High Tg PCB Manufacturer Durable High Temperature PCBs

High Tg PCBs are specialized printed circuit boards designed to withstand extreme temperatures without compromising performance or reliability.

WellPCB is a high Tg PCB manufacturer operating two advanced PCB manufacturing facilities with full capabilities for PCB fabrication, thermal design review, and high-reliability PCB assembly. We provide expert guidance on material selection and thermal design — delivering precision-built high Tg PCBs for demanding applications.

- High Tg PCB prototyping and assembly with 2 to 6 day turnaround

- Certified high-temperature PCB manufacturing with comprehensive testing

- Expert thermal design support for extreme environment applications

ISO9001 ISO13485

ISO14001

IATF

16949

IPC-A-610H International

Certification

Fully Automated

AOI Inspection

- PCB Manufacturer

- High Tg

High Tg PCBs for Demanding Environments

High Tg PCBs are printed circuit boards made with flame-retardant fiberglass reinforced epoxy material that can withstand high temperatures without deformation, delamination, or degradation of electrical and mechanical properties.

WellPCB manufactures high Tg PCBs using certified fabrication with high-temperature PCB materials such as IT180, S1000-2M, and Rogers 4350B. These materials have a Tg value exceeding 170°C and a decomposition temperature (Td) over 300°C, allowing them to withstand high temperatures during lead-free soldering and reflow processes.

Our substrate options include FR4, high Tg FR4, PTFE, aluminum, and ceramics for low CTE and high-temperature stability. We provide expert guidance on glass transition temperature management and design for high temperature durability, delivering precision-built high Tg PCBs ready for lead-free soldering and extreme thermal cycling.

Our process supports PCB fabrication with up to 64 layers, 1.8 mil / 1.8 mil minimum trace/space, and 0.1mm mechanical drill holes. Every printed circuit board undergoes IPC Class 2/3 compliant manufacturing with AOI, X-ray, and impedance testing to ensure dimensional accuracy, electrical continuity, and mechanical strength.

These PCBs maintain low thermal expansion (CTE-z ≤ 45 ppm/°C) and long T260/T288 delamination resistance, making them ideal for high-temperature applications in automotive, industrial, and aerospace systems.

Our High Tg PCB Manufacturer Capabilities

Our manufacturing capabilities support the specific material, structural, and processing requirements of high Tg PCBs. From multilayer stack-ups to precision drilling and advanced thermal profiles, every step is calibrated to handle high-performance laminates and maintain reliability under elevated operating conditions.

We offer high Tg PCB manufacturing with flexible build times from 2 days to 5 weeks, depending on board complexity, material selection, and order volume.

We support low-volume PCB prototype runs starting at 1 piece, as well as high-volume production exceeding 10,000+ units, ensuring scale for both prototyping and deployment.

| Capability | Specification |

|---|---|

| Build Time | 2 days to 5 weeks |

| Order Volume | 1 piece (prototype) to 10,000+ pcs |

| Scalability | Supports prototyping to mass production. |

| Lead Time Factors | Based on board complexity, material, and finish. |

Our capabilities support 1 to 64-layer printed circuit boards, including high-layer-count HDI stack-ups with via-in-pad, via stacking, and blind/buried vias for signal integrity and heat dispersion in high-temperature applications.

We build with IPC Class 2 and Class 3 standards for mechanical and electrical performance in environments with aggressive thermal cycling.

We support minimum trace/space widths of 1.8 mil and minimum mechanical drill holes of 0.1 mm with a 4 mil annular ring tolerance.

This allows high-density routing and compact pad arrays for high-tg PCBs used in automotive control systems, embedded computing, and advanced power conversion.

We utilize certified high-temperature PCB materials, including S1141 FR-4, S1000-2M FR-4, IT180, and Rogers 4350B, with Tg values ranging from 175°C to 280°C, Td (decomposition temperature) as high as 390°C, and T260/T288 delamination times up to 60 minutes.

These flame-retardant fiberglass reinforced epoxy materials provide a stable mechanical structure and electrical insulation when exposed to high thermal loads.

We manufacture high Tg PCBs with finished board thicknesses ranging from 0.1 mm to 12 mm, supporting rigid stack-ups for thin mobile devices to thick, thermally reinforced industrial controllers.

