LED PCB Board Supplier Manufacturer

- LEDs are semiconductor diodes that belong to the category of

electroluminescent lights. - LED PCBs are single or double color LEDS that come in white or blue.

- LED assembly PCB is the soldering of Light-emitting diodes to a PCB, by a manufacturer, along with a small chip that produces light when electrically connected.

Looking for a Reliable LED PCB Board Manufacturer & Supplier?

WellPCB is a trusted LED PCB board manufacturer, offering high-quality LED lighting PCB assembly services. We specialize in custom LED PCB designs and provide durable, efficient solutions for various LED applications. As a trusted supplier, we deliver top-notch LED PCB assemblies with precise craftsmanship.

- Professional engineer review; strict quality control for each process.

- Advanced Testing Technology To Ensure the Quality such as AOI Test, E-Test, X-RAY, Impedance Control.

- Wne committed to helping customers get the highest quality products and services with competitive prices (especially multilayers PCBs).

- FR4,High TG FR4, High-frequency Material, Rogers PCB, Metal based PCB.

- Superior customer service (personal to personal).

What Is an LED PCB

Assembly?

LEDs are semiconductor diodes that belong to the category of electroluminescent lights. And they produce light by combining sufficient energy gaps with charge-carrier pairs in a semiconductor. LED PCBs are single or double color LEDS that come in white or blue.

Hence, they act as indicator lights for membrane switches. And they are most suitable under rubber keypads and polyester materials. So, LED PCB Assembly is the soldering of Light-emitting diodes to a PCB, by a manufacturer, along with a small chip that produces light when electrically connected.

From the name, this type of PCB has two or more layers of LED PCB. The numerous layers stick together with the help of a special type of glue. Also, you can find different insulators in between the layers. The work of the insulators is to keep the LED from melting because of excess heat.

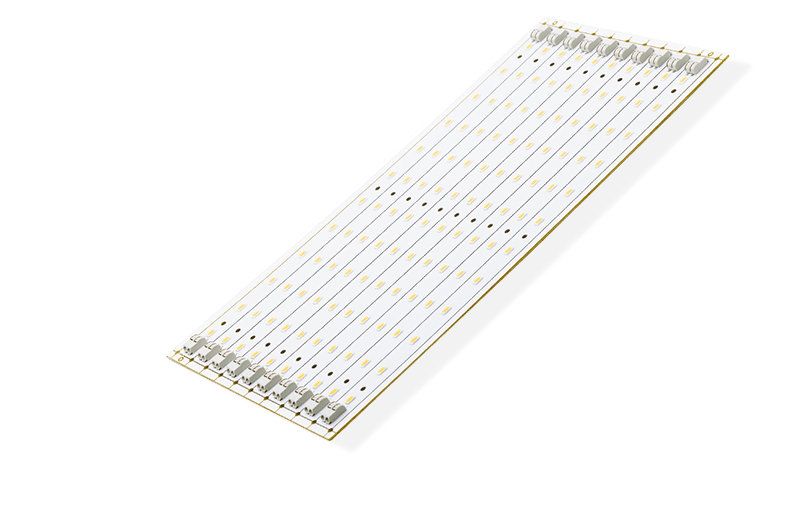

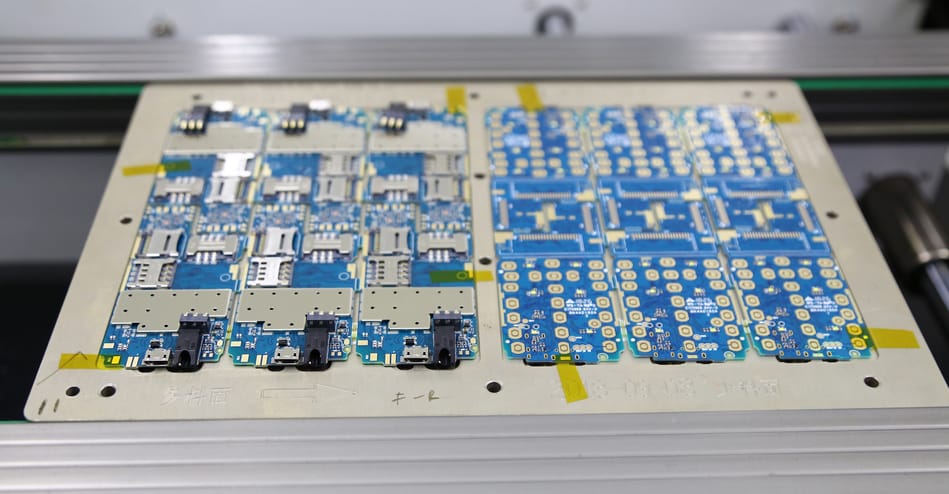

led pcb assembly

Capabilities

Here are the major types of LED printed circuit boards available in the market.

Single Layer LED PCB

The single-layer LED PCB has only one layer of the substrate or one side of the circuit. The single layer is usually made of copper, which is a great conductor.Also, this PCB is relatively straightforward, very simple to design, and pretty affordable.

Multi-Layer LED PCB

From the name, this type of PCB has two or more layers of LED PCB. The numerous layers stick together with the help of a special type of glue. Also, you can find different insulators in between the layers. The work of the insulators is to keep the LED from melting because of excess heat.

Hybrid LED PCB

This PCB comprises a non-thermal material merged with a base metal like aluminum.

Most times, the hybrid LED PCB comes with an aluminum substrate and a conventional FR4 binding.

With both materials joined together, it’s simple for the PCB to dissipate heat, making it more rigid but less flexible.

Flexible LED PCB

Flexible LED PCBs consist of a flex material that can twist in any direction without breaking. So, they come in different forms like single, double, and even multiple layers. However, they are one of the most expensive LED PCBs because you need to print the circuit on them. Hence, they are durable, and you can use them for environmentally hazardous areas.

Rigid LED PCB

This PCB is the exact opposite of the flexible LED PCB. The rigid PCB is quite stiff and doesn’t bend easily like the flexible ones. But, most manufacturers prefer to use it when they want an electronic device to stay in shape. So, you’ll mostly find them on computers. And they come in various forms; single, double, and multiple.

Why Is LED PCB Assembly

Essential?

These days, with many electric devices getting smaller and thinner, more engineers and manufacturers use LED PCBs. Hence, using LED PCBs comes with loads of benefits.

Ease of Use and Flexibility of Multiple LED components

- It’s effortless to modify and tune the color function of multiple LED components within the same LED when you use LED PCBs.

- That way, you can have a variety of colors and color temperature in one PCB.

- You can also have different light fixtures meeting other lighting requirements with boards that have diverse materials, sizes, and shapes.

Ingenious Lower Power Consumption

- With LED PCBs, you can be sure of saving a lot of power consumption.

- So, if you’re a green advocate, you’ll love this option.

Effective Heat Dissipation

- Like we mentioned earlier, LED PCBs usually work with metalcore and aluminum components. /li>

- Hence, you won’t face overheating issues because its dielectric thermal conductive material helps dissipate heat effectively.

Wide Variety of Choices

- LED PCBs usually come in different intensities, sizes, and colors.

- Thus, there are always a lot of options to choose from that will fit your requirements.

Supports Membrane Switches

- You can use LED PCBs for either copper flex membrane switches or silver flex membrane switches.

- And you can use the membrane switches for modern electrical appliances like kidney dialysis machines, touch screen phones, etc.

Moisture and Dust Resistance

- This feature means that LED PCBs aren’t affected by moisture or dust because of their material components.

Lightweight

- Generally, LED PCBs are usually lighter than many other PCBs.

- That’s why most technology companies use them in producing modern tech devices like smartphones, tablets, etc.

The Applications of the LED PCB

Assembly

Because LED PCBs have outstanding design flexibility, exceptional energy efficiency, and low cost, you can incorporate them in various lighting applications. And they are as follows:

Automotive

- In the automotive industry, LED PCBs are useful in headlights, brake lights, car indicators, and many other applications.

- Also, low cost and durability are other factors that make LED PCBs suitable for the automotive industry.

Medical

- You can find High-powered LED lights used in medical examinations and theaters.

- And these LED PCBs are responsible for powering these LED lights because of their heat transfer features and sturdiness.

- Hence, with the LED PCBs, these medical equipment tend to function correctly—not minding the traffic cycling the hospital to use the equipment.

Computer

- In computer applications, LED indicators and displays are quite popular.

- Hence, LED PCBs are a suitable solution for the heat sensitivity of computers.

- That’s why you can find LED PCBs used in computer components like CPU boards and power devices because of their high capacity to transfer and dissipate heat.

Telecommunications

- LED PCBs are also suitable for telecommunication devices because of their excellent heat transfer feature and surrounding machinery.

- Therefore, LED PCBs create a massive effect on the telecommunications industry.

What Are the Design Techniques Applied for LED PCB Assembling?

When it comes to the LED PCB assembly, there are some design techniques you can apply.

Pitch

Pitch is a design method you can use on different parts of the board. And there’s an effective way to achieve this feat if you’re dealing with the copper layer. Hence, it’s imperative to cover one side of the board with pads arranged in the matrix.

Also, the assembled LED has four pads, and the components usually get arranged on the driver’s side. And avoiding a large LED is essential for resolution and display effect, especially for a smaller LED pitch.

Also, it’s crucial to note that there is a range you should use. Hence, the LED pitch is usually between 1.0 to 4.0 (mm). And the or SMT pitch ranges between 0.45 to 1.6 (mm).

LED Installing Holes

The LED installing holes are non-penetrating, and they have individual specifications. So, the installing holes should have a board thickness of -0.5mm. Plus, it’s vital to stick to a drilling angle of about 1300. Also, it’s ideal to have a depth tolerance of not more than ±0.2mm. The diameter tolerance, on the other hand, should be ±0.5mm.

If you notice that the holes have inadequate distance at the copperless area, you have to plate through holes. That way, your copper won’t be bare at the margin of vias.

Laser Drilling Blinding Vias

If you design your stack as a laser drilling one and your boards have a minimum of two layers, it’s safe to use the electrical soldering blind through the filling method. However, you should know that this method is expensive, and it comes with some complications. Plus, it’s best to design your laser drilling blind vias if your stack board has over two layers.

Solder Mask Opening Pad

If you opt for this design technique, you have a goal to ensure your pads are highly consistent. Hence, you can use copper on your pads. That way, you’ll stop the solder mask from peeling.

Space Between Outer Margins and Outer Pads

- Prototype orders placed within 24 hours

- Normal lead time (5-7 working days for some PCBs prototypes and small batch production)

- Faster lead time (48 hours for some PCBs prototypes and small batch production)

7 Ways to Avoid LED

PCB Setbacks

Solder Mask Oil Color Unconformity

- This situation usually happens when there are so many elements. Also, strict production conditions could play a role.

- But, you can avoid this by picking the best technique and control parameters.

- Also, it translates to reliable production technologies and years of experience by the manufacturer.

Circuit Scratch

- You may experience a circuit scratch when your pads have high density. And the high density is usually on the part of the LEDs.

- It's possible to curb this issue by reducing the line pitch.

- Accept T/T, cash, credit card, PayPal, bank transfer, etc.

- That way, it enhances the angle between the pad and line.

Board Angle Defects

- Board angle defects occur when the LED board has fragile side angles.

- It could also happen if the boards have a high thickness. But, you can avoid it by adding a base plate.

- The base plate serves as a protective measure.

Warpage

- Board warpage could result when the board has a lot of pads.

- And the pads have high density. Plus, the driver side of the pad has large blocks of copper.

- In this case, you have to work towards flatness. You can achieve flatness on the board when you ensure that the warpage is under 0.5%.

Degrading Functions

- You may experience degrading function when a whole row of LEDs fail.

- So, you can tackle this issue by relying on either solder mask oil removal or destruction of components.

Pad Outline

- A high omission ratio is inevitable—especially when you arrange your pad in the matrix.

- So, the best way to handle this problem is to focus on procedure control.

Solder Mask Oil Peeling

- Solder mask peeling occurs due to exposure to energy. And you can handle this issue by applying secondary exposure.

- But, it's vital to note that secondary exposure may affect the solder mask consignment capacity.

Why Choose Us for LED PCBs?

In China, we pride ourselves as one of the biggest PCB manufacturers. And it’s because we deliver top-notch products and services to meet all of your project demands.

So, whether you’re ordering a small, mid, or large-scale, we’ve got you covered 100 percent.

Are you interested in getting a free quote today?

FAQs - LED PCB Manufacturer

Obtain a quick LED PCB quotation through our convenient online quote system at WELLPCB.com. You may also email us your Gerber files and project details to receive a formal quote within 24 hours.

Should you experience any issues or dissatisfaction with your LED PCB boards, please contact us immediately via email. We guarantee a reply within 24 hours and offer re-fabrication, a complete refund, or account credit without needing the return of defective products.

Order cancellations incur fees based on the production stage of your LED PCB order. Please immediately contact us and confirm your cancellation via email or fax for record purposes.

Yes, we can switch your shipping method if another courier offers a faster delivery option for your LED PCB boards, aiming to enhance your ordering experience.

