Contents

- 1 What is rohs2?

- 2 What restricted materials does RoHS2 stipulate?

- 3 How vital is rohs2 compliant

- 4 How to fulfill RoHS 2 regulations in the PCB manufacturing industry

- 5 How to test PCB products to meet rohs2 regulations

- 6 What is the difference between RoHS2 and the original RoHS?

- 7 Understand ROHS 2 exemption

- 8 Industries where RoHS 2 is applicable

- 9 General questions about RoHS2

- 10 Summary

What is rohs2?

To begin with, RoHS in full stands for Restriction of Hazardous Substances.

It traces its origins to the European Union and puts restrictions on using hazardous chemicals in the manufacture of electronic equipment.

RoHS 2, or the Recast RoHS 2 Directive 2011/65/EU published in 2011, is another directive with even more restrictions.

RoHS 2 took effect on the entire EU member states in 2013 to replace the original RoHS. Even though it’s the same as the first directive, this one is somewhat broad.

It tends to impose extra obligations on EEE manufacturers. Therefore, it means that those in the PCB industry must also adhere to RoHS 2 directives.

Some of the notable directives here include proper affixation of CE markings on the finished products.

Another one involves producing technical documentation to demonstrate conformity and self-reporting non-compliance.

What restricted materials does RoHS2 stipulate?

RoHS 2 is an environmental regulation standard that remains a significant challenge, especially for the EEE industry.

There are many banned substances that electronic manufacturers continue to find challenging.

Ther Some of the most affected ones are those in the manufacture of PCBs. Some chemicals are so hard to avoid using during PCB manufacture.

Some of the restricted materials that RoHS 2 bans during the manufacture of electronics include the following:

- Polybrominated Diphenyl Ethers (PBDE): <1000 ppm

- Polybrominated Biphenyls (PBB): <1000 ppm

- Hexavalent Chromium: (Cr VI) <1000 ppm

- Mercury (Hg): <1000 ppm

- Lead (Pb): <1000 ppm

- Cadmium (Cd): <100 ppm

The above are some of the banned substances under the RoHS 2 directive. Nobody is sure as to whether there will be more additions in the future.

However, as things appear, there might be additional restrictions on other substances in the future. If such chemicals prove to be hazardous, then the list will surely increase.

