China Flex PCB Assembly Supplier & Manufacturer

WellPCB provides China flex PCB assembly services for compact, high-reliability electronic products. We manufacture single-sided, double-sided, and multi-layer flexible circuits designed for space-saving layouts and durable bend performance.

- Production thicknesses from 0.05 to 0.8 mm with impedance control tolerance ±5 Ω (advanced: ±3 Ω).

- Lead times from 3 to 6 days standard, with expedited 2 to 4 day options available.

- All builds tested with AOI and flying probe.

ISO9001 ISO13485

ISO14001

IATF

16949

IPC-A-610H International

Certification

Fully Automated

AOI Inspection

- PCB Manufacturer

- PCB Assembly Service

- Flexible

Flex PCB Manufacturer and Assembly Services

WellPCB manufactures precision flex PCB boards, including flat flexible cables, HDI flex circuits, and multi-layer flex PCBs with impedance control, coverlay, and optional stiffeners. We offer full in-house production from PCB design review through fabrication, surface finishing, and final assembly, supporting flex PCB prototypes and production quantities.

Our flex circuits are built for applications requiring tight bend radius, mechanical durability, and space efficiency using high-temperature polyimide substrates, precise coverlay application, and multilayer stackups.

Manufacturing Process & Specifications:

Every flexible circuit undergoes copper-clad laminate cutting, mechanical or laser drilling, copper electroplating, and circuit patterning through dry film photolithography and UV exposure. Final builds are finished with OSP, HASL, immersion gold, or immersion silver surface treatments, and structurally reinforced with optional stiffeners.

All boards are processed with 3 mil trace/space, 4 mil pad clearance, and advanced surface treatment like OSP, immersion silver, or ENIG. Production thicknesses range from 0.05 to 0.8 mm with impedance control tolerance ±5 Ω (advanced: ±3 Ω). All builds are tested with AOI and flying probe to ensure quality and reliability.

Our Flex PCB Manufacturer

Capabilities

WellPCB manufactures flex PCBs with layer counts from 1 to 6, with ultimate builds extending to 10 layers for specialized multi-layer flex circuits.

Fabrication uses polyimide base materials such as Shengyi SF305, Songxia RF-775, and Taihong PI, supporting dielectric stability, thermal resistance, and fine-line processing.

Production tolerances include a minimum 3 mil trace/space, 0.1 mm laser drill, and 0.15 mm mechanical drill, with pad-to-pad clearance down to 4 mils (3 mils in high-density designs).

Finished board thickness ranges from 0.05 mm to 0.5 mm (up to 0.8 mm for advanced builds), with finger width tolerance ≥0.1 mm (≥0.05 mm for precision contacts).

| Specification | Details |

|---|---|

| FPC Base Material (Adhesive) | Shengyi SF302: PI=0.5 mil, 1 mil, 2 mil; Cu=0.5 oz, 1 oz Shengyi SF305: PI=0.5 mil, 1 mil, 2 mil; Cu=0.33 oz, 0.5 oz, 1 oz |

| FPC Base Material (Adhesiveless) | Songxia RF-775/777: PI=1 mil, 2 mil, 3 mil; Cu=0.5 oz, 1 oz (Ultimate: PI=1 mil, 2 mil, 3 mil; Cu=2 oz) Xinyang: PI=1 mil, 2 mil; Cu=0.33 oz, 0.5 oz, 1 oz Taihong: PI=1 mil, 2 mil; Cu=0.33 oz, 0.5 oz, 1 oz Dubang AP: PI=1 mil, 2 mil, 3 mil, 4 mil; Cu=0.5 oz, 1 oz (Ultimate: PI=1 mil, 2 mil, 3 mil, 4 mil; Cu=2 oz) |

| Layer | 1-6 Layers (Ultimate: 7-10 Layers) |

| Thickness of Finished Product (Flex part, no stiffener) | 0.05-0.5 mm (Ultimate: 0.5-0.8 mm) |

