PCB Board Manufacturer Top PCB Fabrication Company

- 72-hour lead time for standard 1 to 12-layer PCB prototypes

- PCB fabrication with copper weights up to 28 oz, HDI support, and up to 64-layer stackups

- ISO 9001, RoHS, and UL-certified PCB manufacturer

- Full turnkey PCB assembly services

ISO9001 ISO13485

ISO14001

IATF

16949

IPC-A-610H International

Certification

Fully Automated

AOI Inspection

- Home

- PCB Manufacturer

Full-Cycle PCB Manufacturing

You Can Rely On

At WellPCB, we manage every stage of your PCB project under one roof, from DFM optimization and material selection to fabrication, assembly, testing, and global delivery.

By keeping all core processes in-house across our ISO-certified facilities, we maintain strict control over quality, lead time, and cost, ensuring your printed circuit boards meet the highest industry standards from prototype to production.

Technical Capabilities & Specifications:

Our advanced fabrication capabilities include complex rigid, flex, and rigid-flex printed circuit boards with capabilities from 1 to 64 layers. Our in-house fabrication lines handle precision specifications including 1.8 mil trace/space, 3 mil microvias, and PCB fabrication with copper weights up to 28 oz with HDI support and up to 64-layer stackups.

We offer comprehensive surface finishes including HASL, Lead free HASL, ENIG(+ G/F), Immersion silver/Tin, OSP, ENEPIG, and bare copper to meet diverse application requirements.

Our Capabilities As a PCB Manufacturer

We support PCB stackups from 1 to 64 layers, including complex high-density interconnect (HDI) architectures such as 1+n+1 through 8+n+8 and 18L any-layer interconnect structures.

Our via technologies include blind, buried, via-in-pad, stacked microvias, and via-in-via designs, supporting an aspect ratio of up to 40:1 for robust multilayer PCB performance in high-reliability environments.

| Feature | Specification |

|---|---|

| Supported Layer Count | 1 to 64 layers |

| HDI Stack-Up Architectures | Configurations such as 1+n+1, 2+n+2, up to 8+n+8; 18L any-layer interconnect supported. |

| Via Technologies | Blind vias, buried vias, stacked microvias (laser-formed, 4 to 6 mil), via-in-pad (VIP), via-in-via, skip vias. Supports staggered or stacked via structures with copper-filled and resin-filled options. Laser via diameter: 3 to 6 mil (0.075 to 0.15 mm); mechanical via minimum: 0.1 mm. |

| Maximum Aspect Ratio | Up to 40:1 for high-reliability multilayer builds. |

| Minimum Drill Size | Mechanical: 0.1 mm; Laser: 3 to 6 mil (0.076 to 0.15 mm). |

| Finished Board Thickness | 0.1 to 12 mm. |

| Via Copper Plating Thickness | ≥25 µm (1 mil); uniformity within ±10%. |

| Dielectric Thickness Control | Prepreg layers down to 0.075 mm ±10% precision. |

| Stack-Up Symmetry Options | Symmetrical and bookbinder (asymmetrical) stack-ups are supported. |

| Impedance Control Support | Supported on specified layers; single-ended and differential; tolerance ±5% |

Our fabrication capabilities achieve trace widths and spacings down to 1.8 mil (0.045 mm), ideal for fine-pitch components and HDI layouts. We support PTH diameters down to 0.08 mm, minimum routed slot widths of 0.5 mm, and silkscreen minimum line widths of 4 mil.

Solder mask dam resolution is 3 mil, with routing tolerance maintained within ±0.04 mm for precise board outlines and mechanical features.

We manufacture PCBs with finished copper weights ranging from 0.5 oz to 28 oz (≈1000 μm), supporting both signal integrity and high current applications.

Final board thickness options span from 0.1 mm to 12 mm, enabling fabrication of ultra-thin flex boards to thick, heavy-copper PCBs for power electronics.

