Contents

What Are the Differences Between SMD VS SMT?

Engineer working with circuits

SMD and SMT technologies are very similar but still different to some extent.

Technology

Surface mount technology (SMT) is a technology of mounting and soldering surface-mounted devices (SMDs) onto a printed circuit board (PCB). On the other hand, SMDs are the electronic components we place on the PCB using Surface mount technology.

Type of Components

SMT is a mounting technology and thus doesn’t have components. Conversely, you can classify SMDs as either active or passive components.

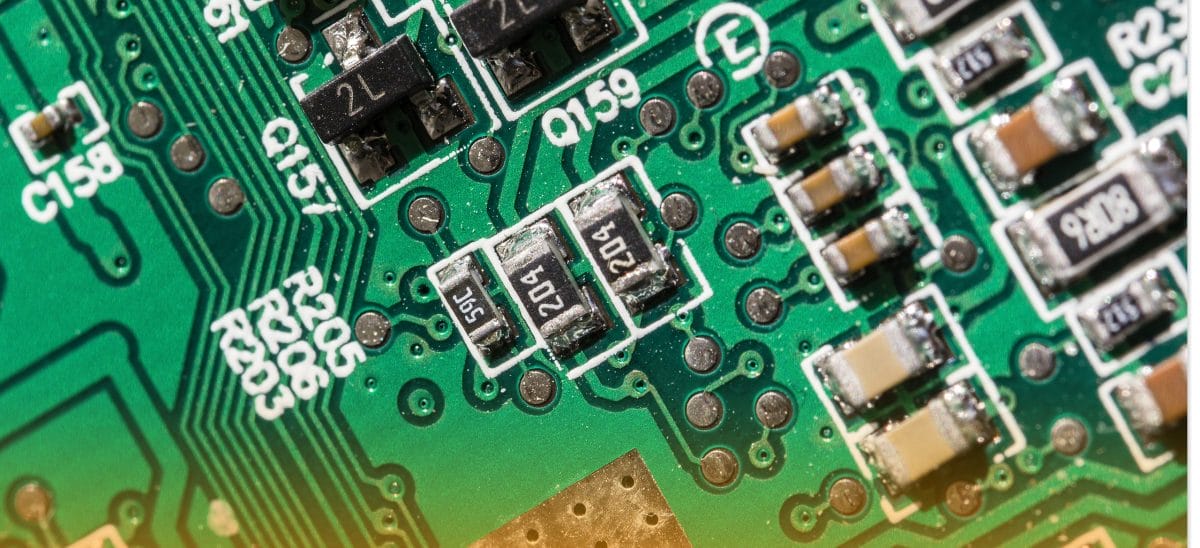

Passive components do not consume electric energy. Additionally, they allow the signal features to pass through without change and include capacitors, resistors, wave filters, antennas, couplers, and inductors.

On the other hand, active SMDs consume or convert electrical energy to other forms of energy. Examples include integrated circuits (ICs), diodes, valves, triodes, transistors, and silicon-controlled rectifiers.

