Contents

- 1 What is Purple PCB

- 2 Why Select a Purple PCB?

- 3 How are Purple PCBs Created?

- 4 Best Material for Purple PCB Fabrication

- 5 Different Types of Purple PCB

- 6 Plating Methods for Purple PCBs

- 7 Difference Between Standard Purple PCBs and Heavy Copper Purple PCBs

- 8 Alternatives to White Silkscreen Print for Purple PCBs

- 9 Advantages and Disadvantages of Purple PCBs

- 10 How to Make Color Commercial PCBs

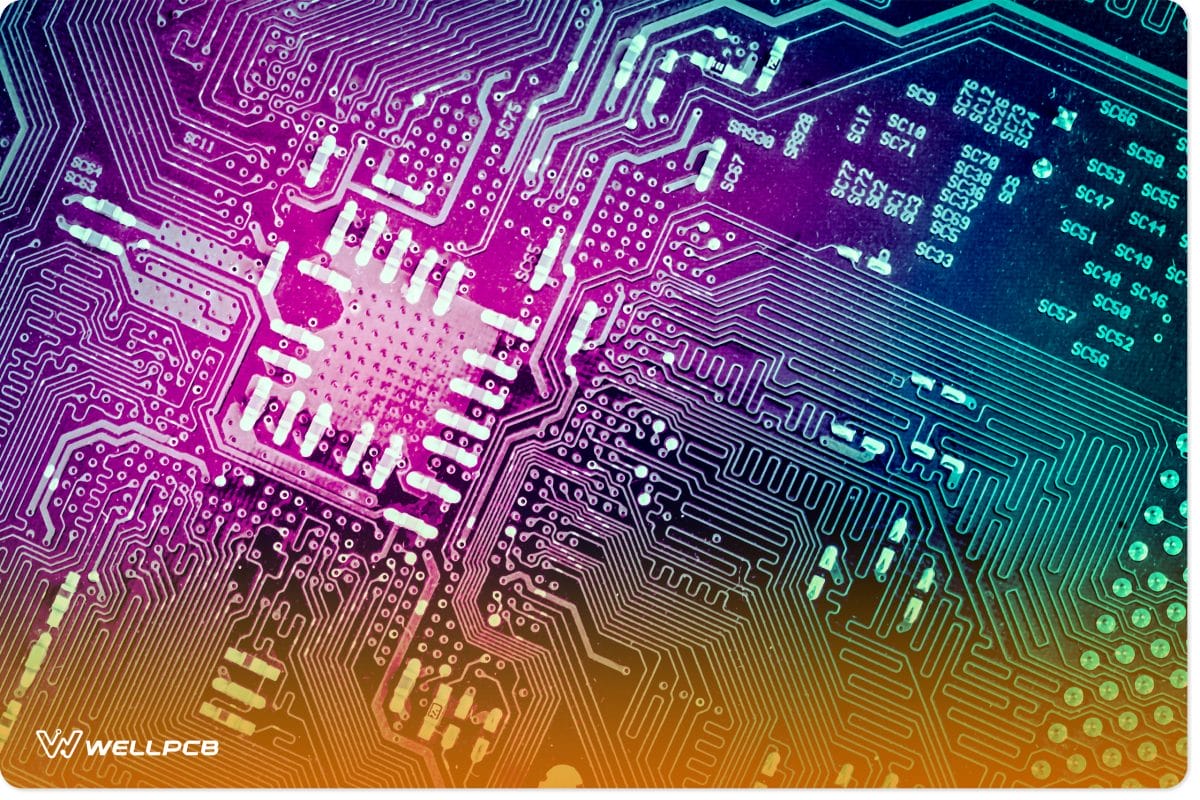

What is Purple PCB

What is Purple PCB

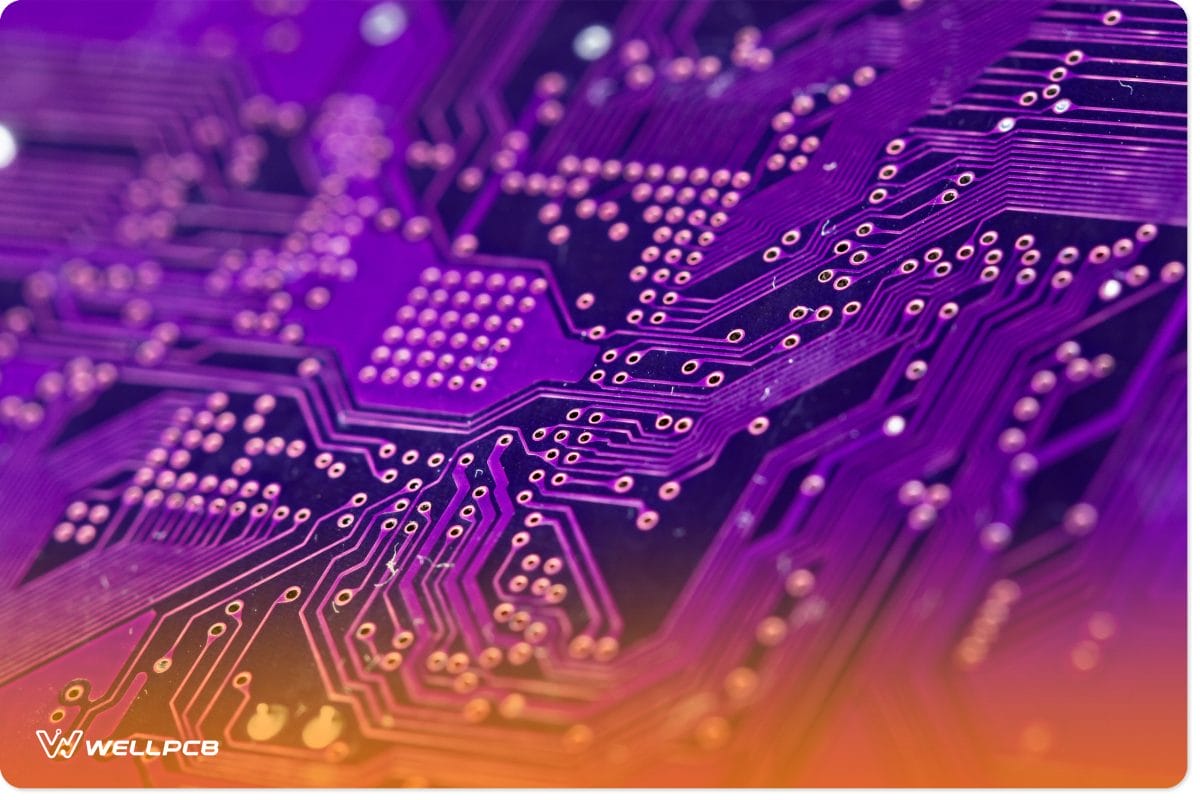

Typically, the color of the PCB comes from the solder mask.

A purple PCB has a purple solder mask. This color is not standard, so you may need to place an order with your manufacturer to have purple PCBs supplied.

Manufacturers offer different standards and may charge differently depending on the order placed.

In most cases, you may need to pay a premium when you order a purple PCB.

However, most users prefer green PCBs despite no restriction on the color chosen.

It is all about what you like and your preferences.

People use different colors depending on the use they want to put the PCB to.

However, most users find working with white or black solder masks challenging because it is difficult to see the traces when troubleshooting.

About PCB

It is essential to note that there is always a difference between solder masks used in special situations. For instance, in high-impedance circuits, specific colors may be chosen to reduce leakage, which is characterized by impedances.

Also, there are cases where colors must be avoided. For instance, there are cases where a transparent PCB is required. In such a case, you may need to choose one that can serve your needs.