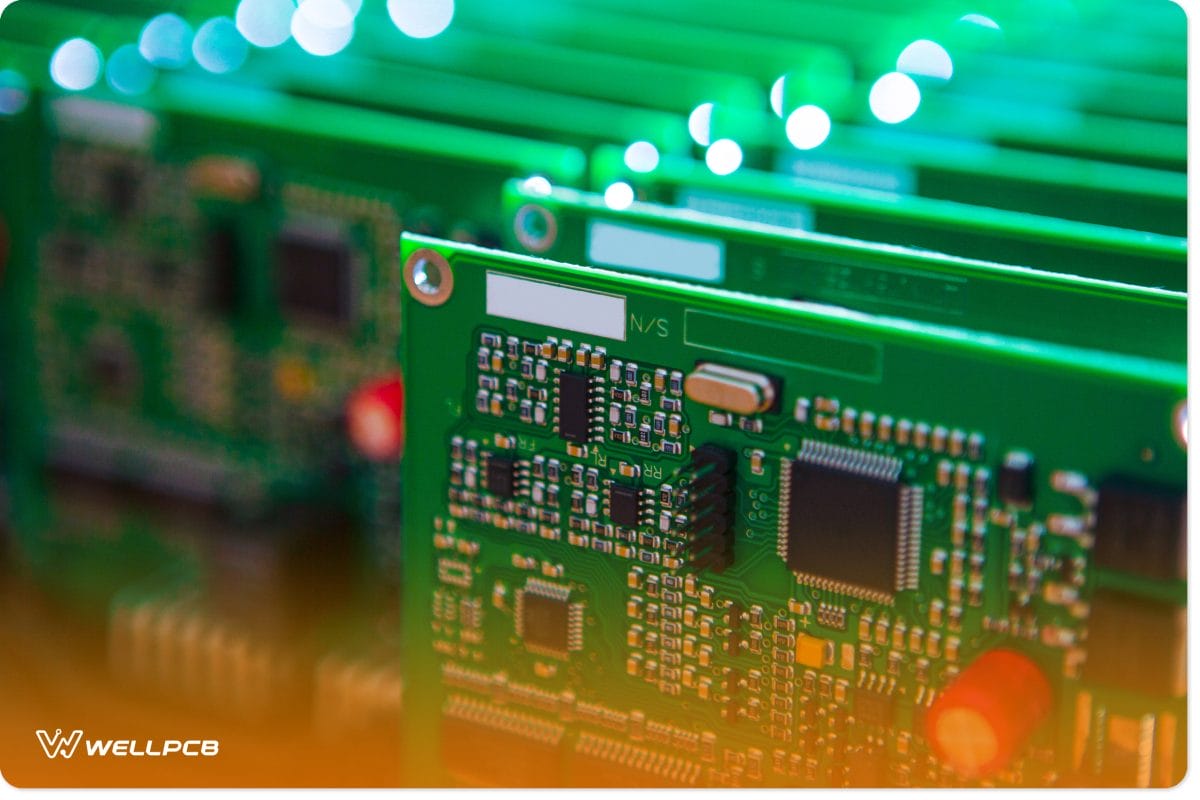

(The required RoHS material)

How vital is rohs2 compliant

According to scientific and environmental reports, the globe is on the receiving end of hazardous chemicals.

Most of these chemicals are those that manufacturers use in the production of electrical and electronic equipment.

Besides the environment, humans also suffer from these hazardous chemicals. Lead, for instance, is a chemical that can cause cancer when it has long-term exposure to the human body.

RoHS 2 standards are essential as the restrictions are hazardous to the environment.

They are harmful in terms of occupational exposure, especially during the production and recycling of electronic products.

However, with RoHS, there’s a significant depreciation of such dangers during electronics manufacture.

Companies that are RoHS 2-compliant stand in a better place.

But how, you may ask. Such firms show that they care for their customers. They relay the image that they produce products that don’t contain harmful effects.

By doing so, such firms gain their customers’ trust, an aspect that sees them quickly edging out competition from rival firms.

(A close image of RoHS-compliant boards)

How to fulfill RoHS 2 regulations in the PCB manufacturing industry

Implementation of RoHS 2 Directives and the Penalties

The first step towards the fulfillment of RoHS 2 directives is its full implementation. PCB makers need to accept the fact that compliance is inevitable.

Unless they want to be out of business, they need to ensure that they undertake the RoHS 2 directives’ full implementation.

Hence, the moment full implementation becomes achievable, what follows should be the penalties that apply.

There should be penalties on those who disobey the laid down RoHS 2 rules and regulations. These fines need to be highly severe to ensure that firms fear breaking them.

If there’s proof beyond doubt that a circuit company is flouting such rules, then they must pay hefty fines.

Such would act as a lesson to other PCB companies who attempt to use hazardous chemicals during manufacture.

Employee training

Learning, training, and undertaking some reskilling of the workforce should be never-ending in nature.

And so, learning is a continuous process.

Are the employees better trained on matters concerning the implementation of RoHS 2? If the fulfillment of RoHS 2 should go as planned, then employee training is necessary.

Untrained employees aren’t in any position to see the completion of RoHS 2 regulations.

If you are to produce printed circuit boards that meet industry standards, you must train your workforce.

Better yet, you need to train them on how to go about manufacturing boards consisting of the recommended chemicals.

Some of the best PCB firms have some of the best-trained personnel in circuit manufacture under RoHS 2 compliance guidelines.

So, make sure that you train your workforce.

As such, you may have to consider investing in a modern-day, online, and customizable Learning Management System software.

Such will enable you to achieve some of the best employee training, especially on RoHS 2 guidelines.

Avoiding some wrong everyday operations

Anything can go wrong when manufacturing PCBs that adhere to RoHS 2 guidelines. Some operations can go wrong, an aspect that may see you rolling out products that are not RoHS 2-compliant. If you want to ensure that your products meet RoHS 2 guidelines, you must avoid the wrong basic operations.

But how do you avoid wrong everyday operations here? It’s quite simple. All you have to do is ensure that everything is right from the start.

Also, make sure that every step and every process is right. You need to streamline everything from the chemicals used to the machine you’ll use.

This way, rest assured of boards that meet RoHS 2 directives.

Prepare relatively complete production documents.