Size of Components

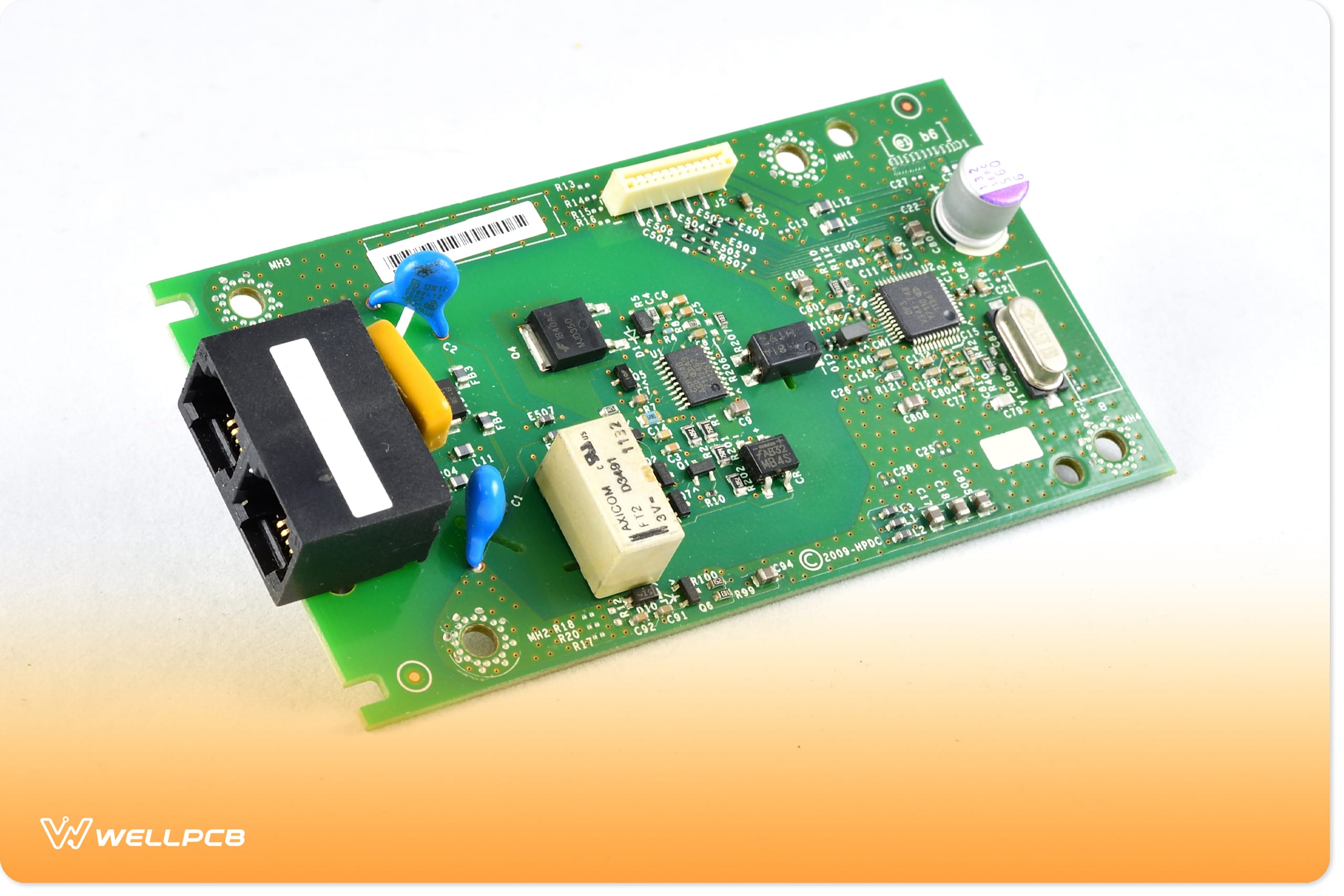

Set of ready-to-use Printed Circuit Boards with Surface Mounted Components.

SMTs do not have components but mount SMD components onto a circuit board. On the other hand, SMT components have very minute pins that are roughly a tenth of the through-hole components (THC). Examples of the SMD packaging sizes include 2225, 1812, 01005, 0402, 0201, 0603, and 0805.

SMT vs. SMD: How to choose?

Surface mount technology (SMT) and surface-mounted devices (SMDs) have the following advantages.

SMT

- First, It allows manufacturers to place more components on the printed circuit boards. In this way, you’ll get a compact and lightweight PCB design.

- Secondly, SMT boards have high mechanical performances and are robust even under high-vibration conditions. Also, its high-end electronic components allow for multitasking.