Our copper weight capability spans from 0.33 to 28 oz per ft², with ±10% uniformity tolerance across the panel.

This allows for high current handling, minimized voltage drop, and enhanced heat resistance in dense or power-hungry designs.

Thicker boards and heavy copper configurations are available for high heat or high-load switching environments, including automotive power systems and aerospace converters.

We provide a full range of surface finish options for compatibility with high-temperature reflow profiles and lead-free assembly processes.

Available finishes include ENIG for reliable pad flatness and extended shelf life, OSP for fine-pitch PCB assembly, immersion silver for high-speed signal transmission, immersion tin for connector-based designs, and HASL or lead-free HASL for general-purpose applications.

These finishes are applied with precise thickness control and are validated for performance during high Tg PCB fabrication, including exposure to multiple thermal excursions during double-sided assembly.

Our minimum printed circuit board size starts at 2 mm x 5 mm, with profile accuracy maintained to ±0.1 mm across the panel.

We apply solder mask to one or both sides based on file specifications, using high-temperature-stable liquid photoimageable materials. Mask colors include green, white, blue, black, red, and yellow, each formulated to maintain adhesion and thermal endurance during high-temperature PCB processing.

We print silkscreen legends in white, black, or yellow using non-conductive epoxy ink, suitable for all supported FR-4 material and high Tg substrate surfaces.

We support advanced structural features in our high Tg printed circuit boards for applications with tight space, mounting, or interconnect requirements. Gold fingers are fabricated with 30 to 50 µin hard gold over nickel and beveled for insertion-ready contact interfaces.

Countersink and counterbore holes are machined with ±0.05 mm depth tolerance to support flush fasteners and embedded hardware.

Blind and buried vias are laser or mechanically drilled and registered with ±2 mil positional accuracy to support HDI stack-ups.

Via-in-pad construction with resin fill and copper cap is available for space-constrained components like BGAs and RF modules.

These mechanical enhancements are integrated during fabrication to meet thermal and dimensional stability requirements in high-temperature applications.

Why Choose WellPCB as Your High Tg PCB Manufacturer?

WellPCB combines material expertise, controlled manufacturing environments, and stringent quality systems to deliver consistent results across every high Tg build. Our experience with thermally demanding designs allows us to support both standard and specialized requirements with precision and repeatability.

18+ Years of High Tg PCB Manufacturing Expertise

Advanced Testing and Inspection Technologies

Broad Range of High Tg Materials

24/7 Technical and Project Support

Competitive Pricing Through In-House Control

Global Certifications and Industry Compliance

What is a High Tg PCBs?

A high-Tg PCB is a printed circuit board made from high-temperature PCB material that has a glass transition temperature (Tg) above 170°C. This is the temperature at which the base material transitions from a rigid state to a softened one.

Compared to standard PCBs with FR-4 rated between 120°C and 170°C, high Tg PCBs maintain mechanical strength, electrical performance, and dimensional stability under high heat and lead-free soldering conditions.

What Materials Are Used in High Tg PCBs?

High temperature PCB materials include advanced FR-4 or specialized laminates with a Tg value above 170°C, a decomposition temperature (Td) greater than 300°C, and a low CTE-z to maintain structural and electrical integrity under high-temperature applications.

IT180

S1000-2M (FR4)

Rogers 4350B

S1000-2M (FR4)

What Are the Features of High Tg PCBs?

The features of high Tg PCBs stem from the thermal and mechanical behavior of their material systems under elevated temperatures. These properties directly influence the board’s performance during PCB fabrication, assembly, and prolonged field operation across demanding environments.

High Resistance to Thermal Stress

Because of their elevated Tg value and tightly controlled thermal expansion, high Tg PCBs resist warping, resin recession, and interlayer delamination under soldering or continuous load.

This makes them ideal for high-temperature applications involving frequent power cycling or sustained heat exposure, such as automotive electronics and industrial drives.

Thermal Shock and Heat Endurance

These boards are designed to survive rapid thermal transitions without layer separation or mechanical distortion.

Compared to standard PCBs, they offer higher thermal shock resistance, retaining integrity through soldering processes, HALT/HASS conditions, and high-power operation.

