Contents

Understanding PCB Drill Sizes

Thus, it is critical only to buy those in which Standard PCB drill sizes have been used when buying PCBs. If you are drilling the holes by yourself, you must buy standard drill sizes PCB machines. If you supply the boards to clients, they may require that you meet specific standards and specifications. The trends are that most houses ask for finished standard hole sizes that allow them to make adjustments depending on their needs.

Non-professionals find it easier to work with predetermined standard hole sizes, so working with Standard PCB drill sizes may give you an upper hand. The machines that drill the holes vary in size, and their designers consider the size of the holes required and the use to which the PCB is to be put.

When planning to purchase drills, considering the aspect ratio between the boards’ thickness and the size of the training to be used is mandatory. It ensures that the aspect ratio is considered, and the PCB must match the capability of Standard PCB drill sizes to be used. For instance, smaller holes that are 0.006’’ require drills that are 0.062’’ while those that are smaller 0.012’’ may require exercises that are less than 0.125.’ Luckily, the most commonly used materials come with their corresponding hole sizes, making your work easier.

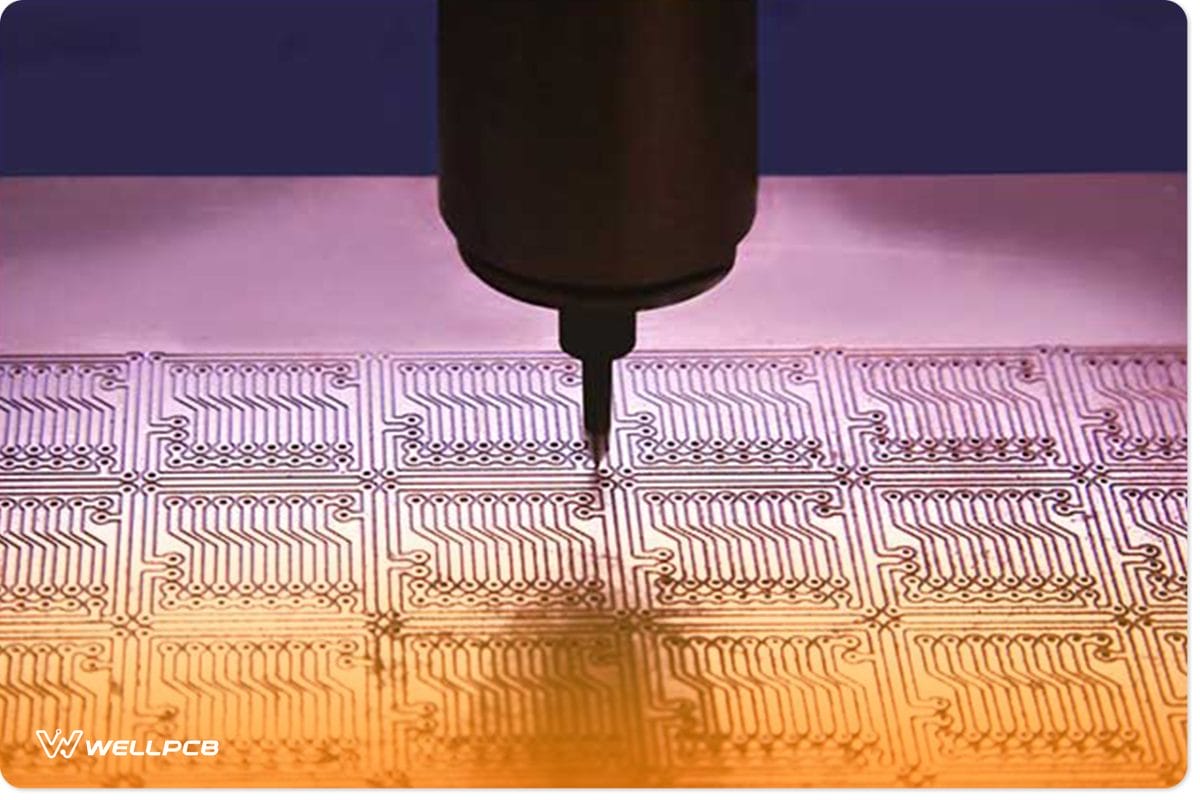

Creating vias may require drilling holes in the PCB and plating them in stacks before they are laminated together. If the hole to be drilled is smaller than 0.001’’, lesser technology may drill the hole. After drilling, the holes may have to be plated and used in circuits with compact designs but have been traced.

