Contents

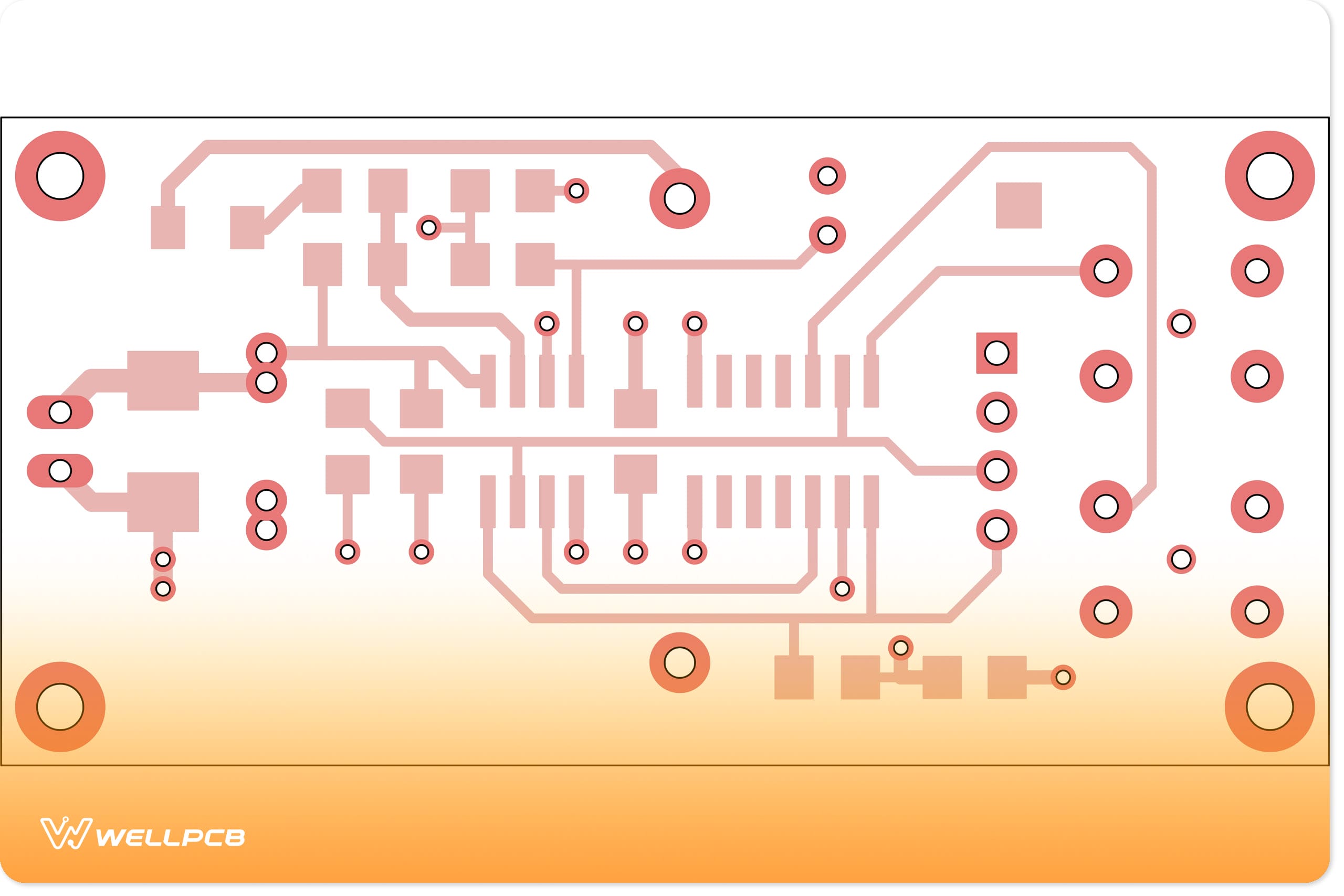

Single-Sided PCBs

Single-sided PCB is the basic one, the spare parts are concentrated on one side, and the circuit is concentrated on the other. Because the wires only appear on one side of them, so we called Single-sided PCB.

Single-sided PCBs come with several strict design limitations. Since there is only one side available, the wiring cannot cross and must navigate around individual paths, making it suitable primarily for simpler, earlier circuit designs.