| Size of Finished Products (Min) | 5 mm × 10 mm (Bridgeless); 10 mm × 10 mm (Bridge) Ultimate: 4 mm × 8 mm (Bridgeless); 8 mm × 8 mm (Bridge) |

| Size of Finished Products (Max) | 9 inch × 14 inch Ultimate: 9 inch × 23 inch (PI ≥ 1 mil) |

| Impedance Tolerance | Single-Ended: ±5Ω (≤50Ω), ±10% (>50Ω) Ultimate: Single-Ended: ±3Ω (≤50Ω), ±8% (>50Ω) |

| Impedance Tolerance | Differential: ±5Ω (≤50Ω), ±10% (>50Ω) Ultimate: Differential: ±4Ω (≤50Ω), ±8% (>50Ω) |

| Tolerance of Finger Width | ±0.1 mm (Ultimate: ±0.05 mm) |

| Min Distance to the Edge of Finger | 8 mil (Ultimate: 6 mil) |

| Min Distance between Pads | 4 mil (Ultimate: 3 mil) |

| Minimum Laser Hole | 0.1 mm |

| Minimum PTH | 0.3 mm |

| Min NPTH Tolerance | ±2 mil (Ultimate: +0, -2 mil or +2 mil, -0) |

| Solder Bridge Min Width (bottom copper < 2OZ) | 4 mil (Green), 8 mil |

| Solder Bridge Min Width (bottom copper 2–4OZ) | 6 mil, 8 mil |

| Overlay Colour | White, Yellow (printed character: White) |

| Type of Surface Treatment | OSP HASL, Lead-free HASL, Immersion gold, Hard gold, Immersion silver, OSP |

| Selective Surface Treatment | ENIG+OSP, ENIG+G/F |

We integrate FR4 stiffeners from 0.075 to 3.2 mm and polyimide stiffeners from 0.025 to 0.225 mm, with adhesive widths controlled to 1.5 ± 0.5 mm and minimum copper clearance of 0.3 mm.

On high-cycle flex designs, these are commonly used for ZIF connectors, edge contacts, and mechanical reinforcement zones.

Stiffener design and placement follow IPC-2223 guidelines for mechanical reinforcement and pad stability in dynamic flex zones.

We offer ENIG, Lead-Free HASL, OSP, Immersion Tin, and Immersion Silver finishes for all flex PCB builds. Surface treatments are applied to exposed copper for solderability, oxidation resistance, and electrical contact durability.

ENIG is preferred for high-density designs and gold finger edge connections; OSP is ideal for prototype runs and flat SMT pads. Selective finish combinations such as ENIG + OSP are available for mixed-performance zones.

Peelable mask can be combined with coverlay for selective solder areas, ZIF connectors, or rework zones. All finishes conform to IPC-455x series standards for surface coatings and meet RoHS-compliant lead-free assembly requirements.

All flexible printed circuit boards can be manufactured with impedance control:

- •Single-ended: ± 5 Ω (≤50 Ω), ±10% (>50 Ω)

- •Advanced builds: ± 3 Ω (≤50 Ω), ±8% (>50 Ω)

These tolerances (as precise as ±3 Ω) are validated through TDR testing and reflect industry-leading control for RF, sensor, and high-speed signal designs. For controlled impedance in RF, medical, and sensor applications.

All flex PCBs undergo AOI, Flying Probe, ICT, and FCT to ensure circuit continuity and electrical performance.

Structural reliability is validated through X-ray inspection, micro-section analysis, peel strength testing, and thermal shock simulation.

We also perform impedance testing on controlled line widths to confirm ±3 Ω or ±5% targets for matched-line designs.

WellPCB provides full flex PCB assembly, including SMT, through-hole, and mixed technology builds.

We support BGA (down to 0.2 mm pitch), QFP (0.15 mm), and fine-pitch component placement with ±30 μm accuracy at CPK ≥1.

Assembly capabilities include conformal coating, box builds, and component sourcing from Mouser, Digi-Key, Arrow, and Avnet. Board sizes range from 50 × 50 mm to 610 × 508 mm.