WellPCB offers a broad spectrum of PCB base materials, including standard FR4, high-Tg FR4, halogen-free, and CEM-3 for general applications.

For specialized performance, we fabricate with Rogers RO4003 and RO4350 for RF circuits, ceramic substrates for thermal stability, polyimide for flexible PCBs, and metal-core materials such as aluminum and copper for LED and power conversion boards.

We support all mainstream and advanced surface finishes, including HASL (leaded and lead-free), ENIG (Electroless Nickel Immersion Gold), ENEPIG, OSP (Organic Solderability Preservative), immersion silver, and immersion tin.

Selective finish combinations such as ENIG+OSP are available for mixed component assemblies, gold fingers, and edge connectors.

Solder mask is available in green, black, blue, white, yellow, and matte variants with hardness up to 6H and flammability rating UL94V-0.

Our high-resolution legend printing uses white, yellow, or black inks with a minimum line width of 4 mil for clear component markings and assembly labels.

All boards undergo 100% electrical testing via flying probe or bed-of-nails methods. Additional reliability testing includes impedance control with ±3 Ω tolerance, thermal shock testing, and warp/twist validation ≤0.5%.

We provide IPC-Class 2 or Class 3 inspection and reporting upon request for applications requiring elevated reliability standards.

WellPCB is certified to ISO 9001:2015 (Quality), ISO 14001:2015 (Environmental), and IATF 16949:2016 for automotive-grade PCBs.

We also hold ISO 13485:2016 certification for medical device compliance. All PCBs are UL-listed, RoHS and REACH compliant, and manufactured to IPC-A-600 and IPC-6012 quality standards.

Why Choose WellPCB?

In-House Production for Full Process Contro

Certified to Global Standards

True One-Stop Electronic Manufacturing

Transparent Quoting & No Hidden Costs

Engineering-Grade Technical Support

Rapid Prototyping with Scale-Up Continuity

Our PCB Manufacturing Process

We manufacture various custom wiring harnesses engineered to meet the electrical, environmental, and mechanical demands of specialized applications across multiple industries.

Gerber Review & CAM Optimization

All incoming Gerber files undergo Design for Manufacturability (DFM) checks and CAM engineering, including layer alignment, drill/rout verification, netlist integrity checks, soldermask clearance review, and impedance modeling.

Inner Layer Imaging & Etching

Photoresist imaging uses LDI (Laser Direct Imaging) systems to define inner-layer copper patterns. Etching removes exposed copper, achieving line/space resolutions as tight as 1.8 mil.

AOI for Inner Layers

Automated Optical Inspection (AOI) detects short/open circuits, line width variations, and registration defects on each inner layer prior to lamination, ensuring early defect containment.

Multilayer Lamination with Prepreg

Layer stackups are consolidated using high-Tg FR4 or specialty prepreg under controlled pressure/temperature cycles. Up to 64 layers are supported, with impedance-controlled dielectric thickness targeting ±10%.

Drilling (Mechanical/Laser)

High-precision CNC drills (±0.025 mm accuracy) form through-holes and vias down to 0.08 mm. For HDI boards, CO₂/UV laser drilling enables stacked microvias, blind/buried vias, and via-in-pad structures.

Electroless Copper Deposition

A catalytic copper layer is chemically deposited to create a conductive base in all hole walls. This seed layer is essential for ensuring uniform subsequent electrolytic plating.

Outer Layer Pattern Plating

Electrolytic copper plating is performed with controlled current density (20 to 30 ASF) to thicken traces and via barrels. Nickel/gold plating may also be applied to selected areas.

Outer Layer Etching

Outer layers are developed using photolithography and etching to define final circuit patterns. All conductive paths are verified against the netlist and CAM data.

Soldermask Application

Liquid photoimageable (LPI) soldermask is screen-coated or spray-applied, then UV-imaged and developed to expose pads and vias. Supported colors include green, black, blue, white, yellow, and matte options.