Excellent PTH Reliability

High Tg PCBs offer superior plated through hole (PTH) performance due to their low CTE-z (45–55 ppm/°C). Reduced thermal expansion prevents cracking in copper barrels during reflow and wave soldering.

The high-temperature PCB material resists softening, warping, or delamination around vias, making these boards suitable for complex, multilayer PCB assembly processes.

Improved Mechanical Strength

Built with high Tg materials, these boards exhibit higher rigidity and long-term dimensional stability.

Their glass transition temperature remains stable during repeated thermal cycling, which reduces fatigue and structural degradation.

This results in printed circuit boards that maintain alignment and bonding in environments where standard FR-4 would fail.

Low Thermal Expansion and Dimensional Stability

The base materials used in high Tg PCBs expand significantly more slowly than conventional FR4 material.

This minimizes misalignment in surface-mounted components, reduces strain on solder joints, and maintains registration across all layers. The result is tighter tolerance control and longer in-field lifespan.

Delamination Resistance and Long-Term Durability

With T260/T288 delamination thresholds of up to 60 minutes, high Tg printed circuit boards offer exceptional bonding performance under prolonged thermal load.

This makes them a strong choice for demanding environments where temperature resistance, mechanical shock, and humidity must all be managed simultaneously.

What Are The Technical Characteristics

of High Tg PCBs?

High Tg PCBs are engineered to perform reliably in environments where standard PCBs would fail due to thermal stress. Their enhanced material properties allow them to maintain structural and electrical integrity at elevated temperatures, making them ideal for high-temperature applications.

| Characteristic | Detail |

|---|---|

| Tg Value | >170°C (glass transition temperature). |

| Td (Decomposition Temp) | >300°C (temperature at 5% weight loss) |

| Material Type | High Tg FR-4, IT180, S1000-2M, Rogers 4350B. |

| Thermal Stability | Withstands reflow soldering and ambient temps >130°C. |

| Time to Delamination (T260/T288) | Up to 60 minutes under thermal load at 260°C or 288°C. |

| Mechanical Strength | High rigidity with reduced deformation under thermal stress. |

| Chemical Resistance | Improved resistance to moisture and corrosive environments. |

| CTE-z (Z-Axis Expansion) | 45 to 55 ppm/°C lower expansion rate minimizes via cracking and delamination. |

How Is Heat Dissipated in High Tg PCBs?

Heat in high Tg PCBs is dissipated through conduction, convection, and radiation, with each integrated into the board’s design based on the thermal profile of the application. These methods work together to protect the board during high-temperature applications, even when using high-quality heat- and temperature-resistant Tg materials.

Conduction

Conduction removes heat through physical contact with thermally conductive elements like copper planes, thermal vias, and heat sinks. In high Tg PCB fabrication, increased copper thickness and metal core substrates improve conduction paths, allowing heat to flow from hotspots efficiently.

Convection

Convection transfers heat into moving air or liquid. In high-power PCB assemblies, components are often aligned with airflow paths, and ventilation or forced air cooling is used to maintain safe operating temperatures. Board layouts may include exposed pad designs or thermal vias to optimize airflow interaction.

Radiation

Radiative dissipation emits thermal energy as infrared waves. While less dominant, it becomes relevant in sealed or passive cooling systems. Using surface treatments with higher emissivity can enhance radiation, especially in extreme temperature environments where conduction and convection are limited.

When Do You Need a High-Temperature PCB?

Not all electronic assemblies require elevated thermal performance, but in designs where consistent exposure to heat is expected, the limitations of standard PCBs quickly become a risk factor.

Thermal Loads Above 130°C

High Ambient or Processing Temperatures

Lead-Free Soldering Requirements

Applications That Use High Tg PCBs

Where Are High-Temperature PCBs Used?

They’re used in applications where PCB temperatures exceed 130°C, including automotive ECUs, EV batteries, industrial inverters, medical sterilization devices, aerospace electronics, and high-power computing systems.

Automotive Electronics

Consumer Electronics

Industrial Electronics

Medical Devices

Aerospace and Defense

How to Order Your High Tg PCB

in 5 Easy Steps

PCB Manufacturing and Order Review Process

Submit Your PCB Design

Upload your Gerber files or use our easy online PCB design tool to create your board layout. Make sure your files are complete and correctly formatted to ensure smooth processing and production accuracy.