We manufacture RF, coaxial, ribbon, overmolded, and waterproof cable assemblies for flex integration.

Custom wire harnesses are available for automotive, medical, aerospace, and robotic applications.

All cable assemblies are thoroughly tested and can be delivered as part of complete electromechanical builds or standalone units.

Why Choose WellPCB?

WellPCB delivers technically driven flex PCB manufacturing with full in-house control, certified processes, and materials qualified for demanding environmental and electrical performance. Our capabilities are built around precision, consistency, and application-specific engineering.

One-Stop Manufacturing & Assembly

WellPCB provides full-spectrum production from flex PCB fabrication to turnkey assembly and custom cable harnesses.

All builds are executed in-house under controlled conditions, eliminating multivendor risks and ensuring consistent process traceability.

Engineering-Driven DFM Support

This early-stage review identifies potential violations and aligns the design with flex fabrication tolerances for high-yield production.

Advanced Material Options

We stock a wide range of polyimide substrates from suppliers like Shengyi, Songxia, and Taihong.

Available configurations include adhesive and adhesiveless base films (0.5 to 4 mil), and copper weights from 0.33 oz up to 20 oz for heavy copper flex circuit applications.

Certified Manufacturing Capabilities

WellPCB is certified to ISO 9001:2015, ISO 14001, IATF 16949, ISO 13485 and UL. All builds are manufactured to IPC-6013 specifications.

Process traceability, controlled documentation, and material tracking are maintained for automotive, aerospace, and defense-grade flexible electronics.

Heavy Copper & Power Flex Expertise

These builds are ideal for hybrid power/signal applications, where mechanical flexibility must be paired with electrical and thermal robustness.

Rapid Turnaround with Global Reach

Standard lead times range from 3 to 6 days, with flex PCB prototypes deliverable in as little as 24 to 48 hours.

All shipments are packaged with anti-static, moisture-proof, and vibration-resistant materials and shipped globally via our preferred logistics partners.

What is a Flex PCB?

A flex PCB is a printed circuit board built on a flexible base material such as polyimide, allowing the circuit to bend, fold, or twist while maintaining electrical function. These boards are engineered for dynamic mechanical conditions and tight enclosures where traditional rigid formats are unsuitable.

They support dense PCB design, reduced weight, and continuous flexing. Flexible circuit boards can be manufactured as single-sided, double-sided, or multi-layer flex circuits, and are built with features like stiffeners, coverlay, impedance control, and surface finishes optimized for assembly and performance in medical, aerospace, and consumer electronics.

What Materials are Used in Flex PCBs?

Flex PCBs are constructed using high-performance materials selected for electrical stability, mechanical flexibility, and thermal resistance. Core layers include polyimide substrates, copper foil, adhesives (if used), and coverlay for insulation.

Flexible Polyimide Substrates

Compared to FR4, polyimide supports a tighter bend radius and dynamic flexing but requires controlled humidity storage due to higher moisture absorption.

DuPont, Pyralux Material Options

Pyralux LF (Low-Flammability): Acrylic-based laminate with or without adhesive and copper. Not UL-rated; suitable for low-heat or non-critical builds.

Pyralux FR (Flame-Retardant): UL-rated material with flame-retardant adhesive and dielectric layers. Designed for reflow-capable, high-temperature applications.

Pyralux AP (All-Polyimide): Adhesiveless construction with double-sided copper; used for high-speed, high-reliability flex circuits requiring fine line width and impedance stability.

Copper Foil

Rolled-annealed (RA) copper is preferred for dynamic flex zones; electro-deposited (ED) for static or low-cycle designs.

Foil weights from 0.33 oz to 2 oz standard (up to 20 oz supported), with 3 mil trace/space depending on foil grade and processing.

Adhesive Systems

Acrylic or epoxy adhesives (12 to 25 μm) are used between copper and substrate in laminated builds.

Adhesiveless constructions eliminate this layer, offering better signal integrity, reduced Z-axis movement, and finer line control for HDI layouts.