It is also possible to work with a PCB with mixed colors.

However, you need to make a particular order from the manufacturer. Such PCBs may be costly and require you to dig deeper into your pocket.

The other benefit of using colored PCBs is using solder mask colors such as red and purple to test your PCB’s functionality.

Using boards with different colors may be critical if you don’t want to get confused.

Why Select a Purple PCB?

There are several reasons for selecting a purple PCB. For instance, you may employ a purple PCB because you want your product to stand out and appear more unique, especially if you use a clear design.

People often associate purple with creativity, wisdom, regalness, femininity, and luxury.

You may also want your products to evoke the same emotions. Purple is also generally a visually striking color.

Technicians working with complex circuitry may have an easier time finding your purple PCB as it contrasts against other green, matte, and metallic colors.

How are Purple PCBs Created?

Purple PCBs are created much like other PCBs. First, they undergo a design process to determine their structure and layout.

Designers use complex pieces of software to achieve this.

Next, the fabricator picks and sources the necessary materials.

This includes copper for the conductive layers and traces, the substrate typically consisting of a reinforced fiber-glass material (FR-4), and the solder mask.

You could consider the solder mask as the most important component of the fabrication process, as the purple PCB gets its distinctive color from it.

The engineers and designer review and print the PCB layout onto the substrate.

Next, they apply and bond a copper layer to the substrate and etch it to remove excess copper.

Finally, they apply the purple solder mask before drying, cleaning, and performing final tests and inspections.

Please visit our guide if you want a more detailed overview of the PCB fabrication process.

Printed Circuit Board Red Stock Photo

Best Material for Purple PCB Fabrication

As with most PCBs, purple PCBs don’t just use FR-4 material. However, this is the most common material in PCB fabrication.

Manufacturers can also employ paperboard substrates that use FR-1, FR-2, and FR-3-based materials.

In addition to these compounds, you can also find purple PCBs that consist of polyester resins, polyimide resins, and epoxy resins.

Manufacturers can also use a combination of these materials to form composite boards (CEM-1 and CEM-2).

Ultimately, Purple PCBs use the same material as other colored boards. Judging the quality of the board requires more than just assessing the type of material it uses.