In the manufacture of any product, complete production documents are essential. In case your production documents aren’t full, then you may end up with circuit boards that aren’t RoHS 2-compliant.

Production documents will tell you what you need to have, the machines you require to use, and the chemicals required.

The moment you’ve prepared your complete production documents, rest assured that you’ll quickly fulfill these regulations.

Choosing the right supplier

Lastly, to fulfill RoHS regulations when it comes to PCB production, make sure that you collaborate with the right supplier.

As a manufacturer, make sure that you only work with reliable suppliers. This way, you’ll ensure that you use the required chemicals when producing your circuit boards.

Failure to source your chemicals from the right supplier is disastrous. You’ll most likely manufacture PCBs that aren’t RoHS-compliant.

In the long run, such suppliers may not have information regarding the best chemicals that are RoHS-compliant.

In the end, you may end up encountering losses, especially if you have to recall your products.

Sourcing for a supplier is quite an effortless process. All you have to do is to search on the internet for reliable ones.

Go through their reviews to find out the best names in the industry. Also, make sure to check their years of experience and the volume of chemicals they push in a single year.

Doing this will ensure that you work with the best suppliers in the market.

(Female employees undergoing RoHS training program)

How to test PCB products to meet rohs2 regulations

Testing PCB products to ensure that they meet all the stipulated RoHS regulations is achievable in several ways.

PCB designers mostly use portable RoHS analyzers to do these tests. The portable RoHS analyzers also go by the name XRF metal analyzers or X-ray fluorescent.

The screen detects restricted metals. With four additional embodiments and RoHS phthalate 2 require different methods of testing such compounds.

For now, though, PCB designers mostly rely on RoHS analyzers to test their products.

(A PCB ready for RoHS X-ray inspection test)

What is the difference between RoHS2 and the original RoHS?

RoHS 2 is an improved version of the original RoHS. The original RoHS only contained a few banned substances.

These are substances not ideal in the manufacture of electrical and electronic equipment. However, ROHS 2 is an expansion of the original RoHS.

RoHS 2 now covers all electronic/electric equipment, spare parts, and cables. As of July 22, 2019, it was a requirement for all electronic companies to be RoHS 2-compliant.

There’s also another notable difference between the original RoHS and RoHS 2 worth noting.

Any product in scope manufactured under RoHS shouldn’t contain any of the six restricted substances.

The firm that places the work on the EU market has to maintain records to show compliance.

RoHS 2, on the other hand, demands additional compliance and good recordkeeping. Manufacturers need to keep a 10-year record.

Recordkeeping should include CE markings, conformity assessment, and self-reporting of any non-compliance.

The difference between RoHS2 and RoHS3

Next, RoHS 2 and RoHS 3 directives are worth every electrical and electronic equipment manufacturer’s attention.

So, what’s the difference between RoHS2 and RoHS3? On March 31, 2015, a new directive came to light.

That was Directive 2015/863, better known by many as RoHS 3. Here, there was the addition of four more substances that were restricted.

The enforcement of RoHS 3 restrictions took effect on July 2, 2019. Like its predecessor, RoHS 3 compliance applies to all proper electronic and electrical equipment marketed in the EU.

However, monitoring control tools and medical devices don’t have to comply with RoHS 3 instantly.

They enjoy an extra two-year grace period before complying with RoHS 3 directives (up to July 22, 2021).

Further discussion of RoHS 4 and RoHS 5

Will there be a RoHS 4? As of now, nobody can predict such exactly. Maybe we shall see RoHS 4 sooner rather than later and the inclusion of 7 other substances.

Some of the seven additional substances that are under asses are Cobalt, Beryllium, and Diantimony trioxide.

Others include Indium phosphide, Nickel, Medium-Chain Chlorinated Paraffins, and Tetrabromobisphenol A.

RoHS 5 is the compliance of 5 out of 6 restricted chemicals/substances but with no lead compliance.

It is essential to note that lead in specific applications for categories 8 and 9 are under the exemption for a few years.