In single-sided PCB production, a diagram is typically created using network printing (screen printing), where resist is applied to the copper surface. After etching, the welding resistance is marked, and then the holes and part shapes are finalized by punching.

While single-sided PCBs serve basic needs, a flexible PCB can provide greater design freedom and functionality, ideal for more advanced applications.

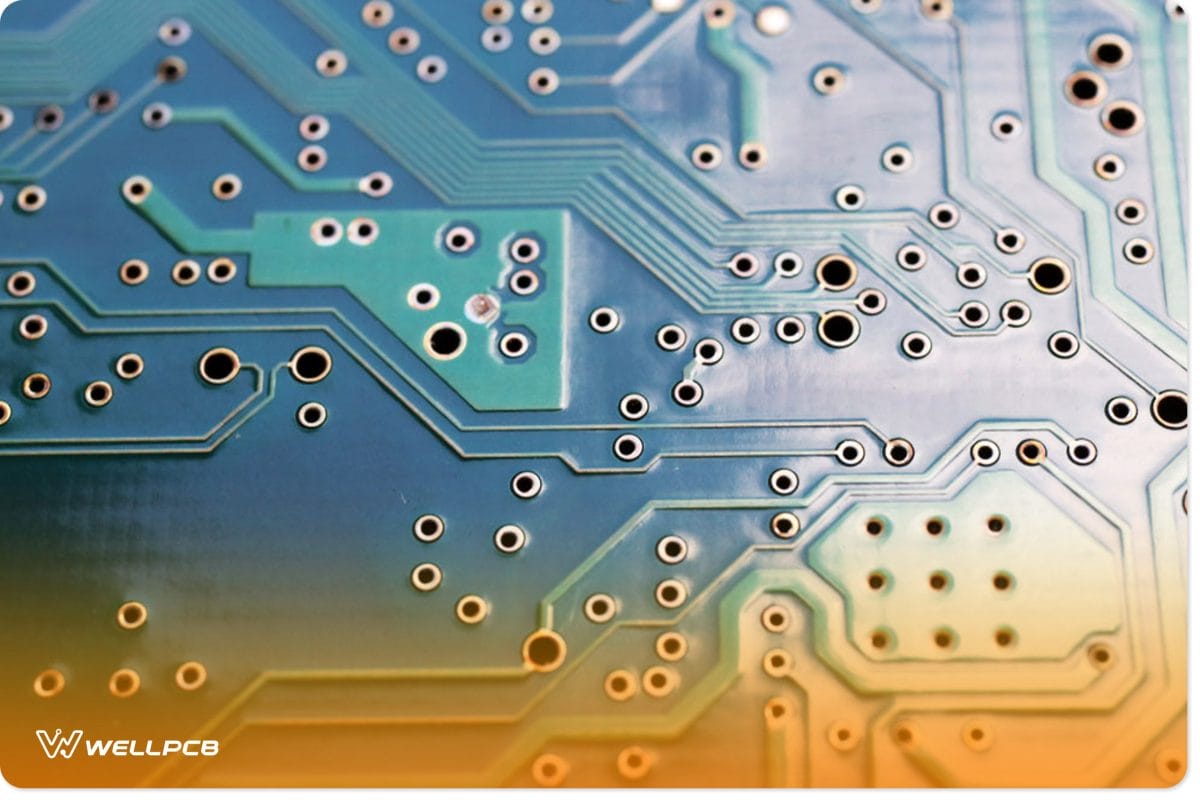

Double-sided PCB

What is a Double-Sided PCB? Strictly speaking, a Double-Sided PCB is one of the important PCB boards useful in the PCB industry.

They allow for the routing of traces around each other by jumping between a top and bottom layer through vias. Generally speaking, there are lines on both sides!

Common PCBs include Printed circuit boards, flexible circuit boards, Aluminum-Based PCBs, and High-frequency boards.

It needs circuits on both sides. Via is the holes on boards coated with metal, and it can connect wires on both sides. The double-sided PCB area is twice as large as the Single-sided PCB, and the wiring is interleaved, better suited for more complex circuits.

Someone may feel confused that if one Single-Sided And Double-Sided PCB, wires on both sides while Electronic parts only one side, is this a Double-sided board or a single one? The answer is obvious.

This kind of board is a Double-sided board; it’s installing a component on the Double-sided board.

Categories of Single-Layer PCB

There are five single-layer PCB types — they have properties that may be useful to you.

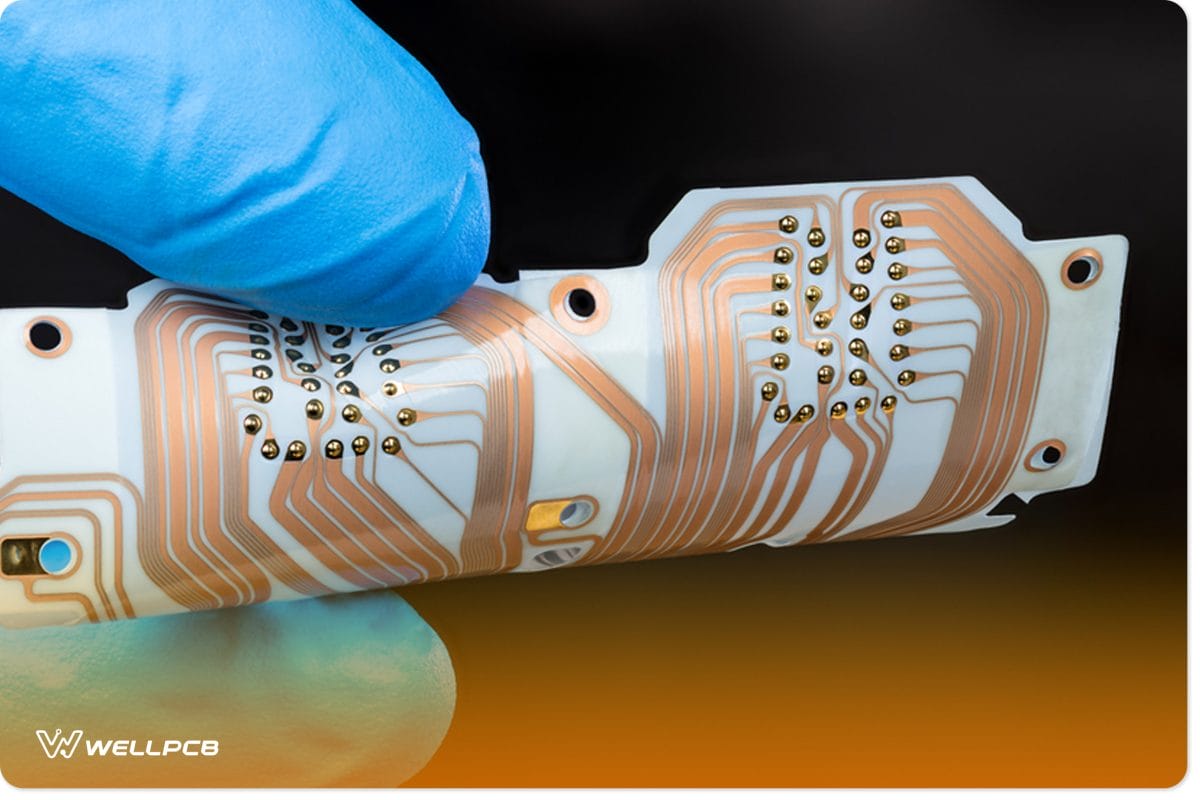

Flexible

Example of a circuit board that bends.

Made of plastic, the single-layer flexible PCB can bend and adapt. However, the downside is that production costs aren’t very low.

Rigid Flex

This board combines plastic and fiberglass, making it tougher than the flexible and single ones. Plus, it’s lighter and smaller than other boards.

High Frequency

Single-layer high-frequency printed circuit boards use materials like polyphenylene oxide or Teflon. These are ideal for Gigahertz frequency circuits.

If you go with this one, consider water absorption, dielectric loss, and thermal expansion.

Rigid

A single-layer rigid PCB has a fiberglass makeup, so it doesn’t bend. Thus, the circuit board won’t break apart easily.

Aluminum Backing

A single-layer aluminum-backed PCB isn’t the same as a circuit board with copper because it contains an aluminum substrate.

Thanks to its thermal insulating materials, it’s also very useful because heat doesn’t go anywhere near the insulating layer.

How Is The Single-Layer Different From The Multi-Layer PCB?

Image showing a multilayer printed circuit board.

When you think about the single-layer PCB, one side has a conductive layer (copper or other material), while the other side may have a fiberglass substrate.

Students and those doing projects pick this one because it’s better to work with.