Different Types of Purple PCB

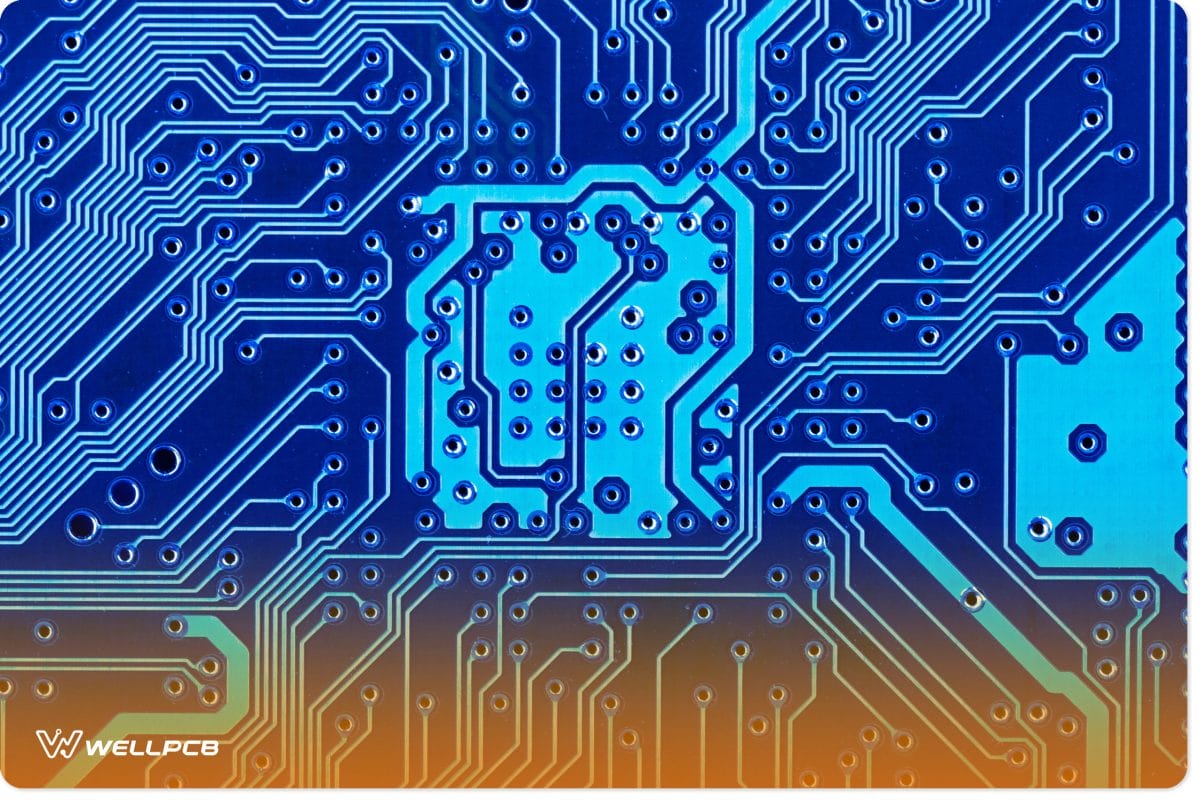

Single-sided PCBs aren’t the only types available to you. As with most colored PCBs, you can find purple in various types and form factors.

These include rigid-flex, flexible, multilayer, double-sided, and rigid PCB.

Plating Methods for Purple PCBs

The four most common plating methods that manufacturers use for purple PCBs are as follows:

- Through/Thru-hole plating

- Reel linkage plating

- Brushing plating

- Finger plated plating

You can learn more about these techniques from our PCB plating guide.