Coverlay Film

Coverlay layout and lamination parameters follow IPC-6013 Type 1/2 for single and double-sided flexible constructions.

What's the Difference Between Flex and Rigid PCBs?

Flex PCBs are constructed entirely from flexible materials like polyimide, allowing the full board area to bend, fold, or twist during use. Rigid-flex PCBs combine one or more rigid layers with integrated flexible layers, enabling 3D routing between rigid sections while limiting flexibility to defined areas within the stackup.

| Feature | Flex PCB | Rigid-Flex PCB |

|---|---|---|

| Core Construction | Manufactured from a flexible polyimide substrate, which is between 0.5 to 4 mil thick, with optional adhesive or adhesiveless layers. | A hybrid structure combining rigid PCB cores (FR4 or BT resin) with laminated flex layers between or across zones. |

| Layer Configuration | Available in single-sided, double-sided, and up to 10-layer flex circuits with coverlay for insulation. | Supports advanced stackups (e.g. 2+N+2) with mixed rigid and flexible layers. Includes via-in-pad, buried/blind vias, and impedance-controlled regions. |

| Mechanical Behavior | Designed for continuous bending, folding, and tight bend radius installations. Optimized for dynamic motion. | Typically, flex-to-install or limited dynamic flex. Rigid sections maintain mechanical stability for connectors or component loads. |

| Assembly | Built for lightweight, connector-free signal routing. Assembled with SMT or through-hole components in flex zones. | Allows direct mounting of components on rigid zones, while flex areas route signals. Reduces interconnect failure by eliminating jumpers and connectors. |

| Use Cases | Ideal for wearables, foldable devices, sensors, cameras, and medical implants with space or motion constraints. | Common in aerospace, medical instrumentation, military electronics, and 3D-assembled modules requiring structural rigidity. |

| Fabrication Complexity | Lower complexity: fewer lamination steps, simpler tooling, faster build times. | Higher complexity: sequential lamination, multicore alignment, and more extensive DRC for rigid/flex interaction. |

| Cost Factors | Lower cost per unit for most builds. Ideal for prototype and volume production where board flexibility is a core requirement. | Higher cost due to material stackup, rigid zone fabrication, and tighter registration tolerances. Best suited for integrated, high-reliability systems. |

What does the Flexible PCB Manufacturing Process Involve?

Our flex PCB manufacturing process is built around fine-pitch tolerances, controlled material handling, and clean room-level imaging steps designed for polyimide-based flexible circuits.

1. Cutting

Copper-clad polyimide laminate sheets are sheared and trimmed to production panel size.

Edges are smoothed to eliminate burrs that may affect registration.

2. Drilling

Mechanical or laser drilling is used to create plated through-holes (PTHs).

While buried or blind vias are not typical for double-layer boards, our systems support them for advanced flex structures.

3. Electroplating

Panels are cleaned and plated with electroless copper, followed by electrolytic copper to build up wall thickness and create electrical interconnects.

4. Pre-Processing & Dry Film Application

A photosensitive dry film is laminated onto both sides of the panel in a low-light cleanroom.

This layer defines the circuit trace pattern during imaging.

5. Alignment & Exposure

Phototools are aligned optically, and UV light hardens the exposed photoresist to lock in the circuit design with ±25 μm accuracy.

6. Development

Unexposed photoresist is removed using a developer solution, leaving only the hardened image areas.

7. Graphic Electroplating

Additional copper is plated over the imaged traces and vias, followed by a tin protective layer for later etching protection.

8. Etching & Resist Strip

Panels are etched to remove unwanted copper and expose the final trace geometry.

Tin is stripped to reveal clean copper features.

9. Degreasing & Cleaning

Chemical cleaning removes all remaining residues to prepare the surface for finishing.

10. Surface Treatment

Final surface finishes like OSP, ENIG, or immersion silver are applied to all exposed copper for solderability and corrosion protection.

11. Coverlay Application

A laser-cut polyimide coverlay replaces the traditional solder mask.

It is applied to both sides for mechanical and dielectric protection.

