Contents

The Basics You Should Know About Custom Boards

PCB Prototype Board

In the first phase of developing a custom board. It is much simpler to use a board designed for prototyping.

Remember that the fabrication and design of PCB will be required when it comes to adding the final touches to the end product.

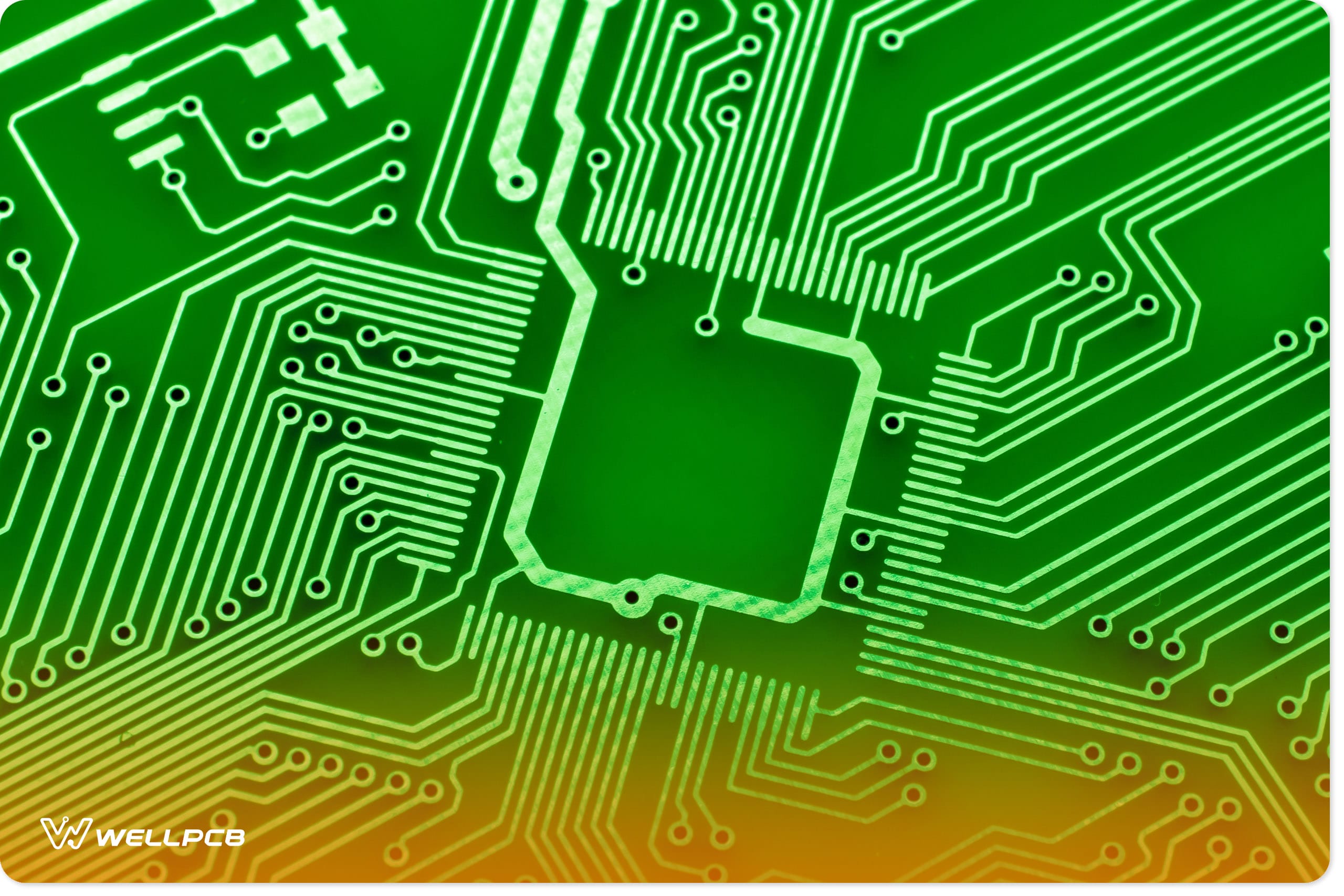

PCB Material

Some PCB materials needed for creating a custom circuit board include the copper-clad board and the positive photoresist.

The copper gathers on a foundation that’s referred to as the substrate.

Designers can choose between one and two layers of copper, depending on what type of board is in use.

There’s a silkscreen that helps make the PCB readable.The substrate, FR4 (Fire Retardant), is a thick foundation for the PCB.

On top of the copper foil is a layer called the solder mask. It’s usually green in color.

Some PCBs do not use these materials.

Instead, they use epoxies, which have the disadvantage of being thermally sensitive.

PCB Types

PCBs come in many types, depending on the intended use. The most prevalent custom circuit boards include:

1. Single-sided printed circuit boards

2. Double-sided PCBs

3. Multilayer PCBs

4. Rigid PCBs

5. Flex PCBs

Printed Circuit Board Components

All electronic components, regardless of their function, have individual components that are essential for various circuits.