Modern Electronics Research Development Facility

Difference Between Standard Purple PCBs and Heavy Copper Purple PCBs

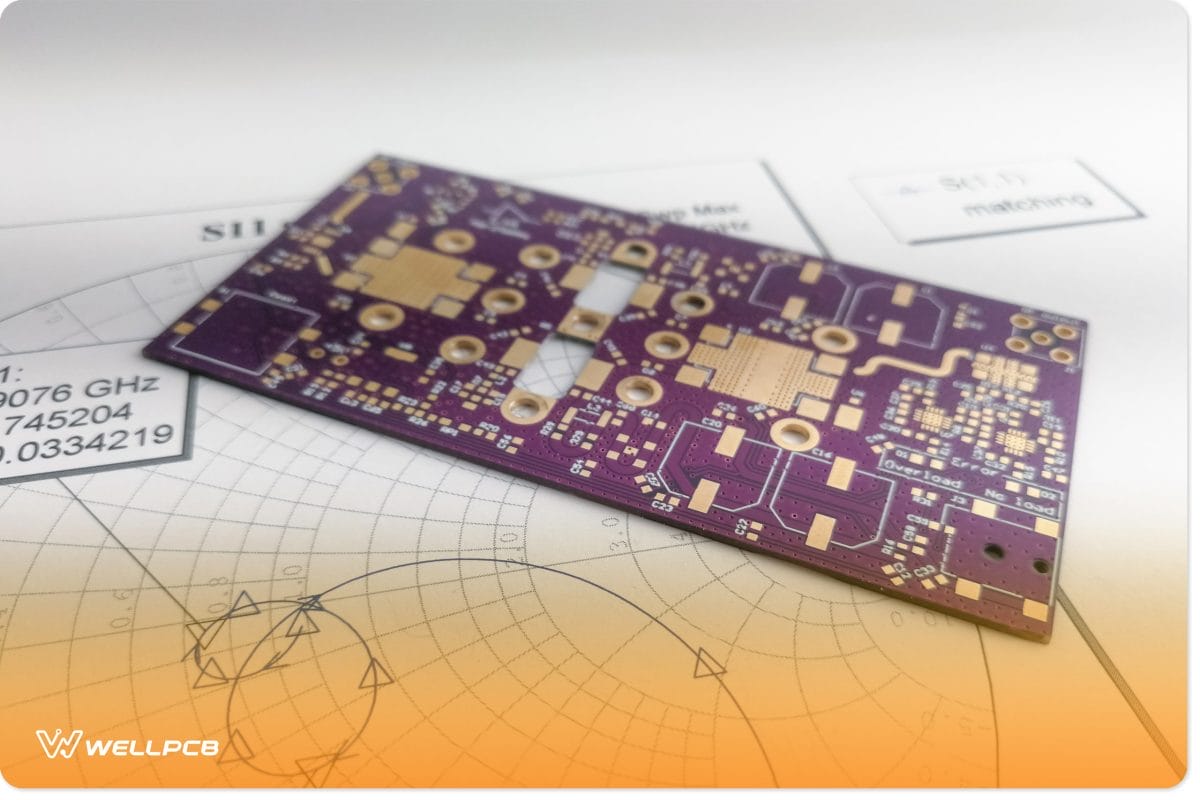

Should you select a standard purple PCB or pay more for a heavy copper purple PCB? To answer this question, you must know the difference between the two.

The standard purple PCB uses only a small amount of copper, whereas its heavy copper counterpart uses a large amount.

Consequently, heavy copper purple PCBs are much thicker and weigh more than standard purple PCBs. Heavy copper purple PCBs can use up to as much as 115 grams of copper. On the other hand, standard copper PCBs use just 28 grams.

Standard PCBs are, therefore, more compact. However, heavy copper purple PCBs exhibit greater conductivity and are thus more suitable for applications that require intense loads.

They also feature high-stress tolerance, which makes them more reliable.

How manufacturers fabricate standard and heavy copper purple PCBs also differs.

For instance, heavy copper purple PCBs require differential etching and step plating, whereas standard PCBs use copper etching and plating.

Heavy copper purple PCBs deliver superior heat distribution and greater tensile strength than the standard variety. However, they tend to be more expensive.