12. Pressing & Solidification

Coverlays are thermally laminated using precise pressure, temperature, and dwell time profiles for a unified flexible structure.

13. Immersion Nickel (Optional)

Additional nickel plating may be applied to exposed pads for wear resistance or gold finger applications.

14. Silkscreen Printing

White ink is screen-printed to label components, test points, and reference marks.

15. Electrical Testing

Flying probe testing verifies open/short integrity of every net against the original netlist.

16. Punching

Finished boards are routed or punched from the production panel to an individual piece format.

17. Final Inspection & Packaging

Each flexible printed circuit board is inspected with AOI for trace defects, pad misalignments, or surface inconsistencies. Qualified boards are sealed in moisture-resistant, anti-static packaging for global shipment.

How to Order Your Flex PCB

in 5 Easy Steps

Submit Your PCB Design

Upload your Gerber files or use our easy online PCB design tool to create your board layout. Make sure your files are complete and correctly formatted to ensure smooth processing and production accuracy.

Select Your PCB Specifications

Customize your order by choosing the technical specifications—number of layers, board dimensions, thickness, copper weight, solder mask color, surface finish, and more. Our intuitive interface helps you configure everything based on your project’s needs.

Get an Instant Quote

Once your design and specs are in place, you'll receive a transparent, instant quote. Pricing updates in real time as you modify options, so you can adjust your selections to match your budget before placing the order.

Confirm Order & Make Payment

Review your entire order for accuracy, including file previews and selected specs. After confirmation, proceed to secure checkout and choose your preferred payment method. You’ll receive an email confirmation with order details.

Production & Delivery

Your PCB moves into production immediately. We’ll keep you updated throughout the manufacturing process. Once completed, your boards are carefully packed and shipped to your door, with tracking information provided for your convenience.

Where are Flex PCBs Used?

Flex PCBs are used in systems where size constraints, dynamic movement, and weight reduction require compact, bend-capable interconnects. Their ability to maintain electrical performance under mechanical stress makes them ideal for harsh and high-density environments.

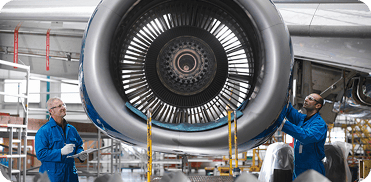

Aerospace

Flexible PCBs are integrated into navigation systems, radar modules, heads-up displays, temperature sensors, and engine control electronics.

Their ability to tolerate vibration, heat, and continuous flexing makes them suitable for confined airborne assemblies where rigid boards are not viable.

Defense

Military-grade systems use flex circuits in CubeSats, portable targeting devices, missile control boards, and wearable gear.

These builds benefit from reduced connector count, lower profile, and reliable circuit performance under mechanical load and thermal cycling.

Medical Devices

Pacemakers, defibrillators, heart monitors, cochlear implants, hearing aids, and pill cameras use flexible circuit boards to meet strict size, shape, and bend requirements for internal or wearable electronics, enabling reliable circuitry in compact, motion-prone environments.

Consumer Electronics

Used in foldable smartphones, fitness trackers, action cameras, and OLED screen modules, flex PCBs enable tight PCB design inside dynamic housings where mechanical flexibility and signal integrity must coexist.

Automotive Electronics

Infotainment systems, ADAS modules, airbags, lighting systems, and digital dash displays use flexible PCBs to route signals through tight enclosures while tolerating engine vibration and heat.

Their controlled bend radius and material endurance are critical to long-term reliability.

Industrial Equipment

Flex boards are implemented in robotic joints, sensor networks, and compact control systems, delivering durable signal paths in motion-heavy and space-constrained environments.

Telecommunications

Base stations, antennas, portable transceivers, and satellite communications hardware use flexible circuits to manage high-frequency signal paths in ultra-compact RF enclosures.

WellPCB is trusted by millions of

businesses and innovators.

Why Choose WellPCB?

