Contents

Quick Turn PCB

Quick turn PCB definition

With time being a crucial factor, many activities today follow strict guidelines to conserve valuable resources. PCB manufacturing is no exception, driving the need for quick-turn PCBs to ensure customers receive their printed circuit boards on schedule.

Fast-turn PCB manufacturing means that the entire process is completed within a short turnaround time, providing several key benefits to customers:

- Reduces delays: Quick-turn PCBs save shoppers significant time that would otherwise be spent waiting for their boards.

- Shortens the manufacturing period: Traditional PCB manufacturing can be lengthy, but with quick-turn PCB options, the production period is significantly reduced, ensuring faster delivery.

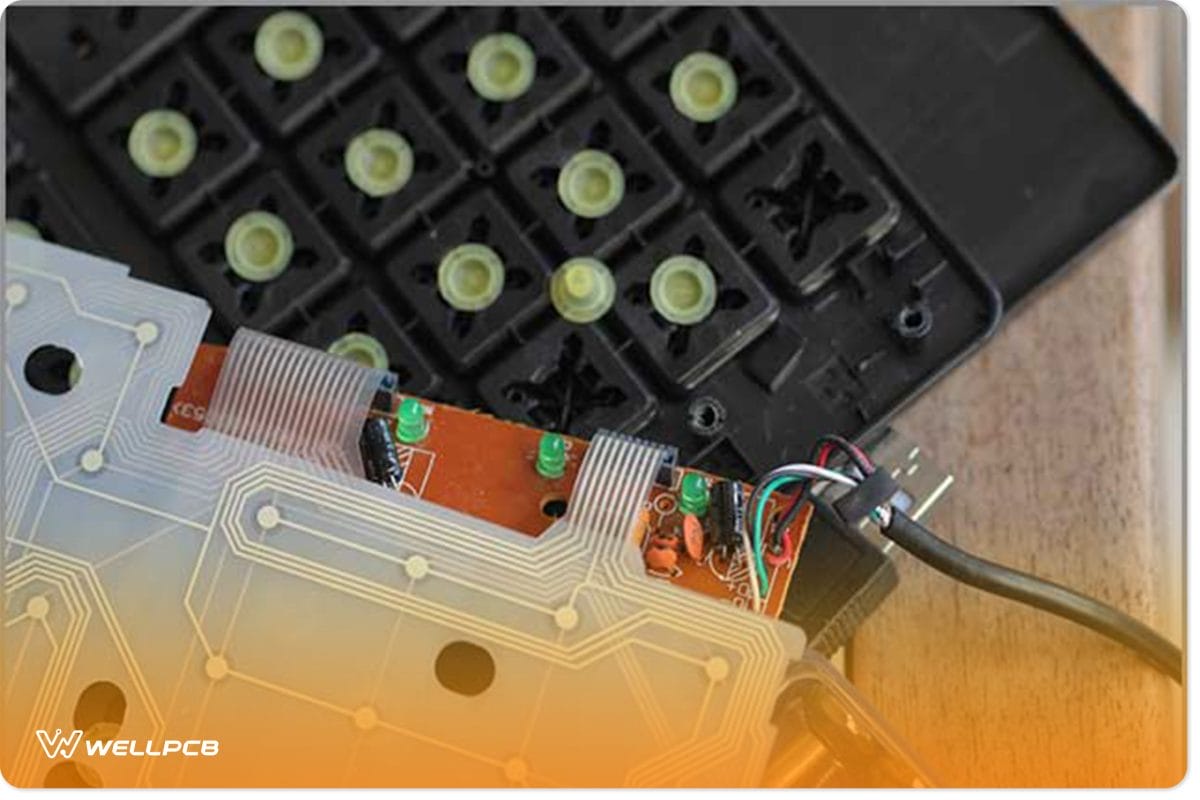

In addition to these benefits, a flexible PCB design allows even greater adaptability, making it ideal for time-sensitive and space-constrained applications.

Quick-turn PCB prototypes

As you may have already read or heard about the concept of prototype PCBs, you are aware that it involves designing a PCB based on the pattern used in a previous version.

A process mainly done for inspection purposes so that any errors and adjustments can be made in good time.

The use of PCB prototypes assists manufacturers in identifying possible defects that may arise on the original PCB and how to deal with them early.

