep you updated throughout the manufacturing process. Once completed, your boards are carefully packed and shipped to your door, with tracking information provided for your convenience.

WellPCB is trusted by millions of

businesses and innovators.

Why Choose WellPCB?

WellPCB stands out among USA PCB manufacturers by delivering superior quality, advanced solutions, and unmatched reliability. With years of experience serving global markets, WellPCB has earned a reputation as one of the top PCB manufacturers in USA.

WellPCB specializes in multilayer PCBs for advanced electronic applications. You can order these boards with $100 off using our special offer, providing high complexity at competitive rates for demanding projects.

Hommer Zhao

Founder and Chief Editor – Hommer Zhao

Welcome! I’m Hommer Zhao, the founder and Chief Editor of WellPCB. With years of experience in the PCB industry, I’m committed to making sure our content is both accurate and helpful. We’re proud to serve a growing community of over 4,000 customers worldwide, and our goal is to provide you with the best resources and support. Your satisfaction is our top priority, and we’re here to help you every step of the way!

Jesse Holland

Technical Manager – Jesse Holland

Hi, I’m Jesse Holland, an Engineer and Technical Manager at WellPCB. With years of experience in PCB design and engineering, I’m here to ensure that every project we work on meets the highest technical standards. I lead our team, focusing on precision and innovation, collaborating closely with clients to provide tailored solutions and expert guidance. Whether you’re facing a complex design challenge or need advice on technical aspects, I’m here to ensure your project is a success from start to finish.

Nathan Jensen

Purchasing Manager – Nathan Jensen

Hi, I’m Nathan Jenson, the Purchasing Manager at WellPCB. I’m responsible for sourcing the best materials and components to ensure our products meet the highest quality standards. With my extensive experience in procurement, I work closely with suppliers to secure reliable and cost-effective solutions while maintaining strong relationships to support our operations. I aim to ensure every project runs smoothly by providing the resources needed to deliver on time and to your satisfaction.

Emma

Sales Manager – Emma

Hey, I am Emma, sales manager at WellPCB. I studied electronic science and technology at university and have served customers for PCB and PCB Assembly service for several years.

I enjoy communicating with customers and our technicians to solve problems, and customers always say, "It's great to have you onboard".

It is my pleasure and honour to be helpful. Contact me now, and you'll know.

Bella and Cassiel

Sales Representatives – Bella and Cassiel

We’re Bella and Cassiel, your dedicated sales representatives at WellPCB. With our extensive knowledge of the PCB industry, we’re here to provide exceptional service and support. We take the time to understand your unique needs and are always ready to offer tailored solutions and advice. Whether you need product recommendations, assistance with your orders, or simply have a question, we’re here to ensure your experience is smooth and seamless at every step.

Mandy and Wendy

Sales Representatives – Mandy and Wendy

We’re Mandy and Wendy, your friendly sales representatives at WellPCB. Passionate about helping our customers, we bring a wealth of experience in the PCB industry to provide you with the best solutions and service. We take pride in building strong relationships with our clients, understanding their specific needs, and offering personalised support to ensure their satisfaction. Whether you’re looking for advice, product information, or assistance with any part of your order, we’re here to make your experience as smooth and efficient as possible.

Our Team

Our skilled engineers and technicians bring expertise and precision to every PCB assembly project. Committed to quality, efficiency, and innovation, our team ensures every order meets the highest UL, IPC, ROHS & REACH standards, delivering reliable solutions tailored to your needs.

- Founder and Chief Editor – Hommer Zhao

- Technical Manager – Jesse Holland

- Purchasing Manager – Nathan Jensen

- Sales Manager – Emma

- Sales Representatives – Bella and Cassiel

- Sales Representatives – Mandy and Wendy

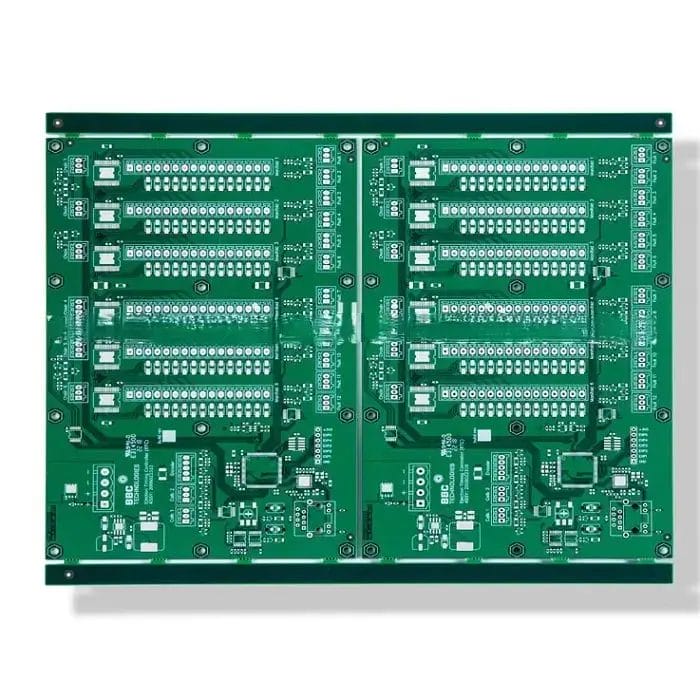

Heavy Copper PCB Case Studies

Case Study

This project features a 6–8 layer heavy copper PCB designed for high-current and high-reliability applications in medical electronics. Built with 15-ounce copper circuit layers, it provides exceptional thermal conductivity, current-carrying capacity, and mechanical durability, all essential for life-critical medical systems.