WellPCB stands out among USA PCB manufacturers by delivering superior quality, advanced solutions, and unmatched reliability. With years of experience serving global markets, WellPCB has earned a reputation as one of the top PCB manufacturers in USA.

WellPCB specializes in multilayer PCBs for advanced electronic applications. You can order these boards with $100 off using our special offer, providing high complexity at competitive rates for demanding projects.

Hommer Zhao

Founder and Chief Editor – Hommer Zhao

Welcome! I’m Hommer Zhao, the founder and Chief Editor of WellPCB. With years of experience in the PCB industry, I’m committed to making sure our content is both accurate and helpful. We’re proud to serve a growing community of over 4,000 customers worldwide, and our goal is to provide you with the best resources and support. Your satisfaction is our top priority, and we’re here to help you every step of the way!

Jesse Holland

Technical Manager – Jesse Holland

Hi, I’m Jesse Holland, an Engineer and Technical Manager at WellPCB. With years of experience in PCB design and engineering, I’m here to ensure that every project we work on meets the highest technical standards. I lead our team, focusing on precision and innovation, collaborating closely with clients to provide tailored solutions and expert guidance. Whether you’re facing a complex design challenge or need advice on technical aspects, I’m here to ensure your project is a success from start to finish.

Nathan Jensen

Purchasing Manager – Nathan Jensen

Hi, I’m Nathan Jenson, the Purchasing Manager at WellPCB. I’m responsible for sourcing the best materials and components to ensure our products meet the highest quality standards. With my extensive experience in procurement, I work closely with suppliers to secure reliable and cost-effective solutions while maintaining strong relationships to support our operations. I aim to ensure every project runs smoothly by providing the resources needed to deliver on time and to your satisfaction.

Emma

Sales Manager – Emma

Hey, I am Emma, sales manager at WellPCB. I studied electronic science and technology at university and have served customers for PCB and PCB Assembly service for several years.

I enjoy communicating with customers and our technicians to solve problems, and customers always say, "It's great to have you onboard".

It is my pleasure and honour to be helpful. Contact me now, and you'll know.

Bella and Cassiel

Sales Representatives – Bella and Cassiel

We’re Bella and Cassiel, your dedicated sales representatives at WellPCB. With our extensive knowledge of the PCB industry, we’re here to provide exceptional service and support. We take the time to understand your unique needs and are always ready to offer tailored solutions and advice. Whether you need product recommendations, assistance with your orders, or simply have a question, we’re here to ensure your experience is smooth and seamless at every step.

Mandy and Wendy

Sales Representatives – Mandy and Wendy

We’re Mandy and Wendy, your friendly sales representatives at WellPCB. Passionate about helping our customers, we bring a wealth of experience in the PCB industry to provide you with the best solutions and service. We take pride in building strong relationships with our clients, understanding their specific needs, and offering personalised support to ensure their satisfaction. Whether you’re looking for advice, product information, or assistance with any part of your order, we’re here to make your experience as smooth and efficient as possible.

Our Team

Our skilled engineers and technicians bring expertise and precision to every PCB assembly project. Committed to quality, efficiency, and innovation, our team ensures every order meets the highest UL, IPC, ROHS & REACH standards, delivering reliable solutions tailored to your needs.