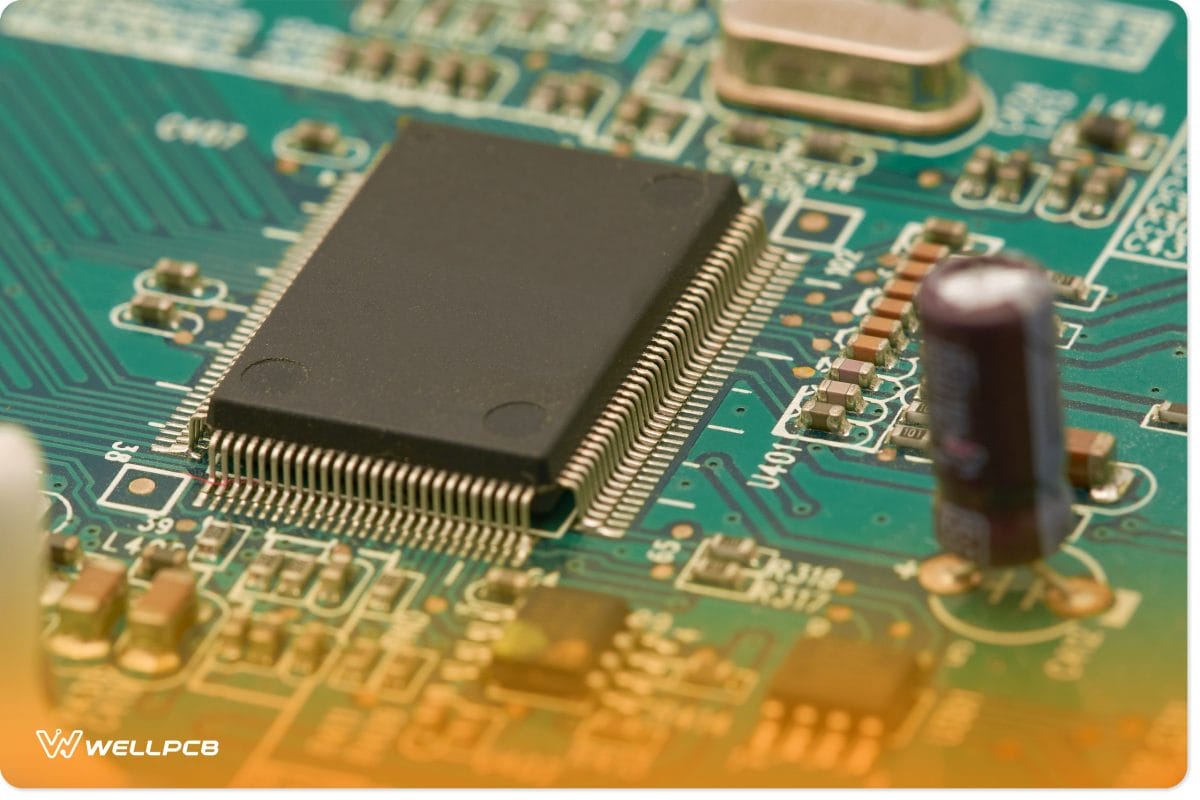

(A board made under original RoHS guidelines)

Understand ROHS 2 exemption

By now, you are well aware that RoHS restricts using certain hazardous chemicals in the manufacture of EEEs.

However, there are specific applications where such may not be possible. There are cases where it may be scientifically and technically challenging to limit their use. In such cases, then RoHS will not apply at all.

RoHS exemptions mostly differ from one jurisdiction to the next. In China, for instance, you’ll find that one prohibited substance has lots of uses in Korea. However, in general, some of the RoHS exemptions include the following:

- Mercury in single-sided capped fluorescent lamps

- Single-ended fluorescent lamps meant for general lighting

- Double-ended straight-tube fluorescent light with trichromatic phosphor, for general lighting

(A close pic of fluorescent lamp PCB)

Industries where RoHS 2 is applicable

There are several industries where RoHS 2 is applicable or may be applicable. First, it applies to business entities that sell or distribute electrical and electronic components.

Those eyes that sell or distribute components, sub-assemblies, or cables to EU nations are also under the directive of RoHS.

If you sell electronics to resellers or distributors who sell them to EU nations, you’ll have to adhere to RoHS directives.

RoHS also dramatically affects the metal industry. For any applications that call for anodizing, metal plating on finishes on electronic components, RoHS applies.

Most of these finishes are common in the production of printed circuit boards. It, therefore, means that the PCB industry also feels the effects of RoHS.