It also gives the manufacturer a chance to add more features to the PCB to improve performance and efficiency. After final fabrication, changes are usually difficult to make, and that is why the prototypes are crucial to the manufacturer.

Quick turn PCB prototypes major on the assembling models of the printed circuit boards just before final fabrication with a time deadline.

Therefore the entire process pegs its relevance on the time that is stipulated.

Manufacturers offer these services to any PCB shoppers keen on getting their PCB within a fast turnaround.

However, the PCB shoppers would need to have some prior requirements for the intended PCB before opting for a quick-turn PCB prototype service to confirm whether or not the specs match the services offered by the provider.

Quick-turn PCB prototypes have advantages. Some of these advantages include the following:

*Saves on cost of manufacture

*Having quick-turn PCBs ensures that the errors and mistakes that could have occurred on the original PCB are avoided.

*Saves the customer time. By checking the design early enough, PCB shoppers can verify the features of the PCB through its quick-time prototype. It helps the manufacturer save time that would have been applied in making changes when the PCB has already been manufactured.

*Enables the manufacturer to make adjustments early. Time is a precious resource, and the manufacturer is always looking to minimize costs while maximizing profits, so quick-time PCB prototypes are essential.

These prototypes enable the manufacturer to get customer feedback early and make any relevant changes suggested before manufacture or fabrication.

Quick-turn PCB prototypes generally take about 24 hours turn-around time to be completed.

Therefore, the customer doesn’t have to wait so long for the Electromagnetic Interference (EMI), which is responsible for many cases of circuit board failure.

EMI causes about 50% of PCB prototypes. It is an efficient way to ensure the quality of the final product.

Quick turn PCB fabrication

With a turnaround time of about 24 hours, quick-turn PCB fabrication is fast and convenient for PCB shoppers.

Most customers would love to outsource their PCBs from professional manufacturers rather than do it in-house, saving the cost of manufacture and a lot of stress.

As a result, manufacturers have to keep pace with the market’s demand, necessitating a quick turnaround of PCB fabrication and manufacture.

At WellPCB, you can quote the PCBs that you want and get a fast turnaround delivery.

Quick Turn Flex PCB

Quick turn flex PCB generally has a turnaround time of 7-10 days fabrication process. The flex PCB has a myriad of advantages, and we can take a look at some of them below:

Flex PCBs suit circuits that require a lot of bending and flexibility. There is a special kind of device that would require their use and application.

Have improved resistance to vibration and movement.

Flex PCBs are designed to be strong enough to withstand vibrations due to the circuit or environment. They are best suited for devices that require vigorous movement.

Incorporates the use of flexible flat cables

Since the circuit bends a lot, the need for these types of cables is evident.

The cables take up less space than traditional wires and bend more. Due to their nature, they last longer and are not prone to destruction.

Ideal for harsh environments.

This WellPCB offers DC motor controllers in both domestic and international markets. We have flexible PCBs that are best for use in harsh environments.

They tend to last in conditions where standard PCBs would otherwise have trouble.

Have high bending properties.

Since they are flexible, these PCBs can bend up to 360 degrees without breaking. A type of flexibility that makes them useful for devices that require bending circuits.

Have high tensile properties.

Flex PCBs can be warped and deformed without easily breaking apart.

Versatile.

Flex PCBs have wide applications. They can be used for more compact devices and in some areas.

Small package size.

Flex PCBs bend and can be stretched a lot, making their packaging easy. You don’t need to contact the freight forwarder often.

However, most Chinese PCB suppliers will provide packaging, as they can easily be placed in small packaging.

After considering the advantages of using a flexible printed circuit board, it is also essential to consider the advantages of manufacturing and assembly.

The following are some of them:

Improved airflow.

Flex PCBs have a better airflow than their counterparts. They are best for circuits that require a lot of air to get in.

Increased reliability.

Flex PCBs are very reliable due to their versatility and properties. They can be used for many devices, and their properties make them survive in areas where standard PCBs would not.

Increased durability.

Due to their high tensile and bending properties, flex PCBs can withstand rough handling. They can be warped and deformed without breaking easily and can also be bent even to 360 degrees without breaking.

They are mainly used in devices that undergo rough handling and extreme conditions, which is why they are termed durable.

Improved heat dissipation.