Product Specifications:

- Main Control Chip: STM32 MCU (various series, ARM Cortex-M)

- Layer Count: 6–8 layers

- Board Thickness: 1.6 mm

- Copper Weight: 15 oz (≈525 µm) on selected power layers

- Base Material: High-Tg FR4 (≥170°C recommended)

- Application: Medical equipment (power modules, controllers, signal processing units)

Case Study

This project centers around a 14-layer thick copper coil PCB with 4oz copper on all layers and a finished thickness of 3.5mm. Engineered for high current handling, magnetic coil integration, and power electronics, the board utilizes via-in-pad technology and a blind via structure (L1–7, L8–14) to deliver efficient signal and power transfer with minimized footprint and resistance. Ideal for magnetic systems, transformer boards, and power converters.

Product Specifications:

- Board Type: 14-layer thick copper coil PCB

- Finished Thickness: 3.5 mm

- Copper Thickness: 4 oz (≈140 µm) on both inner and outer layers

- Layer Stack: 14 layers

- Blind Hole Structure: L1–L7 and L8–L14

- Via Technology: Via-in-pad (VIP)

- Material: High-Tg FR4 or composite high-temperature laminate

- Application: Power inductors, transformers, motor drives, industrial automation

Case Study

This project highlights a 4-layer heavy copper PCB designed for high-current, thermally demanding applications. Built with 105 μm copper (3 oz), the board offers exceptional thermal management, current handling, and durability. It features FR4 TG170 material, ensuring stability under high thermal cycles, and an immersion silver surface finish, making it ideal for both power and signal applications requiring strong solderability and good conductivity.

Product Specifications:

- Layer Count: 4 layers

- Board Thickness: 1.6 mm

- Base Material: FR4 TG170 (High-Tg ≥170°C)

- Copper Thickness: 105 μm (3 oz) on all layers

- Surface Finish: Immersion Silver

- Min Line Width/Spacing: 8 mil / 10 mil

- Application Areas: Power supply boards, industrial drives, motor control, energy systems

Client Feedback On Heavy Copper PCBs

As an R&D manager, I have had an outstanding experience working with WELL-PCB. For many years, our company has entrusted them with the production, assembly, and programming of the boards developed in our R&D unit, and they have consistently exceeded our expectations.

Hamid Reza Moshayedi

R&D Manager

Their work is very impressively perfect. Today, when they check our company PCB board after assemble. They found a fake short point which many engineers has never found in the past years. But that is just designed so. The PCB board quality is excellent. Their service is also excellent.

MikeZ

My friend introduced WellPCB to me, the first try, a little look forward to. I ordered a 47*72 10ps PCB, and I can’t wait to receive my PCB. So I used expedited service and received my PCB in three days. I tested and soldered the PCB, Quality is really good, silkscreen, plating also great.

Warren Cliton

Heavy Copper PCB FAQs

How thick is the copper on a standard PCB?

A standard PCB typically features 1 oz/ft² of copper, corresponding to a finished thickness of 35 μm (±10%). In some designs, especially for enhanced thermal or current-carrying needs, the finished copper may be increased to 2 oz/ft² (≈70 μm) through electroplating. This thickness applies to internal and external layers unless specified differently in the board stack-up.

How do I choose the right thickness of PCB copper?

Selecting the appropriate copper thickness depends on three primary parameters:

- Current-carrying requirement (Amps)

- Permissible temperature rise (°C)

- Trace width and layer type (inner vs. outer)

Use IPC-2221 guidelines or a copper thickness calculator to determine the required cross-sectional area. For example, a 5 mm wide trace on an outer layer with 105 μm copper can safely carry ~50 to 60 A with a 20°C temperature rise in free air. Consider using thicker copper (≥4 oz/ft²) when you need high power density, thermal stress, or mechanical reinforcement.

What is base copper weight?

Base copper weight refers to the initial thickness of the copper foil laminated onto the PCB core or prepreg before any plating is performed. Common base copper weights are 0.5 oz, 1 oz, or 2 oz/ft², equivalent to 17.5 μm, 35 μm, or 70 μm, respectively. During fabrication, this base layer is thickened via electroplating, particularly in PTHs (plated through holes), to meet final design requirements.

What are the benefits of heavy copper PCBs?

Heavy copper PCBs, typically defined as PCBs with ≥3 oz/ft² copper per layer, offer several key advantages:

- High current carrying capacity: Wide, thick copper traces reduce resistive losses and enable current flow >100 A in some designs.

- Improved heat dissipation: Greater copper mass lowers thermal resistance (θJA), helping to transfer heat to external heatsinks or thermal vias.

- Enhanced mechanical strength: Thick copper walls reinforce via barrels and connector pads, improving reliability under thermal cycling and vibration.

- System-level simplification: Supports power and control circuits on a single PCB, reducing wiring, interconnect losses, and overall footprint.

- Long-term durability: Withstands extreme temperature cycling and overload conditions better than standard copper PCBs.

Ready to Partner with a Proven Heavy Copper PCB Manufacturer?

WellPCB delivers the engineering precision and reliability you need from a trusted heavy copper PCB manufacturer. With copper weights up to 20 oz, IPC Class 3 compliance, and full-stack DFM support, we’re ready to manufacture high-performance boards that meet your most demanding electrical and thermal specifications.