These components include LEDs, resistors, batteries, transistors, switches, diodes, and inductors.

How is the Custom Circuit Board Designed?

The Design Basics

Before we get started on the basics of custom Circuit Board design, we need to get familiar with some terminologies. These include:

Schematic Capture

The program allows the operator to create a schematic diagram of the electronic component and other features—a graphical representation of the element.

Gerber Files

These are computer-aided design files. The files are sent to the custom circuit board producers to assist them in building the PCB structure.

PCB Layout Tool

It is a program that allows for applying multiple structures of the wiring connection structure.

Once the construction is complete, the operator can generate CAD files to make the custom circuit board.

The Steps of PCB Design

Different makers of printed circuit boards use different approaches when it comes to the designing of a custom circuit board. We’ve listed the essential steps below:

Step 1: Using Software

Here, the designer chooses suitable software to create a custom circuit board. One such software is EAGLE.

Step 2: Generating the Film

Using the finalized PCB diagram, the operator generates the film.

Step 3: Selecting Raw Materials

Where the intention is to design a simple device, the designer can use pocket-friendly material like paper phenolic bonded with copper foil.

Step 4: The Drilling of Holes

At this stage, machines and drill bits help drill holes. Both a hand machine and a CNC machine are applicable here.

Step 5: Fixing the Image

Here, the designer places a clean copper layer on the printer and stores the designed layout film on the computer before they print the command from the computer using a laser printer.

Step 6: Etching and Stripping

In this stage, the unwanted copper attached to the custom circuit board is removed using different chemicals.

Step 7: Testing

It is the final stage to ensure that the custom circuit board is fully functional.

Do You Know The Custom Circuit Board Software?

Currently, a wide variety of software is available in the market to help design custom circuit boards.

Among the top software include PCB Artist, Altium Designer 17, Ultiboard, DipTrace, SOLIDWORKS PCB, PCBWeb, BSch3V, Gerbv, XCircuit, Eagle PCBs, KiCad EDA, CircuitMaker, DesignSpark PCB, Pad2pad, ZenitPCB, OrCAD, CircuitStudio, PCB123, FreePCB and CUSPICE

Comparing Various PCB Design Programs

As you’ve seen, the list of software used for PCB design is long. We’ll compare two programs from the catalog.

Of course, we can randomly select these two applications. Let’s examine DIPTrace and EAGLE CAD.

DipTrace

This software has many impressive capabilities. It can perform schematic captures linked to the library and create patterns using a decent library editor.

Users of this program can access tutorials and support. The software is also reasonably priced and has visually appealing colors.

Generally, this software is ideal for small and simple custom circuit boards.

EAGLE CAD

This software is capable of electrical rule check, and forward and backward annotation between the PCB and schematic.

So what’s The Best Custom Circuit Board Design Software?

Given that there’s a great deal of circuit board design software in the market, putting your finger on the best among them is easier said than done.

However, some design programs are highly recognizable due to their impressive functionality. One of them is EAGLE.

This software is remarkably user-friendly and moderately priced. It can execute files and copper cladding in batch.