Select Your PCB Specifications

Customize your order by choosing the technical specifications—number of layers, board dimensions, thickness, copper weight, solder mask color, surface finish, and more. Our intuitive interface helps you configure everything based on your project’s needs.

Get an Instant Quote

Once your design and specs are in place, you'll receive a transparent, instant quote. Pricing updates in real time as you modify options, so you can adjust your selections to match your budget before placing the order.

Confirm Order & Make Payment

Review your entire order for accuracy, including file previews and selected specs. After confirmation, proceed to secure checkout and choose your preferred payment method. You’ll receive an email confirmation with order details.

Production & Delivery

Your PCB moves into production immediately. We’ll keep you updated throughout the manufacturing process. Once completed, your boards are carefully packed and shipped to your door, with tracking information provided for your convenience.

WellPCB is trusted by millions of

businesses and innovators.

Why Choose WellPCB?

WellPCB stands out among USA PCB manufacturers by delivering superior quality, advanced solutions, and unmatched reliability. With years of experience serving global markets, WellPCB has earned a reputation as one of the top PCB manufacturers in USA.

WellPCB specializes in multilayer PCBs for advanced electronic applications. You can order these boards with $100 off using our special offer, providing high complexity at competitive rates for demanding projects.

Hommer Zhao

Founder and Chief Editor – Hommer Zhao

Welcome! I’m Hommer Zhao, the founder and Chief Editor of WellPCB. With years of experience in the PCB industry, I’m committed to making sure our content is both accurate and helpful. We’re proud to serve a growing community of over 4,000 customers worldwide, and our goal is to provide you with the best resources and support. Your satisfaction is our top priority, and we’re here to help you every step of the way!

Jesse Holland

Technical Manager – Jesse Holland

Hi, I’m Jesse Holland, an Engineer and Technical Manager at WellPCB. With years of experience in PCB design and engineering, I’m here to ensure that every project we work on meets the highest technical standards. I lead our team, focusing on precision and innovation, collaborating closely with clients to provide tailored solutions and expert guidance. Whether you’re facing a complex design challenge or need advice on technical aspects, I’m here to ensure your project is a success from start to finish.

Nathan Jensen

Purchasing Manager – Nathan Jensen

Hi, I’m Nathan Jenson, the Purchasing Manager at WellPCB. I’m responsible for sourcing the best materials and components to ensure our products meet the highest quality standards. With my extensive experience in procurement, I work closely with suppliers to secure reliable and cost-effective solutions while maintaining strong relationships to support our operations. I aim to ensure every project runs smoothly by providing the resources needed to deliver on time and to your satisfaction.

Emma

Sales Manager – Emma

Hey, I am Emma, sales manager at WellPCB. I studied electronic science and technology at university and have served customers for PCB and PCB Assembly service for several years.

I enjoy communicating with customers and our technicians to solve problems, and customers always say, "It's great to have you onboard".

It is my pleasure and honour to be helpful. Contact me now, and you'll know.

Bella and Cassiel

Sales Representatives – Bella and Cassiel

We’re Bella and Cassiel, your dedicated sales representatives at WellPCB. With our extensive knowledge of the PCB industry, we’re here to provide exceptional service and support. We take the time to understand your unique needs and are always ready to offer tailored solutions and advice. Whether you need product recommendations, assistance with your orders, or simply have a question, we’re here to ensure your experience is smooth and seamless at every step.

Mandy and Wendy

Sales Representatives – Mandy and Wendy

We’re Mandy and Wendy, your friendly sales representatives at WellPCB. Passionate about helping our customers, we bring a wealth of experience in the PCB industry to provide you with the best solutions and service. We take pride in building strong relationships with our clients, understanding their specific needs, and offering personalised support to ensure their satisfaction. Whether you’re looking for advice, product information, or assistance with any part of your order, we’re here to make your experience as smooth and efficient as possible.

Our Team

Our skilled engineers and technicians bring expertise and precision to every PCB assembly project. Committed to quality, efficiency, and innovation, our team ensures every order meets the highest UL, IPC, ROHS & REACH standards, delivering reliable solutions tailored to your needs.