Standard PCB Drill Sizes

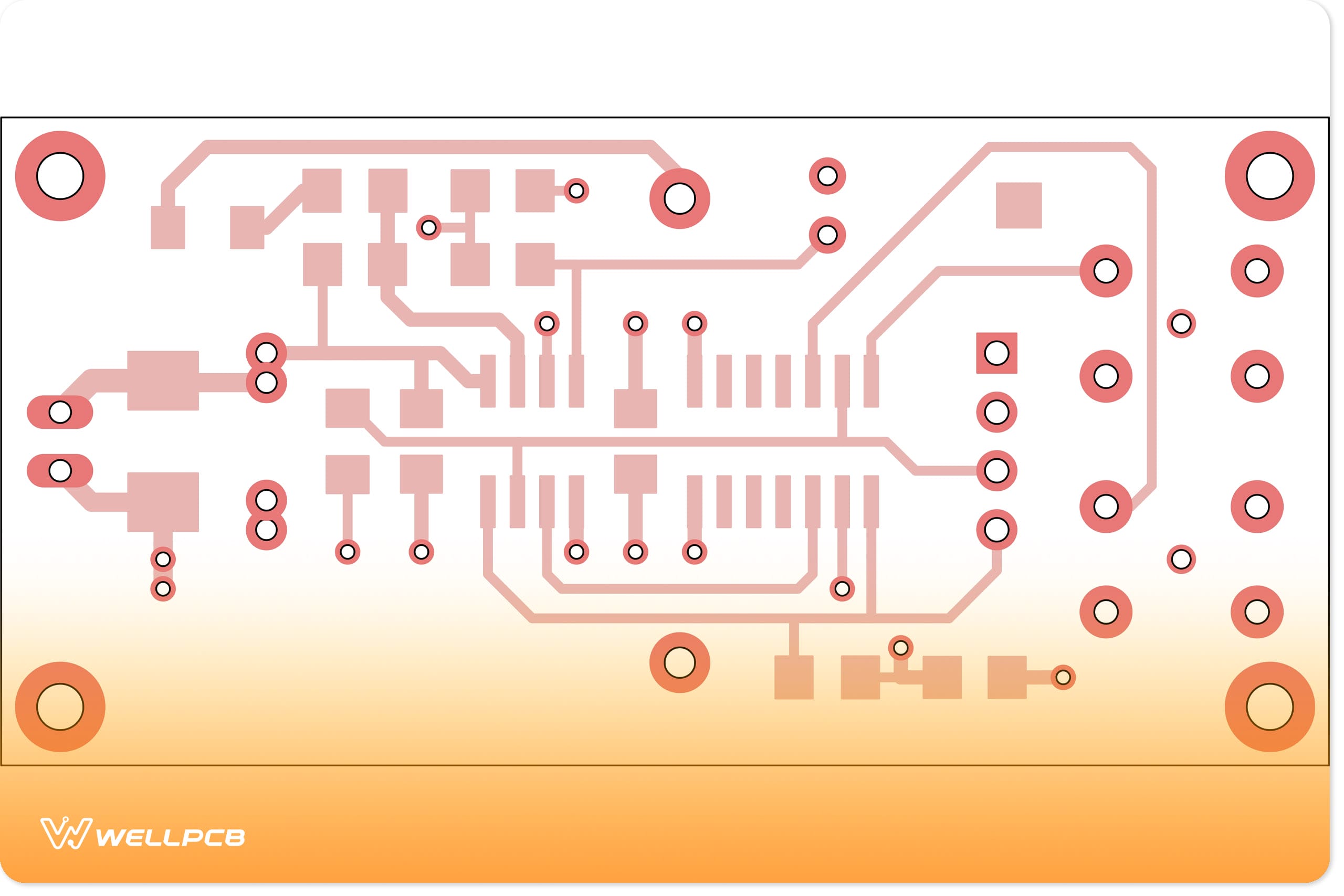

When obtaining the standard PCB drill hole sizes, it may be necessary to follow certain rules to limit wastage. For instance, when the component is Xmm, you should drill an X+ 0.3mm hole. If the component is 0.4mm, drilling a hole about 0.7- 0.8 mm may be necessary. If you make the hole bigger, you will likely end up with more waste when you start soldering. On the other hand, it will be difficult to stuff the components when you make them smaller. Also, notice that it may be difficult to have the PCB plated together.

Decreasing the drill size comes with a host of other problems, including stuffing. Therefore, designing boards that allow you to use standard PCB drill hole sizes is necessary. Also, there is a panel limit of drill holes that are accepted in DSS and SSS. For SSS, it is recommended that you observe a limit of 500 holes, while a maximum of 2000 holes must be observed for DSS panels. You may choose to use inch sizes. However, it is recommended that you use metric units such as 0.1mm, 5.0mm, and so forth. Notice that it is important that you also do your best to minimize overlapping drill holes.

Standard PCB Drill Sizes mm

The table includes a size drill measurement system that provides for metric, fractional, letter, and wire gauge numbers that you should consider using. If you do not know the holes’ correct size to drill in your PCB, the PCB standard drill sizes mm chart could provide you with some reference materials. It makes the whole making process simpler.

Hole making

Mm are used to make standard holes into a workpiece. Other machines may be used to cut and remove unwanted materials but may require milling machines. It may also require specialized tools such as tapping machines and drill presses. You may perform the hole-making process as a secondary machine-making process. It could also be done to add features that were considered costly or to help improve the tolerance of the PCB. The hole is cut from an existing workpiece board and may be characterized by different features depending on the application it is to be put to. In PCB standard drill sizes, the following aspects are imported:

Tolerance – How precise you are in cutting determines the understanding of the PCB. Using sharp equipment and appropriate hole-making tools may increase tolerance.

Depth- the cutting tool used determines the bottom of the hole. It is possible to have a blind or a through-hole.

Standard metric PCB drill sizes

Choosing the right PCB drill sizes determines the kind of work you will finally end up with. The drill chart provides a list of standard sizes that include metric, wire gauge numbers, and letters to choose from. The diameters are shown in both metric Units and English. The fractional sizes are usually listed in inches, and the metrics are all in millimeters to make your work easier.

Conclusion

Having looked at the standard PCB drill sizes and how you can drill holes in your PCBs using the right tools, you should be able to drill holes in your PCBs without a problem. All you have to do is understand the PCB’s needs and purchase the right drill sizes to help drill standard hole sizes.