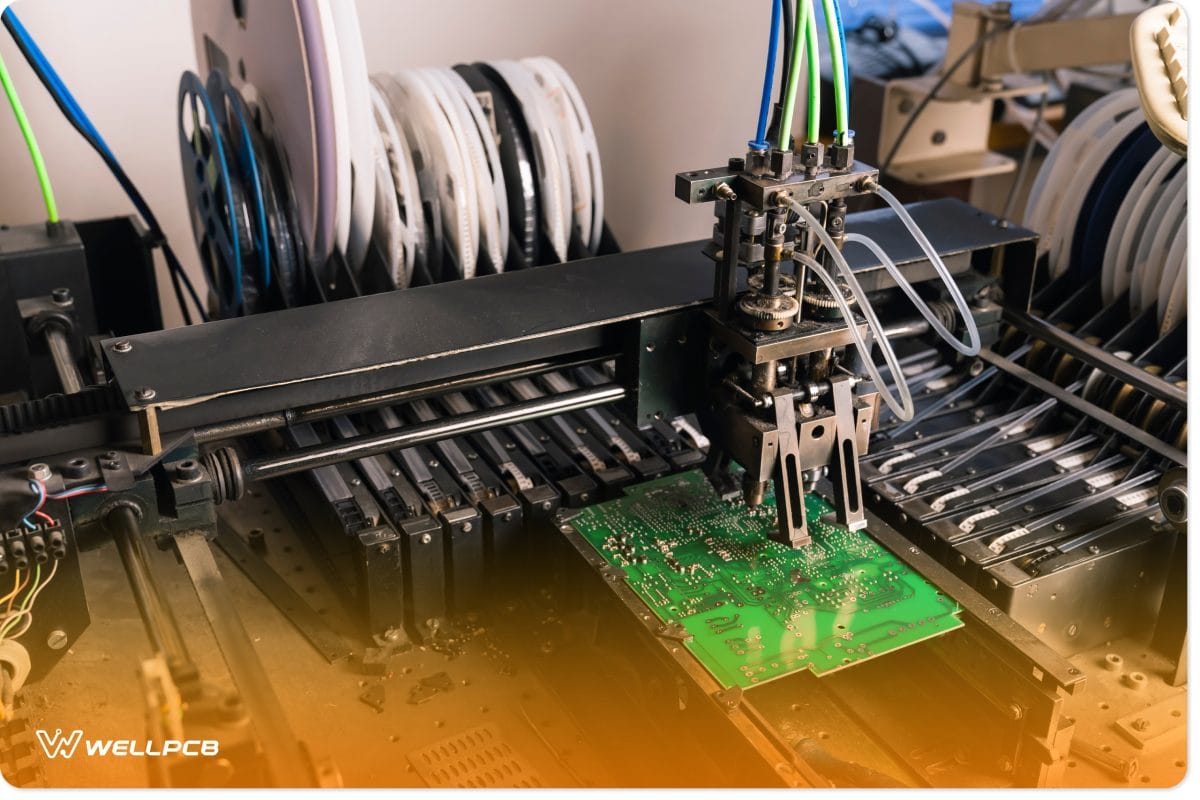

- The use of pick-and-place machines allows for a quicker assembly process. For example, some pick-and-place machines have abilities to place more than 136,000 components each hour.

- Finally, Its parts are cheaper and contribute to lowering manufacturing costs.

SMD

- First, It has low inductance and capacitance levels owing to its small size. SMD resistors are closer to perfect resistors when compared to leaded resistors.

- Secondly, It has higher frequencies and faster speeds than its leaded equivalents.

- Moreover, SMDs have lower power ratings than their leaded equivalents.

- Finally, It allows for denser circuits. It would help if you packed the SMDs closer to achieve the same functionality as the leaded components.

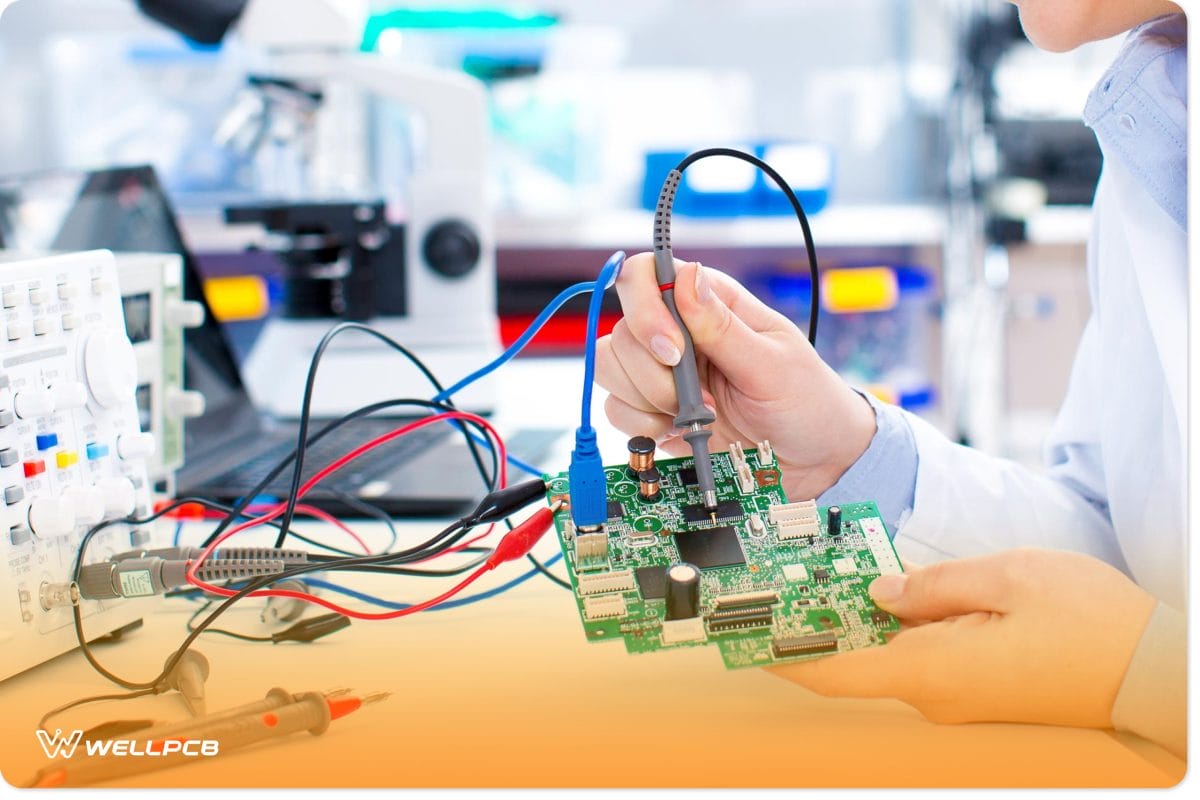

Working surface-mount device assembling electrical components on printed circuit board PCB.

Conclusion

This article introduces two very closely related terminologies you’ll often encounter in your engineering practice. As we’ve seen, SMDs are components mounted onto a circuit board through SMT technology.

SMDs are smaller, lighter, have shorter pins, and can be fine-pitch.

If you’re looking for PCB assembling services, contact us.