- Founder and Chief Editor – Hommer Zhao

- Technical Manager – Jesse Holland

- Purchasing Manager – Nathan Jensen

- Sales Manager – Emma

- Sales Representatives – Bella and Cassiel

- Sales Representatives – Mandy and Wendy

High Tg Manufacturer Case Studies

Case Study

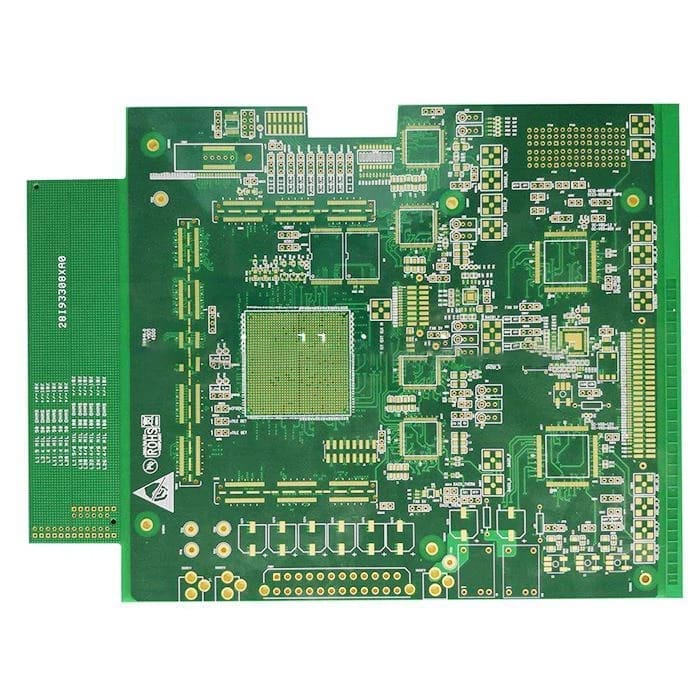

This project features a 28-layer high-density interconnect (HDI) PCB designed for high-speed, high-reliability systems. With a finished thickness of 3.65 mm, an aspect ratio of 15:1, and impedance-controlled design, this board supports complex signal routing, dense via arrays, and critical power distribution. Built with High-TG FR4 and immersion gold surface treatment, it’s ideal for applications that require signal integrity, thermal stability, and multi-signal-layer control.

- Layer Count: 28 Layers

- Board Thickness: 3.65 mm

- Material: High-TG FR4 (Tg ≥170–180 °C)

- Copper Thickness: 1 oz (outer layers) / 2 oz (inner layers)

- Surface Finish: Immersion Gold

- Min. Line Width/Spacing: 3 mil / 4 mil

- Hole-to-Line Clearance (Inner): 8 mil

- Aspect Ratio: 15:1

- Special Requirements: Controlled Impedance

Case Study

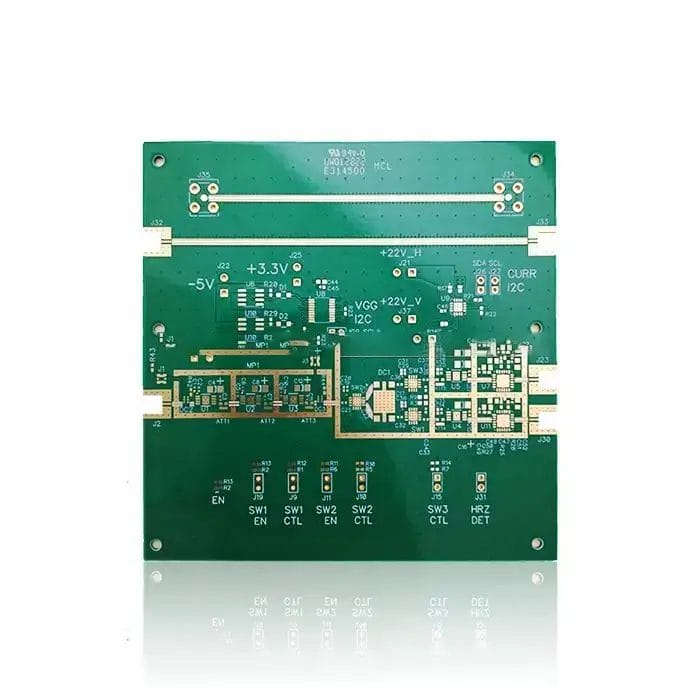

This project focuses on a 6-layer hybrid PCB combining RO4350B high-frequency material with High-TG FR4, developed for medical equipment that demands both RF performance and thermal stability. The use of mixed lamination allows for cost-effective production while maintaining signal integrity on RF-critical layers. It also includes copper slurry plug holes and high-precision plated vias for structural reliability.