Surface Finish Deposition

Surface finishes such as ENIG, ENEPIG, HASL (leaded/lead-free), OSP, immersion silver, and tin are applied to exposed pads. These finishes ensure solderability and long-term oxidation resistance.

Silkscreen Printing

High-resolution legend ink is printed using screen or inkjet methods, with white, yellow, or black options. Line widths down to 4 mil ensure clear component identification.

100% Electrical Testing

All boards undergo electrical testing via flying probe or bed-of-nails to verify netlist compliance, continuity, and isolation. High-voltage and high-resistance leakage testing can be applied for Class 3 builds.

Profiling, V-Scoring, Routing

PCBs are separated using mechanical routing, V-score, or punch tooling. Profiling tolerance is maintained at ±0.04 mm to match mechanical enclosure requirements.

Visual QA Inspection

Final visual inspection checks for soldermask integrity, surface finish consistency, silkscreen legibility, and board edge quality. IPC-A-600 criteria guide acceptance levels.

Anti-Static Packaging

Boards are vacuum-sealed in anti-static packaging with desiccant packs and humidity indicators. Panel or single-unit packaging is available per order specs.

Certified Delivery & Documentation

Each shipment includes test reports, CoC (Certificate of Conformance), dimensional inspection results, and RoHS/REACH compliance documentation as required.

Industries We Serve As a PCB Manufacturer

WellPCB supplies printed circuit boards to various technology-driven industries with distinct electrical, mechanical, and environmental requirements. Our in-house PCB fabrication and assembly services are built to meet strict regulatory, performance, and lifecycle standards, from impedance-critical RF boards to rugged, thermally-managed automotive PCBs.

Automotive & EV

Telecom & RF

Aerospace / Defense

Medical Devices

Industrial Controls

Consumer Electronics

How to Order Your PCB

in 5 Easy Steps

PCB Manufacturing and Order Review Process

Submit Your PCB Design

Upload your Gerber files or use our easy online PCB design tool to create your board layout. Make sure your files are complete and correctly formatted to ensure smooth processing and production accuracy.

Select Your PCB Specifications

Customize your order by choosing the technical specifications—number of layers, board dimensions, thickness, copper weight, solder mask color, surface finish, and more. Our intuitive interface helps you configure everything based on your project’s needs.

Get an Instant Quote

Once your design and specs are in place, you'll receive a transparent, instant quote. Pricing updates in real time as you modify options, so you can adjust your selections to match your budget before placing the order.

Confirm Order & Make Payment

Review your entire order for accuracy, including file previews and selected specs. After confirmation, proceed to secure checkout and choose your preferred payment method. You’ll receive an email confirmation with order details.

Production & Delivery

Your PCB moves into production immediately. We’ll keep you updated throughout the manufacturing process. Once completed, your boards are carefully packed and shipped to your door, with tracking information provided for your convenience.

All Circuit Boards and Assembly Services

WellPCB is trusted by millions of

businesses and innovators.

Why Choose WellPCB?

WellPCB stands out among USA PCB manufacturers by delivering superior quality, advanced solutions, and unmatched reliability. With years of experience serving global markets, WellPCB has earned a reputation as one of the top PCB manufacturers in USA.

WellPCB specializes in multilayer PCBs for advanced electronic applications. You can order these boards with $100 off using our special offer, providing high complexity at competitive rates for demanding projects.

Hommer Zhao

Founder and Chief Editor – Hommer Zhao

Welcome! I’m Hommer Zhao, the founder and Chief Editor of WellPCB. With years of experience in the PCB industry, I’m committed to making sure our content is both accurate and helpful. We’re proud to serve a growing community of over 4,000 customers worldwide, and our goal is to provide you with the best resources and support. Your satisfaction is our top priority, and we’re here to help you every step of the way!