- Founder and Chief Editor – Hommer Zhao

- Technical Manager – Jesse Holland

- Purchasing Manager – Nathan Jensen

- Sales Manager – Emma

- Sales Representatives – Bella and Cassiel

- Sales Representatives – Mandy and Wendy

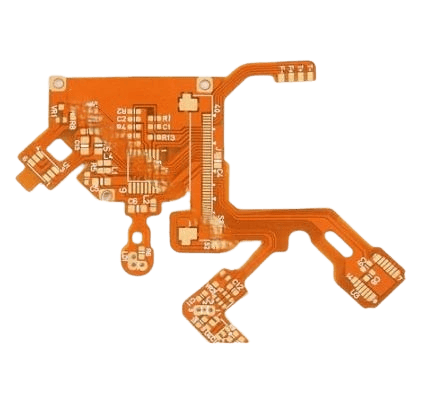

Flex PCB Case Studies

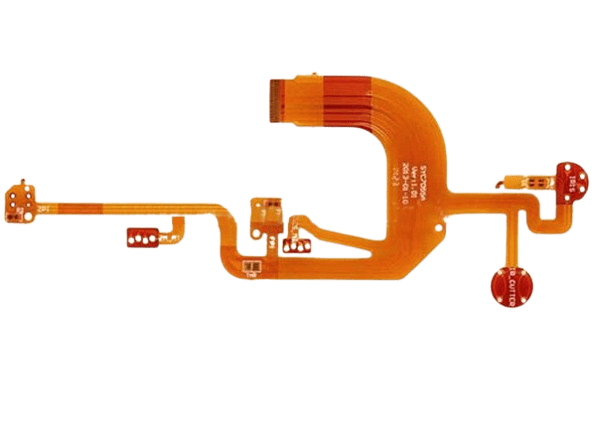

Case Study

A single-layer flex PCB designed for a scanner application, focused on delivering precision signal transmission, mechanical flexibility, and enhanced durability through surface and structural enhancements.

Product Specifications:

- Layer Count: 1 (Single-sided)

- Total Thickness: 0.13 mm

- Material: 1 oz rolled copper with adhesive

- Copper Thickness: 1 oz (35 μm)

- Surface Treatment: Gold Plating

- Min. Line Width / Spacing: 0.1 mm / 0.095 mm

- Reinforcement: FR4 stiffener, 0.5 mm thickness

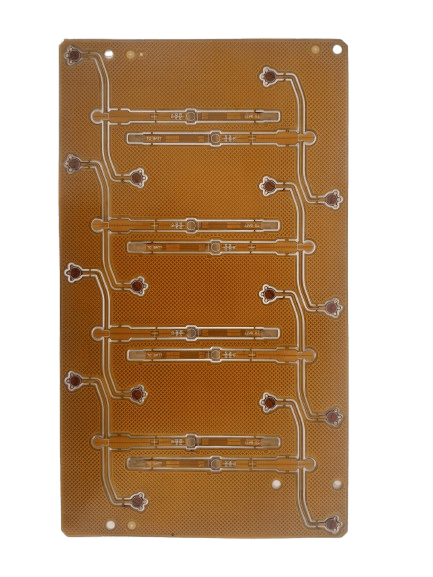

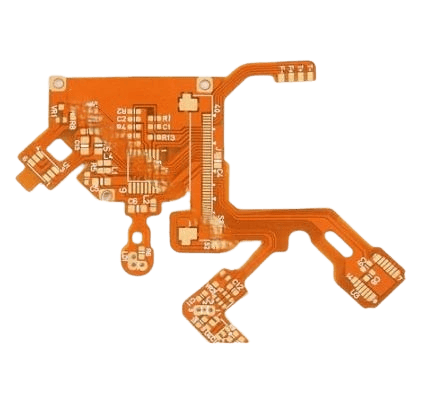

Case Study

This project involves a high-precision multi-layer flexible board developed for use in LCD connectors, focusing on flexibility, signal integrity, and mechanical durability for the flexible connector interface in electronic devices like LCD screens. It includes a multi-layer structure with precise surface finishes and materials to support high-frequency signals while maintaining flexibility and reliability.

Product Specifications:

Material Structure:

- Double-sided adhesive

- Low-loss yellow covering film

- Core buildup: (line copper + glue + high-frequency medium polyimide base material + glue + line copper)

- Outer layers: Low-loss yellow covering film

- Flexibility Requirements: Designed for free bending and winding

- Positional Accuracy (Male Component): ±0.03 mm tolerance

- Thickness: 0.15 mm

- Reinforcement: Front and back reinforced with 0.15 mm steel sheets

- Manufacturing Processes:

- Solder coating

- Plug plating

- Covering layer application

- Film-covered type assembly

- Resistance and welding type shielding torsion

- Surface Treatment: ENIG (Electroless Nickel Immersion Gold, 1 to 2 microinches)

- Minimum Line Width / Spacing: 0.06 mm / 0.09 mm

- Application: Connector components for LCD modules

Case Study

This high-precision ultra-thin flex PCB is engineered for use in advanced medical instruments. The circuit is optimized for biocompatibility, miniaturization, and high signal integrity, meeting the stringent demands of medical environments. It features extremely fine trace dimensions, immersion gold finish, and ultra-thin construction for flexible deployment in compact medical devices.