Product Specifications:

- Layer Count: 6 Layers

- Material: RO4350B + High-TG FR4 (mixed press)

- Copper Thickness: Standard (typically 1 oz or customized)

- Hole Type: Copper slurry plug hole + plated through-hole (PTH)

- Surface Finish: ENIG

- Application: Medical electronics – RF modules, signal acquisition, imaging

- Design Features: Hybrid stack-up, plated vias, tight impedance control

Case Study

This project centers around a 3-layer flexible PCB (FPC) specifically designed for touch screen modules. Leveraging a high-TG base with 1/2 oz no-glue copper, it delivers excellent flexibility, dimensional stability, and signal integrity. The immersion gold finish ensures superior conductivity and bonding performance for fine-pitch connectors. A PI reinforcement layer enhances mechanical support in connector areas.

Product Specifications:

- Layer Count: 3 Layers (FPC)

- Total Thickness: 0.18 mm

- Base Material: No-glue 1/2 oz copper + polyimide (high TG)

- Copper Thickness: 1 oz

- Surface Finish: Immersion Gold

- Min. Line Width/Spacing: 0.055 mm / 0.09 mm

- PI Reinforcement: 0.15 mm thick, attached for mechanical support

- Additional Feature: Stuck PI for localized stiffening

- Application: Capacitive/resistive touch screen modules

High Tg PCB Client Feedback

As an R&D manager, I have had an outstanding experience working with WELL-PCB. For many years, our company has entrusted them with the production, assembly, and programming of the boards developed in our R&D unit, and they have consistently exceeded our expectations.

Hamid Reza Moshayedi

R&D Manager

Their work is very impressively perfect. Today, when they check our company PCB board after assemble. They found a fake short point which many engineers has never found in the past years. But that is just designed so. The PCB board quality is excellent. Their service is also excellent.

MikeZ

My friend introduced WellPCB to me, the first try, a little look forward to. I ordered a 47*72 10ps PCB, and I can’t wait to receive my PCB. So I used expedited service and received my PCB in three days. I tested and soldered the PCB, Quality is really good, silkscreen, plating also great.

Warren Cliton

High Tg PCB Manufacturer FAQs

Which electrical properties of High Tg PCBs should I be concerned about?

The focus is on properties that influence thermal and electrical reliability under load: glass transition temperature (Tg), thermal decomposition temperature (Td), and time to delamination (T260/T288).

Also consider the board’s moisture resistance, its ability to handle required power densities, and the overall thermal endurance of the material system during operation and reflow.

What design considerations are important when working with High Tg PCBs?

High Tg PCB designs must consider the material’s Tg, Td, and time to delamination to ensure thermal stability during assembly and operation. Matching core and prepreg materials with compatible thermal profiles reduces the risk of delamination.

A CTE-z range of 45–55 ppm/°C helps maintain via integrity during thermal cycling. Designers should also account for power density, optimize trace layout for uniform heat distribution, and maintain copper balance across layers to prevent warping during lead-free reflow.

What are some of the challenges that come with using high Tg PCBs?

High Tg PCBs cost more due to the use of specialized materials, and they may require longer lead times because of limited availability. Their increased hardness can cause higher tool wear during drilling, while their thermal properties demand tighter process control during lamination and reflow.

These factors also require design adjustments to manage resin flow, layer bonding, and thermal expansion in multilayer builds.

What is the expected lifespan of a High Tg PCB?

High Tg PCBs can last up to 10 to 15 years in demanding environments, depending on thermal load and design. Their extended lifespan results from greater resistance to delamination, thermal cycling, and material degradation under high temperatures.

The High Tg PCB Manufacturer You Can Trust

Contact us for an expert quote, DFM guidance, small-batch prototyping,

and full production of High Tg PCBs.