Flex PCBs dissipate heat better than standard circuits, a phenomenon contributed to by the fact that they let in the air quickly.

Installation flexibility.

Unlike other circuits, which can pose a challenge during installation, flex PCBs are easy to install due to their flexible nature.

Design freedom.

This just means that the kind of design you use will not be limited when using flex PCBs. Since they are flexible, they give the manufacturer the freedom to choose between various circuit methods.

As you have seen, flexible PCBs have many advantages both during their usage and at manufacture. They give the manufacturer and PCB shoppers a myriad of choices on how to use and apply them. That’s the reason why they are versatile. You can apply for a quick turn flex PCB and experience the advantages for yourself.

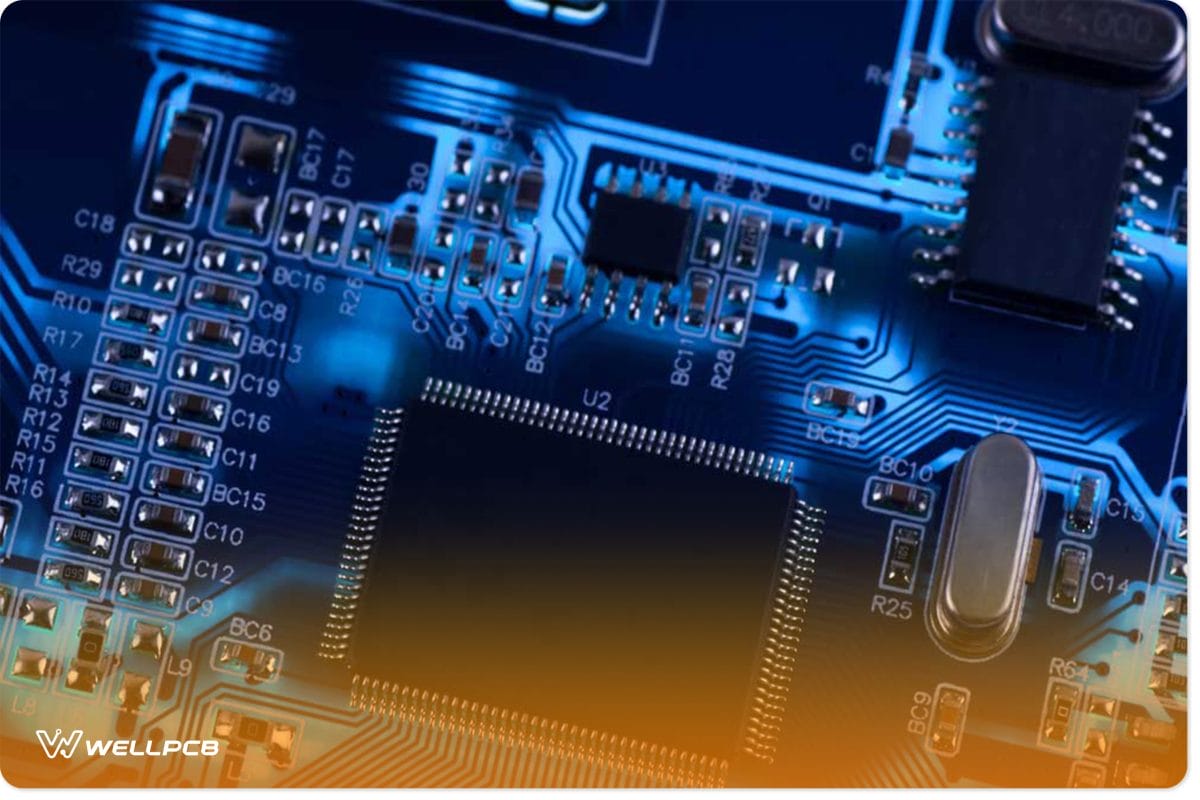

Quick Turn PCB Assembly

In as little as 24 hours, you can get your PCB assembled for you. As PCB shoppers, time is of the essence, so a quick turn PCB assembly is relevant.

For the assembly process to be done quickly, the design of the PCB would also need to be fastened. There are different assembly types that you can get:

* Surface mount. Primarily known as SMT by manufacturers.

* Thru-hole.

* Mixed technology. Usually, a combination of both the surface mount and thru-hole.

* Single or double-sided placement. Here, the manufacturer can place the PCB components on one side, depending on the customer’s needs.