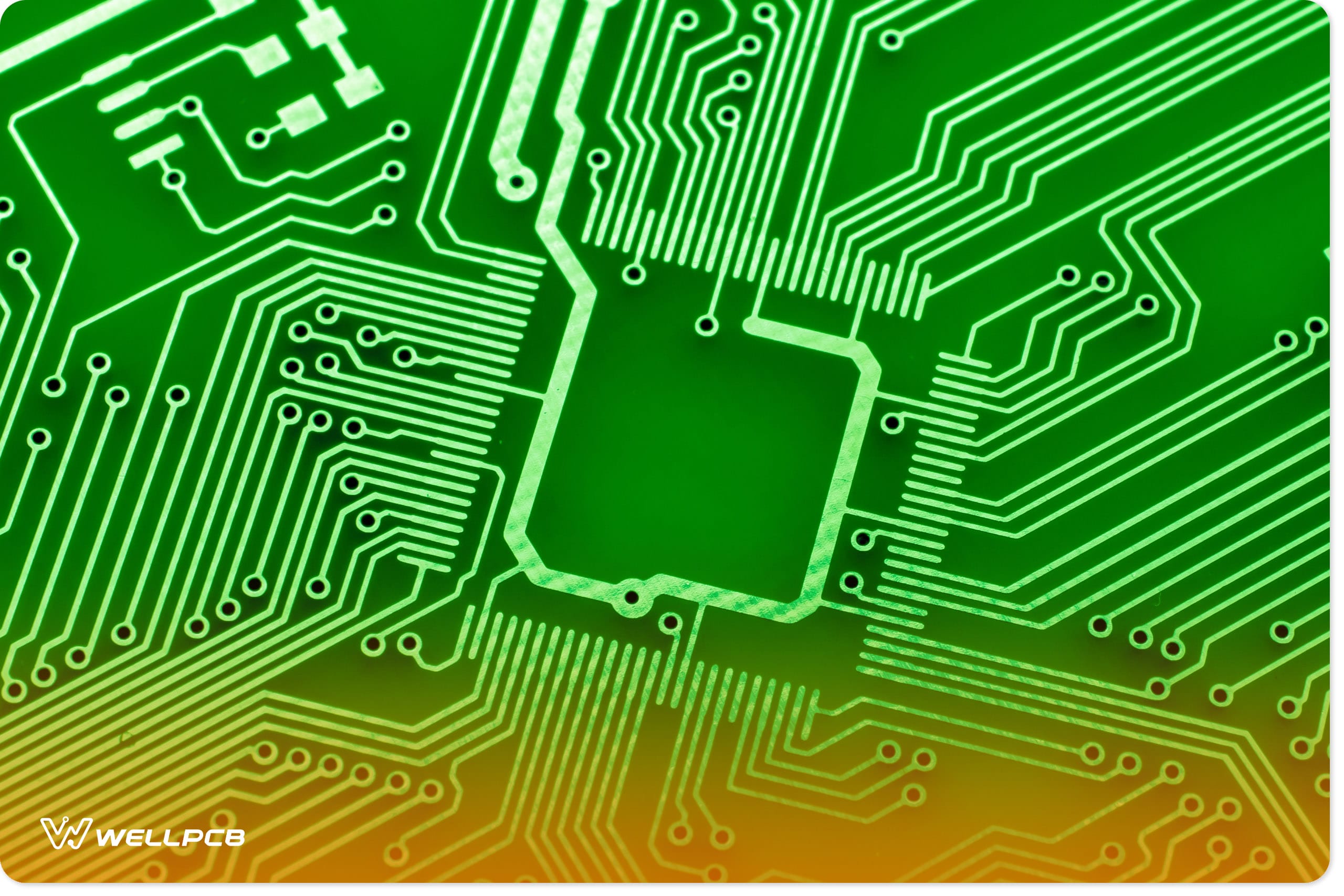

High Power Radio Frequency Printed Circuit

Alternatives to White Silkscreen Print for Purple PCBs

Each PCB has information printed on it. This information marks components and displays warning symbols, data codes, company logos, manufacturers’ marks, and the PCB part number.

Manufacturers prefer white silkscreen, especially on purple PCBs, because it tends to be more visible to the human eye.

However, a manufacturer may elect to use a different color to add some prestige or uniqueness to the PCB. For instance, they may use yellow, red, blue, black, or even gold.

Advantages and Disadvantages of Purple PCBs

As with anything, there are pros and cons to using purple solder masks and PCBS. Some of the benefits are as follows:

- Unique manufacturing branding opportunity

- Purple PCBs offer superior component contrasting, making them easier to inspect

- They do not yellow against lead-free soldering

Some of the drawbacks related to using purple PCBs include:

- High costs

- Purple PCBs may seem less credible than green PCBs

- Silkscreen contrasting issues may make labels and markings (legends) harder to read

How to Make Color Commercial PCBs

Colored commercial PCBs can be made by lying them down using a screen printer. The color may come from solder mask ink, which is then cured. In such a case, photo imaging may be used to make gaps.

Notice that solder mask ink may come in a wide range of colors. However, changing the colors may not be easy since it requires cleaning the printing equipment and the ink, which will waste more time.

Note that vendors may have a limited list of colors, and it may be necessary that you keep the printer settings for your colors.

Black-and-white solder masks should be avoided because they make it difficult to see the tracks. However, whether you choose a purple, black, or green PCB may not matter much since the differences may not be great.

Consequently, choosing among the PCBs that are already on the market may make your work easier.