Jesse Holland

Technical Manager – Jesse Holland

Hi, I’m Jesse Holland, an Engineer and Technical Manager at WellPCB. With years of experience in PCB design and engineering, I’m here to ensure that every project we work on meets the highest technical standards. I lead our team, focusing on precision and innovation, collaborating closely with clients to provide tailored solutions and expert guidance. Whether you’re facing a complex design challenge or need advice on technical aspects, I’m here to ensure your project is a success from start to finish.

Nathan Jensen

Purchasing Manager – Nathan Jensen

Hi, I’m Nathan Jenson, the Purchasing Manager at WellPCB. I’m responsible for sourcing the best materials and components to ensure our products meet the highest quality standards. With my extensive experience in procurement, I work closely with suppliers to secure reliable and cost-effective solutions while maintaining strong relationships to support our operations. I aim to ensure every project runs smoothly by providing the resources needed to deliver on time and to your satisfaction.

Emma

Sales Manager – Emma

Hey, I am Emma, sales manager at WellPCB. I studied electronic science and technology at university and have served customers for PCB and PCB Assembly service for several years.

I enjoy communicating with customers and our technicians to solve problems, and customers always say, "It's great to have you onboard".

It is my pleasure and honour to be helpful. Contact me now, and you'll know.

Bella and Cassiel

Sales Representatives – Bella and Cassiel

We’re Bella and Cassiel, your dedicated sales representatives at WellPCB. With our extensive knowledge of the PCB industry, we’re here to provide exceptional service and support. We take the time to understand your unique needs and are always ready to offer tailored solutions and advice. Whether you need product recommendations, assistance with your orders, or simply have a question, we’re here to ensure your experience is smooth and seamless at every step.

Mandy and Wendy

Sales Representatives – Mandy and Wendy

We’re Mandy and Wendy, your friendly sales representatives at WellPCB. Passionate about helping our customers, we bring a wealth of experience in the PCB industry to provide you with the best solutions and service. We take pride in building strong relationships with our clients, understanding their specific needs, and offering personalised support to ensure their satisfaction. Whether you’re looking for advice, product information, or assistance with any part of your order, we’re here to make your experience as smooth and efficient as possible.

Our Team

Our skilled engineers and technicians bring expertise and precision to every PCB assembly project. Committed to quality, efficiency, and innovation, our team ensures every order meets the highest UL, IPC, ROHS & REACH standards, delivering reliable solutions tailored to your needs.