A quick-turn Bill of Materials (BOM) of a PCB gets fitted onto the board. PCB assembly typically takes anywhere from 24 hours to 5 days at the latest. With WellPCB, the turnaround time is incredible. You will not only get value for your money but also a record turnaround time. The standard or somewhat average assembly time can take anywhere between 5-10 days.

During assembly, different solder types are used.

The manufacturer can either use leaded, lead-free, or water-clean fluxes. The non-leaded variant is usually called the led one due to the environment. The non-leaded solder is also ROHS compliant.

After the assembly process, the PCB is inspected thoroughly to ensure it functions and has no errors. In case of any errors or omissions, rework is carried out. However, rework is discouraged due to its uneconomic nature.

It leads to massive losses and wastage of time while these two are precious resources. To avoid rework, manufacturers use the prototypes to make sure that the original PCB is up and functioning effectively, preventing any possible challenges that may occur later on during the usage of the PCB.

The other method used to check for errors in the DFM analysis is another great way to know if the circuit is functioning well.

We offer free DFM analyses to help you understand whether the PCB’s design may affect its future functioning. We also offer other PCB testing services before manufacture to satisfy quality requirements.

You can think about a quick-turn Bill of Materials (BOM) for a PCB fitted onto an aboard. PCB assembly and get your PCB in a record 24 hours or at least five days.

Quick Turn PCB Manufacturers

Professionals create quick-turn PCBs. Many individuals prefer to outsource their PCBs rather than make them in-house. You can trust the manufacturer of your printed circuit boards.

First, a prototype is essential in the manufacturing of PCBs. The prototypes must be used for various tests before manufacture to ensure that the original PCB does not get any hitches when finally being used. As you may now be aware, the use of prototypes is well justified.

Different regulations and standards guide the manufacture of PCBs.

High standards for prototype boards must be used to reflect the original PCB. One of these standards includes the IPC class 2 specifications, which should be followed closely during the production of PCBs.

The IPC class 2 specifications demand dedicated electronic service products, which are supposed to meet high customer quality standards.

At WellPCB, we ensure that all our PCBs meet the given specifications and requirements. You can, therefore, trust us for high-quality and long-lasting Printed Circuit Boards.

As technology evolves, we invest in modern equipment to ensure that the quality standards are at par with the current market.

It is in line with our target to serve the PCB shoppers effectively.

PCB manufacturers have licenses for their operations and follow the standards of production.

We ensure that all the products we sell to the customers are of good quality and meet the criteria.

Feel free to visit our website and check out what we offer regarding PCBs.

Quick Turn PCB China

There are numerous PCB manufacturers in China. Choosing a PCB shop on which manufacturer to work with can be a challenge. It is often a competitive market, and the best quality is usually the savior.

If you are looking for high quality, then WellPCB has you covered.

We have been in the industry for an extended period and have understood most of our customers’ needs and requirements. Our products have the right amount of quality and are manufactured according to the standards that govern PCB manufacture and production. We conduct tests and analyses on the PCBs to ensure that they meet the client’s needs and are free of errors and issues.

You can count on us to deliver a quick-turn PCB in China or outside the country. For PCB prototypes, the turnaround time is just 24 hours.

In the manufacturing and assembly, you can expect anywhere from 5-10 days on average.

To judge which manufacturer to use, you can use the following pointers:

* Speed. The speed of delivery matters a lot. Having stated that time is money, we cannot overlook the importance of a quick turnaround delivery. At WellPCB, you will have your order delivered on time without any delays.

* Efficiency. The services you get from the manufacturer should be efficient and serve the purpose.

* Quality. The quality of the products is vital. You should pick a manufacturer that delivers quality products. The products should also meet the manufacturer’s requirements and several standards.

* Price point. Finally, the amount you pay for the PCB also matters. For pocket-friendly prices, WellPCB has you covered too. t to mean that the standard is low, but just a pointer to the value for money our customers enjoy.

Conclusion

In summary, quick-turn PCBs save time and money. They don’t require changes after the manufacturing process is complete, so both the manufacturer and PCB shopper can save time.

It also saves money, as rework is avoided by manufacturing prototype PCBs right before the manufacturing process.

The turnaround time for these PCBs is also fast, thus saving time.

In case of any inquiries, you can contact us through the following leads: