Contents

- 1 Make Sure They Have a Proper Set of Guidelines

- 2 Check to See the Type, Quality, and Quantity of Machines

- 3 Know the Type of Quality Inspection Procedure They Use

- 4 What is the Number of Production Lines They Have?

- 5 Make Sure They Have Stock for Basic Components

- 6 Know the Order Size and Time Limit They Provide

- 7 Find Out Their Application Method for Solder Paste

- 8 Do They Employ Qualified Workers for Pick and Place?

- 9 Are Their Lead and Non-lead Production Lines Separated?

- 10 Check to See if They Have Proper Storage

- 11 Conclusion

Make Sure They Have a Proper Set of Guidelines

Over the years, many manufacturers in China have poorly sourced and maintained the production processes, resources, and guidelines. They’re more focused on quick mass production rather than effective product manufacturing.

Having a proper set of guidelines is crucial for every production company to avoid any mistakes. Similarly, it allows them to maintain repeatability during the entire production process with a clear and compelling production manual and training scheme.

That is why proper guidelines and training can be seen at the core of every successful company. While having direct control over resources and human error isn’t always feasible or practical, providing the proper manuals, instructions and training can maximize production quality, speed, and overall results.

For this reason, utilizing a good operation manual, proper quality management systems, and training schemes for new employees is critical. If a printed circuit board supplier doesn’t have any of these, you might face some uncertainty.

Rigidity during designing is not something that most customers would want from a circuit manufacturer. Because of this, it is necessary to arrange with the desired company. They should have available work schemes and guidelines that can be redone and manufactured according to the customer’s requirements.

While it is convenient and easy to fix printed circuit boards, it isn’t simple for every customer to know the techniques and manage them independently. The PCB manufacturer must be ready to provide professional servicing to satisfy the buyers in such a case.

Check to See the Type, Quality, and Quantity of Machines

The innovation of technology has added new ideas and designs to the industry so that nobody would require any obsolete or old software products. Along those lines, it is ideal to pick a printer circuit manufacturer and supplier that uses the most recent technologies to ensure each circuit works up to the latest standards.

Old design, new model, the accuracy of each component and machine, the number of feeders that they can handle, and whether the devices are Chinese or Japanese models are crucial since they can easily affect productivity and yield.

If machines do not have great accuracy, they will not be able to manage the installation of the more minute components that have small footprint packages, such as the 0201 SADkinds. Furthermore, older machines having poor repair and maintenance while being used for manufacturing can, for example, slow down the entire production process because of any defects in the device.

Another thing to remember when choosing a PCB manufacturer is that all the parts of the production process should be done with the company’s facilities. Most manufacturers have each step managed within their facility, but low-quality manufacturers can outsource products to other facilities for gluing or drilling.

Outsourcing of manufacturing can be problematic since there is no control over the guidelines and standards by one company, which can result in inconsistency issues. Each process should be performed in-house to ensure proper procedures, efficiency, and quality control.

Know the Type of Quality Inspection Procedure They Use

Any person knows that quality control is essential when undertaking any manufacturing operations in China. You should select a manufacturer partner that performs in-house testing so that it is easier to verify issues at the company level before any shipments are made. PCB testing should never be outsourced because of its unreliability.

There are essentially two or three quality control procedures for circuit board assembly procedures that you can implement. However, not all suppliers use all the methods, and some conduct their examinations poorly. These examinations include:

Visual Examination by Humans: First, visual observation ensures that all the components are appropriately soldered. It is usually done by operators who can spot abnormal fragments or configurations manually. This examination is an absolute must in any manufacturing organization that produces printed circuit boards.

Visual Examination by Machines: Second, Automated Optical Quality Control is used to speed up the first process of visual quality checking to ensure the results are reliable. Usually, this is done by a machine that uses a camera to make picture comparisons through optical recognition. It helps to locate the proper component at its good location.

Functional Test: A third functional test ensures that the PCB machine functions appropriately during production. It is usually done by turning on the machine, entering the desired input, and observing and checking the resulting output.

What is the Number of Production Lines They Have?

If you have a large volume of products to manufacture and have a crunch time on your delivery, then you might want to look into how fast a PCB manufacturer can produce and supply your order. If a company has to manage multiple demands simultaneously, it’s not a bad thing.

Having multiple lines running at the same time is excellent for multitasking and speeding up the production process. It will enable the PCB manufacturer to handle all the orders quicker by running multiple productions in parallel. Just make sure to choose a PCB company that has a backup plan in case it gets overbooked.

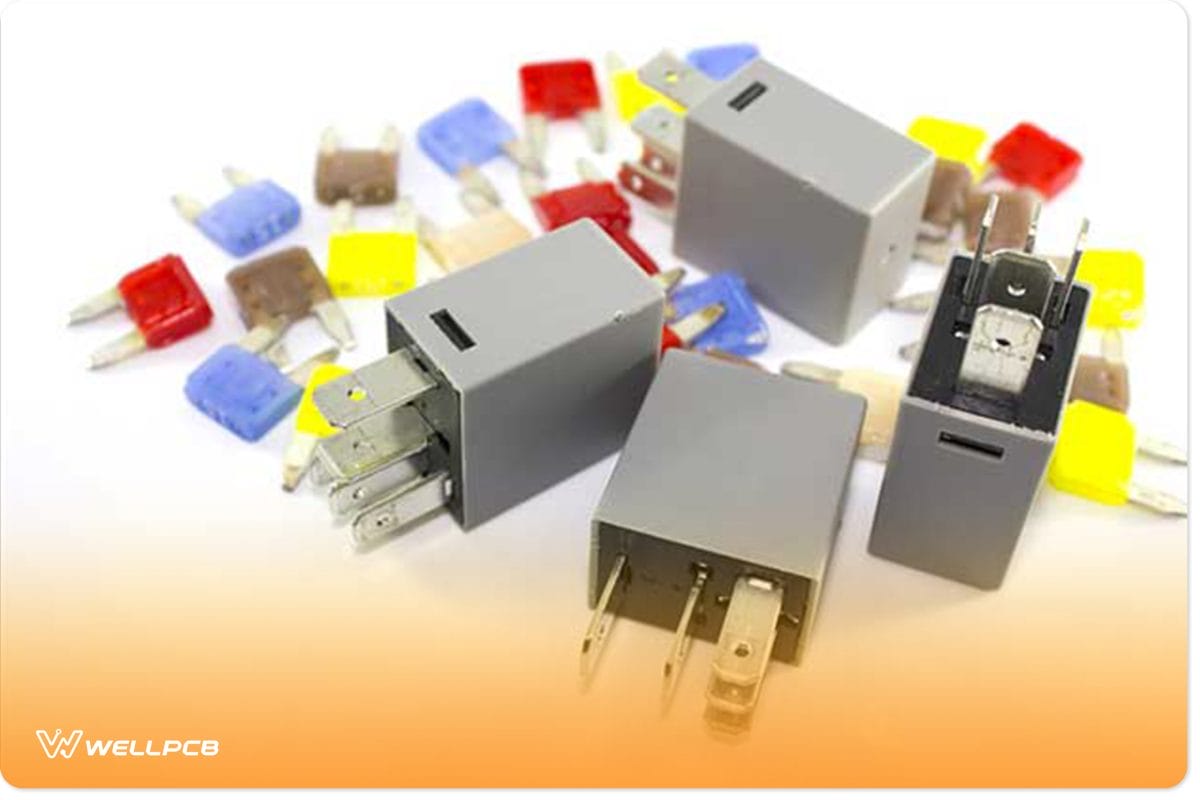

Make Sure They Have Stock for Basic Components

Generally, printed circuit board assemblers will have standard components like resistors, capacitors, diodes, transistors, or inductors. These backup stocks can be helpful since you won’t have to stock them yourself, making keeping stock inventory much more accessible.

The diversity of components for countless products will require you to buy many different parts and units. Since they mainly sell by a minimum order quantity (MOQ) of around 4000 to 5000 pieces per reel, you may Lewis have something unnecessary. That is why it is better to have a PCB manufacturer that can handle the cost of other parts.

Components make up a considerable part of the PCB budget, so you should choose a PCB manufacturer of the right size that can optimize the costs of such features using economies of scale. PCB manufacturers with more extensive order lists can quickly maximize these costs due to their size.

Smaller companies, however, will not have ease finding better prices or deals with other component manufacturers. That is why you need to search for more prominent manufacturers that can handle bulk components and get them at a fraction of the cost.

Know the Order Size and Time Limit They Provide

Before starting any mass production, you will have to make some circuit board prototypes that can be used in small-scale productions. That is why you should check to see if a PB manufacturer can manage prototypes and small productions before starting a business with them.

One of the ways you can manage this situation is by having two partner companies: one that works on the prototype and the other for mass production. However, this isn’t ideal since there can be consistency issues in the processing and final product.

It is always ideal to have consistency between the two phases of product development and product manufacturing. So, you should make sure that a company can make some small-scale and mass productions to ensure that they can follow through with the processes later on.

Time is also a very crucial element that is a part of any business and production process. The PCB manufacturer and supplier should be able to handle all due dates effectively. They must have the required work capacity to supply the PCBs in time. It is where the poor rate comes in.

The defective rate is the number of PCBs that have to be reworked after production per 100 units produced. This rate is a crucial consideration since it indirectly has a part in the delivery time. Many manufacturers in China falsely advertise that their poor rate is less than 1%. Research and talk with different companies to see which one offers better production styles and rates.

Find Out Their Application Method for Solder Paste

Is the solder paste application manual or automatic using a machine? Human error is usually more likely to occur than machine error. So, it is ideal to partner with a circuit board manufacturer that uses semi-automatic or automatic machines.

A human applying solder paste with their hand can slide it into the wrong position very easily without noticing it. It can lead to a massive concern of short-circuiting. However, a machine can be programmed to ensure repeatability so that no such mistakes are made. In case of an application error, you need to make repairs, and the process can continue.

Do They Employ Qualified Workers for Pick and Place?

Important to choose a supplier that has the ideal workforce to handle the production of the circuit boards. It is imperative to see if the company has a good team of designers and professionals with the right skills. It can help you to handle the intricate details of production.

Occasionally, you cannot install a specific component with a pick-and-place machine during production. For example, suppose there is a component with a particular shape that makes it hard to hold. Or, there is one that isn’t available in trays or reels. In that case, an operator needs to install the component by hand on the circuit board.

Make sure that the operators of a PCB company have appropriate training to do these installations for any component. There are a lot of times when you need precision and microscopes to install micro-components. So, a company’s production team should be able to handle those situations.

Besides training qualifications, employees should also have a strong on hold of communication skills at each level. So, you can deal with all issues through each group properly. It includes order placements, designing, fabrication, assembly, quality checks, and shipment. If each partner is on the same page, the production becomes faster with reduced chances of any crude output.

Are Their Lead and Non-lead Production Lines Separated?

Sometimes, a PCB manufacturer and supplier can use a solder that uses lead for a specific market. On the other hand, they simultaneously make use of non-lead solder paste. It would help ensure that the manufacturer doesn’t mix those two production lines up in such situations.

Official circuit board manufacturers will use physical separations for each production line. It helps eliminate even the possibility of lead dust contaminating lead-free production. These companies usually make use of walls or nets.

Check to See if They Have Proper Storage

China is famous for its humidity levels and hot temperatures, especially during the monsoon season. When you get your PCB components or circuit boards, you must know that they are usually delivered in vacuum seals. The packages have silica gel to deal with humidity. That’s because, without these packaging essentials, oxidation comes into play.

Printed circuit boards and their component pads will oxidize when exposed to air and humidity. It tends to make it hard to reflow or repair them when you have to solder all over again. It makes for waste products.

Be sure that your PCB manufacturer and supplier properly seal each package using vacuum sealing. It also includes the remaining extra components, which can then be used for later production.

Conclusion

WELLPCB is the preferred supplier of PCB. We have the right equipment, procedures, teams, and designs that meet your pcb manufacturing requirements.

We can help you understand any PCB material and provide you with a one-stop turnkey service to build the best-in-class PCB electronics.

If you still have any questions, you can contact us at sales@wellpcb.net. Our team of experts and engineers will be more than happy to help you out.