- Founder and Chief Editor – Hommer Zhao

- Technical Manager – Jesse Holland

- Purchasing Manager – Nathan Jensen

- Sales Manager – Emma

- Sales Representatives – Bella and Cassiel

- Sales Representatives – Mandy and Wendy

Our PCB Manufacturer Case Studies

Case Study

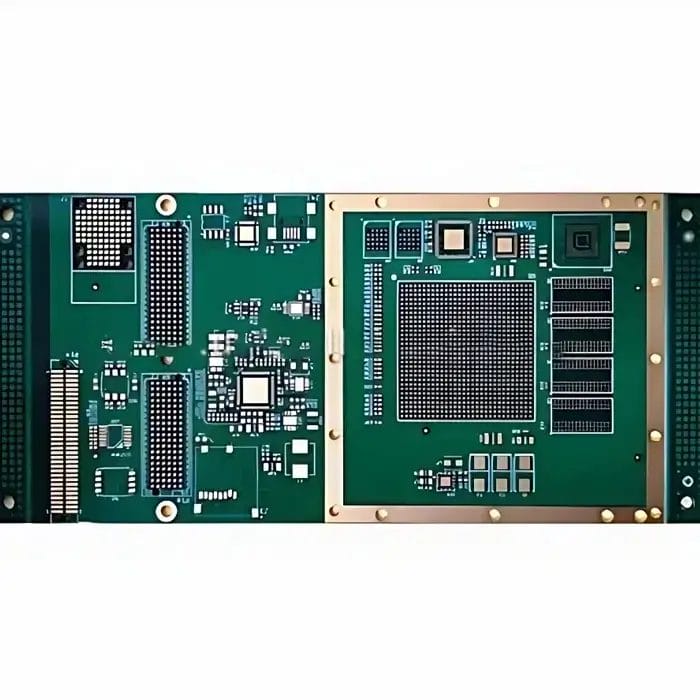

This 16-layer HDI (High-Density Interconnect) PCB is designed for complex electronic systems requiring high-speed signal transmission, dense interconnect routing, and multi-level via structures. It supports ultra-fine trace geometry and advanced stacked via architecture, ideal for applications like network equipment, AI computing boards, and advanced medical or aerospace electronics.

Product Specifications:

- Board Type: 16-layer HDI PCB

- Board Thickness: 1.8 mm

- Inner Layer Spacing: 0.127 mm (127 µm)

- Via Structure: L1–2, L2–3, L1–3, L2–7, L2–15, L15–16

- Line Width / Line Space: 0.076 / 0.076 mm (≈3 mil / 3 mil)

- Material: High-speed/low-loss laminate (e.g., Megtron 6, Isola I-Speed, etc.)

- Copper Thickness: Typically ½ oz inner, 1 oz outer (customizable)

- Surface Finish: ENIG / OSP / Immersion Silver (varies by application)

- Impedance Control: Yes (±10% tolerance for differential pairs)

- Application: AI, servers, data centers, telecom, aerospace

Case Study

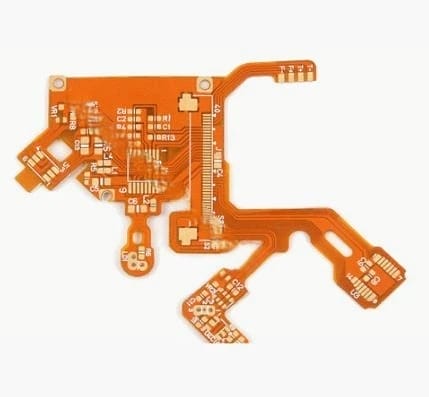

This project involves a high-precision multi-layer flexible board developed for use in LCD connectors, focusing on flexibility, signal integrity, and mechanical durability for the flexible connector interface in electronic devices like LCD screens. It includes a multi-layer structure with precise surface finishes and materials to support high-frequency signals while maintaining flexibility and reliability.

Product Specifications:

Material Structure:- Double-sided adhesive

- Low-loss yellow covering film

- Core buildup: (line copper + glue + high-frequency medium polyimide base material + glue + line copper)

- Outer layers: Low-loss yellow covering film

- Flexibility Requirements: Designed for free bending and winding

- Positional Accuracy (Male Component): ±0.03 mm tolerance

- Thickness: 0.15 mm

- Reinforcement: Front and back reinforced with 0.15 mm steel sheets

- Solder coating

- Plug plating

- Covering layer application

- Film-covered type assembly

- Resistance and welding type shielding torsion

- Surface Treatment: ENIG (Electroless Nickel Immersion Gold, 1 to 2 microinches)