The multi-layer PCB differs because it features multiple layers (2+) with components between insulating layers.

You’ll also find that these don’t generate much noise because they come with ground grids or a ground plane.

Plus, designing them isn’t hard since traces intersect under the board.

This happens until they emerge from the PCB’s top. However, multi-layer circuit boards will cost more.

What’s So Good About The Single-Side PCB?

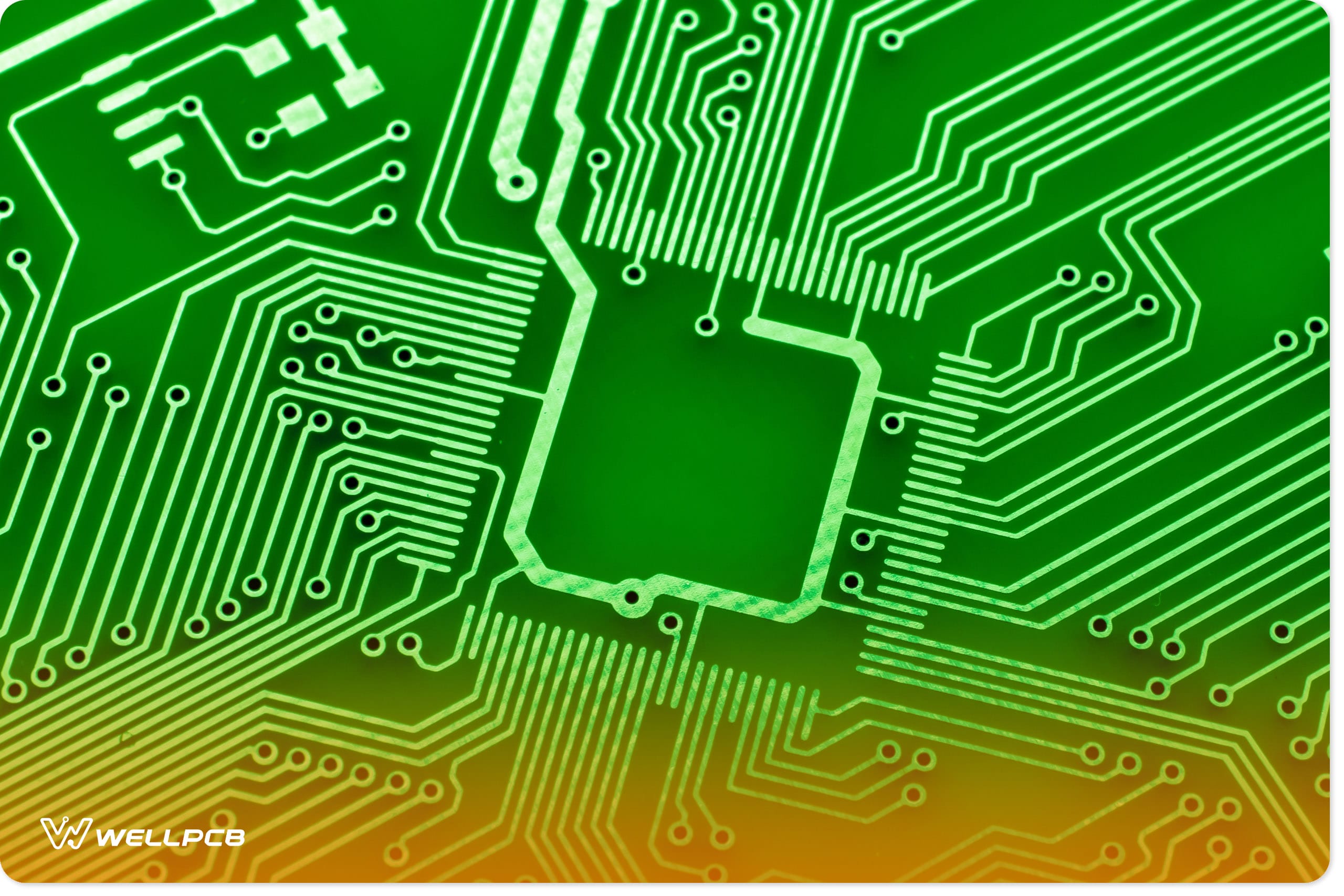

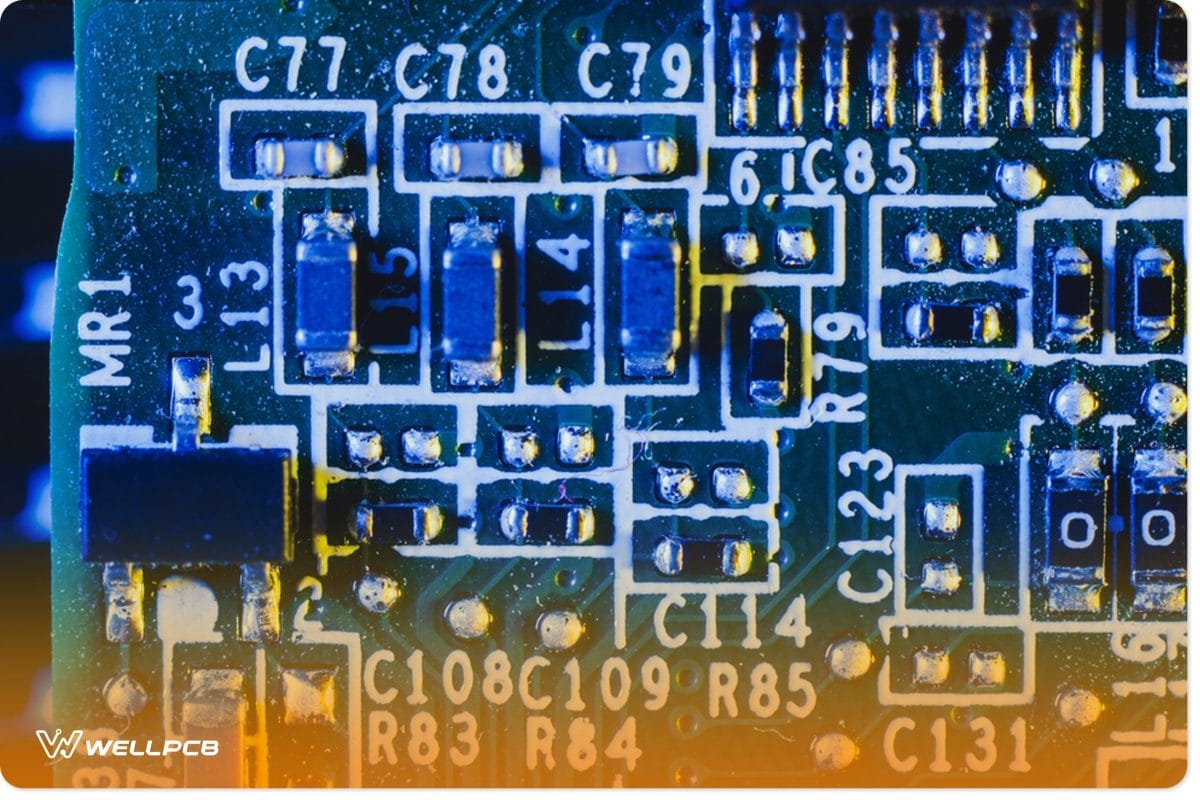

Single-Sided And Double-Sided PCB: Close-up of a PCB.

Single-layer PCBs have all sorts of good things, giving you a better idea of what you’re getting. So take a look at what it offers!

- It doesn’t take long to figure out what’s causing any issues and fix them all.

- Works well with low-density circuits and costs less

- Soldering/desoldering. drilling, and placing each component Isn’t very hard.

- Easy to understand, design, install, and produce

- During fabrication, a single-side PCB is less likely to generate noise and short-circuit.

- You can use a lower jumper for circuit corrections since your components go on a single layer.

Single-Sided And Double-Sided PCB: Is There A 3-layer PCB?

Single-Sided And Double-Sided PCB: Circuit board.

You can get a three-layer circuit board, but few people will use it. That’s because it is more likely to warp.

While laminating, the foil-clad and core structures cool down independently, and those differences create tension that causes the circuit board to warp.

Single-layer PCB & Double-Sided PCB Manufacturers

Single-Sided And Double-Sided PCB: Assembling a PCB.

Not everyone has the right know-how and equipment for creating a single-layer and double-sided board. And that can be troublesome in the long run—especially if you need a project done!

Lucky for you, WellPCB manufactures and assembles single, double, and multi-layer PCBs. Contact us or place your order to get started!