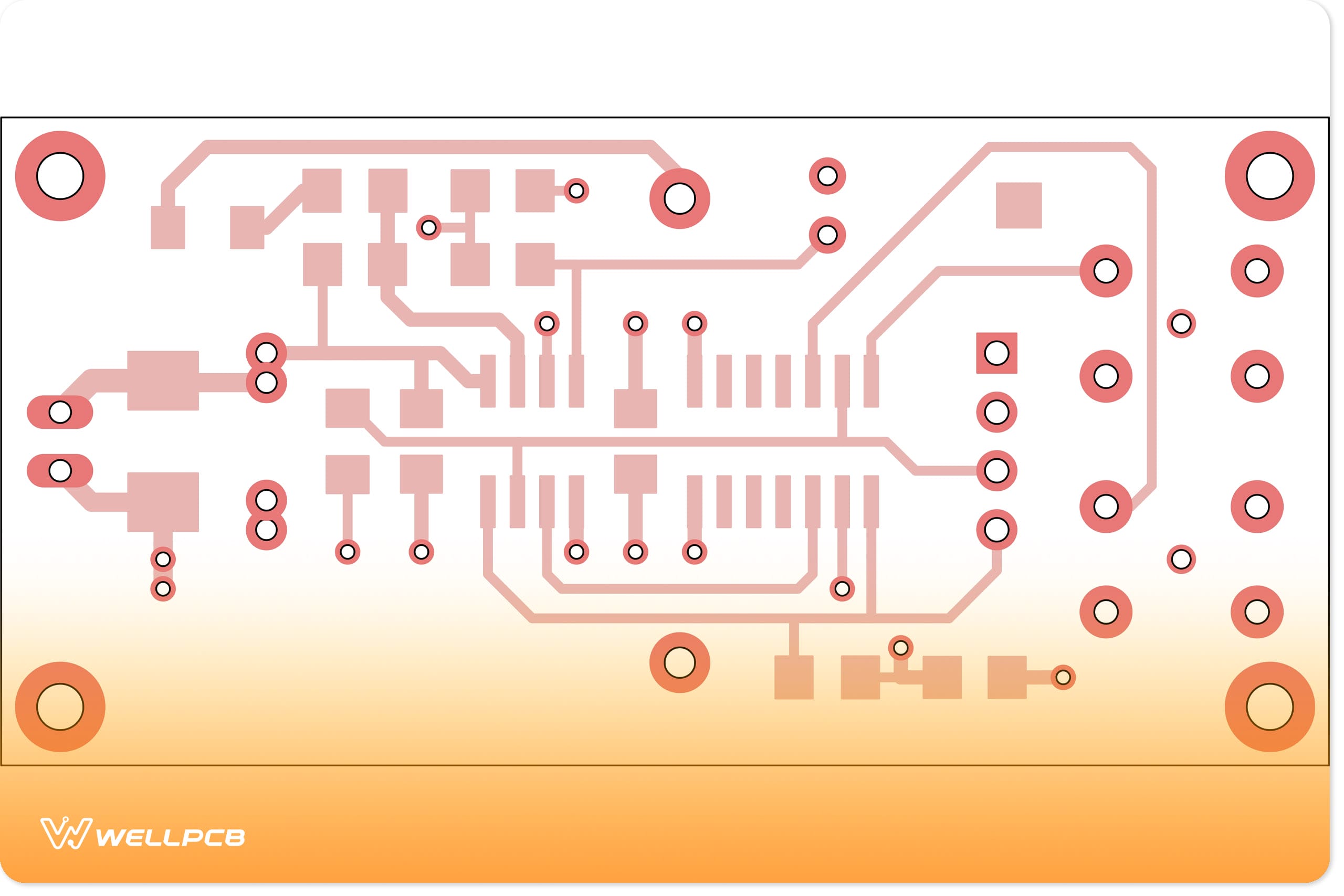

Custom Circuit Board Layout Design

PCB Layout Design

The layout of a printed circuit board requires some technical know-how and calls for the knowledge of software used to make PCBs.

It would be best if you also were conversant with the computer-aided system used to make PCBs and have the skills required to transfer the basic PCB design to the final custom circuit board.

Comparing PCB Layout

When comparing various custom circuit board designs, we look at the following factors:

1. Board size

2. Layers available

3. Power delivery network

4. 3D modelling

5. Differential pair routing

PCB Layout Tutorial

Step 1: Converting the Schematic to a PCB

Once you have completed the schematics, click “convert to PCB” in your specific editor. This will convert the schema to a PCB.

Step 2: Dragging and Dropping the Component

Here, you place the document in the exact position you want it.

If you prefer a neat-looking custom circuit board, you can arrange the components with similar functions next to each other.

Step 3: Sketch a Custom Outline

You must go to the layer menu and select the board outline layer. Then, you click on the outline and delete it.

Next, create your preferred shape using the printed circuit board tools.

Step 4: Copper Area

This step involves joining different parts to one signal. The tools menu allows you to create a copper area.

Step 5: Routing

There are two ways to complete the route. If the current is low when creating the custom circuit board, use the auto-router function at the top of the page.

It’s best to do routing manually if different track sizes are needed.

Step 6: Holes

Irrespective of what you’re designing a custom circuit board for, you’ll still need to mount it on something.

To create holes on the PCB for this function, use the Hole tool on the tools menu.

Step 7: Adding Pictures and Text

To add pictures and text to the PCB, scroll to the tools menu to find the text or picture tool. Position your preferred book or make changes as you wish.

Step 8: Photo View

When you finish the above steps, viewing the result is time. If you’re unhappy with the color or some other feature, you can change it.

If you’re satisfied with the final result, click “fabrication output.” That helps you buy the custom circuit board.

Printed Circuit Board Reverse Engineering

Sometimes, the schematic is not available. In such cases, you can produce replacement parts using the data created from the PCB reverse engineering.

Reverse engineering a custom circuit board can be tedious and challenging, but it is sometimes necessary.

Why We Reverse Engineer PCBs

So why would we bother to reverse engineer circuit boards, given the time and effort involved? Well, here are just some of the principal reasons:

- To replace components on the PCB that have become obsolete

- Reposition some of the board components

- To improve the functionality of the circuit board

- Analyze and enhance security requirements

Conclusion

Given the enormous role that printed circuit boards play in electronic devices, the PCB you choose must be ideal for your needs.

At the beginning of this article, we’ll tell you what’s involved in creating a custom board. I hope this information will help you.

We also promised we’d help you find the right vendor. That’s where WellPCB comes in. When it comes to reliable, cost-effective, and durable products, you can count on us every time.

Our PCB solutions are customized to fit your unique needs.

Would you like to discover more about our high-quality products?

One call is all it takes! We have the best, and it’s all for just you.