(RoHS-compliant PCBs meant for use in the metal industry)

General questions about RoHS2

The following encompasses some of the most general questions that many electrical and electronic experts ask regarding RoHS.

Again, it would help if you remembered that PCB makers are under the umbrella of electronic makers. Here are the questions:

What is the relationship between RoHS and REACH?

REACH (Registration, Evaluation, Authorization, Restriction of Chemicals) is a general regulation.

It addresses the production and subsequent use of chemical substances.

Mostly, it highlights their impact on the environment and human health. The European Chemical Agency (ECHA) monitors all the activities of REACH.

It deals with what they refer to as 197 Substances of Very High Concern (SVHC).

RoHS, on the other hand, restricts substances that are present in electronic/electric equipment. Such would include items such as cabling, wiring, displays, and, of course, circuit boards.

Of importance to note is that you’ll find all RoHS-restricted substances on the REACH-restricted list too. These substances are carcinogenic, reprotoxic, and mutagenic.

They are also bio-accumulative and endocrine disruptors. REACH further controls the products such as enclosures, coatings, paints, and solvents.

What is the relationship between RoHS and WEEE?

WEEE stands for Waste from Electrical and Electrical Equipment. Others refer to it as Directive 2002/96/EC, and It mandates the treatment, recovery, and recycling of electric and electronic equipment.

After August 13, 2006, all applicable products in the EU market needed to be WEEE-compliant. A “Wheelie Bin” sticker became a necessity too.

WEEE compliance aims to encourage the design of electrical components (PCBs-included) with recycling and recovery in mind.

RoHS further calls for the reduction of hazardous substances that electronic manufacturers use.

Seen from another angle, RoHS makes the regulation of dangerous substances while WEE checks for its disposal.

What is the relationship between RoHS and ELV directives?

There’s something regarding the relationship between RoHS and ELV directives worth noting.

First, the End of Live Vehicle deals with automobiles, while the RoHS directive does cover a wide array of electrical and electronic products.

All this is across several electronic industries, such as the printed circuit board industry. The ELV directive touches on electrical cables, wiring, and the components that vehicles use.

The ELV directive saw its implementation way back on July 1, 2003. It’s an old concept that limits the use of mercury, lead, hexavalent chromium, and cadmium.

RoHS took effect just recently in 2013. It’s not an old concept as such compared to ELV.

However, both are restrictive measures aimed at ensuring that companies in electronics manufacture limit the use of harmful substances.

The growing pressure for the manufacture of products free of hazardous substances such as those mentioned above will continue.

There seems to be no end in sight soon for such calls. Soon, there will be a replacement.

The globe will increasingly witness a substitute for products that no longer comply with regulations.

What is the relationship between RoHS and conflict minerals (T3&G)?

The relationship between RoHS and Conflict Minerals is mostly in the Full Materials Declaration (FMD).

More than often, a compliance declaration tends to list RoHS and Conflict Minerals (T3&G) in one place.

Some of the conflict minerals include tungsten, tantalum, gold, and tin. They go by the name 3TG minerals if the tracing of their origins.

In the Democratic Republic of Congo, the mining of cobalt is also active. Cobalt is one of those essential minerals that find heavy use in the production of batteries.

Electric cars mostly use these types of batteries, and their mining is bound to increase in the years to come.

The most significant relationship between RoHS and Conflict Materials (T3&G) is the aspect of self-reporting. Self-reporting ensures compliance with industry standards.

As mentioned earlier, RoHS directives compel companies dealing with electronics to self-report such as proof of submission. The same is true with Conflict Materials (T3&G).

Under the Dodd-Frank Act, the entire public-traded firms have to report to the SEC where their conflict materials originate from in the globe.

(A fully-compliant RoHS PCB-board)

Summary

To sum it all up, we cannot ignore the need to implement RoHS 2 guidelines. If we don’t continue its implementation, then both the environment and human health will feel its impacts.

The impacts are mostly negative. RoHS 2 restricts the use of hazardous chemicals that aren’t fit for humans and the environment.

At WellPCB, we are RoHS 2-compliant and utilize lead-free solder plating on our PCBs. We fully comply with human and environmental health protection laws.

Contact WellPCB should you have any questions regarding RoHS. We can discuss with you its regulation scope and can make your boards more user and environmentally friendly!