- Minimum Line Width / Spacing: 0.06 mm / 0.09 mm

- Application: Connector components for LCD modules

Case Study

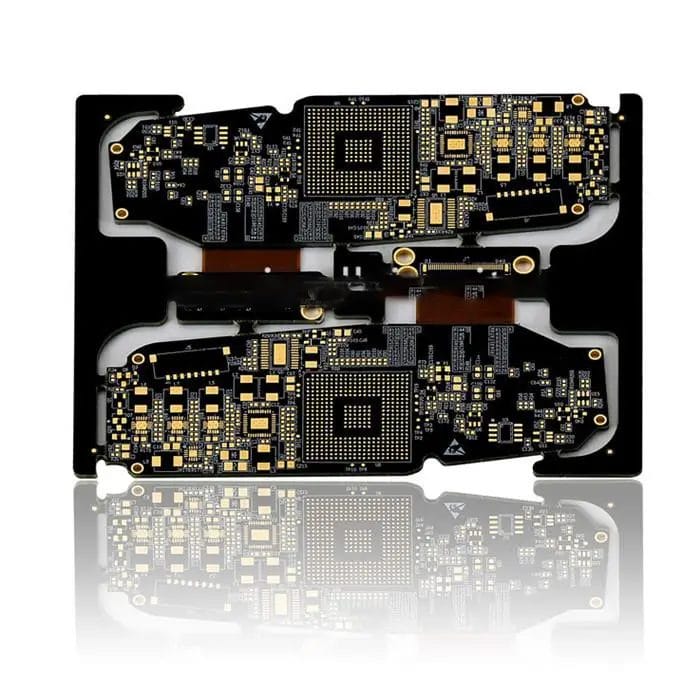

This 10-layer rigid-flex PCB is engineered for smartphone motherboards, integrating high-density routing, multiple interconnects, and flexible sections for space-saving, compact, and lightweight device architecture. Designed for advanced mobile electronics, it offers excellent signal integrity, fine-line capabilities, and durability under thermal and mechanical stress.

Product Specifications:

- Board Type: 10-layer rigid-flex PCB

- Total Thickness: 1.5 mm

- Line Width / Line Space: 3 mil / 4 mil (≈75 µm / 100 µm)

- Solder Bridge Width: 5 mil (≈125 µm)

- Flexible Layers: Polyimide (PI) with rolled annealed copper

- Rigid Layers: FR-4 (high Tg, halogen-free optional)

- Via Type: Blind and buried via (optional for HDI)

- Application: Smartphone motherboards, display drivers, power modules

Client Feedback About Our PCB Manufacturer Services

As an R&D manager, I have had an outstanding experience working with WELL-PCB. For many years, our company has entrusted them with the production, assembly, and programming of the boards developed in our R&D unit, and they have consistently exceeded our expectations.

Hamid Reza Moshayedi

R&D Manager

Their work is very impressively perfect. Today, when they check our company PCB board after assemble. They found a fake short point which many engineers has never found in the past years. But that is just designed so. The PCB board quality is excellent. Their service is also excellent.

MikeZ

My friend introduced WellPCB to me, the first try, a little look forward to. I ordered a 47*72 10ps PCB, and I can’t wait to receive my PCB. So I used expedited service and received my PCB in three days. I tested and soldered the PCB, Quality is really good, silkscreen, plating also great.

Warren Cliton

PCB Manufacturer FAQs

What’s the minimum trace width you support?

We support minimum trace/space dimensions of 1.8 mil (0.045 mm), suitable for fine-pitch HDI and RF applications.

Can you support custom stackups with impedance modeling?

Yes, we provide custom stackup diagrams with dielectric spacing and material data targeting ±3 Ω impedance control, verified through simulation and impedance testing.

Do you provide IPC Class 3 boards?

Yes, we support IPC Class 2 and Class 3 production standards, including inspection protocols and documentation for high-reliability applications.

What is your copper capacity?

We offer finished copper thicknesses up to 1000 μm (approximately 28 oz), supporting high-current and power distribution needs.

What certifications do your factories hold?

Our facilities are certified to ISO 9001:2015, ISO 14001:2015, ISO 13485:2016, and IATF 16949:2016. We also meet UL, RoHS, REACH, and IPC-6012 compliance requirements.

Do you require a minimum order quantity?

No. We support PCB prototype fabrication starting from a single unit, with the same process quality and documentation used for production runs.

Get $100 Off Your First Order with a World-Class

PCB Manufacturer

Partner with WellPCB for high-quality PCB prototype and fabrication services backed by full in-house control, global compliance, and engineering-grade precision. Whether you need a single prototype or a production-scale run, we’re ready to deliver.