Certification

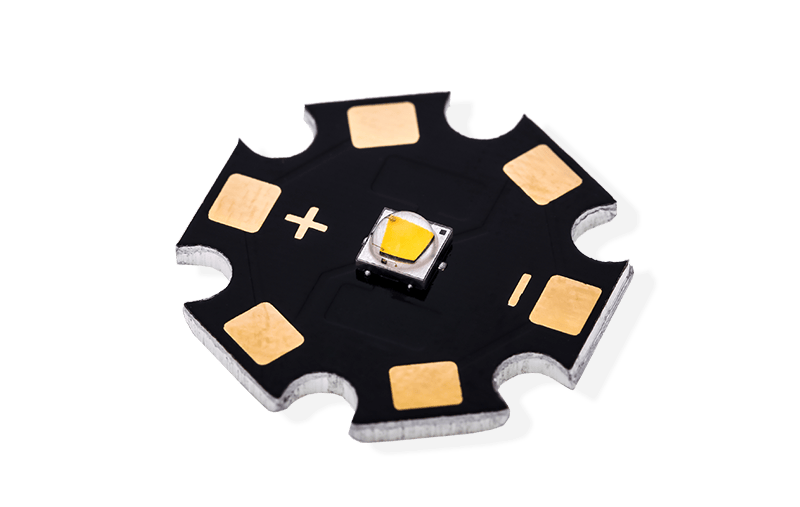

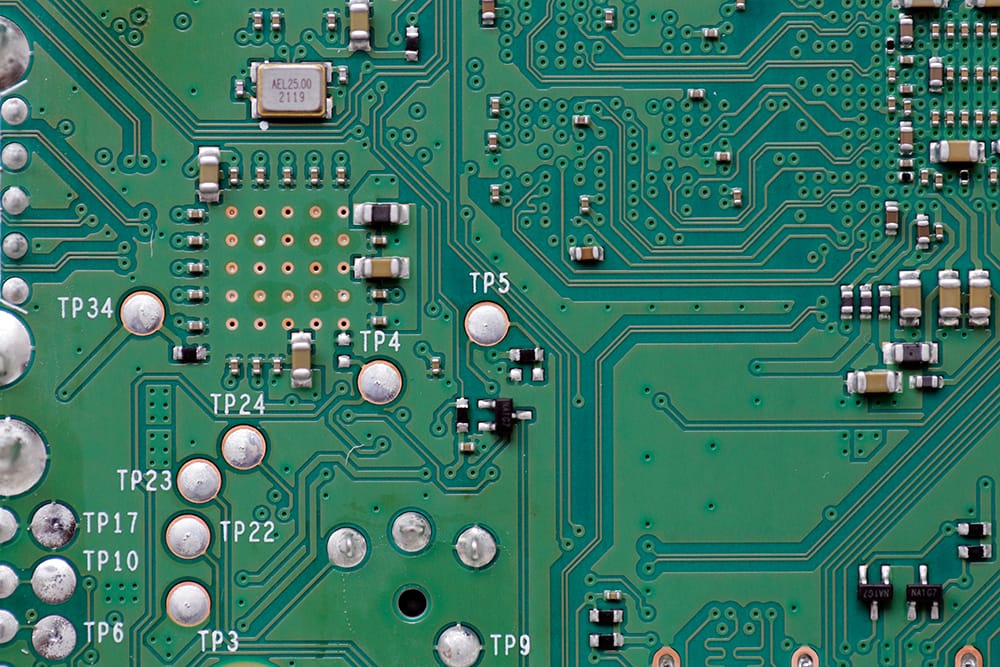

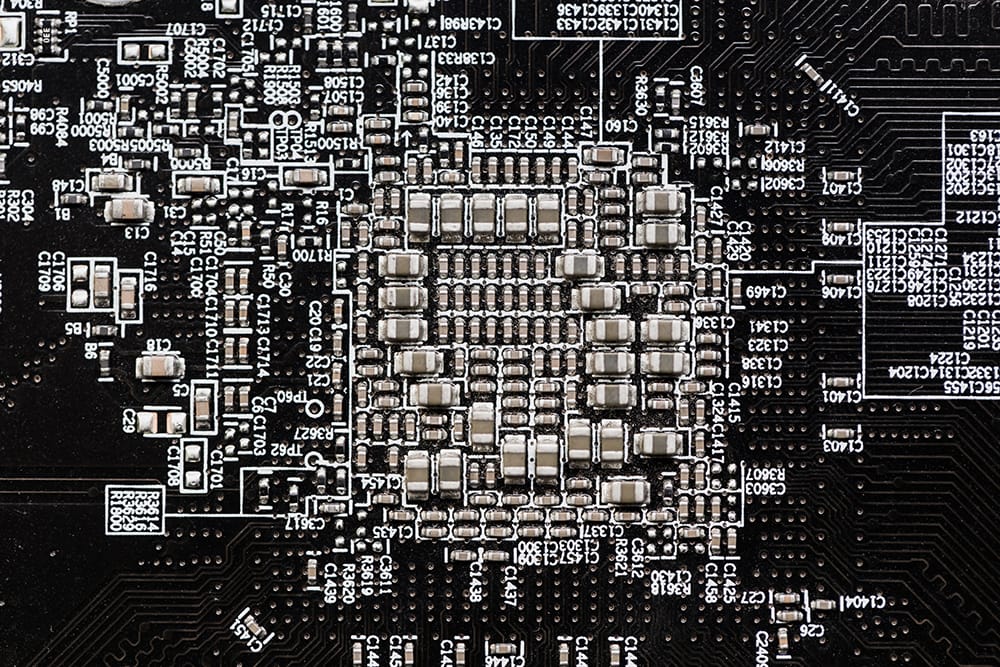

Products Show