Product Specifications:

- Application: Medical instruments

- Board Thickness: 0.025 mm (25 μm)

- Surface Treatment: Immersion Gold (Gold Thickness: 1.0 μm)

- Line Width / Spacing: 2 mil / 2 mil (0.05 mm / 0.05 mm)

- Copper Thickness: 8 μm (approx. 1/4 oz)

- Challenge:

- Ultra-Thin Profile (0.025 mm)

- Fine Line Precision (2/2 mil)

- Thin Copper Thickness – 8 μm

- Thicker-than-standard gold layer thickness – 1.0 μm

Client Feedback On Our Flex PCBs

As an R&D manager, I have had an outstanding experience working with WELL-PCB. For many years, our company has entrusted them with the production, assembly, and programming of the boards developed in our R&D unit, and they have consistently exceeded our expectations.

Hamid Reza Moshayedi

R&D Manager

Their work is very impressively perfect. Today, when they check our company PCB board after assemble. They found a fake short point which many engineers has never found in the past years. But that is just designed so. The PCB board quality is excellent. Their service is also excellent.

MikeZ

My friend introduced WellPCB to me, the first try, a little look forward to. I ordered a 47*72 10ps PCB, and I can’t wait to receive my PCB. So I used expedited service and received my PCB in three days. I tested and soldered the PCB, Quality is really good, silkscreen, plating also great.

Warren Cliton

Flex PCB FAQs

What's the minimum bend radius for a flex PCB?

The recommended dynamic bend radius is 10× the finished flex thickness. For static bends, 6× thickness is acceptable. Designs using 1 oz copper and 2 mil polyimide typically target a 20–25 mm dynamic bend radius to avoid copper fatigue or delamination.

Can flex PCBs be manufactured with heavy copper?

Yes, we support copper weights up to 20 oz for heavy copper flex circuits. These builds are used in high-current or thermal load applications and require adjusted trace spacing, plating control, and thermal profiling during fabrication.

What's the difference between adhesive and adhesiveless flex PCBs?

Adhesive-based flex PCBs are built by bonding copper foil to the polyimide core using a separate adhesive layer, typically acrylic or epoxy. This structure is easier to process but can expand under heat, impact, and fine-pitch registration.

Adhesiveless flex PCBs use copper laminated directly to the polyimide without adhesive, improving dimensional accuracy, reducing moisture uptake, and allowing finer trace geometry. Adhesiveless builds are preferred in HDI, controlled impedance, and thermally demanding designs.

Are your flex PCBs UL-certified?

Yes, we offer UL-certified flex builds. Material selection and stackup design must meet UL 94V-0 flame rating and associated dielectric and construction standards.

What are the key design considerations for flex and rigid-flex PCBs?

For flex PCBs, designers should avoid placing traces over bend areas, use staggered routing on opposing layers, and apply gradual width transitions at connector zones.

For rigid-flex, keep via transitions outside flex regions, maintain uniform stackup symmetry, and isolate rigid/flex interfaces with proper pad relief and adhesive anchors.

In both cases, maintaining controlled bend radius, layer balance, and proper coverlay alignment is critical to avoid delamination and mechanical failure.

These are supported by layout principles outlined in Altium expert Ben Jordan’s Flex PCB Design Best Practices, where IPC-2223 standards guide trace placement, coverlay alignment, and bend radius tolerances in flexible designs.

WellPCB is Your Expert Flex PCB Manufacturer

From design guidance to final mass production, our experienced team is ready to turn your PCB diagrams into real products. Contact us and get a discount on your first order!